Abstract

This article contains an outline of the development of the classic wind mill with some additional attention to developments in the Netherlands.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Windmills can be found in many countries, but an exceptionally wide variety of windmills emerged in the Netherlands. That has to do with the Dutch Golden Age in the late 16th and 17th centuries when the Dutch Republic dominated world trade, created a vast colonial empire and operated the largest fleet of merchantmen of any nation.

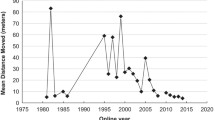

At that time, the windmills were one of the most important drivers of the Dutch economy. The number of mills per inhabitant was large. In their hey-day there may have been 9000 windmills at work in the Netherlands, roughly equal to the number of mills in England, a country with two and a half as many inhabitants ([Wailes, 1948], p. 1).

The development of life on earth proceeds according to the principle of variation and selection. Something similar happens in technology. Inventions are modified, the successful variants survive and are in turn modified again until a certain perfection is achieved. This also applied to the development of wind mills until the moment when other machines took over their tasks. In this article we provide a reconstruction of the development of mill technology focused on the Netherlands.

2 Mills Preceding the Wind Mill

In Antiquity the water powered windmill for grinding grain was preceded by the animal-powered mill. Animal-powered mills are no longer in use in Europe, but there they were in full use from the Middle Ages until the 19th century. See Fig. 1 for one of the last operating mills of this kind in the Netherlands. It was not a grain mill but a churning mill.

Our starting point is a water-powered flour mill described by the Roman military engineer Vitruvius (circa 80–70 BCE – after circa 15 CE) in his De Architectura. A paddle wheel causes a horizontal axis to rotate. Two gears transfer that rotation to a vertical shaft to which the upper millstone of a grinding couple is attached.

In Book X, Chapter 5, Sects. 1 and 2 of De Architectura Vitruvius wrote: “Wheels are used in rivers in the same way as described above. Round the outside, paddles are fixed, and these, when they are acted on by the current of the river, move on and cause the wheel to turn. […] at one end of the axle a toothed drum is fixed. This is placed vertically on its edge and turns with the wheel. Adjoining this larger wheel there is a second toothed wheel placed horizontally by which it is gripped. Thus the teeth of the drum which is on the axle, by driving the teeth of the horizontal drum, cause the grindstones to revolve. In the machine a hopper is suspended and supplies the grain, and by the same revolution the flour is produced” ([Vitruvius, 1931–34]], pp. 304–307). Figure 2 shows a picture from Barbaro’s 1567 century translation of Vitruvius De Architectura (Barbaro, 2019).

In the High Middle Ages (1000–1300 CE) in Europe mills of the kind described by Vitruvius became the ubiquitous productive power. Yet revolutionary changes were on the way.

3 The First Windmills

3.1 The Post Mill

The horizontal-axis windmill is a development of the 12th century, first used in northern France, eastern England and Flanders. The first windmill of this type was the post mill. Kealy has argued that it was “English, rather than Continental technicians, who first tamed the whistling free air” ([Kealy, 1987], p. 7). We won’t argue about it.

What happened? See Figs. 3 and 4. Probably someone considered a watermill powered by a vertical waterwheel as described by Vitruvius, in his or her mind replacing the waterwheel with a wheel with blades driven by the wind. This was in itself a spectacular idea. The oldest form of sail lining on the wings is square-rigged sail lining. Just like on old square-rigged sailing ships an equal amount of sail is carried on either side of the wing. There is undoubtedly an influence here from experience with sailing ships. In order to catch the wind and give driving power sails must have the correct angle of weather resembling that of a propeller, to catch the wind and give driving power. In the more modern wings with a sail on one side of the wing this usually is 5 degrees at the tip and about 25 degrees at the heel, measured from the plane of rotation.

A post mill (Source: [Ramelli, 1976], Plate 133).

Moreover, in Western Europe the wind direction varies considerably. The second novelty of the post mill is that it solves this problem. In order to set the windmill to the wind, the whole mill was made rotatable. The image of three post mills in Siberia (see Fig. 3) suggests that one experimented with the number of wings and also - see the mill on the right - with the position of the drive shaft. The mill on the right of Fig. 3 suggests that one also looked at how the mill functioned when the drive shaft was placed at the bottom, analogous to the situation in Vitruvius’ mill. The post mills were grain mills.

The post mill reached the Netherlands in the 13th century. The body of the mill that houses the machinery is mounted on a big vertical post around which it can be turned. The vertical post is kept steady by supporting beams. Post mills have an arm projecting from them on the side opposite the sails. The arm, combined with a ladder, serves to rotate the mill into the wind by hand.

Edward Kealy wrote: “The post-mill was a daring construction. Harmonizing its various parts was an authentic test of the genius of the carpenters and millwrights” ([Kealy, 1987], p. 18). The big wheel on the windshaft inside the mill is in English called the ‘brake wheel’, because it is also used to brake the mill. Just like in the later mills, the brake in the early standard mills may have consisted of a band brake of wood that could be tightened in some way.

3.2 The Tower Mill

At a certain moment, in the 14th century or before, another brilliant mind must have realized that the transmission from the horizontal or slightly inclined windshaft to the main upright shaft makes it possible to disconnect the cap, with the windshaft fixed in it, from the rest of the mill. The windshaft must then preferably be slightly inclined for stability. We can then rotate the cap without losing the connection of the gearing. This requires that the bottom of the cap and the top of the rest of the mill are coinciding circles with the central shaft in their center. The cap with the horizontal windshaft and the wings is very heavy and if we prevent horizontal movement, the cap may lie loose. To turn the cap we need rollers of some sort. The led to the first offspring of the post mill: the tower mill.

This has consequences for the shape of the mill. Because the bottom of the cap has become circular and the sail cross should be able to move around the building, it is very natural to make the building circular or give it the shape of a regular hexagon or octagon. Because the wind shaft is slightly tilted, the mill can be wider at the bottom. That provides extra space.

Because the whole body can be rotated the post mill is a so-called ground winder. The tower mill, however, is a cap winder. According to a serious Dutch source initially in all tower mills the winding mechanism was inside the cap ([Stokhuyzen, 2007], p. 72).

Such a cap winder with the winding mechanism inside is called an inside winder. There usually is an internal windlass with spokes.

Inside winders have the disadvantage that the miller has to climb into the tower to set the mill to the wind. If the wind direction turns further, he will only notice it later and he will have to climb to the top of the tower again.

So allegedly for a long time the tower mills were inside winders. In the 16th century tower mills that are outside winders appeared. Outside a tail pole is connected to the cap and by means of a series of small posts or eye-bolts around the mill and a winch the tail pole and with it the cap can be turned. Yet, the idea of the tail pole is so simple, that we feel we cannot exclude that outside winder tower mills existed already in the 15th century.

The tower mills were also grain mills. See Figs. 5 and Fig. 6 for some 16th century tower mills. They are all outside winders.

Picture of a tower mill (Source: [Ramelli, 1976], Plate 132)

4 Developments in the Netherlands in the 15th Century: Polder Mills

4.1 The Hollow Post Mill

At the end of the 14th century there were two types of mill: the post mill, which was a ground winder, and the tower mill, which was a cap winder. In the 15th century a new ground winder, the hollow post mill, and new cap winders, the round conical stone mill and the smock mill, appeared. At a certain moment it occurred to someone that the post of the post mill could be made hollow and the rotation of the wings could be transferred to a main upright central shaft rotating inside the post. By means of gearing the rotation of this shaft could then be transferred to a fixed horizontal axis in the base of the mill. In precisely the same way, but now reversed, in which in the tower mill the cap can move with respect to the body of the mill, the body of the mill can rotate with respect to this fixed horizontal axis. This idea led in the Netherlands to the so-called hollow post mill. In this way we can set the sails to the wind and let the mill drive a paddle wheel in order to help drain a polder.

In the Netherlands, the hollow post mills are called wipmolen and they were mostly used for drainage. See Fig. 7. In France, the Moulin Cavier was a hollow post mill used for corn milling. See Fig. 8.

A hollow post mill (Source: [Van Natrus, 1734]).

Numerous lakes in the Netherlands were drained from the 15th century to the 17th century. This hardly happened in the 18th century. In the 19th century, on the other hand, some remaining large lakes were drained, such as the huge Haarlemmermeer. In the 19th century steam engines were used, but earlier the hollow post mill and a successor of the tower mill, the wooden Dutch polder mill were used. We will discuss the Dutch polder mill below. Such mills are called in English smock mills. The mill apparently got its English name from its resemblance to smocks worn by farmers in the past.

4.2 Smock Polder Mills

The disadvantage of the stone tower mill was that it was heavy. In the Netherlands, polygonal wooden cap winder polder mills, the smock mills, were developed out of the tower mill in the 15th century. They were used for the draining of polders. Originally they all used a paddle wheel.

The tower mill also led to round conical stone mills which have walls that are less thick. See Fig. 9.

5 Developments in the 16th and Early 17th Centuries

5.1 Inventions

We saw above that in the 16th century outside winders appeared: tower mills but also Dutch polder mills. At the end of the 16th century, the economy of the Netherlands flourished. This was the time when mill technology was refined. It was also the period in which Simon Stevin tried to design better mills with the help of theoretical considerations. See [Koetsier, 2010].

There are two types of gears in a mill: cog wheels and pinions. Cog wheels have wooden teeth and pinions consist of two round discs between which bars are placed. The wheels are masterpieces of artisan craftsmanship. They are often made of oak wood. The cogs and bars are made of a harder type of wood. The cogs of two interlocking wheels must be made of different kinds of wood, otherwise rapid wear will occur. Practice shows this, allegedly. With two meshing wheels, the number of meshing cog or bars of the smaller wheel may not be a divisor of the number of cogs of the other wheel. This prevents the same cogs or bars from always interfering with each other which would cause local wear ([Stokhuyzen, 2017], pp. 97–98). Beeswax is used as a lubricant.

Octogonal smock mill with paddle wheel (Source: [Van Natrus, 1734]).

At the time there were many trade secrets in the millwork industry that were only passed on orally. Some were based on experience acquired over centuries, others were new.

In the Netherlands only a few names are known of men who made innovative inventions in mill construction. One of them was Symon Hulsebosch. At the time the Archimedean screw pump was known. It consisted of a helical surface that was fixed inside a pipe. By tilting the pipe and turning it water could be lifted. However, when the pump is used, the weight of the helical surface, the pipe and the water must be supported. If such a pump is enlarged too much, it will weigh too much, bend and break. In 1634 Symon Hulsebosch realized that the helical surface did not have to be fixed in the pipe. It is sufficient to place that surface at an angle in a semi-circular gutter. This seems to be an originally Dutch invention.

In this form the screw pump appeared to function better than the paddle wheel. In many mills the paddle wheel was replaced by a screw pump, but not in all of them ([Stokhuyzen, 2017], pp. 111–113).

Another inventor, whose name we know, was Cornelis Corneliszoon van Uitgeest (Circa 1550 - circa 1607). He realized that the rotation about the horizontal axis created in the base of a hollow post mill used for drainage could also be used otherwise. By using a crankshaft the rotating movement could be converted into an up and down movement. This could power saw blades. In the history of humanity, Corneliszoon was not the first to have this idea, but in his case the idea was quickly developed and proved to be extremely effective.

Corneliszoon possibly was hardly literate. In any case, he had a rather awkward drawing style. See Fig. 11 for drawings accompanying the patents for a wind-powered sawmill (left) on December 15, 1593 and for crankshafts (right) on December 6, 1597, that were granted to Cornelis Corneliszoon van Uitgeest by the States of Holland, the highest administrative body in Holland.

Drawings accompanying Corneliszoon’s patents (Source: [Bonke et al., 2004]).

The drawings show a hollow post mill that drives a crankshaft that moves a saw blade up and down. There is also a pinion on the axle that drives a large wheel, which in turn drives a pinion that moves a rack so that the tree trunk to be sawn is pulled towards the saw.

It is certain that Cornelis Corneliszoon was already thinking of several saw blades. The other drawing shows a shaft with multiple bends with which several saw blades can be driven.

5.2 The Paltrok Mill

After a number of further improvements by others, Corneliszoon’s patents led to a very successful saw mill, the so-called paltrok mill. The name was chosen because the shape of the mill resembles the shape of the garment called ‘paltrok’. See Fig. 12 and Fig. 13. The paltrok mill is specially designed for sawing wood. The brake wheel of the mill drives a crankshaft with three bends at angles of 120 degrees. The left and right bends drive saw frames, while the middle one drives an empty pump frame for stability.

The mill house is supported by a short central wooden post around which the entire mill house revolves. For further support, a rim bearing is mounted on a brick base, on which the mill housing rotates with numerous rollers. Like the hollow post mill the paltrok mill is also a groundwinder.

The paltrok mill was extremely successful. There have been many hundreds of them in the Netherlands. John Reynolds called it the “earliest type of a wind driven saw mill, introduced in Holland” ([Reynolds, 1970], p. 187).

Paltrok mill: close up of the crankshaft (Source of both pictures: [Van Natrus, 1734]).

5.3 Explosion of Industrial Mills

In the Dutch province Zuid-Holland the paddle wheel managed to maintain itself in the hollow post mills and the smock polder mills. Originally the smock mills were all inside winders but after the 16th century in this part of the country the outside winders took over. In the province Noord-Holland one switched to screw pumps. See Fig. 15. In this part of the country inside winders continued to dominate.

In the 17th century there was a real explosion of industrial mills: husking mills (for husking barley or rice), oil mills, sawmills, paper mills, drill mills (for drilling gun and cannon barrels), cocoa mills, mustard mills, bark mills (they ground oak bark for the tannery), felting mills (for felting woolen cloth), snuff mills (made snuff).

Many industrial mills were located in the Zaan region north of Amsterdam, which is one of the oldest industrial areas in Europe. Figure 14 shows what it looked like in the 18th century.

Smock mill with Archimedean water screw; it is an outside winder (Source: [Van Natrus, 1734]).

An oil mill is all about pressing oil from seeds. Edge runners were used for this. These are heavy stone wheels that roll on their side over a lying stone. Also here Cornelis Corneliszoon contributed to the development. See Fig. 16 and Fig. 17. The key innovation was the combination of two mechanisms: the edge runners which crushed the seeds, and a vertical stamper, which drove wedges squeezing the oil from the pulp and pressing the pulp in the form of cakes. The complexity of the machinery grew in the 17th century when additional stampers made the further processing of the cakes possible, which yielded more oil. Such mills were called double oil mills ([Davids, 2008], p. 177).

Drawing for patent H 23/1597 for an oil mill with edge stones granted to Cornelis Corneliszoon (Source: [Bonke et al., 2004])

6 The Smock Mill in Laren NH

There are still 1170 windmills in the Netherlands, many of which are still operational. We will look at one in some detail because it happens to be located near the author’s home. It is the windmill in Laren in North-Holland. See Fig. 19.

It as an octagonal thatched wooden inside winder. It is now a grain mill, but it has not always been so. The mill once stood elsewhere and was probably a polder mill. See Fig. 10 and Fig. 20. Figure 20 is speculative.

The mill came to Laren in the first half of the 18th century during the period when there was less drainage in the West of the country in North and South Holland and there were therefore too many polder mills. The question of how the transport took place is intriguing.

In England, a mill was sometimes transported in its entirety after the blades and machinery had been removed. The mill was then put on rollers and pulled to a new location. This happened in 1797 in Brighton where 86 oxen moved a mill a distance of more than a mile ([Wailes, 1948], p. 14). It seems that in England smock mills were usually dismantled and reassembled at the new site. There are reports of marking the parts with Roman numerals and packing tarred felt in the joints to make them weatherproof ([Freese, 1957], pp. 152–153). As for the Netherlands Simon Hart has given some examples of mills that were moved from one place to another around the year 1600 ([Hart, 1976], pp. 95–97). The mills were undoubtedly taken apart and transported on rafts or by boat by water over distances of several dozen miles.

The Laren mill was surely also taken apart and largely transported by water. The Netherlands had an excellent system of canals and barges for the transport of people, which also lent itself to the transport of the parts of a mill. The last part of the route on water would have been via the Naarder canal from Muiden to Naarden, which was dug in 1641. There were then another 4 miles to go from Naarden to Laren by horse and cart. At that time the mill had two pairs of millstones. The paddle wheel had been removed. With the arrival of electricity in the village in the early 20th century, one pair of stones was moved to the ground floor. It is now powered by an electric motor. The other pair is still powered by the wind (Fig. 25).

People always tried to make the work in the mill easier. In a flour mill, bags of grain had to be lifted up and bags of flour had to be lowered. The mills were therefore equipped with a sack hoist (Fig. 25).

7 Concluding Remarks

Our story started with Vitruvius’ water powered grain mill. Replacing the paddle wheel in Vitruvius’ mill with a paddle wheel led in Europe to the post mill. The post mill is a ground winder and is at the beginning of two development lines. The first leads to two other ground winders: first the hollow post mill and then the paltrok mill. The second line is a line one of cap winders, first the tower mill and then the round conical mill and the polygonal smock mill. Both the hollow post mill and the smock mill were used extensively for drainage in the Netherlands. Around 1600, not only the extremely successful paltrok sawmill appeared in the Netherlands, but many other industrial mills were also built, with several different functions.

The mills we treated are all ground-sailers, meaning mills whose sails and brakes can be operated from the ground. To catch more wind or to create space inside, windmills were also made higher. This led to the so-called stage mills, tower stage mills or smock stage mills. The round conical stage mills in Schiedam in the Netherlands are the highest in the world. Six of them still exist. See Fig. 26.

References

Bonke H., et al.: Cornelis Corneliszoon van Uitgeest, uitvinder aan de basis van de Gouden Eeuw, Zutphen (2004)

Davids, K.: The Rise and Decline of Dutch Technological Leadership, Technology, Economy and Culture in the Netherlands, 1350–1800, Two Volumes, Leiden (2008)

Freese, S.: Windmills and Millwrighting, Cambridge (1957)

Hart, S.: Geschrift en Getal, Dordrecht (1976)

Edward, J.: Harvesting the air, Windmill Pioneers in Twelfth-Century England. The Boydell Press (1987)

Koetsier, T.: Simon Stevin and the rise of Archimedean mechanics in the renaissance. In: [Paipetis&Ceccarelli, 2010], pp. 85–112 (2010)

Paipetis, S., Ceccarelli, M., (eds.), The Genius of Archimedes – 23 Centuries of Influence on Mathematics, Science and Engineering. Springer, Dordrecht (2010). https://doi.org/10.1007/978-90-481-9091-1

Ramelli, A.: The Various and Ingenious Machines of Agostino Ramelli, Dover Publications (1976)

Reynolds, J.: Windmills & Watermills, London (1970)

Stokhuyzen, F., de Groot, E., et al.: Molens , de nieuwe Stokhuyzen, Uitgeverij Waanders in Zwolle & Vereniging de Hollandsche Molen in Amsterdam (2017)

van Natrus, L., Polly, J., van Vuuren, C.: Groot volkomen Moolenboek, Deel 1, Amsterdam (1734)

Vitruvius: Vitruvius on architecture, Volume 2, London, W. Heinemann; New York, Putnam (1931–1934)

Barbaro, D.: Daniele Barbaro’s Vitruvius of 1567, Translated and Annotated by Kim Williams, Springer Nature Switzerland AG (2019)

Wailes, R.: Windmills in England, a study of their origin, development and future, London (1948)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Koetsier, T. (2024). Windmills in the Netherlands. In: Ceccarelli, M., Aslan Seyhan, I. (eds) Explorations in the History and Heritage of Machines and Mechanisms. HMM 2024. History of Mechanism and Machine Science, vol 47. Springer, Cham. https://doi.org/10.1007/978-3-031-54876-5_6

Download citation

DOI: https://doi.org/10.1007/978-3-031-54876-5_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-54875-8

Online ISBN: 978-3-031-54876-5

eBook Packages: EngineeringEngineering (R0)