Abstract

Gels are systems that consist of solid and liquid components and have a semisolid consistency. Both hydrogels and oleogels are types of gels; the difference between the two lies in the polarity of the solvent entrapped in the gel. In their natural state, hydrogels are polar, while oleogels are apolar systems. Combining oleogels with hydrogels results in the creation of a new kind of gel system called bigels. There have been discoveries of applications for bigels in a wide variety of industries, including the food business, the pharmaceutical industry, and the biomedical industry, among others. In order to properly describe their properties, several distinct procedures, including microscopic techniques, thermal characterization, and rheological approaches, are used. Texture analyzers (also known as static mechanical testers) are used in the process of identifying the mechanistic properties of these systems. In order to explore the interactions between the molecules, X-ray diffraction (XRD) and Fourier transform infrared (FTIR) spectroscopy are used in the research process to explore the interactions between the molecules. In this chapter, the primary focus is placed on different types of bigel systems, materials used in their formation, the factors that affect their properties, the techniques used to characterize them, and the applications of these techniques, especially in the field of food science.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

14.1 Introduction

In comparison to earlier gel formulations, bigels are a relatively modern formulation. Bigel is a biphasic semisolid system derived from two different gel phases, that is, oleogel as the hydrophobic phase and hydrogel as the hydrophilic phase [1]. These gels are the result of combining oleogel and hydrogel in a certain ratio and homogenizing the mixture at a high shear rate. The composition of bigels contributes to their physicochemical and functional properties. Bigels combine the best features of both hydrogels and oleogels, allowing them to circumvent their core issues. As a result, these biphasic systems outperform the two gels individually. One of the biggest benefits of bigels is that they may be used to transport both lipophilic and hydrophilic bioactive compounds. When compared to other biphasic systems (emulsions and emulgels), which rely on surfactants for stability, these gels have superior thermodynamic and kinetic stability due to the semisolid structure of both phases [2]. Bigels have greater physicochemical stability because the mobile phases are trapped in the three-dimensional network of the oleogel and the hydrogel, resulting in a more finely dispersed structure. As a result, they do not suffer phase separation even when maintained at room temperature for up to 6–12 months. Such gels have moisturizing and cooling properties, enhanced spreadability, improved drug permeability, and the ability to modify the drug release rate [3]. Bigel systems are particularly desirable to the pharmaceutical, cosmetic, and food industries because of these traits. Also, there is a possibility to change the physical properties of bigels by adjusting the quality of any single phase [4]. Depending on the requirement and the commercial applications, various materials can be used to synthesize bigels. The ultimate characteristics of bigels are determined by the nature of the hydrophobic and hydrophilic phases [5]. As a result, the distinct phases are crucial in selecting suitable materials for these phases. The aqueous phase (hydrogel) is formulated mainly using synthetic or natural hydrophilic polymers (e.g., agar, sodium alginate, gelatin, carrageenan, and pectin) that forms a colloidal network of polymer chains in the water. The hydrophobic phase (oleogel) for bigel matrices has been developed using fatty alcohols and fatty acids, plant-derived wax, glyceryl stearate, and policosanol as oleogelators [6, 7] and various vegetable oils as the oil phase [8]. Based on the component used for individual phases, the characteristics of bigels vary, and these changes can be characterized in terms of physical, mechanical, electrical, structural, and rheological properties [9]. This chapter will deal with different types of bigels, materials used, factors affecting bigels, characterization techniques, and food/nutrition-based applications of bigels.

14.1.1 Types of Bigels

The formulation and physicochemical properties of various bigels have been the subject of an in-depth study conducted by scientists over the last decade. Bigels can be differentiated into four categories according to the spatial organization and the nature of oleogels and hydrogels. The following are the different categories of bigels with a distinct set of qualities (Fig. 14.1) [10]:

-

Oleogel dispersed in hydrogel (O/H): The formation of this kind of bigel involves dispersing the oleogel inside the architecture of the hydrogel. Numerous researchers have looked at this kind of bigels for several applications. For instance, Zhu et al. [11] fabricated bigels by combining glycerol monostearate-beeswax-based oleogel with high acyl gellan gum hydrogel in varying quantities. The microstructure of bigels revealed the scattered presence of oleogel. The incorporation of the spherical oil droplets into the continuous hydrogel matrix indicates the establishment of an oleogel-in-hydrogel structural configuration.

-

Bicontinuous bigel: These bigels are formulations in which both phases appear to be continuous. Formation of such bigels involves an oleogel fraction of ~60% when the oil phase turns into a continuous phase. The hydrogel phase does not form droplets in these situations and gets thoroughly mixed within the oleogel phase, creating bicontinuous structures. Kodela et al. [12] formulated bigels by varying the ratios of agar hydrogel and stearyl alcohol oleogel. The microscopic examination of bigels revealed that, at greater proportions of oleogel, the interior phase was not spherical but had irregular-shaped features. This demonstrated that when the oleogel fraction was raised over a critical limit, bicontinuous bigels were formed.

-

Hydrogel dispersed in oleogel (H/O): In this type of bigel, the hydrogel is present as the dispersed phase within the continuous matrix of oleogel. For delivering lipophilic bioactive chemicals, Zheng et al. [13] created bigels from carrageenan hydrogel and monoglyceride oleogels. H/O bigel has the same structure as water-in-oil emulsions, but both the water and oil phases are in the gel state.

-

Complex bigel: These systems are prepared by homogenizing an emulsion gel with the oleogel phase in different fractions. To create a complex matrix-in-matrix type at the highest oleogel fraction, Lupi et al. [10] used extra virgin olive oil as the oil phase, a combination of policosanol and glyceryl monostearate as the oleogelator, and low methoxyl pectin as the hydrogelator. The highest oleogel percent yielded this matrix-in-matrix structure.

Bigel systems are further classified as conventional or unconventional based on whether they are made using monocomponent oleogel and hydrogel phases or multicomponent oleogel/hydrogel phases [15]. Conventional bigels are made by adjusting the concentration of a single component, such as oleogel or hydrogel. In order to optimize the rheological features of the resulting bigel systems, conventional bigel systems have been extensively investigated in the literature as a function of several aspects, such as oleogel/hydrogel ratio and hydrogelator type. Certain studies have shown that combining atypical bigel systems with normal ones is possible. These innovative solutions resulted in better technical and functional results. Unconventional bigels include multicomponent oleogel/hydrogel-based bigels, emulsion gel-based bigels, and colloidal particles-based bigels. Such bigels bring up new alternatives for upgrading the technological features of conventional bigels [15].

14.2 Materials Used in the Preparation of Bigels

Several compounds are utilized for the formation of hydrogels and oleogels. The application of the formed bigels heavily influences the choice of these compounds. Hydrogels can be obtained using natural and/or synthetic polymers. It is possible to describe hydrogels as jelly-like systems in which an appropriate hydrogelator, either naturally occurring or synthetically produced, creates a three-dimensional (3D) network to entrap the polar or aqueous phase. Natural polymers such as polysaccharides (e.g., starch, alginate, and agarose) and proteins (such as collagen and gelatin) have been widely utilized. Natural polymers may be modified using synthetic monomers via graft copolymerization, allowing them to be used to make superabsorbent hydrogels. Graft copolymerization (GCP) of gum polysaccharides with various vinyl monomers is one of the most researched and reliable methods for altering natural polymers. In recent years, interest has risen in synthesizing GCP-based polysaccharides, which permit combining the favorable characteristics of synthetic and natural polymers. Grafting may be accomplished by the use of standard redox grafting procedures, microwave irradiation, irradiation, or electron beams [16]. Water-soluble linear polymers such as polyvinyl alcohol (PVA) and polyvinyl pyrrolidone (PVP) have also been employed among synthetic polymers [17, 18]. The formation of hydrogels from these polymers can be accomplished via a variety of crosslinking processes, including (a) chemical reaction between the polymer chains, (b) ionizing radiation, and (c) physical interactions, such as entanglements [19].

Like hydrogels, several oleogel systems are also required to fabricate bigels. An oleogel is a semisolid substance composed of liquid oil trapped inside a network of structuring molecules called an oleogelator. Gelator molecules typically self-assemble to produce a 3D network stabilizing the oil phase. This is accomplished by developing physical connections through Van der Waals and hydrogen bonding, which encourage crystallization, crosslinking, and stacking of molecules. The liquid phase found in the formulation of oleogels is usually a vegetable oil derived from plants. Examples of such oils include sunflower oil [20, 21], extra virgin olive oil [22], rice bran oil [23], sesame oil [24], linseed oil [25], soybean oil [26], almond oil [27], jojoba oil [28], canola oil [29], and tea tree oil [28]. Some biocompatible systems also use medium-chain triglycerides and isopropyl myristate as the oil phase [9]. Materials such as monoglycerides, phytosterols, and waxes show good oil-structuring abilities. The excellent gelation capability of oleogelators allows them to meet application-specific features. Based on molecular weight, oleogelators can be classified as low-molecular-weight oleogelators (LMWOs) and high-molecular-weight oleogelators (HMWOs) (Fig. 14.2). The LMWOs used in the oleogel formulation include monoglycerides, glyceryl fatty acid esters, ceramides, natural waxes, hydroxylated fatty acids, wax esters, lecithin, phytosterols, oligopeptides, glyceryl monostearate, and sorbitan monoesters [17, 26, 30, 31]. Furthermore, lecithin is a well-known natural oleogelator that comprises biological systems’ richest group of phospholipids. It is obtained chiefly from sunflower, soybean, and egg yolk. Lecithin permits bioactive molecules to be incorporated into the aqueous and organic phases. Other LMWOs used in bigels include 12-hydroxystearic acid, stearyl alcohol, cetyl alcohol, and fumed silica [32]. Polymers are used as HMWOs and they can be categorized into proteins and polysaccharides (Fig. 14.2). Some examples of these polysaccharides are ethylcellulose (EC), hydroxypropyl methylcellulose, pectin, chitin, xanthan gum, guar gum (GG), kappa-carrageenan, alginate, hyaluronic acid, and chitosan, while examples of these proteins include gelatin, caseinate, soy protein isolate, and alpha-lactoglobulin [33]. But as of now, the only direct method for making oleogels made of polymers is to employ EC, a chemically altered version of the naturally occurring polymer cellulose [34].

Widely available oleogelators used for bigel formulation. (Reproduced from [35], under the terms of the Creative Commons CC-BY license)

14.3 Factors Affecting the Formation of Bigels

Usually, bigels are of O/H type when the oleogel concentration is less than 50%. Then, they change into a bicontinuous type when the oleogel concentration is ≥60%. The H/O type of bigels is formed after raising the oleogel concentration to ≥75%. Therefore, various structural morphologies may be generated by varying the oleogel: hydrogel ratio, which can considerably impact the rheological behavior of bigels [11]. However, if the gel network is damaged by the shearing action, the phase separation of bigels may happen. The most significant element dictating the rheological behavior of bigels appears to be the mass or volume ratios of oleogels and hydrogels. According to several studies, higher oleogel percentages improve the hardness, smooth texture, cohesion, stickiness, viscosity, larger yield stress values, and stability of bigels. After a specific oleogel:hydrogel ratio, the system might start to become hydrogel-dominated, which may limit the good influence of oleogel fraction on bigels characteristics.

Once the hydrogel content exceeds the oleogel fraction, the rheological and textural properties depend on the hydrogel fractions. For instance, it has been shown that a higher percentage of hydrogel results in harder bigels. The spreadability, work of shear, hardness, stickiness, work of adhesion, and percent stress relaxation of bigel systems are all considerably affected by the concentration of the hydrogelator [4]. In addition to hydrogelator concentration, the physicochemical attributes of bigels may be influenced by the composition of the hydrogelator. Compared to the system containing linear polysaccharides, bigels using branched polysaccharides as hydrogelators usually have superior gel strength and enhanced deformation resistance but inferior stress relaxation capabilities. Hence, the physicochemical properties of the bigel might change eventually [23].

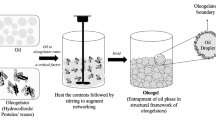

In a recent publication, Lu et al. [36] developed an O/H type of bigel system to deliver nutraceuticals such as curcumin and epigallocatechin gallate (EGCG). They utilized glycerol monostearate (GMS) as an oleogelator and gelatin as a hydrogelator. Curcumin and EGCG were dissolved in the oleogel and hydrogel phases, respectively. Investigation of such a system revealed that the hardness and viscosity of the bigels increased with the GMS content. The bigels containing higher GMS content resulted in a stable crystal network structure, which enhanced their mechanical and thermal stability (Fig. 14.3). This study also revealed that the release of the mentioned nutraceutical also depended on the amount of the gelator. Such findings proved that the physicochemical properties of bigels can be altered by varying the gelator concentration. Also, bigels can codeliver nutritional compounds depending on their polarities and can be utilized to develop functional foods.

Schematic for the formulation of an O/H type of bigel system. (Reproduced from [36], with permission from American Chemical Society)

14.4 Characterization Techniques of Bigels

As materials and the preparation methods vary, the characteristics of bigels differ accordingly. In general, preliminary characterization is carried out to confirm the formation of bigels through the tube inversion method [37, 38] and determine whether the material flows under its weight. A proper bigel is deemed to have formed if the sample does not flow. After bigels have been formed, several characteristics, including color, consistency, smoothness, transparency, viscosity, and pH, are assessed [39]. Bigels are frequently referred to as milky white systems, a characteristic linked to light dispersion from interfaces of both phases. They often have a smooth feel and are opaque [20]. Researchers have further characterized bigels based on mechanical strength, electrical properties, thermal stability, rheological, antimicrobial efficiency, and bioactive agent release rates [30, 38, 40]. Researchers have looked at the feasibility of using some food-grade bigels as fat replacers by studying their mechanical properties, rheology, and thermal stability. In this section, we shall discuss the different techniques that are utilized for the characterization of bigels.

14.4.1 Compositional Analysis

Fatty acid profiling largely determines vegetable oil’s properties, composition, and uses in the oleogel phase. Characterization of the lipid component of foods by fatty acid analysis provides crucial data on feed and food quality. FAME (fatty acid methyl ester) analysis is regarded as an important method for characterizing fats and oils and estimating the total fat content in food products. FAME is the end product of the transesterification of fats with alcohol. This technique facilitates the determination of the presence or absence of trans-fatty acids in the formulation of bigels when analyzed using a gas chromatography instrument [29]. Following the quantification of total FAME in the derived sample, the total quantity of fat in the form of triglycerides is determined using the original sample weight.

Lipid oxidation is a chain of processes negatively affecting oil-based food products’ quality and shelf life. Such a process of lipid oxidation involves the reaction between unsaturated fatty acids and oxygen to generate lipid hydroperoxides. The generated hydroperoxides are then broken down into small, volatile compounds such as aldehydes and ketones. These minute molecules generate off-flavors and aromas, reducing the acceptability of lipid-containing products, such as oils and meat. Therefore, examining lipid oxidation factors before using bigels in food items is essential.

According to previous research, the peroxide value (PV) and the p-anisidine value (AV) are often used to measure the amount of primary and secondary oxidation, respectively. The American Oil Chemists’ Society (AOCS)-recommended official iodometric technique “Cd 8-53” is used to determine PV. The iodine generated by potassium iodide given as a reducing agent to the oxidized sample dissolved in a chloroform-acetic acid combination is measured by titration. The released iodine is titrated with conventional sodium thiosulfate (Na2S2O3·5H2O) to a starch endpoint. AOCS “Cd 18-90” is used to determine the AV of samples spectrophotometrically [29]. Conventionally, the AV value is defined as 100 times the optical density measured at 350 nm in a cuvette of a solution containing 1.00 g of oil in 100 mL of a solvent/reagent combination. This technique detects the quantity of aldehydes (mostly 2-alkenals and 2,4-dienals) in samples, including vegetable fats and oils, by reacting the aldehydic compounds in the oil and p-anisidine in an acetic acid solution. With the use of the following formulae, the PV and AV values are determined:

where S is the volume of Na2S2O3·5H2O in the sample titration (mL), B is the volume of Na2S2O3·5H2O in the blank titration (mL), M is the molarity of the thiosulfate solution, and W is the weight of the sample (g).

where AC is the absorbance of isooctane with p-anisidine solution, AS is the absorbance of sample solution, and W is the weight of the sample (g).

14.4.2 Mechanical Characterization

Textural characteristics are most likely the most researched aspect of bigels. Bigels may be evaluated via texture analysis by assessing their mechanical resistance to stress. Various equipment, including viscometers [9], rheometers [13], and mechanical testers [17], are used to study the mechanical characteristics of bigels, such as viscosity and stress relaxation. Different characteristics (such as sample surface, sample shape, sample mass, and test speed) significantly impact the results obtained by the abovementioned instruments. In a basic gel strength measurement, a 0.5-inch-diameter cylinder probe is penetrated into the gel system at a constant pace. The gel strength is expressed as the maximum force necessary to travel a certain distance before irreversible deformation. However, by probing further into the gel, the rupture force and elasticity/brittleness of the gel may be determined [1].

The viscoelastic properties of bigels are reflected in the results of a textural investigation called stress relaxation (SR). An SR analysis involves inserting a probe into the formulation until a certain distance. The result is a force equal to its theoretical maximum, indicated by the symbol F0. Then the strain is held constant for a specific period (known as the relaxation period). During this period, the measured force diminishes rapidly and approaches a near-constant asymptotic value. This forge value is known as residual force (Fr), which marks the resistance faced by the retained elastic portion of bigels. Overall, the bigel stress relaxation profiles are similar to the viscoelastic solid stress relaxation profiles. The percent SR (%SR) is calculated using the following equation:

where Fr is the residual force and F0 is the maximum force.

A recent study by Shaikh and co-authors (2022) tailored the properties of GG-hydrogel and candelilla wax/sesame oil oleogel by incorporating date palm-derived cellulose nanocrystals (dp-CNC). The SR profiles of bigels were obtained using a mechanical tester, and data were used to evaluate the %SR (Fig. 14.4). The F0 value of the control sample (BG0) was reported to be lower than the dp-CNC-containing bigels (BG1-BG4). Subsequent addition of dp-CNC significantly increased F0 values of the formulations, and F60 values followed a trend comparable to F0 values. The calculated parameter, %SR, provides a rationale for the fluidity of bigel formulations. A higher %SR number corresponded to a more fluid-like formulation. Bigels with lower dp-CNC content had more elastic components, while bigels with greater dp-CNC content had more fluidic components [41]. Consequently, via SR investigations, the viscoelastic nature of bigel formulations may be identified, which is useful for customizing their characteristics.

Stress relaxation study of bigels with increasing concentration of dp-CNC*. (a) SR profile, (b) F0, (c) F60, and (d) %SR profiles. (Reproduced from [41], under the terms of the Creative Commons CC-BY license). (*BG0, BG1, BG2, BG3, and BG4 contain 0-, 5-, 10-, 15-, and 20-mg dp-CNC, respectively)

Non-Newtonian pseudoplastic flow and shear-thinning behavior of bigels have also been established using rheological experiments. According to these findings, a higher amount of hydrogel strengthens the hydrogen bonds in the polymeric network of bigels. As a result, the stiffness and viscosity of bigels increase. The viscosity of oleogels is measured using a cone and plate viscometer. Typically, measurements are taken with a shear rate between 20 and 100 s−1 at room temperature. Non-Newtonian fluid viscosity profiles can be defined by fitting the data to an equation based on the Ostwald-de Waele power law:

where τ is the shear stress, K is the flow consistency coefficient, γ is the shear rate, and n is the power law index, which measures the shear-thinning property.

The viscoelastic nature of bigels can also be studied through creep experiments. A reduction in the viscosity of bigels was seen as the number of creep cycles increased [1]. Bigel with a lower oleogel concentration had a higher % creep recovery than bigel with a higher oleogel content. The creep experiment data can be fitted into the four-element Burgers mathematical model for viscoelasticity (Eq. 14.5). The Burgers model is a standard linear viscoelastic model that is used to characterize the viscoelastic behavior of polymeric systems. This model demonstrates all of the fundamental characteristics of viscoelasticity: when a load is applied, the model undergoes elastic deformation, followed by creep, which leads to permanent deformation. It comprises an immediate elastic recovery followed by a decreasing rate of creep recovery with permanent deformation. In other words, once the tension is removed, the model assumes that the sample partly recovers from the deformation.

where η0 is the pure viscosity of the material, t1 is the retardation time, Jc(t) is the creep compliance at any time t, J1 is the retarded creep compliance, and J0 is the instantaneous creep compliance.

14.4.3 Structural Characterization

The most fundamental method for characterizing the morphology of bigels is to examine them under a microscope. Many studies have described microscopic methods for assessing bigel structural features and investigating the reciprocal distribution of organic and aqueous phases within bigels (Table 14.1). Different optical parameters such as droplet size distribution (DSD) or polydispersity of the dispersed phase can also be extracted from the microphotographs using different software. Such types of software include Image J software [42], Microtrac software [27], NI Vision Assistant-2010 software [21], and DHS Image database software [10]. DSD is calculated by computing the breadth of the droplet size distribution, which yields a dimensionless number known as the SPAN factor [23]. The SPAN factor is calculated as follows:

where D10, D50, and D90 represent the cumulative particle size distribution of 10, 50, and 90%, particles, respectively.

Fourier transform infrared (FTIR) spectroscopy determines the functional groups and chemical interactions present in bigel formulations [46]. Many bigel systems have been studied using an FTIR spectrophotometer in the attenuated total reflectance (ATR) mode in the wavenumber range of 4000–500 cm−1 [38, 47]. Both the polymer composition in the hydrogel and the proportion of gels affect the FTIR spectrum of bigels. FTIR is also employed to determine the involvement of hydrogen bonding in the bigel structure. Bigels often show a wide peak in their FTIR spectra in the wavenumber region of 3300–3200 cm−1 [48]. This peak arises primarily due to the hydrogel’s intramolecular or intermolecular hydrogen bonding. The FTIR spectroscopy method has also been used to evaluate interactions or compatibility between bioactive chemicals and bigels [49].

X-ray diffraction (XRD) analysis of bigel systems is performed to comprehend the amorphous or crystalline nature of bigels [6, 13, 36]. This study may be used to examine crystal characteristics. XRD analysis provides information on the crystalline organization, crystal shape, size, and molecular packing inside crystals. The shape of the crystals is determined using small-angle and wide-angle X-ray diffraction. Co-K has been usually reported as the radiation source (λ = 1.79 Å). The X-ray diffractometer is usually operated at 35 kV and 25 mA during the analysis of the samples. Evaluation of the samples is being performed within the diffraction angles from 5° to 50° (2θ) at a rate of 5° 2θ/min. Diffraction profiles were often deconvoluted to obtain accurate peak positioning and calculate other dependent parameters. These parameters include d-spacing (d), crystallite size (D), lattice strain (ε), and dislocation density (δ). By using Brag’s law (Eq. 14.7), we can determine the d-spacing, and using the Debye-Scherrer equation (Eq. 14.8), we can calculate the crystallite size [50]. The lattice strain and dislocation density can be calculated using Eqs. 14.9 and 14.10. Quilaqueo et al. [29] recently investigated the function of hydrogel type in the production of bigels (beeswax/canola oil-based oleogel and alginate hydrogel) for fat substitutes in cookies. The X-ray diffraction pattern of bigels revealed semicrystalline solid with crystalline and amorphous components (Fig. 14.5).

where λ is 1.79 Å, n is an integer value, and θ is the diffraction angle.

where k is the Scherrer constant, β (radian) is the full width at half maxima (FWHM) at 2θ.

X-ray pattern, confocal image, and structural behavior for beeswax-alginate bigel. (Reproduced from [29], under the terms of the Creative Commons CC-BY license)

where ε is the lattice strain, β (radian) is the FWHM at 2θ, and θ is the diffraction angle.

where δ is the dislocation density and D is the crystallite size.

14.4.4 Thermal Characterization

Thermal analysis refers to a set of procedures that measure a physical property of a substance and its reaction product(s) as a function of temperature. As the bigel is heated, its physical characteristics are often measured, including its temperature, thermal expansion, or thermodynamic parameters such as heat capacity, enthalpy, and entropy. Differential scanning calorimetry (DSC) is the most common method for the thermal investigation of bigels. Thermogravimetric analysis (TGA) and dynamic mechanical analysis (DMA) are also being utilized for such purposes. The choice of thermal analysis technique depends on the type of gel and the properties that need to be studied. DSC measures the difference in the heat needed to raise the sample and reference temperature as a function of temperature. In general, the temperature of the sample holder rises linearly as a function of time in DSC analysis. A DSC experiment yields a curve of heat flow versus temperature or time. The area under the curve is proportional to the heat flow. By integrating the peak corresponding to a certain transition, this curve may be used to derive transition enthalpies. DSC may also detect more subtle physical changes such as glass transitions. For thermal analysis of bigels, a small amount of bigel samples can be used. The sample is usually put in an aluminum crucible sealed with a pierced aluminum lid. The reference is taken as a sealed empty pan. After that, heating and cooling thermal scanning are performed for each sample. Melting profiles are captured across a specific temperature range. The analysis is performed under an N2 environment maintained at a 40-mL/min flow rate. The heating and cooling DSC profiles can be obtained by scanning at a rate of 3.0 °C/min in the required temperature range [51].

Figure 14.6 represents a DSC thermogram of bigels with sucrose esters (SEs) with different hydrophilic-lipophilic balance (HLB) values. The study was carried out by Golodnizky et al. [51] to explore the effect of different SEs on the structure and properties of bigels (glycerol/gelatin water phase and GMS/Lecithin/SE oil phase). DSC analysis facilitated the determination of the oleogel’s melting temperature and the hydrogel’s evaporation temperature. The first peak, at ~59 °C, was present only in the bigel thermograms but absent in the thermogram of the hydrogel. As a result, this peak was associated with the melting temperature of GMS in oil. The second and third peaks were ascribed to the evaporation of free and bound water molecules from the bigel system, respectively. DSC analysis makes it possible to predict the thermal behavior of bigel systems prepared with different components.

DSC thermogram of H1 (black curve, bigel with SE of HLB1), H2 (dashed black curve, bigel with SE of HL21), H6 (dotted gray curve, bigel with SE of HLB6), and the water phase (gray curve). (Reproduced from [51], under the terms of the Creative Commons CC-BY license)

14.4.5 Electrical Properties

Recent interest has focused on instrumental approaches for characterizing samples because of their quick measurement times and lack of destructive effects. The electrical characteristics of a product or substance are measured to determine its quality. Bigels’ electrical characteristics may be analyzed using an impedance analysis. The mobility of the polymer chains in a bigel sample causes resistance to the passage of current (resistivity) and the capacity to store energy in an electric field (capacitance) when an alternating current is applied. This method, specifically, keeps track of how the impedance (Z) of the sample changes as a function of the angular frequency of an applied voltage signal. In a wide frequency range, the impedance spectrum contains all the information about the electric characteristics of the bigel system. The frequency of the alternating current used in the measurement can affect the results, as the polymer chains would respond differently at different frequencies. At low frequencies, the movement of the polymer chains is dominated by viscous behavior, and the gel would have a relatively high resistivity and low capacitance. At high frequencies, the movement of the polymer chains is dominated by elastic behavior, and the gel would have a relatively low resistivity and high capacitance. This information can be used to study the gel’s microstructure, including the polymer chains’ size and distribution and the material’s viscoelastic properties. Additionally, the resulting data can be used to determine the gel’s storage modulus, loss modulus, and tan delta, which can indicate the elasticity and viscosity of the gel. Impedance analysis can also be used to monitor changes in gels with respect to time.

Figure 14.7 represents the impedance profile of bigels with an increasing concentration of dp-CNC in GG-hydrogel and sesame oil/candelilla wax oleogel, as reported by Shaikh et al. [41]. The impedance profile suggests the presence of typical capacitive behavior, where the impedance is high in the low-frequency range and reduces at high-frequency ranges. The authors correlated the observed impedance with the microstructure of bigels. They stated that smaller and homogenous droplets in hydrogels acted as numerous small capacitive elements, which increased the impedance of bigels.

Impedance spectrum of bigels. (Reproduced from [41], under the terms of the Creative Commons CC-BY license)

14.5 Food-Based Applications of Bigels

Bigels are used in a variety of food applications. Different combinations of hydrogels and oleogels have been used to formulate bigels. Recent studies show that they have been used as thickening agents in food products to give them the desired texture and fine-tune their properties [29, 52]. As a fat replacer in low-fat and fat-free products, they can provide a creamy texture and mouthfeel similar to that of full-fat products. The water retention properties of bigels have been helpful in meat products. Recent works of literature suggested that applying bigels in sausages and deli meats can help retain moisture and improve texture and juiciness [53]. Bigels can encapsulate flavors, nutrients, and other food ingredients and release them in a controlled manner over time. Such systems are versatile and valuable tools for food scientists and manufacturers to improve the texture and taste of food. Using bigels in food is a relatively new development, and scientists are now working on modifying bigels’ characteristics, so they may be used as fat replacements. There has been the suggestion that bigels may be used instead of fat in foods such as butter and cream cheese. Ghiasi et al. [54] were the first to show that low-fat beef patties prepared using bigels had better cooking properties than animal-fat burgers, proving bigels as a fat alternative in meals. In a recent article, researchers have tried to develop bigels consisting of gelatin hydrogels and GMS-enhanced EC oleogels using the component-induced catastrophic phase inversion method and studied their 3D-printing application in food [55]. Since the continuous phase consisted of EC oleogels, these bigels exhibited remarkable fluidity, making them more appropriate as 3D printing ink. The suggested procedure of catastrophic phase inversion of bigels gives the means to regulate the type of bigels by modifying the composition to acquire the desired physical attributes. This kind of adjustable bigels may readily replace conventional solid fat. Another group of researchers evaluated the role of bigels as fat replacers in cookies [29]. The oleogel phase comprised of beeswax and canola oil. On the other hand, the hydrogel phase consisted of sodium alginate and carboxymethylcellulose. The cookies obtained using the developed oleogels had a hardness similar to those with original shortening. This application showcased the huge potential of bigels as a fat substitute. Table 14.2 lists some of the recent applications of bigels as a fat replacer in food products.

14.6 Conclusion

Researchers have been experimenting with semisolid systems such as bigels, created by altering conventional gels such as hydrogels and oleogels, for potential usage in the food and nutrition industry. Recent years have seen the development and refinement of a variety of bigel formulations to meet the requirements of various applications, especially in the food industry. These bigels have been regarded as fat mimetics due to their potential to replace solid fats, for instance, butter. When it comes to substituting solid fats in food items, bigel is a particularly tempting alternative since they have successfully proven its functioning in multiple applications. Bigels may be used to improve the fatty acid profile of a product and can also be utilized to deliver lipid-soluble bioactives, both of which are advantages over traditional methods of achieving these goals. However, when such gel-based products are utilized as the fat phase in margarine and spread, issues have been encountered in producing the right mouthfeel, hardness, and long-term stability. This opens the door to further investigation and modification of such fat systems to make them acceptable for the necessary food application. This chapter focuses on different types of bigel systems, the materials used in their synthesis, the variables that affect the characteristics, the methods that have been developed to characterize them, and their application in the food industry. The properties of bigels can be tailored by modifying their composition and structure, making them a promising area of research for scientists and engineers. Although research has been done on such systems, no commercially viable solutions exist. Therefore, further research is needed to fully understand and exploit the capabilities of these derived systems.

Abbreviations

- AV:

-

p-Anisidine value

- DMA:

-

Dynamic mechanical analysis

- dp-CNC:

-

Date palm-derived cellulose nanocrystals

- DSC:

-

Differential scanning calorimetry

- DSD:

-

Droplet size distribution

- EC:

-

Ethylcellulose

- EGCG:

-

Epigallocatechin gallate

- FAME:

-

Fatty acid methyl ester

- FTIR:

-

Fourier transform infrared

- GCP:

-

Graft copolymerization

- GG:

-

Guar gum

- GMS:

-

Glycerol monostearate

- H/O:

-

Hydrogel dispersed in oleogel

- HLB:

-

Hydrophilic-lipophilic balance

- HMWOs:

-

High-molecular-weight oleogelators

- LMWOs:

-

Low-molecular-weight oleogelators

- O/H:

-

Oleogel dispersed in hydrogel

- PV:

-

Peroxide value

- PVA:

-

Polyvinyl alcohol

- PVP:

-

Polyvinyl pyrrolidone

- SEs:

-

Sucrose esters

- SR:

-

Stress relaxation

- TGA:

-

Thermogravimetric analysis

- XRD:

-

X-ray diffraction

References

Shakeel A, Lupi FR, Gabriele D, Baldino N, De Cindio B (2018) Bigels: a unique class of materials for drug delivery applications. Soft Mater 16:77–93

Sharma C, Agrawal D, Goyal R, Sharma AK, Khandelwal M (2021) Organogel: a new approach in topical drug delivery system. Eur J Pharm Med Res 8:304–307

Singh VK, Qureshi D, Nayak SK, Pal K (2018) Polymeric gels. Elsevier, pp 265–282

Shakeel A, Farooq U, Iqbal T, Yasin S, Lupi FR, Gabriele D (2019) Key characteristics and modelling of bigels systems: a review. Mater Sci Eng C 97:932–953

Raytthatha N, Vyas J, Shah I, Upadhyay U (2022) Bigels: a newer system–an opportunity for topical application. Hamdan Med J 15:113

Yang J, Zheng H, Mo Y, Gao Y, Mao L (2022) Structural characterization of hydrogel-oleogel biphasic systems as affected by oleogelators. Food Res Int 158:111536

Fayaz G, Calligaris S, Nicoli MC (2020) Comparative study on the ability of different oleogelators to structure sunflower oil. Food Biophys 15:42–49

Pang M, Shi Z, Lei Z, Ge Y, Jiang S, Cao L (2020) Structure and thermal properties of beeswax-based oleogels with different types of vegetable oil. Grasas Aceites 71:e380–e380

Martín-Illana A, Notario-Pérez F, Cazorla-Luna R, Ruiz-Caro R, Bonferoni MC, Tamayo A, Veiga MD (2021) Bigels as drug delivery systems: from their components to their applications. Drug Discov Today 27:1008

Lupi FR, Shakeel A, Greco V, Rossi CO, Baldino N, Gabriele D (2016) A rheological and microstructural characterisation of bigels for cosmetic and pharmaceutical uses. Mater Sci Eng C 69:358–365

Zhu Q, Gao J, Han L, Han K, Wei W, Wu T, Li J, Zhang M (2021) Development and characterization of novel bigels based on monoglyceride-beeswax oleogel and high acyl gellan gum hydrogel for lycopene delivery. Food Chem 365:130419

Kodela SP, Pandey PM, Nayak SK, Uvanesh K, Anis A, Pal K (2017) Novel agar–stearyl alcohol oleogel-based bigels as structured delivery vehicles. Int J Polym Mater Polym 66:669–678

Zheng H, Mao L, Cui M, Liu J, Gao Y (2020) Development of food-grade bigels based on κ-carrageenan hydrogel and monoglyceride oleogels as carriers for β-carotene: roles of oleogel fraction. Food Hydrocoll 105:105855

Singh VK, Qureshi D, Nayak SK, Pal K (2018) In: Pal K, Banerjee I (eds) Polymeric gels. Woodhead Publishing, pp 265–282

Shakeel A, Farooq U, Gabriele D, Marangoni AG, Lupi FR (2021) Bigels and multi-component organogels: an overview from rheological perspective. Food Hydrocoll 111:106190

Mittal H, Ray SS, Okamoto M (2016) Recent progress on the design and applications of polysaccharide-based graft copolymer hydrogels as adsorbents for wastewater purification. Macromol Mater Eng 301:496–522

Sahoo S, Singh VK, Uvanesh K, Biswal D, Anis A, Rana UA, Al-Zahrani SM, Pal K (2015) Development of ionic and non-ionic natural gum-based bigels: prospects for drug delivery application. J Appl Polym Sci 132(38) 42561. https://doi.org/10.1002/app.42561

Behera B, Dey S, Sharma V, Pal K (2015) Rheological and viscoelastic properties of novel sunflower oil-span 40-biopolymer–based bigels and their role as a functional material in the delivery of antimicrobial agents. Adv Polym Tech 34

Ahmed EM (2015) Hydrogel: preparation, characterization, and applications: a review. J Adv Res 6:105–121

Bollom MA, Clark S, Acevedo NC (2020) Development and characterization of a novel soy lecithin-stearic acid and whey protein concentrate bigel system for potential edible applications. Food Hydrocoll 101:105570

Behera B, Sagiri SS, Pal K, Pramanik K, Rana UA, Shakir I, Anis A (2015) Sunflower oil and protein-based novel bigels as matrices for drug delivery applications—characterization and in vitro antimicrobial efficiency. PPTEn 54:837–850

Lupi F, Gentile L, Gabriele D, Mazzulla S, Baldino N, De Cindio B (2015) Olive oil and hyperthermal water bigels for cosmetic uses. J Colloid Interface Sci 459:70–78

Paul SR, Qureshi D, Yogalakshmi Y, Nayak SK, Singh VK, Syed I, Sarkar P, Pal K (2018) Development of bigels based on stearic acid–rice bran oil oleogels and tamarind gum hydrogels for controlled delivery applications. J Surfactant Deterg 21:17–29

Singh VK, Banerjee I, Agarwal T, Pramanik K, Bhattacharya MK, Pal K (2014) Guar gum and sesame oil based novel bigels for controlled drug delivery. Colloids Surf B Biointerfaces 123:582–592

Wróblewska M, Szymańska E, Szekalska M, Winnicka K (2020) Different types of gel carriers as metronidazole delivery systems to the oral mucosa. Polymers 12:680

Mukherjee S, Ash D, Majee SB, Biswas GR (2020) Studies on Span based Soy-bigels with HPMC. Res J Pharm Technol 13:353–360

Andonova VY, Peneva PT, Apostolova EG, Dimcheva TD, Peychev ZL, Kassarova MI (2017) Carbopol hydrogel/sorbitan monostearate-almond oil based organogel biphasic formulations: preparation and characterization of the bigels. Trop J Pharm Res 16:1455–1463

Kanoujia J, Parashar P, Singh N, Saraf SA (2021) Tea tree and jojoba oils enriched bigel loaded with isotretinoin for effective management of acne. Indian J Nat Prod Resour 12(1):158–163

Quilaqueo M, Iturra N, Contardo I, Millao S, Morales E, Rubilar M (2022) Food-grade Bigels with potential to replace saturated and trans fats in cookies. Gels 8:445

Maji R, Omolo CA, Jaglal Y, Singh S, Devnarain N, Mocktar C, Govender T (2021) A transferosome-loaded bigel for enhanced transdermal delivery and antibacterial activity of vancomycin hydrochloride. Int J Pharm 607:120990

Scholten E (2018) in Edible oleogels. pp 285–305 Elsevier

Patel A, Mankoč B, Sintang MB, Lesaffer A, Dewettinck K (2015) Fumed silica-based organogels and ‘aqueous-organic’bigels. RSC Adv 5:9703–9708

Feichtinger A, Scholten E (2020) Preparation of protein oleogels: effect on structure and functionality. Foods 9:1745

Gravelle AJ, Davidovich-Pinhas M, Zetzl AK, Barbut S, Marangoni AG (2016) Influence of solvent quality on the mechanical strength of ethylcellulose oleogels. Carbohydr Polym 135:169–179

Pascuta MS, Varvara R-A, Teleky B-E, Szabo K, Plamada D, Nemeş S-A, Mitrea L, Martău GA, Ciont C, Călinoiu LF, Barta G, Vodnar DC (2022) Polysaccharide-based edible gels as functional ingredients: characterization, applicability, and human health benefits. Gels 8:524

Lu Y, Zhong Y, Guo X, Zhang J, Gao Y, Mao L (2022) Structural modification of O/W Bigels by glycerol Monostearate for improved co-delivery of curcumin and epigallocatechin Gallate. ACS Food Sci Technol 6:975

Soni K, Gour V, Agrawal P, Haider T, Kanwar IL, Bakshi A, Soni V (2021) Carbopol-olive oil-based bigel drug delivery system of doxycycline hyclate for the treatment of acne. Drug Dev Ind Pharm 47:954–962

Vergara D, Loza-Rodríguez N, Acevedo F, Bustamante M, López O (2022) Povidone-iodine loaded bigels: characterization and effect as a hand antiseptic agent. J Drug Deliv Sci Technol 72:103427

Andonova V, Peneva P, Georgiev GS, Toncheva VT, Apostolova E, Peychev Z, Dimitrova S, Katsarova M, Petrova N, Kassarova M (2017) Ketoprofen-loaded polymer carriers in bigel formulation: an approach to enhancing drug photostability in topical application forms. Int J Nanomedicine 12:6221

Corredor-Chaparro MY, Vargas-Riveros D, Mora-Huertas CE (2022) Hypromellose–Collagen hydrogels/sesame oil organogel based bigels as controlled drug delivery systems. J Drug Deliv Sci Technol 75:103637

Shaikh HM, Anis A, Poulose AM, Madhar NA, Al-Zahrani SM (2022) Development of Bigels based on date palm-derived cellulose nanocrystal-reinforced Guar Gum hydrogel and sesame oil/Candelilla Wax Oleogel as delivery vehicles for Moxifloxacin. Gels 8:330

Hamed R, Mahmoud NN, Alnadi SH, Alkilani AZ, Hussein G (2020) Diclofenac diethylamine nanosystems-loaded bigels for topical delivery: development, rheological characterization, and release studies. Drug Dev Ind Pharm 46:1705–1715

Singh VK, Anis A, Banerjee I, Pramanik K, Bhattacharya MK, Pal K (2014) Preparation and characterization of novel carbopol based bigels for topical delivery of metronidazole for the treatment of bacterial vaginosis. Mater Sci Eng C 44:151–158

Wakhet S, Singh VK, Sahoo S, Sagiri SS, Kulanthaivel S, Bhattacharya MK, Kumar N, Banerjee I, Pal K (2015) Characterization of gelatin–agar based phase separated hydrogel, emulgel and bigel: a comparative study. J Mater Sci Mater Med 26:1–13

Rehman K, Amin MCIM & Zulfakar MH (2014) Development and physical characterization of polymer-fish oil bigel (hydrogel/oleogel) system as a transdermal drug delivery vehicle. J Oleo Sci:ess14101

Singh VK, Anis A, Al-Zahrani S, Pradhan DK, Pal K (2014) FTIR, electrochemical impedance and iontophoretic delivery analysis of guar gum and sesame oil based bigels. Int J Electrochem Sci 9:5640–5650

Patel ND, Kanaki NS (2021) Quality evaluation of the Tugaksheeree samples by ATR-FTIR spectroscopy using multicomponent analysis. J Nat Prod 11:377–382

Barragán-Martínez LP, Molina-Rodríguez A, Román-Guerrero A, Vernon-Carter EJ, Alvarez-Ramirez J (2022) Effect of starch gelatinization on the morphology, viscoelasticity, and water structure of candelilla wax–canola oil–starch hybrid gels. J Food Process Preserv 46:e16520

Saffold AC, Acevedo NC (2021) Development of novel rice Bran Wax/Gelatin-based biphasic edible gels and characterization of their microstructural, thermal, and mechanical properties. Food Bioprocess Technol 14:2219–2230

Fasolin LH, Martins AJ, Cerqueira M, Vicente A (2021) Modulating process parameters to change physical properties of bigels for food applications. Food Struct 28:100173

Golodnizky D, Davidovich-Pinhas M (2020) The effect of the HLB value of sucrose ester on physiochemical properties of Bigel systems. Foods 9:1857

Dong Y, Wei Z, Xue C (2021) Recent advances in carrageenan-based delivery systems for bioactive ingredients: a review. Trends Food Sci Technol 112:348–361

Guo J, Cui L, Meng Z (2022) Oleogels/emulsion gels as novel saturated fat replacers in meat products: a review. Food Hydrocoll 108313

Ghiasi F, Golmakani M-T (2022) Fabrication and characterization of a novel biphasic system based on starch and ethylcellulose as an alternative fat replacer in a model food system. Innov Food Sci Emerg Technol 78:103028

Jiang Q, Wang Y, Du L, Li S, Liu Y, Meng Z (2022) Catastrophic phase inversion of bigels characterized by fluorescence intensity-based 3D modeling and the formability for decorating and 3D printing. Food Hydrocoll 126:107461

Baltuonytė G, Eisinaitė V, Kazernavičiūtė R, Vinauskienė R, Jasutienė I, Leskauskaitė D (2022) Novel formulation of Bigel-based vegetable oil spreads enriched with Lingonberry Pomace. Foods 11:2213

Zampouni K, Siachou C, Katsanidis E (2022) Design of biphasic structures for replacing saturated fats in food systems. Pub Health Tox 2(Supplement 1):A107. https://doi.org/10.18332/pht/149613

Martinez RM, Magalhaes WV, Da Silva SB, Padovani G, Nazato LIS, Velasco MVR, Da Silva Lannes SC, Baby AR (2021) Vitamin E-loaded bigels and emulsions: physicochemical characterization and potential biological application. Colloids Surf B Biointerfaces 201:111651

Acknowledgments

Ms. Somali Dhal would like to express her gratitude to NIT Rourkela for the fellowship that she was awarded for completing her master’s thesis.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Dhal, S., Cerqueira, M.A., Kim, D., Pal, K. (2024). Bigels: An Innovative Hybrid of Hydrogels/Oleogels for Food Applications. In: Palla, C., Valoppi, F. (eds) Advances in Oleogel Development, Characterization, and Nutritional Aspects. Springer, Cham. https://doi.org/10.1007/978-3-031-46831-5_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-46831-5_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46830-8

Online ISBN: 978-3-031-46831-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)