Abstract

The use of monoglycerides (MGs) as oil structuring agents has gained considerable attention in the last two decades due to their ability to create solid fat mimetic materials. This chapter provides a comprehensive analysis of MG oleogels, focusing on their fundamental properties. It examines the characteristics of MGs as effective gelators and describes the various factors that influence oleogel formation. By gaining insight into the mechanisms driving MG crystallization and gelation, it becomes feasible to engineer oleogels with customized functionalities for specific applications. The physicochemical properties of MG oleogels are also discussed, including their structural, rheological, textural, and thermal properties, in addition to their stability. Finally, the chapter concludes with a brief discussion of challenges and future research directions in the dynamic field of MG oleogels, aiming to inspire further advancements and innovation in this promising area of study.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

5.1 Introduction

Monoglycerides (MGs) are important emulsifiers extensively used in the food industry due to their great ability to stabilize oil and water phases. The utilization of MGs in oil structuring is relatively recent, with the earliest studies emerging around 2000 [1, 2]. This line of research has been mainly driven by the necessity of having solid and semisolid fats without trans fatty acids and with reduced levels of saturated fatty acids, while exhibiting properties comparable to conventional fats [3]. MGs fall within the classification of low-molecular-weight gelators (LMWGs), which usually self-assemble into crystalline structures that form supramolecular systems able to entrap oil. The properties and functionality of LMWG oleogels are directly related to their structural building blocks [4]. Numerous studies have demonstrated that the MG crystalline structure can provide oleogels with optimal levels of hardness, stability, spreadability, plasticity, and elasticity [5, 6].

By acquiring a thorough understanding of the factors that impact MG crystallization and gelation, it becomes possible to strategically manipulate physical process parameters. This level of control allows for the engineering of structures with tailored functionality to meet the desired requirements for specific applications. This chapter provides an overview of the fundamental characteristics of MG oleogels. First, the pivotal attributes of MGs that have been studied as gelators are presented, followed by a description of the process parameters that influence MG oleogel formation. Afterward, an examination of the physicochemical properties of these gels is conducted, emphasizing the variables that can be changed to optimize these properties. Finally, the challenges and future research directions related to MG oleogels are identified.

5.2 Production of Monoglyceride Oleogels

5.2.1 Sources and Types of Monoglycerides

MGs are lipid molecules formed by a glycerol backbone and a fatty acid (FA) attached to one of its hydroxyl groups. The esterification position determines their classification as either 1-MG or 2-MG, with the former referring to an attachment at an extreme position and the latter at an internal position. In addition, MGs are further classified based on the length and saturation level of the carbon chain. The presence of two hydroxyl and one acyl groups confers amphiphilic properties upon MGs, making them nonionic surfactants with exceptional emulsifying capabilities. Therefore, they find widespread application across diverse industries that require the stabilization of mixtures comprising oily and aqueous phases [7].

MGs offer several advantages when incorporated into food formulations, specifically in oil structuring. First, MGs are considered safe food additives that are already approved for use [8, 9]. Second, they are predominantly derived from vegetable oils, such as palm, soybean, sunflower, or rapeseed oil. Third, they are usually obtained in highly pure form, with purities ranging from 90% to 95% [10]. Lastly, but not less importantly, MGs are widely available in the market at a relatively affordable cost [11]. In fact, the Global Distilled Monoglyceride market was valued at USD 869.9 million in 2021–2022 and is expected to grow at a compound annual growth rate of 4.4% during 2021–2026 [12] and 7.92% for 2023–2030 [13].

Table 5.1 presents data on representative commercial MG mixtures used for oil structuring purposes. These mixtures are usually characterized by their purity, FA composition, and MG isomer identification. Although the specific isomer ratio is not usually reported, it is known that commercial MGs predominantly consist of over 90% saturated 1-MG [14]. Saturated monoglycerides (SMGs) have been the primary focus of research as gelators, with only a limited number of contributions in the literature regarding unsaturated monoglycerides (UMGs) [3]. In general, oil structuring experiments have involved testing SMG blends comprising approximately equal proportions of palmitic (C16:0) and stearic (C18:0) acid (~40–60% each) as well as blends with a high stearic acid content (>90%) [3]. It has been reported that concentrations between 2% and 5% of these gelators in oil are sufficient to obtain a nonflowing soft solid, while concentrations between 5% and 10% are required for oleogels with a high level of structuration (oil binding capacity >90%) [3]. On the other hand, it has been observed that SMGs with medium-chain FA (≤C10:0) or UMGs with high 2-UMG content are ineffective in structuring oils, even when used at concentrations of up to 20% SMG [15] or 10% UMG [14], respectively. Table 5.1 also provides the melting point of the different MGs, which depends on their purity degree and FA composition. This information is essential to establish a suitable heating temperature for oleogel production. Another factor to consider in oleogel production is the source of the MGs, particularly when MGs are derived from hydrogenated palm oil and meeting sustainability criteria is a requirement.

5.2.2 Factors Affecting Monoglyceride Oleogel Formation

MG oleogels are physical gels prepared by a simple and direct method, which involves dispersing a relatively low amount of MG in oil, followed by heating and stirring to allow solubilization, and subsequent cooling to form a complex solid network of crystalline particles that entraps the oil [3]. As MGs are cooled in the presence of a hydrophobic solvent, they undergo various molecular reorganizations that lead to the formation of inverse bilayers. These bilayers then grow and organize into lamellar platelet microstructures, which serve as the fundamental building blocks of the network [22]. The microplatelets intersect and create junction zones that contribute to the formation of the oleogel’s structure as well as its mechanical and rheological properties. These microstructures are held together by noncovalent interactions, such as van der Waals forces and hydrogen bonds [23]. The oil is retained in the three-dimensional (3D) crystalline structure because of a complex interplay of factors not fully identified, such as surface forces (adsorption) [24,25,26].

The ultimate structure of the gel is significantly influenced by size, shape, clustering, and interaction of the crystals. Therefore, all factors that can affect the formation and characteristics of the crystalline network, as well as the interaction between MGs and oil, influence the physical properties of MG oleogels. Several factors have been identified as having an impact on the properties of MG oleogels, among them: MG type and concentration [27, 28], oil type [17, 29], heating temperature [30], stirring speed [31], cooling rate/temperature [19], shear rate during cooling [22], and storage time and temperature [32, 33]. It has also been reported that MG oleogel formation can be modified by the presence of additional components [34,35,36] as well as by using ultrasound technologies [37, 38], which have the potential to alter MG crystallization kinetics. For a comprehensive overview of how that technology has been applied for this purpose, please see Chap. 11.

5.3 Physicochemical Properties of Monoglyceride Oleogels

The following subsections focus on the analysis of SMG oleogels prepared by the direct method and cooled under static conditions, where their properties were examined after a short aging period (12–72 h after preparation), unless explicitly stated otherwise.

5.3.1 Structural Characteristics

The nanoscale structure of SMG oleogels can be characterized by the elucidation of the polymorphic forms of their crystals, using small- and wide-angle X-ray scattering techniques. Multiple studies have reported the presence of β and, to a lesser extent, sub-α phases [17, 39, 40]. The β form is the most thermodynamically stable, while the sub-α form is indicative of an unset gel [40, 41]. According to previous studies, the crystalline molecular organization of SMG (mixtures of palmitic and stearic acid) in oils (from medium- and long-chain triglycerides) remained unchanged when the concentration varied from 5% to 10% or even from 10% to 70% [17, 37, 42, 43]. In this concentration range, SMG molecules crystallized in the triclinic β form and exhibited a lamellar thickness ranging from 46 to 49 Å. However, when the amount of a monostearin-rich SMG was increased from 10% or 15% to 20%, the interplane spacing expanded to 66 Å [44]. These results demonstrate that the molecular organization is highly dependent on the MG composition and concentration.

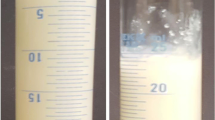

The image in Fig. 5.1a shows the visual characteristics of an MG oleogel, revealing its homogeneous appearance and semi-solid consistency. The crystalline morphology of SMG oleogels is characterized by platelets that exhibit a needle-like appearance under polarized light microscopy due to the orientation of the platelets respect to the glass cover slip and projection of the crystals in the focal plane (Fig. 5.1b–d). These crystals tend to aggregate and form clusters. Thus, the resulting architecture of the crystal network may exhibit sandwich-like or spherulitic/rosette-like structures, or irregular patterns, depending on factors such as the type of MG, and the presence of impurities, traces of water, or particles [19, 28, 45,46,47]. Additionally, the processing conditions play a crucial role in crystal nucleation and size. By implementing conditions of either high supercooling or high supersaturation, a fast nucleation rate can be achieved that facilitates the formation of numerous smaller and uniform crystals, thereby enhancing the spatial distribution of mass.

Images of saturated monoglyceride oleogels showing (a) the macroscopic structure, (b) the microstructure as observed by polarized light microscopy (reproduced from [48], with permission from John Wiley & Sons), (c) crystal platelets embedded in amorphous rapeseed oil (aRO) visualized by cryo-scanning electron microscopy (reproduced from [40], with permission from Elsevier), and (d) crystal platelets from a chia oleogel sample de-oiled with isobutanol—following the procedure described by [49] with slight modifications—visualized by scanning electron microscopy (micrograph from our laboratory)

5.3.2 Rheological Properties

Rheological properties analysis in SMG oleogels provided valuable insights into their viscoelastic behavior and stability. The elastic and viscous moduli, G′ and G″, are usually determined by frequency sweep tests in the linear viscoelastic region. Rheological measurements have revealed that SMG oleogels had a solid-like behavior (G′ > G″), with G′ remaining constant throughout the frequency sweep when concentrations of 5% SMG or higher were used [2, 31, 44]. This indicated that SMG oleogels had a stable gel structure with a predominantly elastic nature. Figure 5.2 shows the maximum G′ values of SMG oleogels reported in various studies, including unpublished data from our laboratory. These values were recorded from oscillatory tests conducted at or around 20 °C on oleogels formulated with various oils—arranged in decreasing order of unsaturated fatty acid (UFA) content—and SMG concentrations within the typical range. With increasing SMG concentration, a global trend can be observed in Fig. 5.2, indicating a corresponding increase in G′. This rise in gel elasticity can be attributed to the presence of a higher solid mass that is distributed more evenly throughout the material, resulting in enhanced crystal-crystal interactions, as suggested by previous studies [1, 42]. Furthermore, the region exhibiting the highest G′ values seems to correspond to oils with higher UFA content, suggesting that SMG may have improved structuring capabilities when combined with these oils. In particular, it has been reported that long-chain monounsaturated FAs (MUFAs) favored the packing of SMG crystals in a cohesive gel [29]. Alternatively, it is possible that the cocrystallization of saturated triglycerides from oils could be hindering the formation of the SMG crystalline network. In addition to FA composition, other oil-related factors such as polarity and viscosity have been demonstrated to exert a significant influence on the ability of SMG to form strong networks [17]. While the type of oil does impact the characteristics of the gel, it would be conceivable to attain materials with similar values of G′, given appropriate adjustments in the SMG concentration and other variables not considered in this particular analysis (e.g., cooling temperature, storage time, etc., and disregarding disparities in test conditions). This finding instills optimism, as it suggests the feasibility of producing oleogels with desirable attributes using oils readily obtainable in different geographical regions worldwide.

Elastic moduli (G′) values of oleogels from saturated monoglyceride (SMG) (C16:0 and C18:0 mixtures) and different oils: castor oil (CS), high oleic sunflower oil (HOSO), hazelnut oil (HA), canola oil (CA), high oleic safflower oil (HOSA), rapeseed oil (RA), sunflower oil (SF), flaxseed oil (FX), extra-virgin olive oil (EVO), peanut oil (PE), soybean oil (SY), corn oil (CO), cod liver oil (CL), and virgin olive oil (VO). The oils were labeled from 1 to 14, with 1 being the oil with the highest content of unsaturated fatty acids and 14 being the lowest. The small figures on the right side are the projections of G′ in the oil plane (top) and the SMG plane (bottom). (Data from [2, 4, 6, 15, 17,18,19,20, 22, 27,28,29,30,31,32, 38, 42, 44, 45, 50, 51] and unpublished data from our laboratory)

The gelation point of SMG oleogels determined by temperature sweep tests was found to coincide with the formation of the crystalline network [19]. Furthermore, the gel point increased with increasing SMG concentration [2, 28, 47] and was also influenced by the composition of SMG [28]. For example, an oleogel made from a high-purity monostearin (94%) showed a higher gel point temperature than that of an oleogel made from a mixture of monostearin (38%) and monopalmitin (54%) [28].

The thixotropic behavior of SMG oleogels has been analyzed to evaluate their capacity for recovering their original structure after shear force application. Remarkably, when SMG was used in concentrations ranging from 8% to 15%, the gels showed a thixotropic recovery of up to 94% [52]. According to authors, this finding suggests that the crystalline network within the gels has the capacity to dissociate in response to high shear forces and subsequently reassemble and reorganize once the shear force is removed. Conversely, recoveries between 49% and 61% were recently reported for 6% SMG oleogels dynamically produced on a margarine pilot plant [48]. This disparity between results underscores the necessity for conducting pilot plant studies under diverse conditions. Specifically, it is crucial to investigate gelation under static conditions, which has shown promising outcomes in terms of improved recovery properties in laboratory-scale experiments. Such findings will have significant implications for industrial applications.

5.3.3 Textural Properties

Although textural characteristics in SMG oleogels have been studied to a lesser extent, they are of paramount importance. These characteristics are closely linked to the consistency, stability, and sensory attributes of the final product, which in turn have significant implications for food applications and consumer satisfaction. Hardness, to a greater extent, and adhesiveness, cohesiveness, spreadability, and fracturability have been the properties generally investigated in SMG oleogels [3]. Hardness values of SMG oleogels from various studies, along with unpublished data from our laboratory, are presented in Fig. 5.3. These values were obtained through texture profile analysis (TPA)—two cycles of penetration—or penetrometer tests carried out at sample temperatures between 5 and 20 °C in oleogels formulated with different oils, arranged in a descending order based on their UFA content, and SMG concentrations within the typical range. Compared to commercial products, SMG oleogels were softer than stick margarines (21.5 N and 15.5 N [53]), but had a consistency similar to spreadable margarines (1.6 N [31]). Increasing the SMG content allowed for gels to exhibit enhanced resistance to deformation, which can be ascribed to the greater amount of crystallized material and greater number of gelator-gelator interactions. The highest hardness values (∼5–5.5 N) have been reported for 10% SMG in flaxseed, peanut, and extra-virgin olive oils (9–11 in Fig. 5.3) with UFA contents ranging from 83% to 89%. On the other hand, it has been observed that variations in the cooling temperature during the gelation process have a significant impact on hardness of SMG oleogels. Cooling the samples at 30 °C, as opposed to 5 °C, resulted in a substantial increase in hardness of up to 39% [19]. The authors found that higher cooling temperatures led to the formation of longer crystal aggregates that conferred greater resistance to the first penetration cycle in the TPA test, whereas lower cooling temperatures produced gels composed of smaller crystals that exhibited enhanced resistance to deformation in the second penetration cycle.

Hardness values for oleogels from saturated monoglyceride (SMG) (C16:0 and C18:0 mixtures) and different oils: castor oil (CS), high oleic sunflower oil (HOSO), hazelnut oil (HA), canola oil (CA), high oleic safflower oil (HOSA), rapeseed oil (RA), sunflower oil (SF), flaxseed oil (FX), extra-virgin olive oil (EVO), peanut oil (PE), soybean oil (SY), corn oil (CO), cod liver oil (CL), and virgin olive oil (VO). The oils were labeled from 1 to 14, with 1 being the oil with the highest content of unsaturated fatty acids and 14 being the lowest. The small figures on the right side are the projections of hardness in the oil plane (top) and the SMG plane (bottom). (Data from [6, 17, 19, 23, 27, 31, 32, 38, 45, 51, 54] and unpublished data from our laboratory)

In addition, the adhesiveness of oleogels formulated with hazelnut oil, olive oil, and high oleic sunflower oil (HOSO) has shown a positive correlation with SMG concentrations, indicating the development of stronger attractive forces between the gel and probe surfaces due to increased crystalline material [6, 27]. Conversely, as the SMG content increases, the cohesiveness of oleogels tends to decrease [27, 31, 45]. This behavior can be explained by considering that the cohesiveness parameter determines the material’s resistance to a second deformation work (W2) relative to the first deformation work (W1). If the increase in W2 is smaller than the increase in W1 due to the rise in SMG, the cohesiveness of the oleogel is reduced [31].

5.3.4 Thermal Properties

Melting and crystallization temperatures play a critical role in defining the functionality of a fat product. This makes it necessary to determine the thermal events during heating and cooling cycles of oleogels using differential scanning calorimetry. Heating of oleogel samples—without prior erasing their thermal memory—is required to determine intrinsic material properties. Different thermogram patterns have been observed during the melting of SMG oleogels, with some exhibiting a single endothermic peak [4, 16, 33, 45, 54], while others show multiple endothermic events [29, 55, 56]. These variations in thermogram profiles may be due to SMG composition and/or differences in temperature-time analysis conditions. On the other hand, increases in SMG content have been observed to correlate with significant increases in both onset and peak melting temperatures, as well as melting enthalpies [4, 38, 56]. It is well-established that higher levels of supersaturation can lead to greater amounts, interactions, and organization of crystalline material. The enthalpy value reflects the energy needed to induce thermal transformations in the material, including crystal melting/formation and polymorphic changes. Therefore, it is positively affected by the amount and organization level of crystallized material [57]. For example, when the SMG concentration in HOSO oleogels was increased from 3% to 6%, a twofold increase in melting enthalpy was observed [45]. In contrast, variations in the cooling rate during oleogel formation have not shown significant effects on the aforementioned variables. For example, the onset, peak, and enthalpy of melting of 6% SMG oleogels were observed to change from 57.4 °C, 61.6 °C, and 11.8 J/g to 51.7 °C, 62.8 °C, and 11.5 J/g, respectively, when the cooling rate was changed from 0.1 to 10 °C/min. It is interesting to note that some commercial products, which are targeted for replacement by oleogels, exhibit melting points in the range of 30–32 °C (interesterified products similar to butter), 38–42 °C (pastry and puff pastry margarines), 44–47 °C (refined bovine fats and regular shortenings), 40–50 °C (roll-in shortenings), and 44–54 °C (roll-in margarines) [58, 59]. Given the comparatively lower melting points of these materials in relation to SMG oleogels, it is mandatory to corroborate the suitability of SMG oleogels in the desired application to establish whether they meet the intended requirements.

On the other hand, the introduction of perturbations during the stage of oleogel formation has been proposed as a strategy to modify its final properties. However, minor or no differences in melting behavior have been observed when oleogels were dynamically formed or when high-intensity ultrasound (HIU) was applied during gelation [38, 48, 54].

5.3.5 Stability and Shelf Life

The structural stability of SMG oleogels is directly related to the ability of the crystalline network to retain oil. This property, usually referred to as oil binding capacity (OBC), quantifies the amount of oil that remains bound within the oleogel after it has been subjected to centrifugation or other oil release techniques. Several studies have shown that SMG concentration notably affects OBC. For example, when SMG concentration was increased from 3–5% to 10%, OBC increased from 69.3–80.9% to 93.8–99.8% [18, 27, 31, 51]. Therefore, using 10% of SMG in the oleogel ensures a network strong enough to hold and retain the whole volume of oil [3]. Moreover, OBC has been found to improve in the order monolaurin < monostearin < glycerol monobehenate [21]. Notably, the highest OBC values were consistently reported when using HOSO compared to more saturated oils such as coconut oil or polyunsaturated oils like sunflower oil [29,30,31]. Oleogel formation conditions also affect its final stability. The presence of a homogenous structure comprising small crystals, achieved through the use of high cooling rates or HIU, has been related to high OBC [19, 27, 31, 38]. In addition, oleogelation under static conditions, rather than using shear, resulted in the formation of stronger structures with higher OBC [22].

When discussing the stability of SMG oleogels, time is one of the most important factors. It is known that, after the cooling stage, a stabilization or annealing period of typically 12–72 h at temperatures between 4 and 25 °C is required to achieve semi-stable properties. Nevertheless, it is important to note that the network built by MG crystals has been shown to be a dynamic structure [3, 48]. As a result, some structural and chemical instabilities may occur in oleogels during prolonged storage [6, 32, 41]. SMG oleogels of hazelnut oil stored at 26 °C were shown to undergo a gradual rearrangement from sub-α phase toward more stable β-crystal structures over a period of about 7 days. This transformation involves the segregation of chiral MGs, resulting in denser structures and the release of initially trapped oil [39, 41]. In general, storage of SMG oleogels at low temperatures can delay changes in physicochemical properties [6, 32, 41]. For instance, no significant variations in the main physicochemical parameters were observed in SMG oleogels of HOSO during 21 days of storage at 5 °C [32]. After 2 months, crystal size, hardness, and elasticity were the properties most negatively affected, with variations over 30%. Nevertheless, polymorphism and melting behavior were not changed throughout the whole storage time, while OBC and fractal dimension slightly decreased. Similarly, hardness and adhesiveness of SMG oleogels from virgin olive oil gradually decreased as the storage time increased, with higher incidence at higher temperature (20 °C vs. 4 °C) for a period of up to 90 days [6]. These findings suggest that it is imperative to evaluate oleogel properties according to the storage conditions and intended end use.

In terms of chemical stability, one of the major concerns when using unsaturated oils is their potential oxidative deterioration. However, it has been shown that SMG oleogels exhibit slower primary and secondary oxidation processes than the corresponding oils [16, 32, 42, 55]. This suggests that SMG structural arrangements could act as physical barriers capable of hindering the movement of oxidation reagents, thereby extending the useful life of unsaturated oils.

5.4 Potential Applications of Monoglyceride Oleogels in the Food Industry

SMG oleogels have been extensively studied as a full or partial solid fat replacement in a wide range of food products, such as spreadable, bakeries, confectioneries, and meat products, in addition to being evaluated for specific technological functionalities like oil migration inhibition, emulsion stabilization, and lipid oxidation stability enhancement [5]. In addition, they have been investigated as carrier matrices for liposoluble bioactive compounds in the development of health-promoting food systems. For more detailed information on food applications and uses as delivery and protection of bioactive molecules, see Chaps. 26 and 17, respectively.

5.5 Nutritional Aspects of Monoglyceride Oleogels

MG oleogels are part of the wide range of lipid materials developed to address the elimination of trans FAs and the reduction of saturated FAs in industrially processed foods. This implies that a significant aspect of reformulating food products with oleogels involves evaluating the improvement in the nutritional profile of these products. The degree of improvement depends on the oleogel composition (including oil type and type and amount of gelator), fat composition of the replaced material, and level of substitution (partial or complete). Specifically, when SMG oleogels are used, there is a contribution to the saturated FA content due to the chemical nature of SMG that must be considered. However, based on the available evidence regarding the biological effects of FAs, opting for an SMG mixture rich in stearic acid may offer an additional advantage when choosing a gelator. This is supported by findings indicating that stearic acid, in contrast to palmitic acid, does not elevate total cholesterol and low-density lipoprotein levels [60, 61].

Additionally, SMG oleogels can be designed to provide health benefits beyond replacing SFAs with UFAs. Some studies have explored the possibility of incorporating lipid-soluble bioactive compounds, such as phytosterols, curcumin, β-carotene, lupeol, and quercetin, into the oleogel [5, 43]. This allows for the development of controlled release systems with potential anticancer, anticholesterol, anti-inflammatory, and other beneficial activities.

5.6 Conclusions

This chapter provides an overview of MG oleogels, specifically examining the factors influencing crystallization and gel formation, along with their key physicochemical properties. Given the remarkable advantages offered by MGs as gelators and the favorable mechanical properties of oleogels formulated with them, it is imperative to devote more attention to improving the weak properties of these materials to resemble more closely those of traditional solid fats while improving long-term stability. Exploring innovative technologies and incorporating additional components capable of modifying the structural characteristics of the crystalline network are currently viable strategies to enhance oleogel properties that need to be addressed in more depth. In this regard, it would be interesting to advance in the use of bioactive compounds, which can provide added health value to fat substitutes. Finally, the transition from laboratory to pilot plant experiments is essential to gain valuable insight into the technical and economic feasibility of scaling up the MG oleogel production process for industrial applications.

Abbreviations

- CA:

-

Canola oil

- CL:

-

Cod liver oil

- CO:

-

Corn oil

- CS:

-

Castor oil

- EVO:

-

Extra-virgin olive oil

- FA:

-

Fatty acid

- FX:

-

Flaxseed

- G′:

-

Elastic modulus

- G″:

-

Viscous modulus

- HA:

-

Hazelnut oil

- HIU:

-

High-intensity ultrasound

- HOSA:

-

High oleic safflower oil

- HOSO:

-

High oleic sunflower oil

- LMWG:

-

Low-molecular-weight gelator

- MG:

-

Monoglyceride

- MUFA:

-

Monounsaturated fatty acid

- OBC:

-

Oil binding capacity

- PE:

-

Peanut oil

- RA:

-

Rapeseed oil

- SF:

-

Sunflower oil

- SMG:

-

Saturated monoglyceride

- SY:

-

Soybean oil

- TPA:

-

Texture profile analysis

- UFA:

-

Unsaturated fatty acid

- UMG:

-

Unsaturated monoglyceride

- VO:

-

Virgin olive oil

- W1:

-

First deformation work

- W2:

-

Second deformation work

References

Ojijo NKO, Kesselman E, Shuster V, Eichler S, Eger S, Neeman I, Shimoni E (2004) Changes in microstructural, thermal, and rheological properties of olive oil/monoglyceride networks during storage. Food Res Int 37:385–393. https://doi.org/10.1016/j.foodres.2004.02.003

Ojijo NKO, Neeman I, Eger S, Shimoni E (2004) Effects of monoglyceride content, cooling rate and shear on the rheological properties of olive oil/monoglyceride gel networks. J Sci Food Agric 84:1585–1593. https://doi.org/10.1002/jsfa.1831

Palla CA, Dominguez M, Carrín ME (2022) An overview of structure engineering to tailor the functionality of monoglyceride oleogels. Compr Rev Food Sci Food Saf 21:2587–2614. https://doi.org/10.1111/1541-4337.12930

Fasolin LH, Cerqueira MA, Pastrana LM, Vicente AA, Cunha RL (2018) Thermodynamic, rheological and structural properties of edible oils structured with LMOGs: influence of gelator and oil phase. Food Struct 16:50–58. https://doi.org/10.1016/j.foostr.2018.03.003

Palla CA, Dominguez M, Carrín ME (2022) Recent advances on food-based applications of monoglyceride oleogels. JAOCS, J Am Oil Chem Soc 99:985–1006. https://doi.org/10.1002/aocs.12617

Öǧütcü M, Yılmaz E (2014) Oleogels of virgin olive oil with carnauba wax and monoglyceride as spreadable products. Grasas Aceites 65:e040. https://doi.org/10.3989/gya.0349141

Nitbani FO, Tjitda PJP, Nurohmah BA, Wogo HE (2020) Preparation of fatty acid and monoglyceride from vegetable oil. J Oleo Sci 69:277–295. https://doi.org/10.5650/jos.ess19168

U.S. Food & Drug Administration (2021) CFR - Code of Federal Regulations title 21 - part 172 -Food additives permitted for direct addition to food for human consumption. In: U.S. Food Drug. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=172.840. Accessed 14 Dec 2021

EFSA Panel on Food Additives and Nutrient Sources added to Food (ANS) (2017) Re-evaluation of mono- and di-glycerides of fatty acids (E 471) as food additives. EFSA J 15. https://doi.org/10.2903/j.efsa.2017.5045

Barfod NM, SparsØ FV (2007) Structure and function of emulsifiers and their role in microstructure formation in complex foods. In: Understanding and controlling the microstructure of complex foods

Rocha-Guzmán NE, Cháirez-Ramírez MH, Pérez-Martínez JD, Rosas-Flores W, de Ornelas-Paz JJ, Moreno-Jiménez MR, González-Laredo RF, Gallegos-Infante JA (2021) Use of organogel-based emulsions (o/w) as a tool to increase the bioaccessibility of lupeol, curcumin, and quercetin. JAOCS, J Am Oil Chem Soc 98:1177–1188. https://doi.org/10.1002/aocs.12528

360ResearchReports (2020) Global distilled monoglyceride market research report 2020. https://www.360researchreports.com/global-distilled-monoglyceride-market-15046641. Accessed 5 Jun 2021

Research reports world (2023) Global food grade distilled monoglyceride market research report 2023

Chen C, Zhang C, Zhang Q, Ju X, Wang Z, He R (2021) Study of monoglycerides enriched with unsaturated fatty acids at sn-2 position as oleogelators for oleogel preparation. Food Chem 354. https://doi.org/10.1016/j.foodchem.2021.129534

Monié A, Franceschi S, Balayssac S, Malet-Martino M, Delample M, Perez E, Garrigues JC (2022) Study of rapeseed oil gelation induced by commercial monoglycerides using a chemometric approach. Food Chem 369. https://doi.org/10.1016/j.foodchem.2021.130870

Pan J, Tang L, Dong Q, Li Y, Zhang H (2021) Effect of oleogelation on physical properties and oxidative stability of camellia oil-based oleogels and oleogel emulsions. Food Res Int 140. https://doi.org/10.1016/j.foodres.2020.110057

Valoppi F, Calligaris S, Barba L, Šegatin N, Poklar Ulrih N, Nicoli MC (2017) Influence of oil type on formation, structure, thermal, and physical properties of monoglyceride-based organogel. Eur J Lipid Sci Technol 119. https://doi.org/10.1002/ejlt.201500549

Fayaz G, Polenghi O, Giardina A, Cerne V, Calligaris S (2021) Structural and rheological properties of medium-chain triacylglyceride oleogels. Int J Food Sci Technol 56:1040–1047. https://doi.org/10.1111/ijfs.14757

Palla C, de Vicente J, Carrín ME, Gálvez Ruiz MJ (2019) Effects of cooling temperature profiles on the monoglycerides oleogel properties: a rheo-microscopy study. Food Res Int J 125. https://doi.org/10.1016/j.foodres.2019.108613

Bin Sintang MD, Rimaux T, Van De WD, Dewettinck K, Patel AR (2016) Studying the oil structuring properties of monoglycerides and phytosterols mixtures. Eur J Lipid Sci Technol A 119:1500517

Li J, Guo R, Bi Y, Zhang H, Xu X (2021) Comprehensive evaluation of saturated monoglycerides for the forming of oleogels. LWT 151. https://doi.org/10.1016/j.lwt.2021.112061

da Pieve S, Calligaris S, Co E, Nicoli MC, Marangoni AG (2010) Shear Nanostructuring of monoglyceride organogels. Food Biophys 5:211–217. https://doi.org/10.1007/s11483-010-9162-3

Rosen-Kligvasser J, Davidovich-Pinhas M (2021) The role of hydrogen bonds in TAG derivative-based oleogel structure and properties. Food Chem 334. https://doi.org/10.1016/j.foodchem.2020.127585

Blake AI, Marangoni AG (2015) The use of cooling rate to engineer the microstructure and oil binding capacity of wax crystal networks. Food Biophys 10:456–465. https://doi.org/10.1007/s11483-015-9409-0

Abdallah DJ, Weiss RG (2000) n-Alkanes gel n-alkanes (and many other organic liquids). Langmuir 16:352–355. https://doi.org/10.1021/la990795r

Patel AR (2017) A colloidal gel perspective for understanding oleogelation. Curr Opin, Food Sci, p 15

Giacomozzi AS, Carrín ME, Palla CA (2018) Muffins elaborated with optimized Monoglycerides Oleogels: from solid fat replacer obtention to product quality evaluation. J Food Sci 83:1505–1515. https://doi.org/10.1111/1750-3841.14174

López-Martínez A, Morales-Rueda JA, Dibildox-Alvarado E, Charó-Alonso MA, Marangoni AG, Toro-Vazquez JF (2014) Comparing the crystallization and rheological behavior of organogels developed by pure and commercial monoglycerides in vegetable oil. Food Res Int 64:946–957. https://doi.org/10.1016/j.foodres.2014.08.029

Ferro AC, Okuro PK, Badan AP, Cunha RL (2019) Role of the oil on glyceryl monostearate based oleogels. Food Res Int 120:610–619. https://doi.org/10.1016/j.foodres.2018.11.013

Rocha-Amador OG, Gallegos-Infante JA, Huang Q, Rocha-Guzman NE, Rociomoreno-Jimenez M, Gonzalez-Laredo RF (2014) Influence of commercial saturated monoglyceride, mono-/diglycerides mixtures, vegetable oil, stirring speed, and temperature on the physical properties of organogels. Int J Food Sci 2014. https://doi.org/10.1155/2014/513641

Palla C, Giacomozzi A, Genovese DB, Carrín ME (2017) Multi–objective optimization of high oleic sunflower oil and monoglycerides oleogels: searching for rheological and textural properties similar to margarine. Food Struct 12:1–14. https://doi.org/10.1016/j.foostr.2017.02.005

Giacomozzi AS, Carrín ME, Palla CA (2021) Storage stability of Oleogels made from Monoglycerides and high Oleic sunflower oil. Food Biophys 16:306–316. https://doi.org/10.1007/s11483-020-09661-9

Zampouni K, Soniadis A, Moschakis T, Biliaderis CG, Lazaridou A, Katsanidis E (2022) Crystalline microstructure and physicochemical properties of olive oil oleogels formulated with monoglycerides and phytosterols. LWT 154. https://doi.org/10.1016/j.lwt.2021.112815

Cotabarren IM, Cruces S, Palla CA (2019) Extrusion 3D printing of nutraceutical oral dosage forms formulated with monoglycerides oleogels and phytosterols mixtures. Food Res Int 126. https://doi.org/10.1016/j.foodres.2019.108676

Rodríguez-Hernández AK, Pérez-Martínez JD, Gallegos-Infante JA, Toro-Vazquez JF, Ornelas-Paz JJ (2021) Rheological properties of ethyl cellulose-monoglyceride-candelilla wax oleogel vis-a-vis edible shortenings. Carbohydr Polym 252. https://doi.org/10.1016/j.carbpol.2020.117171

Bhattarai M, Penttilä P, Barba L, Macias-Rodriguez B, Hietala S, Mikkonen KS, Valoppi F (2022) Size-dependent filling effect of crystalline celluloses in structural engineering of composite oleogels. LWT 160. https://doi.org/10.1016/j.lwt.2022.113331

Valoppi F, Salmi A, Ratilainen M, Barba L, Puranen T, Tommiska O, Helander P, Heikkilä J, Haeggström E (2020) Controlling oleogel crystallization using ultrasonic standing waves. Sci Rep 10. https://doi.org/10.1038/s41598-020-71177-6

Giacomozzi A, Palla C, Carrín ME, Martini S (2020) Tailoring physical properties of monoglycerides oleogels using high-intensity ultrasound. Food Res Int 134. https://doi.org/10.1016/j.foodres.2020.109231

Chen CH, Terentjev EM (2011) Colloid-monoglyceride composites in hydrophobic solutions. Colloids Surfaces A Physicochem Eng Asp 384:536–542. https://doi.org/10.1016/j.colsurfa.2011.05.020

Verstringe S, Moens K, De Clercq N, Dewettinck K (2015) Crystallization behavior of monoacylglycerols in a hydrophobic and a hydrophilic solvent. Food Res Int 67. https://doi.org/10.1016/j.foodres.2014.10.027

Chen CH, Terentjev EM (2009) Aging and metastability of monoglycerides in hydrophobic solutions. Langmuir 25:6717–6724. https://doi.org/10.1021/la9002065

da Pieve S, Calligaris S, Panozzo A, Arrighetti G, Nicoli MC (2011) Effect of monoglyceride organogel structure on cod liver oil stability. Food Res Int 44:2978–2983. https://doi.org/10.1016/j.foodres.2011.07.011

Calligaris S, Valoppi F, Barba L, Anese M, Nicoli MC (2018) β-Carotene degradation kinetics as affected by fat crystal network and solid/liquid ratio. Food Res Int 105. https://doi.org/10.1016/j.foodres.2017.11.062

Cerqueira MA, Fasolin LH, Picone CSF, Pastrana LM, Cunha RL, Vicente AA (2017) Structural and mechanical properties of organogels: role of oil and gelator molecular structure. Food Res Int 96:161–170. https://doi.org/10.1016/j.foodres.2017.03.021

Giacomozzi AS, Palla CA, Carrín ME, Martini S (2019) Physical properties of Monoglycerides Oleogels modified by concentration, cooling rate, and high-intensity ultrasound. J Food Sci 84:2549–2561. https://doi.org/10.1111/1750-3841.14762

Kesselman E, Shimoni E (2007) Imaging of oil/monoglyceride networks by polarizing near-field scanning optical microscopy. Food Biophys 2:117–123. https://doi.org/10.1007/s11483-007-9038-3

Lupi FR, Greco V, Baldino N, de Cindio B, Fischer P, Gabriele D (2016) The effects of intermolecular interactions on the physical properties of organogels in edible oils. J Colloid Interface Sci 483:154–164. https://doi.org/10.1016/j.jcis.2016.08.009

Rondou K, De Witte F, Rimaux T, Dewinter W, Dewettinck K, Verwaeren J, Van Bockstaele F (2022) Multiscale analysis of monoglyceride oleogels during storage. JAOCS, J Am Oil Chem Soc 99:1019–1031. https://doi.org/10.1002/aocs.12645

Sánchez-Becerril M, Marangoni AG, Perea-Flores MJ, Cayetano-Castro N, Martínez-Gutiérrez H, Andraca-Adame JA, Pérez-Martínez JD (2018) Characterization of the micro and nanostructure of the candelilla wax organogels crystal networks. Food Struct 16:1–7. https://doi.org/10.1016/j.foostr.2018.02.001

Fayaz G, Calligaris S, Nicoli MC (2020) Comparative study on the ability of different Oleogelators to structure sunflower oil. Food Biophys 15:42–49. https://doi.org/10.1007/s11483-019-09597-9

Yılmaz E, Öğütcü M (2014) Properties and stability of hazelnut oil organogels with beeswax and monoglyceride. JAOCS, J Am Oil Chem Soc 91:1007–1017. https://doi.org/10.1007/s11746-014-2434-1

Ashkar A, Laufer S, Rosen-Kligvasser J, Lesmes U, Davidovich-Pinhas M (2019) Impact of different oil gelators and oleogelation mechanisms on digestive lipolysis of canola oil oleogels. Food Hydrocoll 97. https://doi.org/10.1016/j.foodhyd.2019.105218

Merchán Sandoval J, Carelli A, Palla CA, Baümler E (2020) Preparation and characterization of oleogel emulsions: a comparative study between the use of recovered and commercial sunflower waxes as structuring agent. J Food Sci 85:2866–2878. https://doi.org/10.1111/1750-3841.15361

da Silva TLT, Danthine S (2021) Effect of high-intensity ultrasound on the oleogelation and physical properties of high melting point monoglycerides and triglycerides oleogels. J Food Sci 86:343–356. https://doi.org/10.1111/1750-3841.15589

Kamali E, Sahari MA, Barzegar M, Ahmadi Gavlighi H (2019) Novel oleogel formulation based on amaranth oil: physicochemical characterization. Food Sci Nutr 7:1986–1996. https://doi.org/10.1002/fsn3.1018

Si H, Cheong LZ, Huang J, Wang X, Zhang H (2016) Physical properties of soybean Oleogels and oil migration evaluation in model praline system. JAOCS, J Am Oil Chem Soc 93:1075–1084. https://doi.org/10.1007/s11746-016-2846-1

Toro-Vazquez JF, Morales-Rueda JA, Dibildox-Alvarado E, Charó-Alonso M, Alonzo-Macias M, González-Chávez MM (2007) Thermal and textural properties of organogels developed by candelilla wax in safflower oil. JAOCS, J Am Oil Chem Soc 84:989–1000. https://doi.org/10.1007/s11746-007-1139-0

RDC (2023) http://www.refineriadelcentro.com.ar/es/catalogo. Accessed 18 Jun 2023

Rodriguez-Velazquez S Fat. In: Rodriguez-Velazquez S (ed) Chemistry of cooking. https://chem.libretexts.org/Bookshelves/Biological_Chemistry/Chemistry_of_Cooking_(Rodriguez-Velazquez). Accessed 18 June 2023

Kris-Etherton PM, Griel AE, Psota TL, Gebauer SK, Zhang J, Etherton TD (2005) Dietary stearic acid and risk of cardiovascular disease: intake, sources, digestion, and absorption. Lipids 40:1193

FAO (2010) Fats and fatty acids in human nutrition: report of an expert consultation

Acknowledgments

The authors acknowledge the financial support by the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) (PIP 2021–2023 No. 101968), the Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) (PICT-2021-GRF-TI-00273), and the Universidad Nacional del Sur (UNS) (PGI 24/M172) in Argentina. The authors would also like to thank Ing. Martina Domínguez for her help in preparing the samples for SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Palla, C., Carrín, M.E. (2024). Monoglyceride Oleogels. In: Palla, C., Valoppi, F. (eds) Advances in Oleogel Development, Characterization, and Nutritional Aspects. Springer, Cham. https://doi.org/10.1007/978-3-031-46831-5_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-46831-5_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46830-8

Online ISBN: 978-3-031-46831-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)