Abstract

Nowadays, experts are discussing the issue of water taking into account the Declaration of Dublin, in which the topic of water is treated like a sustainable issue. This declaration was presented in 1992. It is a fact that the scarcity and inadequate use of freshwater are leading us to a nonrational and sustainable development from an ecological point of view (N.R.W.C. Committee 1993; Chapman 2006; Walsh et al. 2006). Health and well-being, food security, and industrialization are other threatened areas, which are affecting ecosystems on which all human beings depend. That is the reason why to secure a future, it is necessary to have an effective management of water and soil resources.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

3.1 Introduction

Nowadays, experts are discussing the issue of water taking into account the Declaration of Dublin, in which the topic of water is treated like a sustainable issue. This declaration was presented in 1992. It is a fact that the scarcity and inadequate use of freshwater are leading us to a nonrational and sustainable development from an ecological point of view (N.R.W.C. Committee 1993; Chapman 2006; Walsh et al. 2006). Health and well-being, food security, and industrialization are other threatened areas, which are affecting ecosystems on which all human beings depend. That is the reason why to secure a future, it is necessary to have an effective management of water and soil resources.

Within the acceptable minimum ethics, it should be noted that the general environment, including water resources in particular, is a heritage of mankind that we have inherited, and that we must protect for future generations. Proper management must certainly rely on the three commonly accepted principles of solidarity, subsidiary, and participation (F.I. Report 2009).

Solidarity recognizes that all men have equal rights to participate in environmental and water resources; subsidiary states that can make a lower social group, it is better than form a larger social group. Participation leads to the integration of the different users in the management of the environment and its resources (Sekoulov 2002).

In the agro-food industry, there is considerable water consumption due to the different kinds of processes and unit operation in which water is involved (e.g., cleaning, cooling, pasteurizing, etc.). In addition to this, good water quality and quantity are essential for food processing (Bazilian et al. 2011; Casani and Knøchel 2002; Palumbo et al. 1997). On the other hand, large volumes of wastewater are generated as a result of the need to use water in these processes. For instance, in Germany, 30 m3 of wastewater is generated per ton of frozen carrot produced, 1.2 m3 for apple juice, and 4.15 m3 in beer production (Yang et al. 2007). Therefore, wastewater treatment and water management are fundamental concerns to ensure water supply over the years.

Wastewater effluents are continuous when water input and output exists in the different processes for food production. They can be derived from cooling and heating systems (condensers, cooling towers, and boilers) or industry cleaning processes (cleaning-in-place systems for the internal surface of pipes, vessels, process equipment, filters, and other accessories). Discontinuous wastewater effluents can also be generated from intermediate operations such as soaking, raw material cleaning, scalding, etc., and are prone to be the most polluted. Wastewater from the agro-food industry is characterized by high organic content, cleaning agents, salts, and suspended solids. High levels of Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) as well as considerable seasonal changes in flow and composition make their treatment difficult (Todd and Josephson 1996). Costs associated with water are the result of an elevated consumption of high-quality water plus wastewater treatments and the cost of wastewater disposal. Therefore, searching for profitable alternatives becomes necessary in order to minimize consumption as well as searching for environmentally friendly wastewater treatment strategies, which will be determined by the taxes applied to each effluent (Gray 2005). In the food and beverages industry, effluent charges were the principal factor in inducing water polluters to invest in biological wastewater technologies in the Netherlands (Casani and Knøchel 2002). This is an essential and determinant factor for the development of new wastewater treatments and establishing their potential markets. An increasing need exists for creating an appropriate tax designed to encourage water treatment and savings.

A reconsideration of traditional irrigation practices is starting and a new appreciation of the advantages of traditional know-how is beginning to appear. However, pressures on irrigating farmers are continuing to require them to increase irrigation efficiency, achieve higher water productivity, and use less water. Yet there is often a lack of assistance for them to develop and adopt improved approaches and techniques appropriate to these changing farming objectives, however keeping farmers’ objectives of financial and social nature. In addition, perceptions of an urban society that highly prioritizes environmental preservation for future water allocation are also challenging farmers’ attitudes and requiring new approaches.

A new communication model has to be developed that could lead to a better understanding of water use in agriculture and demonstrate why performance improvement must occur within the context of the needs of the society and the objectives of farming (Elizaquível et al. 2011, 2012; Sánchez et al. 2012). New approaches are required to properly define and account for each item of water use and productivity with water conservation and saving being the primary drivers to achieve higher performance (García-Pérez et al. 2013). From this perspective, the performance concepts need to be differently defined, understood, and applied. In other words, we need a new model in terms of conceptualization of water use performance that can be understood by users, managers, and decision makers alike. This improved conceptualization can then provide a common framework around which actual water use (hopefully monitored water use—debate over words is not very useful if the actual volumes involved are only approximate) can become sustainable for large and small farmers or other users, in all climates and in societies with different degrees of development, utilizing a wide range of technologies (Chan et al. 2009; Kalbar et al. 2012; Muga and Mihelcic 2008; Tomar and Suthar 2011; Travis et al. 2012).

The terms water conservation and water saving are generally associated with the management of water resources under scarcity. However, these terms are often used with different meanings within specific scientific and technical disciplines or in the water user sector considered. Often, both terms are used synonymously. The term water conservation is used here to refer to every policy, managerial measure, or user practice that aims to conserve or preserve the water resource, as well as to combat the degradation of the water resource, including its quality. Differently, the term water saving describes the avoidance of loss of water by limiting or controlling water demand and use for any specific purpose (Muga and Mihelcic 2008; Jin et al. 2013), including the avoidance of wastes and the misuse of water.

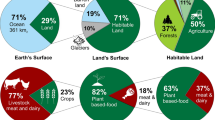

In practice, these terms or perspectives are complementary and interrelated. Water conservation plays a major role in rain-fed agriculture and when irrigation is supplemental of rainfall (Chan et al. 2009; Muga and Mihelcic 2008; Wang et al. 2012), but it is essential in all water use systems, often as a means to achieve water saving. Water conservation can play a major role in agricultural and landscape irrigation considering that predictions for climate change indicate a concentration of rainfall and an increase of its intensity. A coupling of soil and water conservation is then essential to increase water infiltration and storage in the soil profile as well as to control soil evaporation.

Water conservation increases the amount of consumptive use by crops and natural vegetation, sometimes called the green water fraction, and assists in preserving the quality of flows that are often called the blue water, the general good quality environmental water (Rodriguez-Garcia et al. 2011). Water savings usually refer to the blue water fraction. Despite it often not being easy to distinguish between “conservation” and “saving,” these terms should not be used synonymously. For example, questions related to preservation and upgrading of water quality are essential in water conservation but are rarely relevant to the usual ideas of water saving. It is arguably a modern tragedy that considerable volumes of the scarce resource can and are being lost or wasted due to lack of clarity of terms used and miscommunication between those involved. This is analyzed in most papers in this issue, with the various authors adopting a variety of approaches. Yet, communication must also apply to specific fields or scales: our main focus in this chapter is water use at the farm scale, or a group of users served by the same system, not basin planning, or water allocation. Therefore, the aim of this chapter is twofold: (1) to demonstrate the confusion of the terms used both between and within disciplines and groups of users, and the resulting potential for poor use of water and (2) to suggest alternative terms that could gain wide acceptance and common usage. Some case study applications are used to illustrate the use of these terms and ideas.

Two important aspects must be analyzed in the field of water; (i) The physicochemical characteristics of water according to the nature and source of the water and (ii) Water as a fact of life. In this regard, considerations of water as life support, clean water and its uses, wastewater and the effects of pollution, and the health considerations of drinking water cannot be ignored (Muga and Mihelcic 2008).

The general principle in wastewater treatment is to remove pollutants from the water by getting them to either settle or float, and then removing this material. Some pollutants are easily removable. Others must be converted to a settleable form before they can be removed. Treatment facilities are designed in stages. Each stage either removes particles from the wastewater or changes dissolved and suspended material to a form that can be removed. A modern wastewater treatment plant (WWTP) may include the following stages: (i) influent, (ii) primary treatment, (iii) secondary treatment, and (iv) tertiary treatment and effluent discharge (Walsh et al. 2006).

In the final stage, the disinfection process has the objective to eliminate all the pathogen agents to prevent plant and human diseases. While most of these microorganisms are not pathogens, pathogens must be assumed to be potentially present. Thus, whenever wastewater effluents are discharged into receiving waters which may be used for water supply, swimming, shell fishing, or if its quality is really good, it can be used in food production, and the reduction of bacterial numbers to minimize health hazards is a very desirable goal (Abdel-Raouf et al. 2012).

A variety of physical or chemical methods are capable of destroying microorganisms under certain conditions. Physical methods might include, for example, heating to boiling or incineration or irradiation with X-rays or ultraviolet rays. Chemical methods might theoretically include the use of strong acids, alcohols, or a variety of oxidizing chemicals or surface active agents (such as special detergents). However, the treatment of wastewaters for the destruction of pathogens demands the use of practical measures that can be used economically and efficiently at all times on large quantities of wastewaters which have been treated at various degrees (Pablos et al. 2013).

The prevalent use of chlorine has come about because chlorine is an excellent disinfecting chemical and, until recently, has been available at a reasonable cost. However, the rising cost of chlorine coupled with the fact that chlorine even at low concentrations is toxic to fish and other biota, as well as the possibility that potentially harmful chlorinated hydrocarbons may be formed, has made chlorination less favored as the disinfectant of choice in wastewater treatment. As a result, newer technologies are showing promising results, such as the use of nano-catalysts like titanium dioxide (TiO2) as disinfection agent by the photocatalysis process (Bodaghi et al. 2013; Fang et al. 2013; Hossain et al. 2014; Lin et al. 2013; Liu et al. 2013; Wang and Lim 2013).

Another important process related to wastewater treatment is that of metal removal to obtain the best water quality for reuse in food production (Bonnett et al. 2006; Lalov et al. 2000).

Heavy metal ions and waste dye are two major industrial pollutants, and many methods have been developed to remove them from wastewater (Ahluwalia and Goyal 2005; Nguyen et al. 2006; Monteagudo et al. 2006; Asma et al. 2006). In recent years, various methods including foam flotation, filtration, microbial reduction, chemical oxidation, reverse osmosis, coagulation and flocculation, biological treatments, photo degradation, and adsorption have been developed for treating dye contaminated wastewater. Among these methods, adsorption is known to be a promising technique due to the ease of operation and comparable low cost of application. These processes may be ineffective or extremely expensive, especially when the metals in solution are in the range of 1–100 mg/L (Liu and Lu 2011; Kasmuri et al. 2011).

Heavy metal pollution represents an important environmental problem; environmental contamination by heavy metals is of growing concern because of health risks on live organisms. At least 20 metals are classified as toxic and half of these are emitted into the environment in quantities that pose risks to human health. Accumulation of metals like Cd, Cr, Cu, Hg, and Zn, in humans has several consequences such as growth and developmental abnormalities, mental retardation, and a wide range of other illnesses (Liu and Lu 2011; Kortenkamp et al. 1996; Wang et al. 2008; Thiele 1995).

The above-mentioned are traditional methods of effluent treatment, nevertheless these methods have to be supplemented with modern and more effective means of treatment and this is where bioremediation becomes relevant providing several techniques for cleaning up pollutants by means of biological tools (Shetty 2006). Biological tools include living and nonliving microorganisms for removal or recovery of toxic substances from wastewater. The natural affinity of biological compounds for metallic elements could contribute to the purification of wastewater polluted with metals (Şahin and Öztürk 2005). The biosorption process is a feasible option as it is efficient and cheap. Compared with conventional methods for removing toxic metals from effluents, the biosorption process has the advantages of low-operating cost, minimization of volume of chemicals and biological sludge to be disposed of, and high efficiency in detoxifying very dilute effluents (Shetty 2006).

There are many different types of biosorbents like (i) Active biomass belonging to algae, bacteria, or fungi; (ii) Nonactive kind of biosorbent which is essentially a waste product or a by-product of a fermentation process; and (iii) Abundant natural materials or polymers.

There is a small degree of selectivity, in solution, from numerous biosorbents in the collection of heavy metals. The mechanism of metal sequestration can occur by processes such as complexation, chelation, ion-exchange or coordination; or physical mechanisms like adsorption or precipitation. However, since biomaterials used for sorption are complex, a number of these mechanisms could be occurring simultaneously. Biomaterials have several chemical groups: acetamide groups in chitin, amino and phosphate groups in nucleic acids, amino, amide, sulfhydryl and carboxyl groups in proteins, and hydroxyls in polysaccharides, which could potentially attract and sequester metal ions. The efficiency of a biosorption process depends not only on the binding properties of the biosorbents, but also on the composition of the wastewater that will be used for treating (Şahin and Öztürk 2005; Volesky and Holan 1995; Krishnani and Ayyappan 2006; Barros et al. 2006).

Polymers are used like biosorbents because they have different properties that should be considered, such as degradation, hydrolysis and mechanical shearing, and chemical and mechanical stability. Some polymers possess a flexible structure and at certain hydrodynamic conditions the shape of such polymers can change so that they will pass through the membrane even though their mass is more than the molecular weight cut-off (MWCO) of the membrane (Shetty 2006; Geckeler and Volchek 1996).

Among the many other low-cost absorbents identified, chitosan has the highest sorption capacity for several metal ions (Chauhan et al. 2012; Juang and Shiau 2000; Laus et al. 2007; Liu et al. 2011; Sankararamakrishnan et al. 2007; Sobahi et al. 2010). Chitosan ([β-(1→4)-2-amine-2-desoxy-D-glucose]) is a natural polysaccharide that is formed by altering the N-deacetylation of its precursor, Chitin. Chitin is the second most abundant natural polymer, and is widely distributed in nature, especially in the exoskeletons of marine invertebrates such as prawn, crab, and lobster.

The difference between chitin and chitosan is essentially related to the possibility to solubilize the polymer in dilute acidic media. Therefore the degree of acetylation (DA), which is related to the population balance of acetylated and deacetylated (100-DA) groups, is essential to define these two terms. When chitin is deacetylated in heterogeneous conditions, the solubility in aqueous acidic media is achieved for DA generally below 30 %. Nevertheless, on reacetylating chitosan it is possible to observe a solubilization up to DA close to 60 %. As a consequence, the frontier between chitin/chitosan can be located at a DA of 60 %. An effect of the DA can be appreciated in the chitosan, which is a polymer semicrystalline and the degree of crystallinity is a function of the degree of deacetylation. In addition, the amino groups in chitosan structure are responsible for complex formation between metal ions and the polymer chain (Bhatnagar and Sillanpää 2009; Bolto et al. 2004; Szyguła et al. 2009; Domard and Domard 2002).

Chitosan chelates five to six times greater amounts of metal than chitin, this effect is attributed to the free amino groups present in the chemical structure of chitosan caused by deacetylation process; this fact is used in several important applications, and specifically for wastewater treatment because it can absorb dye molecules, remove proteinaceous matter, and metallic ions, including Cu(II), Co(II), Ni(II), Hg(II), and Zn(II), either physically or chemically (Kasmuri et al. 2011; Alves and Mano 2008; Babel and Kurniawan 2003; Hu et al. 2013; Kamari and Ngah 2009; Milosavljević et al. 2011; Xi and Wu 2004).

Finally, after the above information was described, the main route for sustainability and water management is to produce recycled water or treated at high quality, which is sure to meet the demand in a sustainable way and which in turn benefits to the environment.

To obtain these results, we start with wastewater from the laboratory and sanitary services from the Airport Campus of the Universidad Autónoma de Querétaro (UAQ), where five WWTPs are located to treat the entire campus sewage. After this water is disinfected and made metal free, it can be potentially used in the food production field.

3.2 Experimental Conditions

3.2.1 Wastewater Treatment Plant

Treatment plants were designed primarily to address 0.5 Ls-1 flow. The plant consists of two round containers, which are contained one within the other, that is, are coupled concentrically. The first container is in the aerobic reactor which holds the water treatment process with a diameter of 3.68 m, while the second container is in the accumulated treated water, and both containers are connected by a pipe 10 cm in diameter. The second container has a double function: the first function is it serves as a settling process, while the second serves as a clarification process. The container has a diameter of 2.12 m and the plant receives wastewater continuously through a pipe 7.62 cm in diameter. The wastewater is pumped from a lift reception to the first container and has an air supply system and two pipes in which are located the second container in one of the pipes. The fats pump back to the main container and the other pipe is intended to return to the first deposit the settled sludge accumulated; finally the treated water is conducted from the second tank through a pipe 10 cm in diameter to the said pipe.

The physicochemical and biological characteristics of the wastewater were monitored monthly, and these measurements were pH, temperature, sludge volume index, and total and fecal coliform organisms.

3.2.2 Solar Photocatalysis Disinfection

3.2.2.1 Synthesis and Characterization of the Ag:TiO2 Catalyst

The synthesis of the TiO2 substrate was obtained by slowly dissolving the titanium precursor (titanium isopropoxide, 97 % Aldrich, TTIP) in an organic solvent (isopropanol, 99.9 %, J.T. Baker). The titanium solution was continuously magnetically stirred for 20 min under nitrogen atmosphere. The hydrolysis process was then performed by adding water into the flask containing precursor/solvent mixture and magnetically stirred for 1 h (Esquivel et al. 2013). The molar ratio of the precursors and solvents are, 0.03:4.2:1 for TTIP:H2O:isopropanol, respectively. For the Ag-modified TiO2 samples, the precursor was silver nitrate 99.9 % (Sigma-Aldrich). This precursor was added separately by dissolving it into the water used for the hydrolysis reaction at different weight percentages (0.005, 0.01, and 0.1 wt%). The obtained sol was transferred into Teflon-lined vessels and placed on a turn table for uniform heating using a microwave reaction system (Synthos 3000, Anton Paar). The change in temperature in the reaction vessel was monitored automatically by the dual-IR temperature probe and the solutions were continuously stirred at medium speed (300 rpm). The heating procedures were conducted for 30 min at 215 °C for 60 min using microwave radiation of 600 W, and finally the system was cooled down to room temperature. The obtained powder was filtered and washed with deionized water several times and room temperature dried for 18 h, and subsequently dried at 80 °C for 20 h in a conventional furnace. A calcination process was carried out at 550 °C for 3 h to improve the sample crystallinity. The catalyst characterization of the surface morphology analysis of the materials was carried out by Scanning Electron Microscopy (SEM) with a microscope JEOL JSM-6060 LV. The accelerating voltage employed was 15 kV. Elemental analysis was performed by Energy Dispersive X-ray Spectroscopy (EDS) (EDS Oxford Inca X-Sight coupled to a MT 1000, Hitachi). Also, the morphology analysis was carried out by high-resolution transmission electronic microscopy (HRTEM) using a JEOL JEM 2000FX microscope. The catalysts were crushed and dispersed ultrasonically in acetone at room temperature and then spread onto a perforated carbon–copper microgrid. The operational accelerating voltage was 200 kV using a filament of LaB6. Bandgap energy (E bg) values were determined from diffuse reflectance measurements (Cary 5000 UV–Vis-NIR Varian spectrophotometer) by applying the Kubelka–Munk function. X-ray diffraction analyses (XRD) were obtained using a Bruker D8 advanced diffractometer equipped with a Cu seal tube to generate Cu Kα radiation (λ = 1.5406 A) within the Bragg angles 10 < 2θ < 80° in steps of 0.01°. Raman spectroscopy measurements were acquired with LabRAM HR, Horiba Scientific equipment with an Nd:YAG laser (λ = 532 nm, output power of 80 mW). The samples were analyzed with a power of 6 mW over an area with a diameter of 1.5 μm using a microscope on 10X objective.

3.2.2.2 Photocatalysis Tests

The photocatalytic activity of the synthesized samples was evaluated in disinfection process in a real residual-treated water at pH = 7, by quantification of the more likely number of pathogen agents to form colonies and by differentiation of those microorganisms by biochemical reactions in diverse mediums. In each test, 50 mg of the photocatalyst was dispersed in 100 mL of the residual-treated water magnetically stirred for 30 min in the darkness before irradiation. The system was illuminated using the solar radiation of a spring day in the city of Santiago de Querétaro, Qro. This represents between 800 and 1,000 Wm−2 around 12:00 am and 03:00 pm. At given irradiation time intervals and after 3 h of total reaction time, the samples were taken out and the pathogen microorganism removal was evaluated.

3.2.2.3 Microbiological Identification and Differentiation Test

Using a bacteriological water test based on the microorganism growth in two presumptive mediums (Lactose and Sodium Lauryl Sulfate, BD Bioxon) at concentrations of 10−1, 10−2, and 10−3, the disinfection effectiveness process was tested. In the presumptive test, the mediums once seeded were incubated at 35 °C for 24 h. If the samples show the presence of gas, it can be noticed as a positive sample. After the presumptive test, the positive samples were seeded inoculant 1 ml in the confirmative mediums, EC, MIO, and Green Bright Billis (BD Bioxon). The tubes were incubated for 24 h at 35 °C, and the presence of gas means a positive sample. Finally for the differential tests, the positive samples from the confirmative tests, were seeded in a petri dish containing shigella and salmonella medium (BD Bioxon) and Macconkey agar (BD Bioxon) for 24 h at 35 °C (Ervin et al. 2010; Gilbride 2014; Scaglia et al. 2014).

3.2.3 Metal Removal

Chitosan synthesis was made in two ways: in the traditional method with several modifications, which include four-steps depigmentation, decalcification, deproteinization, and deacetylation and is reported elsewhere (Otakara and Yabuki 1991; Jing et al. 2012; Kumar et al. 2012; Reicha et al. 2012; Xu et al. 2011). The modification consists in reducing the concentrations of sodium hydroxide (NaOH) and hydrochloric acid (HCl), and substituting the alkali reagent for potassium hydroxide (KOH) (Elizalde-Peña et al. 2007). Additionally, decalcification, deproteinization, and deacetylation were carried out in a microwave reaction system (Synthos 3000, Anton Paar) with the following conditions: Decalcification: HCl 6 M for 30 min at 50 °C; Deproteinization: alkali solution 1 M for 30 min at 180 °C; and Deacetylation: alkali solution 30 % (v/v) for 15 min at 110 °C.

After deacetylation, the samples were washed thrice with hot deionized water and filtered, with a final oven dried process at 60 °C, for 2 h. The samples were characterized by infrared spectroscopy in a Perkin Elmer infrared spectrometer to obtain the acetylation degree by means of the integration of characteristic bands at 1320 and 1420 cm−1 according to Eq. (3.1), exposed by Brugnerotto et al. (2001).

And therefore, deacetylation degree (DD):

3.2.3.1 Flame Atomic Absorption Spectrophotometry

In order to observe chelating effect by chitosan, all products obtained with major DD were placed in contact with a stock solution of copper. Stock solution was diluted to concentrations of 1, 2, 3, 4, and 5 mg/L in 1 % nitric acid for calibration curve. The measurements were carried out in a Perkin Elmer absorption atomic spectrophotometer. In a vessel was placed 12.5 mL of a copper stock solution, with concentration of 5 mg/L, 12.5 mg of chitosan obtained, as blank Chitosan (Sigma Aldrich, without additional purification), and 1 mL of 5 % HCl with constant stirring, and placed in centrifuge to 3,400 rpm for 40 min. After this the samples were filtered to measure.

3.3 Results

3.3.1 Physicochemical Characteristics of the Wastewater

In Table 3.1 is presented the characteristics of the wastewater produced within the UAQ. Prior to the activated sludge treatment, it can be noticed that the pH is slightly basic and the pathogen agent's presence is above the regular value of highly polluted water. These characteristics are important to see if the biological process is working to achieve the elimination of the pathogen agents and to try to reach a neutral pH.

The increment of the sludge volume index shows how the microorganisms grow and how it helps in the organic matter removal. The amount of microorganisms let us know the behavior of the WWTP and how fast the organic matter can be eliminated from the wastewater to obtain treated water. The microorganisms’ growth is considered to be an exponential growth and it can be confirmed with the data shown in Fig. 3.1.

Also from Fig. 3.2, it is possible to observe how the pH value from the wastewater changes by an average value of 7.5, showing how much the water is polluted with several substances such as chemical compounds with low toxicity from material wash from the lecturing laboratories.

It took almost 6 months to achieve the optimal and sustainable amount of microorganisms responsible in the organic matter removal. The flow of wastewater increased gradually as demand grew in the UAQ, which allows the proper microorganism growth.

After the wastewater is treated by the activated sludge process, the characteristics of the treated water are summarized in Table 3.2.

Once the majority of the organic matter has been removed, proper disinfection process is needed to avoid the propagation of diseases to animals, plants, and human beings.

3.3.2 Disinfection

Prior to the disinfection process, the titanium dioxide catalyst was synthesized by the sol–gel method. The morphological characterization is not shown in these results because they were already published (Esquivel et al. 2013). For the crystal analysis, X-ray diffraction test were carried out. In Fig. 3.3 is presented the results of the 0.1, 1, and 10 %w Ag-doped TiO2, showing that with thermal treatment at 550 °C which was presented in the experimental conditions, it is possible to see how the sample is getting ordered. The diffraction peaks detected in 2θ (25.4, 37.8, 48.1, 53.9, 55.2, 62.8, 68.6, 70.3, 75.1°) indicates the presence of the crystalline anatase phase (JCPDS no.: 00-004-0477).

From the diffraction pattern peak intensity, a preferential orientation of the plane (101) can be proposed. No diffraction signal appears showing the rutile phase. Also, no signal can be attributed to other crystalline phases of silver oxide compounds. As mentioned, no presence of rutile phase was observed in any of the tested materials, that is why the fraction of anatase XA is considered to be 1 (Petrovic et al. 2011). Even when no silver oxide or rutile phases are present in the samples, a decrease in the crystallinity is noticed and this can be attributed to the presence of silver in the TiO2 crystal (Fujishima et al. 2008).

The grain crystal size calculated by the Debye–Scherrer equation for the unmodified TiO2 shows an average crystal size of 29 nm. As regards the Ag-doped TiO2, the crystal size is slightly smaller than the TiO2 samples and the values are between 13 and 9 nm.

The crystal phase of the TiO2 and Ag-TiO2 photocatalyst was also confirmed with micro-Raman spectroscopy (Fig. 3.4a, b). Using this technique it was possible to observe that TiO2 sample shows only four typical lines corresponding to anatase phase, 147 (Eg), 401(B1 g), 516(A1 g), and 640(Eg) cm−1, having good agreement with those reported for the anatase phase (Horikoshi et al. 2011). In case of the Ag-doped samples at the different amounts of dopant used, the same signals are presented (Fig. 3.4a). No presence of the rutile phase is detected as was observed in the XRD results, too. Finally, as in the XRD analysis, the increment in the %w of the dopant, the intensity of the signals decreases, and in the 10 %w Ag-doped sample, three new signals are presented as can be noticed from Fig. 3.4b.

The new signals can be attributed to the presence of silver in the TiO2 lattice (Hamal and Klabunde 2007) as oxide, which cannot be seen in the XRD analysis.

Another characterization test carried out was the bandgap value measurement by diffuse reflectance analysis and with the Kubelka–Munk function (Christy et al. 1995). According to the %w of silver aggregated to the synthesis the bandgap value does not change between them, it only changes in comparison with the pure TiO2, from 3.2 to 3.15 eV (Table 3.3), a slight change, which is attributed to the presence of Ag and this change will lead us to propose that the material can be activated with solar light.

Once the material was characterized, the disinfection process took place. The treated water used contained 28/100 mL of more likely number of total fecal coliforms. A suspension of the treated wastewater and the catalyst pH 7 was recirculated in a tubular photoreactor and after 3 h under solar light exposure, the samples were taken out to incubate the presumptive test of total fecal coliforms.

In Fig. 3.5 is presented the presumptive media inoculated with the disinfected water. As can be seen, the presence of gas in tubes of the test of disinfection using pure TiO2 shows that in three of three tubes of the 10−1 concentration were positive and two tubes of three on the 10−2 concentration also were positive. By converting these results with a more likely number table (Ervin et al. 2010; Gilbride 2014; Scaglia et al. 2014), the final concentration of total fecal coliforms was 14/100 mL, decreasing the concentration of these microorganisms a 50 % in comparison with the treated wastewater.

For the doped Ag-TiO2 materials, only in two of the three tubes in the concentration of 10−1 for the 10 %w Ag were positive, meaning that with that catalyst, the more likely number of total fecal coliforms was <7.8/100 ml. The rest of the materials remove the 100 % of the total fecal coliforms after 3 h of solar light exposure.

To confirm the presence of fecal coliforms, especially the bacteria Escherichia coli, the confirmative and differential medium were prepared. With the pure TiO2, the bacteria E. coli was present in a concentration <7.8/100 ml. From Fig. 3.6, it is possible to observe that there is no presence of gas in any of the Ag-TiO2 materials tested, concluding that the doped material works as a disinfection agent and the obtained water can be reused for the food production free of pathogen agents.

3.3.3 Metal Removal

From infrared analysis, it is possible to recognize in most of the samples, and blank, representative bands detected in CTS spectrum are in agreement with other literature studies: at 3,400 cm−1 a wide and intense band appears as a result of the stretching vibrations of the –OH and –NH2 groups. The double band that appears at 2,920 and 2,880 cm−1 are due to asymmetric and symmetric stretching vibrations of the –CH2 groups. Bending vibrations of the –NH2 groups and stretching vibrations of C=O groups cause the strong band at 1,657 cm−1 with a shoulder at 1,597 cm−1. This band suggests CTS is a partially deacetylated product. The band at 1,421 cm−1 is caused by vibrations of the –CH2–CO group (characteristic of a ring of the six members). The band at 1,379 cm−1 is attributed to the vibrations of the C–N bond, while the bending vibrations of –OH groups cause the band at 1,320 cm−1. Finally, the strong band at 1,075 cm−1 is due to asymmetric stretching vibrations of the ether functionality (Fig. 3.7) (Flores-Ramírez et al. 2008).

The acetylation was computed using the Brugnerotto’s Equation (3.1) integrating the bands at 1,320 and 1,420 cm−1(Brugnerotto et al. 2001). The results obtained from Eq. (3.2) for DD are shown in Table 3.4, for both synthesis ways and alkali solutions.

These results shows that the deacetylation process was not effective for microwave method, due to short time and lower concentration compared with the traditional method, nevertheless the time and reagent quantity is really low and it is possible to reach highest values by modifying these parameters. Table 3.5 shows the results obtained for copper chelation obtained from Flame Atomic absorption Spectrophotometry; the concentration for the stock solution was determinate, after run calibration curve, in 4.9636 mgL-1 of copper.

It is possible to observe that the percentage of chelation decreases with the DD; this is because the samples have no enough free amino groups, decreasing the chelating capacity. It is also evident that the blank commercial chitosan is the best sample because this sample has around 80 % of deacetylation degree which indicates that the free amino groups’ number is high compared with the samples obtained in the laboratory.

The perspective is that the Chitosan modified with some anionic polyelectrolytes will increase the capacity chelating or natural polymers that provide better mechanical properties like, polyvinyl alcohol, mucilage, polyacrylamide, acrylic acid, etc.

3.4 Conclusion

This study has shown the results of wastewater treatment in purification plants within the UAQ, which is realized by several steps, biological treatment with activated sludge, disinfection process with a photocatalytic material, and metal removal with a natural polymer.

A growing volume from the activated sludge, which increases gradually as demand grew in the UAQ for using water from the sanitary services to the laboratory demands, helps to consume organic matter faster; after the process is evident the significant reduction in total solids, pH, and total fecal coliform become evident and necessary for a disinfection process to prevent disease spread.

The disinfection process was carried out with TiO2 catalyst synthesized by the sol–gel method, and doped with 0.1, 1, and 10 %w of Ag, which after XRD analysis shows the presence of anatase phase and absence of rutile phase; with an average crystal size of 29 nm for pristine TiO2 and for doped material average crystal size between 13 and 9 nm.

The material doped decreased the bandgap to 3.15 from 3.2, raw TiO2, which is attributed to the presence of Ag and this significant change will lead us to propose that the material can be activated with solar light. Thus, in this process for pristine TiO2 there is a microorganism reduction of 50 % compared with the treated wastewater; while the doped material removes 100 % of total fecal coliforms after 3 h of solar light exposure, except for just one tube of 10 %w Ag in the concentration of 10−1.

The confirmative medium shows that for the pure TiO2, E. coli was present in a concentration <7.8/100 ml; and for doped material there is no presence of gas in any sample tested, which indicates that purification process has better performance with doped material and the obtained water can be reused for food production free of pathogen agents.

For the metal removal, the material obtained for traditional method shows high capacity of copper removal compared with material obtained by microwave method, indicating that amino group free number is the most important factor for metal chelation, and these materials could be enhanced with others of similar nature.

In general, the complete process of biological, disinfection, and metal removal, has a high potential to be used to obtain water with enough quality, free of pathogen agents (microorganisms and metal ions), to be reused either for food production or activities that require constant human contact.

References

Abdel-Raouf N, Al-Homaidan AA, Ibraheem BM (2012) Saudi J Biol Sci 19:257–275

Ahluwalia SS, Goyal D (2005) Eng Life Sci 5:158–162

Alves NM, Mano JF (2008) Int J Biol Macromol 43:401–414

Asma D, Kahraman S, Cing S, Yesilada O (2006) J Basic Microbiol 46:3–9

Babel S, Kurniawan TA (2003) J Hazard Mater 97:219–243

Barros AJM, Prasad S, Leite VD, Souza AG (2006) Braz J Chem Eng 23:153–162

Bazilian M, Rogner H, Howells M, Hermann S, Arent D, Gielen D, Steduto P, Mueller A, Komor P, Tol RSJ, Yumkella KK (2011) Energy Policy 39:7896–7906

Bhatnagar A, Sillanpää M (2009) Adv Colloid Interface Sci 152:26–38

Bodaghi H, Mostofi Y, Oromiehie A, Zamani Z, Ghanbarzadeh B, Costa C, Conte A, Del Nobile MA (2013) LWT—Food Sci Technol 50:702–706

Bolto B, Dixon D, Eldridge R (2004) React Funct Polym 60:171–182

Bonnett R, Krysteva MA, Lalov IG, Artarsky SV (2006) Water Res 40:1269–1275

Brugnerotto J, Lizardi J, Goycoolea FM, Arguelles-Monal W, Desbrieres J, Rinaudo M (2001) Polymer 42:3569–3580

Casani S, Knøchel S (2002) Food Control 13:315–327

Chan YJ, Chong MF, Law CL, Hassell DG (2009) Chem Eng J 155:1–18

Chapman H (2006) Desalination 188:105–111

Chauhan D, Jaiswal M, Sankararamakrishnan N (2012) Carbohydr Polym 88:670–675

Christy AA, Kvalheim OM, Velapoldi RA (1995) Vib Spectrosc 9:19–27

Domard A, Domard M (2002) In: Dumitriu S (ed) Polymeric biomaterials. Marcel Dekker, New York, pp 187–212

Elizalde-Peña EA, Flores-Ramirez N, Luna-Barcenas G, Vásquez-García SR, Arámbula-Villa G, García-Gaitán B, Rutiaga-Quiñones JG, González-Hernández J (2007) Eur Polymer J 43:3963–3969

Elizaquível P, Gabaldón JA, Aznar R (2011) Food Control 22:158–164

Elizaquível P, Sánchez G, Selma MV, Aznar R (2012) Food Microbiol 30:316–320

Ervin JS, Russell TL, Layton BA, Yamahara KM, Wang D, Sassoubre LM, Cao Y, Kelty CA, Sivaganesan M, Boehm AB, Holden PA, Weisberg SB, Shanks OC (2010) Water Res

Esquivel K, Nava R, Zamudio-Méndez A, González MV, Jaime-Acuña OE, Escobar-Alarcón L, Peralta-Hernández JM, Pawelec B, Fierro JLG (2013) Appl Catal B 140–141:213–224

Fang Z, Yang J, Cao Y, Zhu L, Zhang Q, Shu D, He C (2013) Procedia Environ Sci 18:503–508

Fujishima A, Zhang X, Tryk DA (2008) Surf Sci Rep 63:515–582

García-Pérez A, Harrison M, Grant B, Chivers C (2013) Biosyst Eng 114:351–356

Geckeler KE, Volchek K (1996) Environ Sci Technol 30:725–734

Gilbride K (2014) In: Helen B (ed) Waterborne pathogens. Academic Press, Amsterdam, pp 231–290

Gray NF (2005) Water technology, 2nd edn. Butterworth-Heinemann, Oxford, p 349–367

Hamal DB, Klabunde KJ (2007) J Colloid Interface Sci 311:514–522

Horikoshi S, Minatodani Y, Sakai H, Abe M, Serpone N (2011) J Photochem Photobiol A 217:191–200

Hossain F, Perales-Perez OJ, Hwang S, Román F (2014) Sci Total Environ 466–467:1047–1059

Hu C-Y, Lo S-L, Chang C-L, Chen F-L, Wu Y-D, Ma J-L (2013) Sep Purif Technol 104:322–326

Jin X, Li E, Lu S, Qiu Z, Sui Q (2013) J Environ Sci 25:1565–1574

Jing H, Guo Z, Guo W, Yang W, Xu P, Zhang X (2012) Bioorg Med Chem Lett 22:3418–3424

Juang R-S, Shiau R-C (2000) J Membr Sci 165:159–167

Kalbar PP, Karmakar S, Asolekar SR (2012) Technol Soc 34:295–302

Kamari A, Ngah WSW (2009) Colloids Surf, B 73:257–266

Kasmuri NH, Idrus NF, Othman NH (2011) Utilization of poly/chitosan as membrane for wastewater treatment. In:2011 IEEE symposium on business, engineering and industrial applications (ISBEIA), pp 581–583

Kortenkamp A, Casadevall M, Faux SP, Jenner A, Shayer ROJ, Woodbridge N, O’Brien P (1996) Arch Biochem Biophys 329:199–208

Krishnani KK, Ayyappan S (2006) In: Ware G, Whitacre D, Albert L, Voogt P, Gerba C, Hutzinger O, Knaak J, Mayer F, Morgan DP, Park D, Tjeerdema R, Yang RH, Gunther F (eds) Reviews of environmental contamination and toxicology. Springer, New York, pp 59–84

Kumar S, Koh J, Kim H, Gupta MK, Dutta PK (2012) Int J Biol Macromol 50:493–502

Lalov IG, Guerginov II, Krysteva MA, Fartsov K (2000) Water Res 34:1503–1506

Laus R, Geremias R, Vasconcelos HL, Laranjeira MCM, Fávere VT (2007) J Hazard Mater 149:471–474

Lin S, Huang R, Cheng Y, Liu J, Lau BLT, Wiesner MR (2013) Water Res 47:3959–3965

Liu J, Lu X (2011) Study on the treatment for chromium—containing wastewater by chitosan. In: 2011 2nd international conference on artificial intelligence, management science and electronic commerce (AIMSEC), pp 6420–6422

Liu H, Yang F, Zheng Y, Kang J, Qu J, Chen JP (2011) Water Res 45:145–154

Liu L, Bai H, Liu J, Sun DD (2013) J Hazard Mater 261:214–223

Milosavljević NB, Ristić MĐ, Perić-Grujić AA, Filipović JM, Štrbac SB, Rakočević ZL, Krušić MTK (2011) Colloids Surf, A 388:59–69

Monteagudo JM, Durán A, Martín IS, Schwab RG (2006) J Chem Technol Biotechnol 81:262–267

Muga HE, Mihelcic JR (2008) J Environ Manage 88:437–447

Nguyen TV, Vigneswaran S, Ngo HH, Pokhrel D, Viraraghavan T (2006) Eng Life Sci 6:86–90

N.R.W.C. Committee (1993) NSW Guidelines for Urban and Residential Use of Reclaimed Water

Otakara A, Yabuki M (eds) (1991) Chitin, chitosan. Gihodou Shupan Kaisha, Japan, pp 9–17

Pablos C, Marugán J, van Grieken R, Serrano E (2013) Water Res 47:1237–1245

Palumbo SA, Rajkowski KT, Miller AJ (1997) Trends Food Sci Technol 8:69–74

Petrovic R, Tanaskovic N, Djokic V, Radovanovic Z, Jankovic-Castvan I, Stamenkovic I, Janackovic D (2011) Powder Technol

Reicha FM, Sarhan A, Abdel-Hamid MI, El-Sherbiny IM (2012) Carbohydr Polym 89:236–244

F.I. Report (2009) Ministry of the environment, rural and marine affairs

Rodriguez-Garcia G, Molinos-Senante M, Hospido A, Hernández-Sancho F, Moreira MT, Feijoo G (2011) Water Res 45:5997–6010

Şahin Y, Öztürk A (2005) Process Biochem 40:1895–1901

Sánchez G, Elizaquível P, Aznar R (2012) Int J Food Microbiol 152:9–13

Sankararamakrishnan N, Sharma AK, Sanghi R (2007) J Hazard Mater 148:353–359

Scaglia B, D’Imporzano G, Garuti G, Negri M, Adani F (2014) Sci Total Environ 466–467:888–897

Sekoulov I (2002) Water Sci Technol 45:315–320

Shetty AR (2006) Metal anion removal from wastewater using chitosan in a polymer enhanced diafiltration system. Worcester Polytechnic Institute, Massachusetts

Sobahi TRA, Abdelaal MY, Makki MSI (2010) Arabian J Chem

Szyguła A, Guibal E, Palacín MA, Ruiz M, Sastre AM (2009) J Environ Manage 90:2979–2986

Thiele DJ (1995) Metal detoxification in eukaryotic cells. Crisp Data Base of National Institute of Health, Washington

Todd J, Josephson B (1996) Ecol Eng 6:109–136

Tomar P, Suthar S (2011) Desalination 282:95–103

Travis MJ, Weisbrod N, Gross A (2012) Ecol Eng 39:81–89

Flores-Ramírez N, Luna-Bárcenas G, Vásquez-García, SR, Muñoz-Saldaña J, Elizalde-Pena EA, Gupta RB, Sanchez IC, González-Hernández J, Garcia-Gaitan B, Villasenor-Ortega FJ (2008) J Biomater Sci Polym Edn 19:259–273

Volesky B, Holan ZR (1995) Biotechnol Prog 11:235–250

Walsh E, Babakina O, Pennock A, Shi H, Chi Y, Wang T, Graedel TE (2006) Technol Soc 28:45–61

Wang X, Lim T-T (2013) Water Res 47:4148–4158

Wang X, Tang Y, Tao S (2008) Adsorption 14:823–830

Wang X, Liu J, Ren N-Q, Duan Z (2012) Bioresour Technol 126:31–40

Xi F, Wu J (2004) J Chromatogr A 1057:41–47

Xu T, Xin M, Li M, Huang H, Zhou S, Liu J (2011) Carbohydr Res 346:2445–2450

Yang H, Wang L, Zehnder AJB (2007) Food Policy 32:585–605

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Pérez-Sánchez, L. et al. (2014). Water Recycling in Biosystems for Food Production. In: Guevara-Gonzalez, R., Torres-Pacheco, I. (eds) Biosystems Engineering: Biofactories for Food Production in the Century XXI. Springer, Cham. https://doi.org/10.1007/978-3-319-03880-3_3

Download citation

DOI: https://doi.org/10.1007/978-3-319-03880-3_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-03879-7

Online ISBN: 978-3-319-03880-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)