Abstract

Ethylcellulose (EC) is unique among oleogelators, as it is the only polymer allowed in foods which is capable of being directly dispersed in edible oils. The resulting network is supported by interpolymer physical crosslinks, entrapping the liquid oil phase. These oleogels can have a broad range of mechanical and rheological properties, depending on the polymer molecular weight, oil type, and the presence of polar compounds such as free fatty acids or various food-grade amphiphilic surfactants. Combining EC with some low-molecular-weight crystalline oleogelators has also been shown to produce a synergistic enhancement in gel strength due to the formation of hybrid networks. Appropriate selection of crystalline gelators can be used to enhance various technofunctional traits such as oil binding, gel strength, rheological behavior, and large deformation characteristics. EC-based oleogels have been used as a fat substitute in a variety of food applications and as margarine and shortening mimetics. They have also been explored as a means of modulating digestion and release of lipid-soluble bioactives. These EC-based multicomponent oleogels show considerable promise for developing more accurate fat mimetics that match the broad range of performance and sensory characteristics of traditional fats.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 General Properties of EC

Cellulose is an unbranched linear homopolymeric carbohydrate made up of repeating β(1➔4)-linked d-glucose residues. The highly linear conformation allows cellulose to form extensive inter- and intramolecular hydrogen bonds and assemble into hierarchical structures known as microfibrils, which provide structural support in the cell walls of plants. Ethylcellulose (EC) is a chemically modified derivative of cellulose used in a wide range of applications across numerous industries, including manufacturing, pharmaceuticals, cosmetics, and agriculture [1, 2]. It possesses excellent flexibility, extensibility, film forming and water-barrier properties and is considered physiologically inert. As such, EC finds uses in tablet coatings and binders, drug delivery and controlled release applications, food-printable inks, and as a component of barrier coatings [3,4,5,6]. It has also been explored for several biomedical [7] and drug delivery applications [8].

Industrially, EC is produced by reacting alkalized cellulosic biomass with ethyl chloride gas in the presence of a catalyst, inducing the formation of ethyl ether bonds at the hydroxyl moieties of carbons C2, C3, and C6 (Fig. 7.1a). The alkaline treatment opens the cellulose crystal structure, increasing accessibility to the hydroxyl groups, and causes the formation of alkoxide ions [9]. The extent of ethoxylation will impact the polymer’s physical properties and technical performance. Common commercial grades are prepared with an ethoxy content of ~48–49.5% [10], corresponding to a degree of substitution of ~2.4–2.5 [11]. This level of substitution renders the polymer insoluble in water, but soluble in a variety of organic solvents, and produces a minimum in the glass transition temperature (Tg), occurring in the range of 125–140 °C [11].

EC is commercially classified according to its viscosity, measured as a 5 wt% solution in an 80/20 mixture of toluene and ethanol at 25 °C. These values are reported in units of centipoise, and will be abbreviated to denote this classification (e.g., 10 cP EC; EC10). It has been shown that EC viscosity is positively correlated to the average molecular weight (MW) of the polymer [12, 13], which has a direct impact on the performance of EC as an oleogelator. Figure 7.1b demonstrates that viscosity is also positively correlated to Tg, which progressively increases from ~125 to ~140 °C for 10, 45, and 100 cP varieties [12]. It has also been shown that microcrystalline domains remain in the EC polymer, which are expected to be unsubstituted. Both differential scanning calorimetry (DSC) [14] and X-ray scattering [12] approaches have confirmed there is a reduction in the extent of crystallinity after heating the polymer above its melting temperature (Tm; ~180–190 °C). This suggests a greater number of unsubstituted hydroxyl groups would be available for gel formation upon melting, and firmer oleogels have been reported when heating to Tm, as compared to those heated slightly above Tg (190 and 140 °C, respectively) [15]. However, standard protocols for producing EC oleogels generally restrict heating to ≤160 °C to minimize thermally induced lipid oxidation and EC depolymerization [16,17,18]. It is thus expected that the crystalline regions would remain in EC-based oleogels, and the breakdown in crystallinity is not expected to influence gel properties.

7.2 Structuring Edible Oils

7.2.1 EC as a Single-Component Gelator

Commercial-grade ethylcellulose is known to be compatible with various lipid-based compounds, including natural waxes, fatty acids, fatty alcohols, and triglyceride oils [11]. The concept of using EC to structure liquid vegetable oils was first explored by Aiache and coworkers for cosmetic applications [19]. In this study, a triglyceride oil was reacted with polyoxyethylene glycol to obtain a mixture of both ethoxylated mono- and diglycerides, and mono-, di-, and triglycerides. It was reported that heating mixtures of EC powder (2–9 wt%) in the ethoxylated oil to the polymer’s Tg formed clarified dispersions. Upon cooling, these mixtures produced viscous solutions to paste-like suspensions, depending on the polymer concentration.

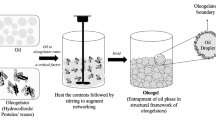

The use of EC in lipid-based systems was expanded to edible vegetable oils by Laredo et al. [20], who demonstrated that self-supporting gels could be produced using an equivalent heating/cooling procedure. It was proposed that heating above the Tg facilitated dissolution of the polymer due to an increase in molecular flexibility. Upon cooling, the individual chains return to a more rigid state, promoting the formation of inter- and intramolecular hydrogen bonds between the unsubstituted hydroxyl groups. At sufficiently high concentrations, a system-spanning, self-supporting network will form, entrapping the liquid oil. The physical nature of the polymer-polymer junction zones was demonstrated through a shift in the OH-stretching band of EC by Fourier transform infrared (FTIR) spectroscopy [20]. The mechanical strength of these gels has also been shown to decrease with increasing temperature [15], providing further indirect evidence for the physical nature of the polymer network. In general, the minimum polymer concentration to form a self-supporting gel is ~4–6 wt% EC, depending on the polymer MW and composition of the oil phase [21, 22]. The mechanical strength of vegetable oil–based EC oleogels has been extensively characterized and depends on a variety of factors, including EC viscosity and concentration, oil type, processing conditions, and the presence of small MW surfactants. These are discussed in greater detail below.

7.2.1.1 Polymer MW and Processing Conditions

Commercial grades of EC are available in viscosities ranging from 4 to 300 cP, but the practical range for structuring triglyceride oils is generally accepted to be those ranging from 10 to 45 cP [21, 23]. Lower viscosity varieties form a less entangled network with fewer intermolecular junction zones and thus require higher concentrations to form self-supporting gels. Higher MW versions form stronger gels, but the corresponding increase in Tg (Fig. 7.1b) means they must be heated to a higher temperature to sufficiently disperse the polymer for gel formation [16, 24]. This process can contribute to both thermal oxidation of the oil phase and also result in depolymerization and browning of the polysaccharide when heated above 160 °C due to caramelization reactions.

As a potential strategy to reduce the Tg and expand the utility of EC oleogels, Mashhadi and coworkers [25] subjected EC100 to an acid hydrolysis process. Partial hydrolysis was achieved using ethanol and acetic acid in varying ratios and under different heating conditions. They reported a reduction in Tg of ~10–30 °C, with an additional thermal event at lower temperatures, which was attributed to smaller polymer fragments. Firmer oleogels resulted for all hydrolysis conditions, but varied in the extent of this increase. It is noteworthy that the observed reinforcement may have been in part due to the improved dispersibility of lower MW chains when following the same heating protocol required to fully disperse EC100 [21]. Therefore, further investigation would be required to fully characterize the MW distribution of the hydrolysates and explore the potential benefits of this approach relative to using existing commercially available varieties of EC with lower MW.

The mechanical strength of EC oleogels is also positively correlated to polymer concentration and has been shown to follow a power-law scaling behavior [21]. However, the scaling relation depends on numerous factors, including oil type, polymer MW, and the presence of surfactant molecules in the oil phase [21,22,23]. In general, gel strength is positively correlated with the viscosity grade (i.e., MW) [21, 23, 24]. The effect of oil type has been shown to be more complex, as development of thermally induced oxidative byproducts and the presence of polar compounds can dramatically alter solvent/polymer interactions [16, 18, 22]. These factors are discussed in greater detail in the following section.

Processing conditions and gel-setting temperature have also been shown to impact gel strength. Davidovich-Pinhas and coworkers [15] demonstrated that canola oil oleogels prepared with 15 wt% EC20 had a gel strength of ~50 N when allowed to set at temperatures ranging from −20 to 50 °C, while this increased to ~120 N when gelation was allowed to occur at 80–100 °C. A similar trend was seen when incorporating the surfactants sorbitan monostearate and glycerol monooleate, but produced a less dramatic increase in gel strength, with a maximum occurring when gels were allowed to equilibrate at 50–80 °C. An increase in gel strength has also been noted when gels were subjected to a thermal annealing procedure; i.e., initially setting a gel at 20 °C and subsequently reheating to 80 °C for 1 h produced an equivalent enhancement in gel strength to that achieved by initially gelling at 80 °C (unpublished data). These effects were attributed to a temperature-induced weakening and rearrangement of the hydrogen-bonding network supporting the gel. Maintaining the gels at a temperature slightly below their gel point temperature (Tgel) may have provided more opportunity for the polymer chains to take on more extended conformations and establish new interchain interactions, ultimately increasing crosslink density [15]. Therefore, controlling the gelation conditions may provide an effective approach to manipulate the mechanical performance of EC oleogels; however, the impact of thermal history should also be considered if applications require heating/cooling cycles, such as the melting and recrystallization of fats.

7.2.1.2 Solvent Composition

Oil composition has been widely recognized as having a major impact on the mechanical and textural properties of EC oleogels. Laredo and coworkers [20] first reported an increase in gel strength for oleogels produced using canola, soybean, and flaxseed oils, respectively. Due to the lack of polymer-solvent interactions observed by (FTIR) spectroscopy, these differences were attributed to a moderate increase in density of the lipid phase due to the higher degree of acyl chain unsaturation (canola > soy > flaxseed) [20, 21]. While this conclusion was supported by microstructural analysis (i.e., decreased pore size) [26], subsequent work suggested this phenomenon resulted from the build-up of thermally induced polar oxidation by-products [16, 27]. The observed trend in gel strength was therefore associated with a greater susceptibility of the oil phase to undergo oxidative rancidity during the polymer dissolution process. To minimize the impact of the heating procedure, antioxidants and highly controlled and reproducible heating protocols are generally employed.

The polarity of the oil phase and the presence of additional polar compounds have also been shown to have a dramatic impact on both the mechanical and textural properties of EC oleogels. Gravelle and coworkers [22] evaluated the effect of bulk solvent polarity by supplementing soybean oil-based oleogels (11 wt% EC45) with either mineral oil or castor oil. The former is a mixture of alkane hydrocarbons with no dipole moment. In contrast, castor oil is a triglyceride oil consisting primarily of ricinoleic acid (>85%), a derivative of oleic acid with a hydroxyl functional group at carbon 12. While both solvents are miscible in triglyceride oils, only the latter would contribute to hydrogen bonding with the polymer network. Mineral oil reduced the bulk solvent polarity and weakened the resulting gels, which could not be formed above 10 wt% supplementation (Fig. 7.2a).

Mechanical properties of ethylcellulose oleogels supplemented with either castor oil (open circles) or mineral oil (filled diamonds) at varying wt% (φs). Relative gel strength determined by texture profile analysis (a) and macroscopic deformation for oleogels supplemented with 20 wt% castor oil (b) or no supplementation (c). (Panel (a) reproduced from [22], with permission from Elsevier)

The addition of castor oil caused a linear increase in gel strength up to ~10 wt% supplementation, above which a plateau was observed (Fig. 7.2a). Increasing solvent polarity also improved the functional performance of these oleogels. When prepared exclusively with refined, bleached, and deodorized vegetable oils, the resulting oleogels exhibit highly brittle fracture behavior and exude liquid oil at the site of fracture due to the weak solvent-polymer interactions (Fig. 7.2c). The presence of castor oil dramatically increased the gel elasticity and eliminated the occurrence of syneresis (Fig. 7.2b). This suggested the hydroxyl groups in the lipid phase directly interacted with EC, improving solvent-polymer interactions, producing an increase in gel strength and enhanced oil binding. This interpretation was supported by applying the formalism of Hansen solubility parameters to the dose-response effect on molten oleogel viscosity. Optimal solvent-polymer interactions (i.e., maximum viscosity) occurred at ~80 wt% castor oil, corresponding to a maximum in hydrogen bonding interactions, while intermolecular and dispersive forces had little impact on EC solubility and gelation behavior. Similar conclusions have been drawn for EC in other solvents, such as mixtures of vegetable oils and glycerol monooleate [28].

The microstructure of EC oleogels has been visualized using both cryo-scanning electron microscopy (Fig. 7.3a) [26] and atomic force microscopy (Fig. 7.3b–d) [18, 29]. The internal polymeric network appears as a 2-dimensional porous mat or 3-dimensional closed-cell foam with porous walls, depending on the extent of oil removal. Wall thickness has been reported to change based on extraction conditions, but may also be influenced by the composition of the oil phase. Giacintucci and coworkers observed thicker walls in oleogels prepared with extra virgin olive oil (Fig. 7.3b), while these became thinner after deodorization (Fig. 7.3c) and neutralization and bleaching (Fig. 7.3d), which removed naturally present, polar minor compounds. Thicker walls and variations in pore size were proposed to be correlated to higher gel strength; however, variability in the partial solvent extraction procedure should not be dismissed. In spite of this, the thicker pore walls in oleogels prepared with less refined oils (which contain polar minor compounds) may again be indicative of stronger solvent-polymer interactions, which would contribute to enhanced gel strength, as discussed above.

Microstructure of partially de-oiled ethylcellulose oleogels: (a) Scanning electron micrograph of soybean oil-based oleogel (reproduced from [26], with permission from Elsevier); (b–d) atomic force micrographs of an oleogel prepared with extra virgin olive oil (adapted from [18], with permission from Elsevier), which were untreated (b), degummed (c), or degummed, neutralized, and bleached (d)

7.2.1.3 Low-Molecular-Weight Additives

In addition to direct interactions with the bulk solvent, various amphiphilic small molecules with polar functional groups can also have a positive effect on gel strength. These additives generally produced a more dramatic change in gel strength at low concentrations, due to their inherent surface activity. However, their impact is generally dependent on the particular chemical structure [23, 30]. The common food-grade surfactants glycerol monooleate, sorbitan monooleate, and sorbitan monostearate were shown to have a similar effect on the gelation behavior and rheological and mechanical properties of EC oleogels [15]. When incorporated at a 3:1 EC-surfactant molar ratio, both molecules produced an equivalent increase in gel strength and corresponding depression in the gel point temperature (Fig. 7.4a).

(a) Gel strength (filled bars) and crossover temperature (patterned bars) of ethylcellulose (EC) oleogels prepared with 11 wt% 45 cP EC, and a 3:1 EC/surfactant mass ratio in canola oil (adapted from [30], with permission from Elsevier). (b) Normalized gel strength of EC oleogels prepared with canola oil and supplemented with oleic acid (open diamonds) or oleyl alcohol (filled diamonds). X-axis indicates the mass fraction additive supplemented in the oil phase (adapted from [22], with permission from Elsevier)

The addition of oleic acid and oleyl alcohol has also been shown to elicit a dramatic increase in gel strength and elasticity at low concentrations (≤1 wt%; Fig. 7.4b) in soybean oil-based oleogels prepared with 11 wt% EC45. This pronounced effect was attributed to the migration of the polar headgroups to the hydrophilic regions of the EC backbone, enhancing oil-polymer interactions at much lower concentrations than that seen with increasing bulk solvent polarity. The plateau and subsequent decrease in gel strength at high surfactant concentrations (≥10 wt%) can be attributed to further plasticization of the polymer [11]. These formulations also displayed a high level of elasticity and complete lack of syneresis upon deformation, analogous to the gels prepared with castor oil [22]. Fatty acid derivatives such as glycol esters are also commonly employed as plasticizing agents in products formulated with EC to reduce brittleness and improve suppleness and thermoplasticity (e.g., in film and coating applications) [9]. It has been further shown that removing free fatty acids from cold-pressed flaxseed oil caused a significant decrease in the strength of the resulting gel [22]. Taken together, these findings demonstrate that in addition to elevated solvent polarity (e.g., due to thermal oxidation), polar minor compounds can enhance oil-polymer interactions, and serve as effective plasticizers, which can have a dramatic impact on the mechanical and textural properties of EC oleogels.

Incorporating surfactants into EC oleogels may also expand their utility in applications beyond food systems, such as lipid-based printable inks. Kavimughill and coworkers [31] evaluated the gelation properties and hot-melt extrusion performance of EC oleogels (11 wt% EC100) prepared with medium-chain triglycerides and the nonionic surfactant polyethylene glycol monostearate (PGMS40; 40 polyethylene glycol units per stearic acid molecule). The addition of surfactant (0–5 wt%) was positively correlated to gel strength and viscosity, and imparted greater plasticity, which improved printability. Optimum printing and multilayer stacking were achieved with 5 wt% surfactant extruded at 45 °C. The formation of a surfactant crystal network also contributed to the improved printing characteristics.

Taken together, these results demonstrate both the bulk polarity of the lipid phase and presence of surface-active minor components play a strong role in determining the mechanical, rheological, and functional behavior of EC oleogels. Building on this approach, the following section discusses relevant studies which have combined EC with surface-active small molecules that structure oil via the formation of lipid-based crystalline networks.

7.2.2 Multicomponent Oleogels Based on EC

Traditional fats provide a broad range of desirable technofunctional properties in foods. These traits arise through a complex interplay between their chemical composition and processing conditions, which ultimately determines the structural characteristics of the underlying hierarchical fat crystal network and its associated macroscopic performance [32]. Single-component oleogelator systems may be able to replicate certain attributes (e.g., firmness, melting behavior, and fracture stress), but often lack the ability to mimic the full range of behaviors provided by even a single fat source [33]. To expand the functional properties of oleogels and develop improved fat mimetics, the use of binary or ternary oil structuring systems has become an increasingly popular approach. Those systems which produce cooperative networks that synergistically enhance desirable attributes are of particular interest [34, 35].

The ability of EC to directly disperse in edible oil and form an extended polymer network makes it uniquely compatible with other lipid-soluble oleogelators, the majority of which are high-melting point lipid-based compounds [36, 37]. These low-molecular-weight oleogelators (LMOGs) are most commonly incorporated in the oil phase by heating above their melting point. Upon cooling, they assemble into a 3-dimensional crystalline network which entraps the liquid oil phase, analogous to traditional triglyceride fats [32]. Direct oil structuring by crystalline networks has been extensively investigated using gelators such as natural waxes, monoglycerides, and fatty acids, fatty alcohols, and their mixtures [37]. Furthermore, interactions between the polar regions of these crystalline gelators and EC may produce synergistic binary networks. Therefore, introducing a secondary crystalline oil-structuring network could provide functional benefits to EC oleogels, such as promoting favorable melting behavior and plastic flow characteristics. Additionally, EC has been incorporated in some LMOG-based oleogels below its critical gelation concentration (CGC), providing an alternative route to modulate crystallization behavior and performance of the resulting oleogel.

7.2.2.1 Monoglycerides (MGs)

MG-based oleogels have been extensively studied and can impart many of the desirable properties associated with traditional fats [38]. The performance of these LMOGs is intrinsically linked to the polymorphic form and microstructural arrangement of the crystal network, which are largely dictated by the chemical composition of the MGs and processing conditions used during gelation. Incorporating EC has been explored as an alternate route to modulate the rheological and mechanical performance of MG-based oleogels. Lopez-Martínez and coworkers [39] were the first to investigate the impact of EC on crystalline gelator interactions. This group evaluated oleogels using two varieties of MG (~80% palmitic or 50/50 palmitic-stearic) prepared with 2 wt% or 8 wt% MG, either as the sole oleogelator or with 6 wt% EC4. While the authors noted the latter was below the CGC of EC based on previous reports, control gels prepared with EC alone had a complex modulus (G*) of >5000 Pa, suggesting a system-spanning polymer network was able to form. In all cases, the addition of EC caused a dramatic increase in G*. The effect was particularly pronounced for the 8 wt% MG gels, which saw a two-decade increase in G* with EC addition. This was attributed to the formation of a synergistic binary network resulting from a combination of polymer-crystalline gelator interactions and the formation of a crystalline network in the bulk liquid oil entrapped within the EC polymer matrix. During a 2-week storage period, the authors noted the combined system delayed the transition of MG from the sub-α to the β-polymorph [39]. This transition has been shown to cause deleterious effects on MG oleogel performance, including syneresis and the formation of larger crystals, which promote brittleness [40, 41]. Introducing an EC polymer network could therefore potentially be used to modulate the structural properties of crystalline oleogelators at varying length scales to improve the stability and performance of the multicomponent system.

7.2.2.2 Fatty Acid/Fatty Alcohol Mixtures

Both fatty acids [42, 43] and fatty alcohols [44, 45] have been independently explored as single-component crystalline oleogelators. When used in appropriate ratios, these two classes of molecules are also able to co-crystallize, allowing such combinations to serve as a distinct oleogelator system [46]. The acid/alcohol ratio plays a major role in determining the crystal morphology and associated oil binding, mechanical, and rheological properties [47, 48]. It has generally been reported that a 1:3 acid/alcohol ratio minimizes interfacial tension in the crystal unit cell, and the resulting crystal network has been shown to provide improved oil binding and enhanced gel strength [47, 49].

Considering the strong interaction between EC and these low molecular weight amphiphilic molecules (e.g., Fig. 7.4b), multicomponent oleogels combining mixtures of stearic acid and stearyl alcohol with EC have also been explored. Using a 3:7 acid/alcohol ratio, Gravelle and coworkers [50] reported evidence of a direct interaction between the crystalline and polymer networks for oleogels structured with 6 wt% EC45 and 5 wt% small molecules. The addition of EC had a dramatic impact on the microstructural arrangement of these mixed crystals, which appeared smaller and assembled into fan-like structures (Fig. 7.5a). It was proposed this morphology was caused by crystal nucleation along the polymer backbone. However, these interactions did not impact the polymorphic form of the mixed acid/alcohol crystals. The presence of EC also produced an increase in the onset of crystallization for these mixed crystals (Fig. 7.5b). The LMOG mixture similarly caused a ~20 °C reduction in the polymer’s crossover temperature during cooling (i.e., the temperature where the shear elastic modulus and shear storage modulus are equal; G′ = G″), which is commonly taken as a measure of the gel point temperature (Fig. 7.5c). Thermal analysis also demonstrated a dose-response reduction in the Tg of EC with increasing content of the small molecules. This lends further support to the hypothesis that direct polymer-small molecule interactions contributed to the observed mechanical response. Finally, the combined system produced a synergistic enhancement in gel strength, while the change in crystal morphology also reduced brittle flow behavior associated with larger crystals that undergo catastrophic failure during mechanical deformation (Fig. 7.5d). In contrast, when EC was incorporated below its CGC (~4 wt%), the gels were softer, and displayed no brittle fracture during penetration. Subsequent work by the same group further explored the effect of acid/alcohol ratio [51]. Both the crystal type and composition were reported to have a dramatic impact on the resulting crystal morphology and associated performance of these multicomponent oleogelator systems.

Physical properties of oleogels prepared from a 3:7 mixture of stearic acid/stearyl alcohol (StA/StO). (a) Microstructure of StA/StO oleogels without (Panel a, left) or with (Panel a, right) 6 wt% 45 cP ethylcellulose (EC); (b) DSC thermogram of StA/StO crystallization; (c) rheological characterization of EC crossover temperature; (d) large deformation flow behavior evaluated by back extrusion. *CGC—critical gelation concentration. (Adapted from [50], with permission from Elsevier)

7.2.2.3 Free Fatty Acids

Lauric acid is a 12-carbon medium-chain saturated fatty acid found in high quantities in coconut oil (~50%), and contributes to its desirable melting properties. Lauric acid has also been explored as a secondary structuring agent used in combination with EC20 to produce canola oil-based oleogels [52]. When combined, these gelators produced a synergistic enhancement in gel strength. While the polymorphic form of lauric acid was not impacted by the addition of EC, the peak crystallization and melting temperature was depressed as EC concentration increased. This trend was hypothesized to result from steric hinderance induced by EC/lauric acid interactions. Further, the presence of lauric acid dramatically reduced the crossover temperature of EC, consistent with that observed for mixtures of fatty acids and fatty alcohols (noted above). The latter was attributed to EC plasticization and enhanced solvent-polymer interactions promoted by lauric acid. The combined polymer-fatty acid system also showed improved thixotropy relative to oleogels independently structured with EC or lauric acid. Oleogels prepared with a combination of stearic acid and EC have also been shown to produce a synergistic increase in gel strength and high oil-binding capacity [51]. The use of medium- or long-chain fatty acids may thus be a promising way to both modulate the rheological properties of EC oleogels and impart desirable textural characteristics and melting behavior.

EC has also been used to produce oleogels in combination with behenic acid, a 22-carbon saturated fatty acid commonly used in cosmetic and lubrication applications. Ahmadi and coworkers [53] evaluated soybean oil-based oleogels prepared with 6 wt% total structurant at varying EC20/behenic acid ratios. While the addition of EC below its CGC enhanced the rheological response of oleogels predominantly structured by behenic acid, no synergistic enhancement in gel strength was observed for those gels supported primarily by the EC polymer network. Further studies would be required to evaluate the direct impact of behenic acid on EC, such as by fixing EC concentration and varying the content of fatty acid. This work further demonstrated that a 1:5 EC/behenic acid ratio was able to produce stable water-in-oleogel emulsions (5–45 wt% water) without the need for an additional surfactant. In contrast, stable emulsions could not be formed using oleogels structured with behenic acid alone. This suggests EC may modify the crystallization behavior of behenic acid to enhance emulsification activity, and/or directly contribute to the emulsification properties. Further studies will also be needed to explore the emulsification properties of these multicomponent oleogels.

7.2.2.4 Lecithin

Food-grade soy lecithin is a complex mixture of phospholipids and has been shown to form oleogels via spontaneous assembly of tubular reverse micelles in the presence of small amounts of water (~0.2–2.0 wt%) [54]. Multicomponent oleogels have also been produced by combining 10 wt% EC20 with soy lecithin predominantly composed of either unsaturated (18:2) or saturated (18:0) fatty acid acyl chains [55]. The combined systems were reported to produce up to a tenfold increase in G′. Interestingly, this synergistic enhancement was most pronounced at the lowest lecithin concentrations evaluated (1 wt%), while higher concentrations diminished the viscoelastic response. The stress-strain response and yield stress of both EC and EC/lecithin hybrid gels (10 wt% EC, 1 wt% lecithin) were comparable to a commercial lard shortening, but exhibited a higher stress overshoot. This effect was attributed to the polymer network’s ability to withstand higher loading or undergo greater deformation prior to yielding compared to a fat crystal network. Large amplitude oscillatory shear analysis further indicated the solid- to fluid-like response of the binary oleogels was similar to those structured with EC alone, indicating the polymer network dominated the nonlinear viscoelastic response. Both oleogel systems underwent fluidization at higher strain than the commercial shortening. This further indicated the polymer network dominated the rheological behavior and may require a high degree of plasticization or lower crosslink density to accurately mimic the rheological performance of a fat crystal network. Additional studies will be required to confirm the molecular interactions responsible for the dynamic viscoelastic behavior of the EC/lecithin gelator system.

7.3 EC-Based Oleogels as Shortening Mimetics

The development of multicomponent oleogels capable of mimicking the performance of commercial fats has been a particular area of interest across the field of edible oleogels [56, 57]. Several studies have undertaken screening of multicomponent oleogelator systems incorporating EC as an approach to develop edible shortenings with reduced saturated fat and satisfactory rheological and technofunctional behavior. Naeli and coworkers [58] used a response surface methodology to evaluate the rheological performance of oleogels having EC and MG as a base structuring system. The linear viscoelastic behavior was optimized to mimic commercial shortenings using various combinations of palm stearin (as a fat hardstock), hydroxypropyl methylcellulose, and gum arabic (as a thickener). All oleogels were prepared in a laboratory-scale scraped-surface heat exchanger to more accurately mimic the production of commercial shortenings. The optimized oleogels displayed comparable rheological behavior to the commercial standards with only ~16% saturated fatty acids, as compared to ~50–60% in the controls.

Rodríguez-Hernández and coworkers [59] also explored the rheological behavior of EC used in combination with MG and candelilla wax as a potential shortening replacement. Both the binary EC/MG and ternary systems exhibited a similar sharp increase in the complex modulus (G*) during cooling due to the formation of the MG crystal network. Although no distinct rheological response could be attributable to the wax crystallization, the ternary system produced stiffer oleogels (i.e., higher G*). The presence of EC in both the binary and ternary gelator systems dramatically improved the shear recovery, with select formulations displaying a comparable response to commercial shortenings.

The direct formation of water-in-oleogel emulsions structured with EC and MG has also been reported using a hot emulsification approach [60]. Emulsions containing 20 wt% water were prepared by separately forming concentrated glycerol monostearate emulsions and a hot EC4/oil dispersion. The two systems were then combined under shear at 70 °C to produce the final emulsion. Stable emulsions with solid-like rheological properties were achieved with 1 wt% glycerol monostearate and 7 wt% EC4 in high oleic safflower oil. These gels also remained stable after freeze-thaw cycling, which can encourage surfactant desorption and droplet destabilization [61]. It was concluded that EC promoted emulsion stability by enhancing the oil viscosity and/or through direct interaction with the interfacial glycerol monostearate crystals. Although these emulsions had a lower G′ than commercial low-fat spreads, this could potentially be addressed by optimizing the oleogel formulation and processing conditions (e.g., to reduce water droplet size). Thus, various approaches using EC in combination with additional structuring agents have shown considerable potential for developing accurate fat mimetics, and these could be further expanded and optimized for specific applications.

7.4 Conclusion

There has been growing interest in EC as an oleogelator due to its unique ability to be directly dispersed in edible oils and form a physically crosslinked polymer network. The free hydroxyl groups along the polymer backbone also provide a means of forming synergistic interactions with a variety of directly dispersible oleogelators, including monoglycerides, mixtures of fatty acids and fatty alcohols, and inverse lecithin micelles. Due to their unique structuring properties, both single- and multicomponent EC-based oleogels have been incorporated into numerous food systems. EC has been used in chocolate to confer heat resistance [62, 63], modify viscosity and flow behavior [64], and serve as a cocoa butter substitute for saturated fat reduction [65, 66]. Single- and multicomponent EC oleogels have been incorporated into a wide variety of meat products, including frankfurters [21, 67, 68], salami [69], breakfast sausages [70], burgers [71, 72], and liver pâté [73,74,75]. They have also been explored as a milk fat substitute in cream cheese [76], and to develop shortening mimetics for use in baked goods such as cakes [72], breads [77], and biscuits [78, 79].

Beyond direct fat substitution, EC oleogels may serve as a means of modulating lipid digestion and serve as delivery vehicles for lipid-soluble nutraceuticals. O’Sullivan and coworkers [80] demonstrated EC oleogel strength can directly impact both the rate and extent of lipolysis, as well as the bioavailability of a model lipid-soluble nutraceutical (β-carotene) using a static in vitro digestion model. Ashkar and coworkers [81, 82] similarly reported that lipid bioaccessibility is restricted by the EC polymer network and the rate of lipolysis is negatively correlated to gel firmness, which could serve as a means of regulating digestion behavior. Human in vivo trials have also shown that EC-based oleogels may provide an effective means of moderating the elevation of plasma triglycerides in response to a carbohydrate-rich meal [83, 84]. The ability of EC to regulate accessibility to the entrapped lipid phase could also be harnessed for drug delivery applications [8]. The wide adaptability of EC to be combined with complementary gelators thus provides considerable opportunity to further develop EC-based multicomponent oleogels for use as fat mimetics, delivery vehicles for nutraceuticals, and controlled-release applications in both the food and pharmaceutical industries.

Abbreviations

- CGC:

-

Critical gelation concentration

- DCS:

-

Differential scanning calorimetry

- EC:

-

Ethylcellulose

- G*:

-

Complex modulus

- G′:

-

Elastic modulus

- G″:

-

Viscous modulus

- LMOG:

-

Low-molecular-weight oleogelator

- MG:

-

Monoglyceride

- MW:

-

Molecular weight

- Tg:

-

Glass transition temperature

- Tgel:

-

Gel point temperature

- Tm:

-

Melting temperature

References

Dow Cellulosics (2005) Ethocel - Ethylcellulose polymers technical handbook, pp 1–27

Ahmadi P, Jahanban-Esfahlan A, Ahmadi A et al (2020) Development of ethyl cellulose-based formulations: a perspective on the novel technical methods. Food Rev Int. https://doi.org/10.1080/87559129.2020.1741007

Yang D, Peng X, Zhong L et al (2014) “Green” films from renewable resources: properties of epoxidized soybean oil plasticized ethyl cellulose films. Carbohydr Polym 103:198–206. https://doi.org/10.1016/j.carbpol.2013.12.043

Homaee Borujeni S, Mirdamadian SZ, Varshosaz J, Taheri A (2020) Three-dimensional (3D) printed tablets using ethyl cellulose and hydroxypropyl cellulose to achieve zero order sustained release profile. Cellulose 27:1573–1589. https://doi.org/10.1007/s10570-019-02881-4

Wasilewska K, Winnicka K (2019) Ethylcellulose – a pharmaceutical excipient with multidirectional application in drug dosage forms development. Materials (Basel) 12:3386. https://doi.org/10.3390/ma12203386

Adeleke OA (2019) Premium ethylcellulose polymer based architectures at work in drug delivery. Int J Pharm X 1:100023. https://doi.org/10.1016/j.ijpx.2019.100023

Seddiqi H, Oliaei E, Honarkar H et al (2021) Cellulose and its derivatives: towards biomedical applications. Cellulose 28:1893–1931. https://doi.org/10.1007/s10570-020-03674-w

Ashkar A, Sosnik A, Davidovich-Pinhas M (2022) Structured edible lipid-based particle systems for oral drug-delivery. Biotechnol Adv 54:107789. https://doi.org/10.1016/j.biotechadv.2021.107789

Rekhi GSGS, Jambhekar SSSS (1995) Ethylcellulose - a polymer review. Drug Dev Ind Pharm 21:61–77

Dow Pharma & Food Solutions (2016) ETHOCEL ™ Ethylcellulose a technical review a portfolio of versatile solutions to help address a variety of formulation and processing needs

Koch W (1937) Properties and uses of ethylcellulose. Ind Eng Chem 29:687–690

Davidovich-Pinhas M, Barbut S, Marangoni AG (2014) Physical structure and thermal behavior of ethylcellulose. Cellulose 21:3243–3255. https://doi.org/10.1007/s10570-014-0377-1

Sánchez R, Franco JM, Delgado MA et al (2011) Thermal and mechanical characterization of cellulosic derivatives-based oleogels potentially applicable as bio-lubricating greases: influence of ethyl cellulose molecular weight. Carbohydr Polym 83:151–158. https://doi.org/10.1016/j.carbpol.2010.07.033

Lai HL, Pitt K, Craig DQM (2010) Characterisation of the thermal properties of ethylcellulose using differential scanning and quasi-isothermal calorimetric approaches. Int J Pharm 386:178–184. https://doi.org/10.1016/j.ijpharm.2009.11.013

Davidovich-Pinhas M, Gravelle AJ, Barbut S, Marangoni AG (2015) Temperature effects on the gelation of ethylcellulose oleogels. Food Hydrocoll 46:76–83. https://doi.org/10.1016/j.foodhyd.2014.12.030

Gravelle AJ, Barbut S, Marangoni AG (2012) Ethylcellulose oleogels: manufacturing considerations and effects of oil oxidation. Food Res Int 48:578–583. https://doi.org/10.1016/j.foodres.2012.05.020

Fu H, Lo YM, Yan M et al (2020) Characterization of thermo-oxidative behavior of ethylcellulose oleogels. Food Chem 305:125470. https://doi.org/10.1016/j.foodchem.2019.125470

Giacintucci V, Di Mattia CD, Sacchetti G et al (2018) Ethylcellulose oleogels with extra virgin olive oil: the role of oil minor components on microstructure and mechanical strength. Food Hydrocoll 84:508–514. https://doi.org/10.1016/j.foodhyd.2018.05.030

Aiache J-M, Gauthier P, Aiache S (1992) New gelification method for vegetable oils I: cosmetic application. Int J Cosmet Sci 14:228–234. https://doi.org/10.1111/j.1467-2494.1992.tb00056.x

Laredo T, Barbut S, Marangoni AG (2011) Molecular interactions of polymer oleogelation. Soft Matter 7:2734–2743. https://doi.org/10.1039/c0sm00885k

Zetzl AK, Marangoni AG, Barbut S (2012) Mechanical properties of ethylcellulose oleogels and their potential for saturated fat reduction in frankfurters. Food Funct 3:327–337. https://doi.org/10.1039/c2fo10202a

Gravelle AJ, Davidovich-Pinhas M, Zetzl AK et al (2016) Influence of solvent quality on the mechanical strength of ethylcellulose oleogels. Carbohydr Polym 135:169–179. https://doi.org/10.1016/j.carbpol.2015.08.050

Gravelle AJ, Barbut S, Quinton M, Marangoni AG (2014) Towards the development of a predictive model of the formulation-dependent mechanical behaviour of edible oil-based ethylcellulose oleogels. J Food Eng 143:114–122. https://doi.org/10.1016/j.jfoodeng.2014.06.036

Davidovich-Pinhas M, Barbut S, Marangoni AG (2015) The gelation of oil using ethyl cellulose. Carbohydr Polym 117:869–878. https://doi.org/10.1016/j.carbpol.2014.10.035

Mashhadi H, Tabibiazar M, Nourabi A, Roufegarinejad L (2023) Evaluation of the effect of partial hydrolysis ethyl cellulose on physicochemical properties of soybean oil oleogel. Int J Food Sci Technol 58:1195–1203. https://doi.org/10.1111/ijfs.16267

Zetzl AK, Gravelle AJ, Kurylowicz M et al (2014) Microstructure of ethylcellulose oleogels and its relationship to mechanical properties. Food Struct 2:27–40. https://doi.org/10.1016/j.foostr.2014.07.002

Gravelle AJ, Barbut S, Marangoni AG (2013) Fractionation of ethylcellulose oleogels during setting. Food Funct 4:153–161. https://doi.org/10.1039/c2fo30227f

Stortz TA, Marangoni AG (2014) The replacement for petrolatum: thixotropic ethylcellulose oleogels in triglyceride oils. Green Chem 16:3064–3070. https://doi.org/10.1039/c4gc00052h

O’Sullivan CM (2016) In-vitro bioaccessibility and stability of beta-carotene in ethylcellulose oleogels. 1–95

Davidovich-Pinhas M, Barbut S, Marangoni AG (2015) The role of surfactants on ethylcellulose oleogel structure and mechanical properties. Carbohydr Polym 127:355–362. https://doi.org/10.1016/j.carbpol.2015.03.085

Kavimughil M, Leena MM, Moses JA, Anandharamakrishnan C (2022) Effect of material composition and 3D printing temperature on hot-melt extrusion of ethyl cellulose based medium chain triglyceride oil oleogel. J Food Eng 111055. https://doi.org/10.1016/j.jfoodeng.2022.111055

Marangoni AG, Van Duynhoven JPM, Acevedo NC et al (2020) Advances in our understanding of the structure and functionality of edible fats and fat mimetics. Soft Matter 16:289–306. https://doi.org/10.1039/c9sm01704f

Li L, Liu G, Bogojevic O et al (2022) Edible oleogels as solid fat alternatives: composition and oleogelation mechanism implications. Compr Rev Food Sci Food Saf:1–28. https://doi.org/10.1111/1541-4337.12928

Sivakanthan S, Fawzia S, Madhujith T, Karim A (2022) Synergistic effects of oleogelators in tailoring the properties of oleogels: a review. Compr Rev Food Sci Food Saf 1–32. https://doi.org/10.1111/1541-4337.12966

Shakeel A, Farooq U, Gabriele D et al (2021) Bigels and multi-component organogels: an overview from rheological perspective. Food Hydrocoll 111:106190. https://doi.org/10.1016/j.foodhyd.2020.106190

Martins AJ, Vicente AA, Cunha RL, Cerqueira MA (2018) Edible oleogels: an opportunity for fat replacement in foods. Food Funct 9:758–773. https://doi.org/10.1039/c7fo01641g

Wang Z, Chandrapala J, Truong T, Farahnaky A (2022) Oleogels prepared with low molecular weight gelators: texture, rheology and sensory properties, a review. Crit Rev Food Sci Nutr 0:1–45. https://doi.org/10.1080/10408398.2022.2027339

Palla CA, Dominguez M, Carrín ME (2022) An overview of structure engineering to tailor the functionality of monoglyceride oleogels. Compr Rev Food Sci Food Saf 21:2587–2614. https://doi.org/10.1111/1541-4337.12930

Lopez-Martínez A, Charó-Alonso MA, Marangoni AG, Toro-Vazquez JF (2015) Monoglyceride organogels developed in vegetable oil with and without ethylcellulose. Food Res Int 72:37–46. https://doi.org/10.1016/j.foodres.2015.03.019

Chen CH, Terentjev EM (2009) Aging and metastability of monoglycerides in hydrophobic solutions. Langmuir 25:6717–6724. https://doi.org/10.1021/la9002065

Ojijo NKO, Neeman I, Eger S, Shimoni E (2004) Effects of monoglyceride content, cooling rate and shear on the rheological properties of olive oil/monoglyceride gel networks. J Sci Food Agric 84:1585–1593. https://doi.org/10.1002/jsfa.1831

Sagiri SS, Singh VK, Pal K et al (2015) Stearic acid based oleogels: a study on the molecular, thermal and mechanical properties. Mater Sci Eng C 48:688–699. https://doi.org/10.1016/j.msec.2014.12.018

Uvanesh K, Sagiri SS, Senthilguru K et al (2016) Effect of span 60 on the microstructure, crystallization kinetics, and mechanical properties of stearic acid oleogels: an in-depth analysis. J Food Sci 81:E380–E387. https://doi.org/10.1111/1750-3841.13170

Valoppi F, Calligaris S, Marangoni AG (2017) Structure and physical properties of oleogels containing peanut oil and saturated fatty alcohols. Eur J Lipid Sci Technol 119:1–11. https://doi.org/10.1002/ejlt.201600252

Lupi FR, Gabriele D, Greco V et al (2013) A rheological characterisation of an olive oil/fatty alcohols organogel. Food Res Int 51:510–517. https://doi.org/10.1016/j.foodres.2013.01.013

Gandolfo FG, Bot A, Flöter E (2004) Structuring of edible oils by long-chain FA, fatty alcohols, and their mixtures. JAOCS, J Am Oil Chem Soc 81:1–6. https://doi.org/10.1007/s11746-004-0851-5

Blach C, Gravelle AJ, Peyronel F et al (2016) Revisiting the crystallization behavior of stearyl alcohol: stearic acid (SO : SA) mixtures in edible oil. RSC Adv 6. https://doi.org/10.1039/c6ra15142f

Schaink HM, van Malssen KF, Morgado-Alves S et al (2007) Crystal network for edible oil organogels: possibilities and limitations of the fatty acid and fatty alcohol systems. Food Res Int 40:1185–1193. https://doi.org/10.1016/j.foodres.2007.06.013

Callau M, Sow-Kébé K, Nicolas-Morgantini L, Fameau AL (2020) Effect of the ratio between behenyl alcohol and behenic acid on the oleogel properties. J Colloid Interface Sci 560:874–884. https://doi.org/10.1016/j.jcis.2019.10.111

Gravelle AJ, Davidovich-Pinhas M, Barbut S, Marangoni AG (2017) Influencing the crystallization behavior of binary mixtures of stearyl alcohol and stearic acid (SOSA) using ethylcellulose. Food Res Int 91:1–10. https://doi.org/10.1016/j.foodres.2016.11.024

Gravelle AJ, Blach C, Weiss J et al (2017) Structure and properties of an ethylcellulose and stearyl alcohol/stearic acid (EC/SO:SA) hybrid oleogelator system. Eur J Lipid Sci Technol 119:1700069. https://doi.org/10.1002/ejlt.201700069

Haj Eisa A, Laufer S, Rosen-Kligvasser J, Davidovich-Pinhas M (2020) Stabilization of ethyl-cellulose oleogel network using lauric acid. Eur J Lipid Sci Technol 122:1–10. https://doi.org/10.1002/ejlt.201900044

Ahmadi P, Tabibiazar M, Roufegarinejad L, Babazadeh A (2020) Development of behenic acid-ethyl cellulose oleogel stabilized Pickering emulsions as low calorie fat replacer. Int J Biol Macromol 150:974–981. https://doi.org/10.1016/j.ijbiomac.2019.10.205

Bodennec M, Guo Q, Rousseau D (2016) Molecular and microstructural characterization of lecithin-based oleogels made with vegetable oil. RSC Adv 6:47373–47381. https://doi.org/10.1039/c6ra04324k

Aguilar-Zárate M, Macias-Rodriguez BA, Toro-Vazquez JF, Marangoni AG (2019) Engineering rheological properties of edible oleogels with ethylcellulose and lecithin. Carbohydr Polym 205:98–105. https://doi.org/10.1016/j.carbpol.2018.10.032

Pușcaș A, Mureșan V, Socaciu C, Muste S (2020) Oleogels in food: a review of current and potential applications. Foods 9:1–27. https://doi.org/10.3390/foods9010070

Scharfe M, Flöter E (2020) Oleogelation: from scientific feasibility to applicability in food products. Eur J Lipid Sci Technol 122:1–24. https://doi.org/10.1002/ejlt.202000213

Naeli MH, Milani JM, Farmani J, Zargaraan A (2022) Developing and optimizing low-saturated oleogel shortening based on ethyl cellulose and hydroxypropyl methyl cellulose biopolymers. Food Chem 369:130963. https://doi.org/10.1016/j.foodchem.2021.130963

Rodríguez-Hernández AK, Pérez-Martínez JD, Gallegos-Infante JA et al (2021) Rheological properties of ethyl cellulose-monoglyceride-candelilla wax oleogel vis-a-vis edible shortenings. Carbohydr Polym 252:117171. https://doi.org/10.1016/j.carbpol.2020.117171

García-Ortega ML, Toro-Vazquez JF, Ghosh S (2021) Development and characterization of structured water-in-oil emulsions with ethyl cellulose oleogels. Food Res Int 150:110763. https://doi.org/10.1016/j.foodres.2021.110763

Ghosh S, Rousseau D (2011) Fat crystals and water-in-oil emulsion stability. Curr Opin Colloid Interface Sci 16:421–431. https://doi.org/10.1016/j.cocis.2011.06.006

Stortz TA, Marangoni AG (2013) Ethylcellulose solvent substitution method of preparing heat resistant chocolate. Food Res Int 51:797–803. https://doi.org/10.1016/j.foodres.2013.01.059

Stortz TA, Laredo T, Marangoni AG (2015) The role of lecithin and solvent addition in ethylcellulose-stabilized heat resistant chocolate. Food Biophys 10:253–263. https://doi.org/10.1007/s11483-014-9379-7

Ceballos MR, Bierbrauer KL, Faudone SN et al (2016) Influence of EC-medium chain triglycerides blend on the flow behaviour and beta-V polymoprh retention of dark chocolate. Food Struct 10:1–9. https://doi.org/10.1016/j.foostr.2016.10.004

Li L, Liu G (2019) Corn oil-based oleogels with different gelation mechanisms as novel cocoa butter alternatives in dark chocolate. J Food Eng 263:114–122. https://doi.org/10.1016/j.jfoodeng.2019.06.001

Li L, Liu G, Lin Y (2021) Physical and bloom stability of low-saturation chocolates with oleogels based on different gelation mechanisms. LWT - Food Sci Technol 140:110807. https://doi.org/10.1016/j.lwt.2020.110807

Barbut S, Wood J, Marangoni AG (2016) Effects of organogel hardness and formulation on acceptance of frankfurters. J Food Sci 81:C2183–C2188. https://doi.org/10.1111/1750-3841.13409

Barbut S, Wood J, Marangoni AG (2016) Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci 122:155–162. https://doi.org/10.1016/j.meatsci.2016.08.003

Woern C, Marangoni AG, Weiss J, Barbut S (2021) Effects of partially replacing animal fat by ethylcellulose based organogels in ground cooked salami. Food Res Int 147:110431. https://doi.org/10.1016/j.foodres.2021.110431

Barbut S, Wood J, Marangoni AG (2016) Quality effects of using organogels in breakfast sausage. Meat Sci 122:84–89. https://doi.org/10.1016/j.meatsci.2016.07.022

Gómez-Estaca J, Herrero AM, Herranz B et al (2019) Characterization of ethyl cellulose and beeswax oleogels and their suitability as fat replacers in healthier lipid pâtés development. Food Hydrocoll 87:960–969. https://doi.org/10.1016/j.foodhyd.2018.09.029

Adili L, Roufegarinejad L, Tabibiazar M et al (2020) Development and characterization of reinforced ethyl cellulose based oleogel with adipic acid: its application in cake and beef burger. LWT - Food Sci Technol 126:109277. https://doi.org/10.1016/j.lwt.2020.109277

Barbut S, Marangoni AG, Thode U, Tiensa BE (2019) Using canola oil organogels as fat replacement in liver Pâté. J Food Sci 84:2646–2651. https://doi.org/10.1111/1750-3841.14753

Barbut S, Tiensa BE, Marangoni AG (2021) Partial fat replacement in liver pâté using canola oil organogel. LWT - Food Sci Technol 139:110428. https://doi.org/10.1016/j.lwt.2020.110428

Gómez-Estaca J, Pintado T, Jiménez-Colmenero F, Cofrades S (2019) Assessment of a healthy oil combination structured in ethyl cellulose and beeswax oleogels as animal fat replacers in low-fat, PUFA-enriched pork burgers. Food Bioprocess Technol 12:1068–1081. https://doi.org/10.1007/s11947-019-02281-3

Bemer HL, Limbaugh M, Cramer ED et al (2016) Vegetable organogels incorporation in cream cheese products. Food Res Int 85:67–75. https://doi.org/10.1016/j.foodres.2016.04.016

Ye X, Li P, Lo YM et al (2019) Development of novel shortenings structured by ethylcellulose oleogels. J Food Sci 84:1456–1464. https://doi.org/10.1111/1750-3841.14615

Onacik-Gür S, Zbikowska A (2020) Effect of high-oleic rapeseed oil oleogels on the quality of short-dough biscuits and fat migration. J Food Sci Technol 57:1609–1618. https://doi.org/10.1007/s13197-019-04193-8

Onacik-Gür S, Zbikowska A (2022) The effect of green tea extract and oleogels on the physico-chemical properties and oxidative stability of short-dough biscuits during storage. LWT 172:114197. https://doi.org/10.1016/j.lwt.2022.114197

O’Sullivan CM, Davidovich-Pinhas M, Wright AJ et al (2017) Ethylcellulose oleogels for lipophilic bioactive delivery-effect of oleogelation on: in vitro bioaccessibility and stability of beta-carotene. Food Funct 8:1438–1451. https://doi.org/10.1039/c6fo01805j

Ashkar A, Laufer S, Rosen-Kligvasser J et al (2019) Impact of different oil gelators and oleogelation mechanisms on digestive lipolysis of canola oil oleogels. Food Hydrocoll 97:105218. https://doi.org/10.1016/j.foodhyd.2019.105218

Ashkar A, Rosen-Kligvasser J, Lesmes U, Davidovich-Pinhas M (2020) Controlling lipid intestinal digestibility using various oil structuring mechanisms. Food Funct 11:7495–7508. https://doi.org/10.1039/d0fo00223b

Tan SY, Peh E, Siow PC et al (2017) Effects of the physical-form and the degree-of-saturation of oil on postprandial plasma triglycerides, glycemia and appetite of healthy Chinese adults. Food Funct 8:4433–4440. https://doi.org/10.1039/C7FO01194F

Tan SY, Peh E, Lau E et al (2017) Physical form of dietary fat alters postprandial substrate utilization and glycemic response in healthy Chinese men. J Nutr 147:1138–1144. https://doi.org/10.3945/jn.116.246728

Acknowledgments

Andrew Gravelle acknowledges financial support from the USDA National Institute of Food and Agriculture Hatch/Multi-State project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Gravelle, A.J. (2024). Direct Oil Structuring Using Ethylcellulose. In: Palla, C., Valoppi, F. (eds) Advances in Oleogel Development, Characterization, and Nutritional Aspects. Springer, Cham. https://doi.org/10.1007/978-3-031-46831-5_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-46831-5_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46830-8

Online ISBN: 978-3-031-46831-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)