Abstract

In this introductory chapter, we embark on a journey into the world of oleogels, a topic of increasing significance within the food industry. The exploration begins with an examination of the challenges faced by the industry, and particularly in incorporating oleogels into their products, while aligning with current consumer trends. Following, we delve into an important question: What are the historical origins and early uses of oleogels and organogels, and how have these materials evolved over time to become relevant in the food industry today? Then, we present some essential concepts related to oleogels, laying the groundwork for a better understanding of the subsequent chapters in this book. Finally, we offer a description of the main research topics in the field, which will be extensively covered throughout this book.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1.1 Food Industry Needs, Challenges, Trends, and Where Oleogels Fit In

The food industry is continuously changing in response to consumer demands and regulatory guidelines, with new trends and challenges being addressed in different areas among food stakeholders.

Two of the most significant challenges are related to the growing population that needs to be fed with healthy and balanced foods, and the sustainability of the materials, processes, and products. The impact of food production on the environment is mainly related to its impact on greenhouse gas emissions, land and water use, and the loss of biodiversity. Several strategies have been proposed to optimize the agriculture and food processing processes, but in most cases, the implementation cost, related to low efficiency and high prices of ingredients, is limiting the change [1]. This implementation cost will have an impact on the other mentioned challenge, where more and more diversified production is needed.

The global population is suffering from an unbalance distribution of food, where a part of the global population suffers from undernutrition with the consumption of low amounts of food of poor quality (resulting in, for example, hunger and micronutrient deficiencies), and another part is eating too much and in an unbalanced way (resulting in, for example, obesity, diabetes, hypertension, coronary heart disease), being, therefore, a concern for both developed and developing countries [2].

Fats are one of the ingredients within the list of the so-called “Western diet” [3] that has shown an increase in consumption in the last 60 years [4]. A study of 2020, comprising 118 countries from 1960 to 2010, showed that the total calorie intake increased for all countries and the nutritional quality decreased [5]. One of the conclusions of the study was that diets are becoming less healthy and that one of the drivers for this change is the consumption of more fats (i.e., animal-based foods) in detriment of carbohydrates (i.e., plant-based foods). However, it is important to mention that people’s diet can be influenced by different factors that varies across countries and regions, and households (e.g., culture, religion, climate, and traditions).

The need to improve the global diet has been highlighted by several organizations and governments, but it is consensual that it is only possible to have an effective change with the engagement of all relevant stakeholders [6]. With this in mind, the United Nations adopted 17 Sustainable Development Goals for the Global Challenges, in which the food industry plays a major role, particularly in the goals: (2) “Zero hunger,” (3) “Good health and well-being,” (12) “Responsible consumption and production,” and (13) “Climate action” [7].

Food trends are also related to some of the presented challenges, where the consumers’ awareness of the need for healthy and sustainable diets is changing the food industry. One of the main food trends is consumer engagement and empowerment. The behavior and perception of consumers, as well as food producers and retailers, impact companies’ strategies and decisions. Nowadays, consumers seem to be looking for more healthy and more natural products, focused on alternative proteins, and products that can be considered clean label and sustainable. This consumers’ direction is also supported by the EAT-Lancet commission, which suggests that global food consumption should shift to more plant-based foods. This is supported by the fact that plant-based foods can be healthier than the animal counterparts but also due to the environmental impact of animal-based foods [1]. They propose a universal diet based on vegetables, fruits, whole grains, legumes, nuts, and unsaturated oils, with low to moderate amounts of seafood and poultry and low quantities of red meat, processed meat, added sugar, refined grains, and starchy vegetables.

Lipids have a huge role in these healthy diets, since they are essential for the proper development of humans. While some of the essential lipids are present in food and food ingredients, they are also directly added (as animal fat or vegetable oil) conferring important technological and sensorial properties to a great variety of foods, such as spreads, bakery products, margarine, and dairy products. However, during the years, the solutions offered by the industry have been controversial, with the use of trans fatty acids (TFAs) that have already been banned or allowed in very low amounts in several countries [8, 9]. Another strategy is the use of saturated fatty acids (SFAs) that can be obtained by the fractionation of oils, such as palm oil. The low price, texture and rheological properties, high stability against oxidation, and shelf life are among the reasons to use palm oil. However, also in this case, studies have shown that the consumption of saturated fats (except for stearic acid) influences cholesterol levels in the blood and increases the risk of cardiovascular diseases [10]. Guidelines from the World Health Organization for a healthy diet mention that reducing the amount of total fat intake to less than 30% of total energy intake helps to prevent unhealthy weight gain in adults and that we should reduce the use of trans and saturated fats by replacing them by unsaturated and polyunsaturated fats [11]. The European Union has also promoted the development of foods with a healthier lipid profile by allowing companies to claim nutritional aspects on their products (e.g., low fat, fat-free, source of omega-3 fatty acids) [12].

Another problem related to the use of fats by the food industry is the environmental impact of oil production. While this is an issue that involves the entire food system, in the case of lipids, one of the great examples is palm oil. Several studies revealed the considerable impact of their production on deforestation and consequently loss of biodiversity and the release of CO2 [13], bringing an additional problem when palm oil is used. Therefore, the removal of hydrogenated fats and the limitation of the use and consumption of saturated fats have changed the way the food industry looks at lipids.

Despite these issues, the Global Edible Oils and Fats Market is experiencing continuous expansion. The market size is projected to reach USD 831.10 billion by 2030, with a robust revenue-based compound annual growth rate (CAGR) of 7.5% from 2023 to 2030 [14]. In particular, the Margarine Market is expected to grow significantly, from USD 22.12 billion in 2023 to USD 24.93 billion in 2028, at a steady CAGR of 2.42% over the forecast period (2023–2028) [15].

Different strategies have been proposed to meet the real need for healthier, TFA-free, stable, and solid-like fats, which maintain their structure at ambient temperature, assuring a longer shelf-life. One of these strategies is fat mimetics, where the use of physically structured oils, known as oleogels, seems to be one of the most promising routes. They can guarantee the reduction of unhealthy fats or/and their replacement by mono- and polyunsaturated fats and offer technical functionalities similar to fats. This is related to the way they are produced, mostly using only food ingredients and without chemical modification of the lipids, thus presenting some benefits towards sustainability and clean label trends. Based on these advantages, it is possible to think that there is a promising potential market for oleogels. Moreover, with increasing consumer awareness regarding healthy food consumption, the Global Edible Oils and Fats Market is expected to witness an increased demand for the development of healthier products.

1.2 Oil Structuring and Oleogels—A Brief Introduction

Lipids are essential ingredients in food products, contributing to their physicochemical properties, structural integrity, stability, and overall sensory quality. However, the pressing demand for healthier food choices has given rise to a significant challenge: finding and developing healthy alternatives to solid fats while minimizing any adverse effects on product properties and consumer acceptance. When solid fat ingredients are merely replaced with oil, the resulting products generally fail to replicate the quality characteristics of the original ones, particularly in terms of textural attributes, leading to a deficiency that negatively impacts sensory perception and consumer satisfaction [16, 17]. This is one of the main reasons why the food industry and scientists have focused their attention on oil structuring and oleogelation processes, as they allow the development of soft matter structures that possess similar functionality to solid fats. The systems produced by oleogelation using edible oils are called oleogels, also referred to in the literature as organogels (see the next section for a discussion of both terms).

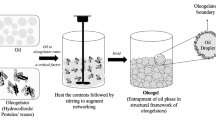

Oleogels are semisolid materials formed by the entrapment of oil within a three-dimensional (3D) gel network composed of structuring agents or gelators added at low concentrations [18]. Structuring agents are compounds with the ability to retain oil after specific physical processing. They are generally classified as either low molecular weight gelators (LMWGs) or high molecular weight gelators (HMWGs). Examples of the first type are fatty acids, monoglycerides, waxes, sterols, and lecithin. On the other hand, HMWGs include polymers and biopolymers such as cellulose derivatives, proteins, and starches, which typically require more processing to form stable structures that immobilize the oil phase. The choice of structuring agent depends on the specific application and the desired properties of the oleogel, allowing for versatility in the development of different oil-based products. A detailed explanation of the physical processes involved in the preparation of oleogels using LMWGs or HWMGs can be found in Chaps. 4, 5, 6, 7, 8, 9, and 10.

As oleogels are mainly formulated with oils (desirable > 90%), they have a lipid profile comparable to that of the edible oil used to produce them, which is of radical importance from a nutritional point of view, as it will be highlighted in Chap. 2. This makes it possible to develop lipid materials not only with reduced SFA and free TFA content but also with a superior lipid profile by selecting oils rich in fatty acids with high biological value such as essential fatty acids. In particular, the use of oils abundant in polyunsaturated fatty acids (PUFA) allows the production of oleogels with health-promoting activity, as PUFA oils have been shown to offer numerous benefits for health, including immune system and blood pressure regulation, cholesterol metabolism, neurological and cognitive function, and insulin resistance, among others [19].

The physical properties of oleogels are the result of a combination of factors, including the chemical composition of the oil and gelator, their respective proportions, and the processing conditions employed during their production. The development of oleogels with fat-mimicking properties requires a comprehensive evaluation of thermal, rheological, textural, structural, and stability properties, as it will be discussed in Chaps. 18, 19, and 21. Additionally, oleogel characterization plays a crucial role in enhancing our understanding of the oleogel itself and determining relevant properties for its applications in various products [20].

1.3 Organogels and Oleogels in History

We are used to thinking that organogels and oleogels are relative recent terms. This is true within the food science area and to some extent in the cosmetics and pharmaceuticals areas, whereas in the case of lubricants or fundamental science these terms have been used for more than a century (organogels) and almost 75 years (oleogels).

First of all, it is important to distinguish between the two terms and define them based on the meanings that have been developed over the last decades: an organogel is simply a gel of an organic solvent where the solvent is entrapped/retained in a three-dimensional network of gelling molecules. An organogel where the organic solvent is an edible oil and gelling molecules are edible is called an oleogel.

In general, organogels have been defined by their preparation methods, where a gelator is added to an organic liquid, the mixture is heated to dissolve the gelator, and then the solution is cooled below the gelation transition temperature [21]. If the reader is already familiar with the field of oleogels, this definition can sound familiar as it is the same procedure used in the preparation of oleogels by the hot direct method; more details can be found in Chap. 4. A more detailed definition of an organogel refers to a “thermally-reversible viscoelastic liquidlike or solidlike material comprised of an organic liquid and low concentrations (typically <2 wt %) of relatively low molecular mass molecules (i.e., gelators)” [21]. However, not only LMWGs are nowadays included in the definition, but also polymer gelators [22]. Also in this case, the definition is quite similar to that of oleogels obtained by the hot direct method. Even though these two definitions could sound familiar, the development of the field and consequently the definition of organogels has changed over time (more information below). The field has been developing since 1920s. One of the first papers reporting the term “organogel” we could find in the literature was published by Neuhausen and Patrick [23] in 1921, although references in the same article about tests to gel organic solvents with silicic acid and a small amount of water date back to 1864. The field has continued its evolution until present days (Fig. 1.1), and during this century of research, the ability of organic gelators like metal salts of fatty acids, fatty acids derivatives, steroid derivatives, anthryl derivatives, aromatic- and steroidal-containing molecules, amino acids, and organometallic molecules to gel organic solvents like linear and cyclic hydrocarbons, alcohols, aldehydes, ketones, and aromatic solvents, to name a few, has been extensively studied [21, 24]. If the reader is interested to further deepen the topic of organogels, they can refer to the reviews by Terech and Weiss [21], Suzuki and Hanabusa [22], and Abdallah and Weiss [24], as well as to the book by Guenet [25].

Number of scientific publications reported by Scopus containing the term “organogel*” or “oleogel*” in the title, abstract, and keywords from 1920 to 2022. The inserted figure is the magnification of the main figure from 1920 to 2009. Note that (*) allows users to search for all terms beginning with the specified word—for example, oleogel/oleogels/oleogelation/oleogelator

From the field of organogels, edible oleogels have been developed. The first example of publications reporting on organogels made with edible oils and gelators in the food science area were those published by Ojijo et al. [26, 27] in 2004. These authors developed oleogels structured with monoglycerides by the hot direct method (mixing, heating, and cooling) using virgin olive oil. Although these structured lipid systems could be classified as oleogels, the term in the food science area was not yet in use. It was not until 2007 that the word oleogel appeared as a keyword in the context of organogels made with edible oils in a paper authored by Pernetti et al. [28]. However, the term “oleogel” can be found even in an earlier paper belonging to the pharmaceutical area published in 2003, in which olive oil was gelled using ethylcellulose as a first step to develop a topical administration incorporating a drug [29]. In the pharmaceutical area, these types of gels appeared already in the 90s, but they were called lipogels [30].

As anticipated at the beginning of this section, it is interesting to know that the term oleogel is about 75 years old (Fig. 1.2). However, in the late 1930s, Steven Kistler, who is well known for developing the first aerogels [31], developed the first aerogel-templated method in which by adding aerogel particles to oils, a thickened oil/grease was obtained that could be used as a lubricant (US2260625A). This method was later brought in the edible oleogel area in 2017 by Manzocco et al. [32] and further developed by Plazzotta et al. [33]. In his patent, Kistler also suggests that “similar results [formation of an oleogel] are obtainable by replacing the swelling liquid of the gel [solvent] with a portion of the liquid to be thickened [oil],” which gives a glimpse of an oleogel preparation method, nowadays called the solvent exchange method, developed in 2015 by de Vries et al. [34]. The solvent exchange method described in Kistler’s patent was further explained in the patent number US2594822A from 1949, where we could find the term oleogel making one of its first appearance: “Another means known to the prior art for the formation of greases of inorganic gels comprises formation of a hydrogel, replacement of water with a water-miscible organic solvent, replacement of the water-miscible organic solvent with an oil-soluble solvent and transference of the resulting organogel to a lubricating oil medium followed by the removal of an oil-soluble solvent to form, finally, an oleogel.” From the same patent, we can also identify the definitions of oleogels and organogels that were used by the research and innovation community in the 1940s–1950s. Oleogels were referred to as gels of lubricating oils, whereas organogels were an intermediate step having the same structure as an oleogel but containing only oil-soluble solvents. It can be seen how these two terms evolved in their definition based on the evolution of the field by just comparing them with those reported at the beginning of this section. Finally, in the same patent, the inventors described that the methods for obtaining oleogels were quite time- and resources-consuming with the need of specialized equipment, and they invented a method for producing a lubricating grease “by having the lubricating oil as the continuous phase gelled by the polyvalent metal hydroxide dispersed therein,” where the reported method showed features that are typical of a direct oleogelation method. From there, efforts have been made to simplify oleogelation methods, for example, by developing processes using colloidal particles and water, with the subsequent evaporation of water (DES0040177MA from 1954), or by using organogels as templates to form oleogels, where one process comprised a “very rapid evaporation of the liquid from the organogel as it is fed to the hot lubricating oil, such evaporation taking place in the presence of an ample supply of oil to replace the volatile liquid displaced by evaporation, minimizes this tendency and causes the line pore structure of the gel material to be retained and carried forward into the oleogel stage” (GB2986518XA from 1958). At this point, the first scientific publication we could find using the word “oleogel” was published by Bondi [35] in 1958.

Number of patents reported by Google Patents under the search term “organogel” or “oleogel” from 2000 to 2022 (search configuration: priority date and text in full documents). This period was selected considering that the patent lifetime is 20 years. The inserted figure shows the search results between 1920 and 1999

It is interesting to note that the historical evolution of oleogel preparation methods started with very sophisticated procedures requiring specialized equipment and multiple steps and proceeded towards more simplified methods. This is the opposite that was observed in the evolution of methods for producing edible oleogels, where simple methods dominated the first decade of development (from 2004), followed by the introduction of production methods requiring multiple steps and specialized equipment (from 2013).

Through a search on Google Patents and Espacenet, we could observe that the trend to use the term “oleogels” continued in many patents. However, the field of application of oleogels in those patents shifted from lubrication (which dominated until the 1970s) to pharmaceutical applications, particularly with the development of topical creams in the 1980s. The 1990s marked further diversification and expansion of the oleogel field of application, including cosmetics, bioadhesives, fuel, veterinary, and feedstuff. During the first decade of 2000s, the use of oleogels for pharmaceutical applications intensified, and the first developments were made in the food area. In the following decade to date (2010–2023), most of the developments have been related to food applications.

This short journey taught us that the meaning of the words “oleogels” and “organogels” morphed over time. We have seen their definitions evolve from those used in the pioneering area of lubricants to the current booming in food science, pharmaceutical, and cosmetic areas. We hope that the reader finds this little excursion into the history of oleogels interesting and that the ideas and visions of the past will inspire possible new methods to obtain edible oleogels.

1.4 Oleogels: Current Areas of Research in the Food Sector

Oleogels are an active area of research with a focus on their potential to replace saturated fats in food products, as well as their use in developing functional foods and bioactive delivery systems. The research topics and knowledge groups in the field of oleogels can be effectively analyzed using Carrot2 (search.carrot2.org), an open-source search results clustering tool. Carrot2 utilizes a clustering process that involves analyzing the content of documents, identifying common terms and phrases, and grouping related documents together into clusters. Figure 1.3 shows the clusters resulting from the analysis of 538 documents from PubMed using the search term “oleogel.” In the visualization, larger bubbles represent clusters with a higher number of publications. The topics that have received more attention in the oleogel field are “Oleogelation Mechanism,” “Emulsions and Stabilization,” “Textural and Rheological” properties of oleogels, “Delivery Systems,” “Application in the Food Industry,” “Crystal Microstructure,” “Protein Oleogels,” and “Crystallization Behavior.” Other topics that have received attention with potential to expand knowledge in the area include “Oleogel and Bigels,” “Oleogel Foams,” “Oxidation during Storage,” “Bioactive Delivery,” and “Processed Meat.”

Other topics of current interest, not identified by Carrot2, include the study of oleogels as a potential tool for modulating lipid metabolism to manage obesity, the production of oleogels using oils obtained by fermentation or extraction from microalgae and insects, the exploration of oleogels in the development of plant-based products, and their application in formulating inks for food 3D printers. While reading this book, the reader will come across both basic and detailed information on all the topics mentioned and many more.

1.5 Conclusions

The need to improve the global diet and the push for sustainable food practices have compelled the food industry and scientists to search for novel lipid materials able to confer technological and sensorial properties to products. The strategy of oleogelation, which has been widely studied in the field of lubricants for almost a century, has served as an inspiration for the development of oleogels, opening up the possibility of creating an infinite number of materials by combining edible oils with compounds capable of retaining oil after specific physical processing. Indeed, numerous studies and patents have been published on oleogels, demonstrating their remarkable potential not only to replace saturated fats in foods, but also to serve as valuable components in the creation of functional foods and efficient bioactive delivery systems. The more knowledge we acquire about oleogels, the more apparent it becomes how vast this field of study is, encompassing numerous topics and potential applications, and the need to delve deeper into each of them. A strong knowledge foundation will provide us with more tools to continue advancing in this fascinating field; thus, we will unlock the full potential of oleogels for the benefit of society and the environment.

Abbreviations

- CAGR:

-

Compound annual growth rate

- HMWG:

-

High molecular weight gelator

- LMWG:

-

Low molecular weight gelator

- PUFA:

-

Polyunsaturated fatty acid

- SFA:

-

Saturated fatty acid

- TFA:

-

Trans fatty acid

References

Willett W, Rockström J, Loken B, Springmann M, Lang T, Vermeulen S, Garnett T, Tilman D, Declerck F (2019) The Lancet Commissions Food in the Anthropocene: the EAT – Lancet Commission on healthy diets from sustainable food systems. Lancet 393:447–492. https://doi.org/10.1016/S0140-6736(18)31788-4

OECD (2019) The heavy burden of obesity: The economics of prevention. OECD Health Policy Studies, OECD Publishing, Paris. https://doi.org/10.1787/67450d67-en

Khoury CK, Bjorkman AD, Dempewolf H, Ramirez-Villegas J, Guarino L, Jarvis A, Rieseberg LH, Struik PC (2014) Increasing homogeneity in global food supplies and the implications for food security. Proc Natl Acad Sci 111:4001 LP–4006. https://doi.org/10.1073/pnas.1313490111

Oberlander L, Disdier AC, Etilé F (2017) Globalisation and national trends in nutrition and health: a grouped fixed-effects approach to intercountry heterogeneity. Heal Econ (United Kingdom) 26. https://doi.org/10.1002/hec.3521

Le TH, Disegna M, Lloyd T (2020) National food consumption patterns: converging trends and the implications for health. EuroChoices n/a. https://doi.org/10.1111/1746-692X.12272

World Health Organization (2021). Obesity and overweight. https://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight. Accessed 10th May 2023

Nations united sustainable development goals. https://www.un.org/sustainabledevelopment/

FDA (U.S. Food and Drug Administration) (2018) Trans fat. https://www.fda.gov/food/food-additives-petitions/trans-fat

European Comission (2019) Commission Regulation (EU) 2019/649. Off J Eur Union 17–20. https://doi.org/10.2903/sp.efsa.2018.en-1433

Zhu Y, Bo Y, Liu Y (2019) Dietary total fat, fatty acids intake, and risk of cardiovascular disease: a dose-response meta-analysis of cohort studies. Lipids Health Dis 18:91

WHO (World Health Organization) (2020) Healthy diet. https://www.who.int/news-room/fact-sheets/detail/healthy-diet. Accessed 10th May 2023

European Commission (2012) Nutrition claims. https://food.ec.europa.eu/safety/labelling-and-nutrition/nutrition-and-health-claims/nutrition-claims_en. Accessed 10th May 2023

Meijaard E, Brooks TM, Carlson KM, Slade EM, Garcia-Ulloa J, Gaveau DLA, Lee JSH, Santika T, Juffe-Bignoli D, Struebig MJ, Wich SA, Ancrenaz M, Koh LP, Zamira N, Abrams JF, Prins HHT, Sendashonga CN, Murdiyarso D, Furumo PR, Macfarlane N, Hoffmann R, Persio M, Descals A, Szantoi Z, Sheil D (2020) The environmental impacts of palm oil in context. Nat Plants 6:1418–1426. https://doi.org/10.1038/s41477-020-00813-w

GlobeNewswire (2023) Global edible oil and fats market to 2030: rising importance of vegetable oils as key functional ingredients bolsters growth. https://www.globenewswire.com/en/news-release/2023/06/02/2681143/28124/en/Global-Edible-Oil-and-Fats-Market-to-2030-Rising-Importance-of-Vegetable-Oils-as-Key-Functional-Ingredients-Bolsters-Growth.html. Accessed 27 July 2023

Mordor Intelligence (2023) Margarine market size & share analysis – growth trends & forecasts (2023–2028). https://www.mordorintelligence.com/industry-reports/margarine-market. Accessed 24 July 2023

Doan CD, Tavernier I, Okuro PK, Dewettinck K (2018) Internal and external factors affecting the crystallization, gelation and applicability of wax-based oleogels in food industry. Innov Food Sci Emerg Technol 45:42–52. https://doi.org/10.1016/j.ifset.2017.09.023

Gavahian M, Tiwari BK, Chu Y, Ting Y, Farahnaky A (2019) Food texture as affected by ohmic heating: mechanisms involved, recent findings, benefits, and limitations. Trends Food Sci Technol 86:328–339. https://doi.org/10.1016/j.tifs.2019.02.022

Patel AR, Dewettinck K (2016) Edible oil structuring: an overview and recent updates. Food Funct 7:20–29. https://doi.org/10.1039/C5FO01006C

Abedi E, Sahari MA (2014) Long-chain polyunsaturated fatty acid sources and evaluation of their nutritional and functional properties. Food Sci Nutr 2(5):443–463

Flöter E, Wettlaufer T, Conty V, Scharfe M (2021) Oleogels—their applicability and methods of characterization. Molecules 26. https://doi.org/10.3390/molecules26061673

Terech P, Weiss RG (1997) Low molecular mass gelators of organic liquids and the properties of their gels. Chem Rev 97. https://doi.org/10.1021/cr9700282

Suzuki M, Hanabusa K (2010) Polymer organogelators that make supramolecular organogels through physical cross-linking and self-assembly. Chem Soc Rev 39. https://doi.org/10.1039/b910604a

Neuhausen BS, Patrick WA (1921) Organogels of silicic acid. J Am Chem Soc 43. https://doi.org/10.1021/ja01441a011

Abdallah DJ, Weiss RG (2000) Organogels and low molecular mass organic gelators. Adv Mater 12:1237–1247. https://doi.org/10.1002/1521-4095(200009)12:17<1237::AID-ADMA1237>3.0.CO;2-B

Guenet J-M (2016) Organogels: thermodynamics, structure, solvent role, and properties. Springer, Cham

Ojijo NKO, Neeman I, Eger S, Shimoni E (2004) Effects of monoglyceride content, cooling rate and shear on the rheological properties of olive oil/monoglyceride gel networks. J Sci Food Agric 84:1585–1593. https://doi.org/10.1002/jsfa.1831

Ojijo NKO, Kesselman E, Shuster V, Eichler S, Eger S, Neeman I, Shimoni E (2004) Changes in microstructural, thermal, and rheological properties of olive oil/monoglyceride networks during storage. Food Res Int 37:385–393. https://doi.org/10.1016/j.foodres.2004.02.003

Pernetti M, van Malssen KF, Flöter E, Bot A (2007) Structuring of edible oils by alternatives to crystalline fat. Curr Opin Colloid Interface Sci 12:221–231

Ruíz Martínez MA, Muñoz De Benavides M, Morales Hernández ME, Gallardo Lara V (2003) Influence of the concentration of a gelling agent and the type of surfactant on the rheological characteristics of oleogels. Farmaco 58. https://doi.org/10.1016/S0014-827X(03)00180-0

Realdon N, Dal Zotto M, Ragazzi E, Dalla Fini G (1996) Drug release from lipogels according to gelling conditions and mechanical treatment. Drug Dev Ind Pharm 22. https://doi.org/10.3109/03639049609041982

Kistler S (1931) Coherent expanded aerogels and jellies. Nature 127:741

Manzocco L, Valoppi F, Calligaris S, Andreatta F, Spilimbergo S, Nicoli MC (2017) Exploitation of κ-carrageenan aerogels as template for edible oleogel preparation. Food Hydrocoll 71. https://doi.org/10.1016/j.foodhyd.2017.04.021

Plazzotta S, Calligaris S, Manzocco L (2020) Structural characterization of oleogels from whey protein aerogel particles. Food Res Int 132. https://doi.org/10.1016/j.foodres.2020.109099

De Vries A, Hendriks J, Van Der Linden E, Scholten E (2015) Protein oleogels from protein hydrogels via a stepwise solvent exchange route. Langmuir 31. https://doi.org/10.1021/acs.langmuir.5b03993

Bondi A (1958) Flow phenomena with oleogels. Trans Soc Rheol 2:303–312

Acknowledgments

Miguel A. Cerqueira acknowledges NUTRI4ICECARE: Ice cream with incorporation of compounds of nutritional interest (NORTE-01-0247-FEDER-045380), co-financed by Norte 2020 and the European Union, through the European Regional Development Fund (ERDF). Camila Palla acknowledges the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) of Argentina. Fabio Valoppi acknowledges the European Union’s Horizon 2020 research and innovation program funding under the Marie Skłodowska-Curie grant agreement No. 836071.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Cerqueira, M.A., Palla, C., Valoppi, F. (2024). Tracing the Evolution of Oleogels: A Historical Overview. In: Palla, C., Valoppi, F. (eds) Advances in Oleogel Development, Characterization, and Nutritional Aspects. Springer, Cham. https://doi.org/10.1007/978-3-031-46831-5_1

Download citation

DOI: https://doi.org/10.1007/978-3-031-46831-5_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46830-8

Online ISBN: 978-3-031-46831-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)