Abstract

Over the last 20 years, polyvinyl chloride (PVC) based composites have garnered attention in the dielectric material research owing to their excellent insulating properties, mechanical strength, flexibility, chemical and thermal stabilities. The influence of various nanoparticles on different dielectric properties of PVC and their applicability in electronic industry are briefly discussed in this chapter. The nature of polymer-filler interface, concentration, type and chemistry of nanoparticles are critical in the final dielectric properties. The influencing factors and improvements of dielectric properties such as permittivity, dielectric loss and break down voltage in PVC polymer composites from mechanism, single and multi-nanoparticles, surface functionalization and ionization are overviewed in this review. This review is expected to help the readers to comprehensively understand the fabrication of PVC composite dielectrics with high performance for various applications.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In these decades, flexible polymer composites have emerged as an excellent candidate for dielectric applications in the electronic industry especially from portable electronic devices to high-efficiency hybrid electric vehicles owing to their cost-effective industrial-scale processability, light weight, superior service life, and environment-friendly nature, excellent flexibility along with high breakdown strength, energy density and dielectric constant, as well as low dielectric loss. The polymer dielectric composites also demand actuators, sensors, capacitors, telecommunication and pulsed power systems [1, 2]. Polyvinylchloride (PVC) is an inexpensive polymeric material, that exhibit excellent insulating properties, wide bandgap, high mechanical strength and flexibility, thermal as well as chemical stability making it a promising candidate in the dielectrics. The miniaturization and integration of electronic gadgets constantly demand flexible energy storage materials with high dielectric constant and minimum loss. Currently, various ceramic fillers owing to their intrinsic high dielectric constant have been utilized in polymer composites to enhance the dielectric properties but, the high volume requirement and low interfacial interaction resulted in a high dielectric loss as well as poor flexibility and process ability to the composites. In fact, conductive nanomaterials are preferable on account of ease of processability, and very low filler dosage for enhancing dielectric properties [3].

Incorporating low loading nanoparticles into polymer matrix owing to their high surface area with homogeneous distribution and structure–property relationship can achieve significant improvement in the dielectric, thermal and mechanical performance of nanocomposites than the conventional composites [4,5,6]. The influence of various nanoparticles such as graphene oxide, Fe2O3, NiO, silica, etc. on dielectric properties and their correlated parameters for PVC based nanocomposites were studied by many researchers. The purpose of this review is to demonstrate various dielectric property requirements and comprehensively summarize various PVC based composites for different dielectric applications.

2 Various Dielectric Properties

As per the dielectric theory, for every material whether conducting or insulating, upon applying a direct or alternating current, there is a range of migration of electric charges. This movement of charges is limited in a dielectric or insulating material, forming a dipole moment between them, consecutively polarizing the material. An electric dipole consists of two equal and opposite charges that are separated by a space or distance. The quality of the system to behave like a dipole refers to the dipole moment and the total dipole moment within a volume occupied is called polarization. The number of dipole moments per unit when all the dipole charges are arranged in one direction determines the polarizability of the material. The dielectric responses in a polymer are mainly associated with dipolar, atomic and electronic polarization over different time and length scales. The dipolar or orientation polarization is closely determined by the relaxation of electric dipoles responding to the alternating electric field in the frequency range up to 108 Hz and exhibiting high dielectric constants. Atomic polarization caused by nucleus displacement and electronic polarization by electron movement in response to the alternating electric fields operates in the infrared or far-infrared frequency range (1013 Hz) and ultraviolet frequency domain (1015 Hz) respectively. Generally, electronic polarization and dielectric responses are closely related to the bandgap of the dielectrics [7, 8].

Dielectric constant

The charge density or dielectric displacement (D) generated in a dielectric medium is proportional to the dielectric field (E) and the proportionality requires an introduction of a constant, k(ε) where k is called the dielectric constant or permittivity of the material placed between the parallel plates.

An absolute permittivity (ε0) is found in vacuum when electric field is supplied and is represented as

The value of ε0 is 8.854 × 10–12 F/m.

Therefore, the dielectric constant or relative permittivity is the ratio of electric field density produced in the medium to that produced in a vacuum by a constant electric field. It can also be defined as the ratio of capacitances of a capacitor filled with given material to the capacitance of an identical capacitor in a vacuum without the dielectric material.

The dielectric material is subjected to an electric field to study its properties and the most important properties are polarization, dissipation, conduction and breakdown. When direct current is applied to a dielectric material, dipoles are aligned in the field direction. Moreover, the applied charge will migrate from one end to the other end, resulting in the phenomenon called polarization. The dielectric material allows charge storage within the material, acting as a capacitor by neutralizing the charges at the electrodes and the capacitance value will be used to determine the permittivity of the material. However, there are two different current types, charging or polarization current IC and loss or conduction current IL in an AC electric field applied across the parallel plate capacitor. Both contribute to determining the dielectric constant. It can be represented as:

The charge storage can be represented in terms of dielectric constants [9] and the above equation can be written as:

The dielectric behaviour of polymer composites is the result of the interaction of matter with an applied electric field that oscillates at different frequencies (f) at a given temperature and is generally described in terms of the complex relative permittivity (εr) corresponding through the equation:

where, ε′ = t × Cp/(A × ε0) reflects material polarizability due to dipole reorientation, deformation of delocalized electron distributions or interfacial polarization (dielectric constant related to the stored energy), i = √−1, angular frequency ω = 2πf and ε″ = t/(ω × Rp × A × ε0) is dielectric loss or energy dissipated inside the material as heat. Here, t is the thickness of the material, A is the area of electrodes, ε0 is the permittivity of free space, Cp and Rp are the equivalent parallel capacitance and resistance of the samples, respectively measured from LCR meter. The inability of a material to polarize and the rate of change in the oscillating period of the applied ac electric field cause to occur dielectric loss. The relaxation time, time is taken for the dipoles in the material or a displaced system to return to their original orientation or equilibrium value entirely depends on the electric field oscillation that causes dielectric loss. When an alternating electric field is applied to a material, there is a delay between the change in the field and the change in polarization represented by the angle δ. The ratio of energy dissipated to the energy stored in the dielectric is called the dissipation factor or loss angle (tan δ = ε″/ ε′) [4, 10]. Broadband dielectric spectroscopy (BDS) represents a powerful tool to measure electrical behaviour in polymer nanocomposites. The feature of broadband frequency ranging from 10–6 to 1012 Hz allows the investigation of various physical phenomena such as molecular mobility, polarization, relaxation, conductivity effects as well as interfacial effects, etc. in composites [4].

3 Preparation of PVC Based Composites and Nanocomposites

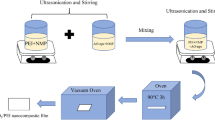

Numerous methods such as ultrasonic mixing, solution blending, and melt blending are used to fabricate the PVC based composites. High-speed mixing of raw materials followed by melt mixing in a twin-screw extruder is also applied to prepare PVC composites for proper dispersion of nanofillers [6]. The simplest ways to make PVC nanocomposites are ultrasonic mixing and solvent casting [3]. In the former process, after the initial stirring of the mixtures of polymer and filler, ultra-sonication is applied for some time to achieve proper filler dispersion. In the solvent casting, both polymer and filler are dissolved/dispersed in suitable solvents separately with the help of a magnetic or mechanical stirrer, then both the solutions are mixed together and finally after dispersion casting, evaporation is necessary for removal of the solvent systems used [11]. Melt mixing is another method to prepare PVC based composites, in which all materials are dry mixed at room temperature to form a uniform mixture followed by a melt mixing process at high temperature using an internal/Brabender mixer [12].

4 Dielectric Insulation Materials

High voltage cables insulated with plasticized PVC (p-PVC) based nanocomposites are widely used in nuclear power plants, various power apparatuses as well as industrial applications. The insulators surround and protect the wire and cable from coming into contact with outside conductors, prevent the wire material from environmental threats such as water, heat and resist electrical leakage as well as fire hazards [13]. Distortion and complete breakdown as a result of carbonization of polymers at the region of sparking can generally happen that may lead to large outages therefore, high rating cables with good insulating properties are essential to keep the system reliable [10]. Compared to the conventional additives, incorporating different nanofillers such as clay, silica, nano metal oxides, carbon nanotube, graphene, etc. can increase the service life of the insulator against degradation. The dielectric behaviour of p-PVC/aluminium oxide (n-Al2O3) prepared by melt mixing under DC biasing field studied by Nikam et al. exhibited an intense frequency and DC bias voltage-dependent parameters such as dielectric constant (ε′), dielectric loss (ε″), and loss tangent (tan δ). The maximum degree of dispersion was reported as up to 4 phr of nano alumina. The unique dielectric behaviour in terms of increased dielectric constant for high dosage (>2 phr) owing to the restricted mobility of dipolar groups by polymer-filler interaction as well as a decrease in dielectric constant with increase in DC bias due to the decrease in grain boundaries activation energy was also reported in their work [5]. The performance of PVC based composites is affected by filler type and concentration in the matrix and numerous studies have explored the effects of filler on the dielectric properties of the composites. The effect of various nanomaterials such as clay, SiO2, ZnO, and Al2O3 on the dielectric properties of PVC composites studied by Thabet et al. revealed that 10 wt% Al2O3 contributes the highest dielectric constant upon other nanoparticles [14]. Mansour et al. investigated the effect of ZnO on the dielectric properties of PVC based nanodielectrics prepared through sonication-solution casting technique and found an enhanced break down strength and decreased dielectric constant (ε′) as well as loss tangent up to 0.14 vol% ZnO indicate good polymer-filler interaction. The improvement in dielectric properties due to good filler dispersibility is qualified for electrical insulation applications [15]. A decrease in dielectric constant (ε′) with an increase in frequency due to less number of dipoles which contribute to polarization is observed for PVC/SiO2 nanocomposites. Moreover, the addition of silica owing to their large surface area along with a change in PVC morphology as well as the space charge distribution caused a reduction in the internal field and dielectric constant to the composite. The α-relaxation due to micro Brownian motion at around glass transition temperature was also observed from the dielectric loss behaviour [16]. Similar behaviour of reduction in permittivity and dielectric loss with frequency owing to the inability of the dipole to follow the field variation at high frequencies was also reported in the case of PU/PVC/CNT as well as multi-walled CNT filled PVC nanocomposites [17, 18]. PVC modified with TiO2, SiO2, and Al2O3 showed variation in dielectric properties based on the chemistry of different oxides and their availability to react with evolved hydrochloric acid. A high value of permittivity in silica filled composite due to the polarizability owing to the hydroxyoxide generation, lack of formation of units susceptible to be polarized due to the acidic behaviour of titania, no significant effect on dielectric permittivity and loss attributed to the amphoteric characteristic of alumina were observed by Ciuprina et al. γ-irradiation on these PVC composites assured good dielectric insulation characteristics especially for the high-frequency regimes as the nanostructures don’t involve difficulties over the frequency domain 102–107 Hz [19]. Mamunya et al. explored the effect of multiwalled carbon nanotube (MWCNT) percolation threshold (φc) on the dielectric properties of PVC based composites. They observed that, below φc = 0.045 vol.%, the dielectric constant (ε′) and loss (ε″) values are frequency-independent while ac conductivity (σac) has a slope close to 1 that demonstrates their insulating properties. However, above φc, Maxwell–Wagner-Sillars (MWS) polarization contributed to a complex dielectric permittivity that resulted in an increase of dielectric constant and loss with frequency drop. Simultaneously, an increase in conductivity that gives a higher contribution to dielectric parameters was also reported [20]. The effect of copper oxide on the dielectric properties of PVC showed an increase in real dielectric permittivity (ε′) with CuO content and a decrease with frequency due to interfacial polarization. The imaginary dielectric permittivity (ε″) curves displayed relaxations, a combined effect of both crystalline chain relaxation as well as interfacial polarization. Increased percentage of CuO resulted in an enhancement of both static and high-frequency dielectric constant but a decrease in the relaxation time (τ0) [21].

Surface modification of nanoparticles is a common method to reduce their surface energy as well as improve the compatibility with polymer and dispersion inside the matrix which has a positive impact on dielectric properties. Ahmad et al. measured the influence of sodium dodecylbenzene sulfonate (SDBS) modified graphene oxide (GOSDBS) nanosheets on the electrical properties of PVC/rice straw (RS) composites prepared by melt mixing. The dissipation factor of the composite was about 0.174 and 0.015 at 20 Hz and 106 Hz respectively. The various functional groups on the basal plane and edges of GOSDBS nanosheets acted as sites for macromolecular-filler interaction as well as scattering points for charge carriers and the composites are useful for electrical insulation in cable industries [12]. Improvement in ac and dc breakdown strength of PVC after incorporating γ-amino propyl triethoxy silane functionalized silica (SiO2) also encourages using these composites as high voltage power cables in a wide application range. 0.5 wt% amino-functionalized SiO2 imparted an ac and dc break down strength of 63.8 kVmm−1 and 75.5 kVmm−1 respectively, corresponding to an enhancement of 14.1% and 16.3% over pristine PVC respectively [10]. The strong interfacial area between vinyl tris (2-methoxy ethoxy) silane functionalized titanium dioxide (TiO2) and PVC owing to the closest surface tension of vinyl silane (γvinyl = 41.1 dyn cm−1) and PVC (γPVC = 41.9 dyn cm−1) enhances the breakdown strength (55.4 kVmm−1) and decreases εr and tan δ revealed better insulation properties suitable for cable insulation [22]. Sodium montmorillonite (Na+-Mt) functionalized with different alkoxysilane, N-(2-aminoethyl-)-3-aminopropyl-trimethoxy-silane (NH2-Mt) (AEAPTS) or 3-mercaptopropyl-trimethoxy-silane (SH-Mt) (MTPS) promoted good exfoliation and high complex permittivity owing to the increased polar group mobility of both intercalants, ammonium salt in the clay or mercapto group in MTPS which is suitable for high voltage devices [23]. Silica micro-powder (SMP), a kind of ultrafine quartz powder has strong insulation characteristics, good chemical resistance, excellent thermal stability and physical properties as well as an environmentally friendly nature without radiation. However, the strong polarity makes interfacial problems and poor compatibility with hydrophobic PVC polymer. The use of isopropoxy trioleate acyl titanate (KTTO), a monoalkoxy fatty acid acyloxy titanate coupling agent significantly improved the interfacial bonding between polymer and filler, hydrophobicity and overall dispersity of silica micro-powder as well as the performance of PVC composites [6]. Incorporating graphene oxide (GO) nanoparticles into polyvinyl chloride (PVC)/polyvinylidene fluoride (PVDF) blend using a pulsed laser ablation technique can also disperse nanoparticles without aggregation resulting in lower hydrophilicity to the composites. Further, an increase in dielectric constant with the addition of GO and a charge hopping conduction mechanism that obeys Jonscher's power law were also observed [24].

The dielectric constant value depends on the number of polarizing dipole per unit volume and their dipole moment. Effect of temperature on the dielectric constant value of PVC/lead oxide (PbO) nanocomposite demonstrated that the huge number of dipoles become ready to orient with an external electric field at a temperature higher than the glass transition owing to the drop in viscosity that enhances the dielectric constant. The authors reported that the presence of lead oxide leads to an improvement of the dielectric constant at a concentration higher than 5 wt%. The restricted dipoles owing to the molecular restriction at the polymer-filler interface interaction zones due to good nanoparticle dispersion cause a reduction in dielectric constant up to 5 wt% PbO loading. However, some restricted dipoles attain sufficient energy to remove the restriction group at high temperatures. The dielectric loss (tan δ) value related to the charge mobility through the polymer backbone was increased with an increase in frequency up to 50 kHz and became constant for further frequency. The maximum value of tan δ occurs when hopping frequency and external field frequency are the same. Pure PVC, as well as PVC/PbO composites, exhibited a decrement in dielectric loss with an increase in frequency due to the tunnelling transition rates of the charge carriers [25]. The morphology and space charge distribution affected by the surface area of the nanoparticles can leads to a reduction in the internal field. The incorporation of La0.95Bi0.05FeO3 nanoparticles into PVC contributed a reduction in relative permittivity as well as dielectric loss to the composites [26]. Thabet et al. reported the usage of different nanoparticles strategy as more effective to reduce the dielectric losses than the singular nanoparticles technology. The electric field distribution in three-phase belted power cables is important to be used as an insulator. Figure 1a, b shows the electric field distribution in PVC based three-core belted power cables with an individual as well as multiple nanocomposites. The multi-nanocomposite of clay (0.1 wt%) + zinc oxide (0.2 wt%)/PVC is more efficient in insulation to withstand electrostatic field distribution due to its low dielectric constant [27].

a and b Effect of individual and multi nanoparticles on electric field distribution in PVC [27].

5 Dielectric Composites for Energy Storage Applications

Conductive nanomaterials offer an enormous network of nanocapacitors extended over the entire insulating polymer matrix resulting in an improved dielectric performance of the polymer nanocomposites through interfacial polarization. The main factors affecting the dielectric properties of the polymer and its composites are polarizability, free volume and conducting-insulating-conducting network [7]. The dipole, atomic and electronic polarizations which arise in response to the applied electric field contribute much to enhancing the dielectric performance of polar polymers. Therefore, polarizability related to the basic polymer structure and free volume is important which is explained by Clausius–Mossotti equation. In dipole polarization, the relaxation time, time is taken by the mobile charge carriers in returning to their original steady-state equilibrium condition determines both dielectric loss and constant. Polymer nanocomposite dielectrics reinforced with two-dimensional materials involving carbon materials, MXenes, oxide ceramics, clays, boron nitride and so on exhibit remarkable properties and great potential in dielectric and energy storage applications. Incorporating ideal electrically conductive MXene flakes, a 2D filler to boost the dielectric performance while maintaining super flexibility of PVC nanocomposites promoted interfacial polarization which endowed high dielectric properties. MXene facilitated the formation of numerous dipoles at the interfaces (number of micro-capacitors) and contributed to the improvement of the energy storage capacity of the composites. 10 wt % MXene displayed a high dielectric constant of 11,800 at 25 Hz and the value decreased to 6100 with an increase in frequency to 1 MHz due to the reduction in charge density or the number of dipoles at high frequency by the rapid and periodic changing of applied ac electric field. The inability of a material to polarize with changing rate of the oscillating electric field resulted in dielectric loss. Minimum dielectric loss with a high dielectric constant is much preferred for dielectric applications. PVC/MXene with 10 wt % filler displayed a minimal dielectric loss of 1.31 at 25 Hz [3].

The combined advantages of high electrical conductivity of filler and dielectric permittivity of hosting polymer with its mechanical flexibility make the polymer composites recommended in charge storage capacitor applications. Compared with batteries and electrochemical capacitors, dielectric capacitors exhibit high working voltage and power density, longer lifespan and greater cycling stability. Many researchers incorporated graphene nano-platelets (GnP) into the PVC matrix to improve its dielectric and mechanical properties and most of the reports included the change in dielectric properties, but lag behind the detailed temperature dependence on dielectric behaviour. Motivated with this Ahmed et al. presented a study on the effect of GnP on PVC nanocomposites prepared by solution casting technique. Both GnP content and increase in temperature made an increase in both permittivities (ε′) as well as dielectric loss (ε″) due to the generation of strengthened interfacial polarization as well as dipole relaxation respectively. At high frequencies, a decrease in the value of ε′(ω) owing to the lag of dipoles behind the applied electric field was also reported. The mechanical strength and conductivity were improved with the increase in GnP dosage [11]. The dielectric spectroscopic studies at different temperatures of PVC/silicon dioxide (SiO2)/montmorillonite (MMT) composites also agreed on the improvement in dielectric constant up to the glass transition temperature. The high dielectric strength for PVC/4 wt% MMT (37) and low value for PVC/4 wt% SiO2/4 wt% MMT (26) nanocomposites were observed because comparatively very higher dielectric constant for nanoparticles than the polymer causes a very low dielectric field to be acted on the nanoparticles and its interface region. As a result, a homogeneous electric field exists and the decrease in a number of quasi-mobile charges as well as dipole moment leads to a low dielectric constant. Decay in dielectric constant with an increase in frequency on account of both interfacial polarization as well as electrical conductivity was more pronounced at high temperatures (90, 110 ℃). The TDC α-peak near the glass transition region due to the reorientation of the dipolar main chain segment and Maxwell–Wagner–Sillars (MWS) relaxation at high temperature associated with the charge trapping at the interface of nanocomposites supported the temperature dependency on their dielectric properties. The capacitance of the nanocomposites explored their application as a capacitor. [2]. Akhina and their co-workers have shown that reduced graphene oxide (RGO) incorporated into plasticized PVC through conventional melt compounding also resulted in an increased dielectric constant making it well suited for applications in the dielectric as well as energy storage devices. The increased number of polymer-filler interface contacts provided numerous sites for the reinforced Maxwell Wagner Sillars (MWS) effect and interfacial polarization that lead to a high dielectric constant of the PVC/RGO composites. Moreover, the dipoles responsible for this polarization couldn’t keep their orientation in the direction of an alternating electric field at high frequency causing a deterioration in the dielectric constant [7]. PVDF/PVC/GO nanocomposite prepared by Elashmawi et al. also yielded an amorphous rich phase and a decrease in dielectric constant (ε′) and dielectric loss (ε″) with an increase in frequency. The polarization due to Maxwell Wagner interfacial polarization resulted in small dispersion in dielectric loss and high dielectric constant at low frequency. More number of polarons (electrons) with an increase in GO and their hoping with an increase in frequency gives rise to an improvement in conductive properties of the composite [28]. Strong dipole–dipole interaction among dodecylbenzene sulfonic acid (DBSA) doped polyaniline (PAND) and PVC at low frequency and room temperature caused an increased dielectric loss factor and permittivity with a decrease of frequency between 0.5–106 Hz. The reduction in charge trapping centres and thereby more number of conducting channels participating in the relaxation process observed resulted in an improved conductivity to the composites [29].

The addition of NiO nanoparticles synthesized by sol–gel method using nickel nitrate hexahydrate and egg white into the PVC polymer matrix owing to their good dispersion in the polymer matrix, semiconductor behaviour, high dielectric constant (ε′ > 10), electrochemical activity and chemical stability has grown great attention for application in energy storage capacitors, solar cells, sensors, display devices, and lithium-ion batteries, etc. [4]. The dielectric property study on PVC/NiO nanocomposites using a broadband dielectric spectrometer in the frequency range of 0.1 Hz to 20 MHz at different temperatures showed the highest value of dielectric constant (ε′) at low frequency side and the value decreased with increase in frequency. At low frequency, the rate of electric field oscillation is smaller than the oscillating frequency of molecules (ω << 1/τ) and thereby dipole arises from C–Cl bond and dipole–dipole interaction among PVC chains reoriented themselves with the applied electric field. At moderate frequency (ω > 1/τ), the dipoles are not completely oriented because of change in electric field direction and hence dielectric constant (ε′) onset to decrease. As the dipoles have no response to the electric field at high frequency (ω >> 1/τ), the dielectric constant (ε′) decreased and reached a constant value. An increase in temperature increased the dielectric constant. At low temperatures, the energy absorbed by molecules is small and a minor number of dipoles contributed to the polarization process. As the temperature increased and reached the glass transition temperature, the intermolecular energy absorption, decrease in polymer viscosity as well as increase in the number of dipolar groups contributed to the increase in ε′ value [4]. Silicon carbide (SiC) owns good thermal, chemical and dielectric properties. Alghunaim et al. introduced silicon carbide (0.02 to 0.06 wt%) into PVC/poly (N-vinyl carbazole) (PVK) blend that showed a sharp increase in both ε′ (2 × 106) and ε″ (3.6 × 106) with filler content towards low frequencies (from 20 MHz to 0.1 Hz) attribute to the orientation of dipole by themselves in the direction of an applied electric field [30]. Incorporating a giant dielectric constant material, calcium copper titanate (CCT) (CaCu3Ti4O12) (~700 at room temperature) in PVC revealed a high dielectric constant to the composite and the value decreased with increase in frequency and increased with temperature rise. Dielectric loss increases with filler content and frequency but dropped with an increase in temperature [31]. Multiphase and multilayer systems can also improve the dielectric as well as energy storage properties of two-dimensional material reinforced nanocomposites [32]. Anti-static multi-layer graphene (MLG) (3.5 wt%) filled PVC composite films prepared by the conventional melt-mixing method exhibited a surface electrical conductivity lower than 3 × 108 Ω per square [33].

High breakdown strength and dielectric constant are the key parameters required for high energy density in capacitors. However, both are generally contrary to each other. To solve this trade-off, Feng et al. prepared a PVC based ternary composites bearing V2C MXene-Cu2O hybrid filler that exhibited a high dielectric constant of 55 and a low loss of approximately 0.085 at 100 Hz as well as a high breakdown strength of 332 MV/m. Quantum sized high polarity micro-regions at the V2C MXene-Cu2O interface imparted a high dielectric constant to the material. The very strong dependence of the dielectric constant on the low-frequency region was also noticed owing to the interfacial polarization due to the electric dipole pairs present at PVC/V2C interface. However, no favourable interfacial dipole orientation could catch up with the change of high-frequency electric field; therefore decrease in dielectric constant was observed. The linearity in conductivity data with elevated frequency supported the electric insulation feature of the composite [34].

High dielectric constant (high-k) polymer composites under integrating high dielectric constant nanofiller with high breakdown voltage, flexibility and ease of processing of matrix have received increased research interest nowadays for various dielectric applications [35]. High-k dielectric nanocomposites based on PVC/multi-walled carbon nanotube (MWCNT) with 4% nanoparticle exhibited a dielectric constant value of 13,066 with low dielectric loss ranging between 0.05 to 1.28 can be useful for capacitive sensors and supercapacitors. Dielectric relaxation measurement showed that the polarity of the PVC matrix and interfacial polarization at PVC and MWCNT strongly affected the dielectric properties [36]. Even though the desired dielectric properties have been realized in many organic–inorganic nanocomposites, achieving high permittivity with low loss at high frequencies is still challenging. To achieve this, neat beta-SiC nanoparticles owing to their low intrinsic bandgap (~2.2 eV) and high inborn conductivity were used in PVC and the produced high-k nanocomposite dielectrics achieved a permittivity of 239 and loss of 0.0074 at a high frequency of 1 GHz [37].

Ionizing radiation is an advanced tool in the scientific community for the functionalization of specific properties to the polymer-based system. Energetic electromagnetic radiation as well as particles with higher energy than the polymer chain dissociation energy is used as an ingenious tool for this purpose. Gamma and 90 meV carbon ions irradiations on the dielectric response of PVA/H3PO4/SiO2 nanocomposites showed an improvement in electrical properties such as ac conductivity, dielectric constant and dielectric loss with the dosage of irradiation, attributed to the formation of low molecular polymeric macromolecules. The effect of 90 meV carbon ions irradiations on electrical properties was higher than that of gamma irradiation. The real and imaginary parts of complex permittivity are related to the capacitance that determines the dipole alignment or polarization as well as the energy needed to align the dipoles respectively. The value of dielectric response is high at low frequency due to the existence of ion pairs that can perform long-range migration and act as localized dipoles. The high electrical conductivity after irradiation proposed the potential applicability of the composite for battery applications [38]. Poly(vinylidene fluoride) (PVDF)/Poly(vinyl chloride) (PVC) blend doped with palladium nanoparticles (PdNPs) prepared by laser ablation technique exhibited an improved segmental motion and the number of ions and charge carriers built on the blend were increased with increasing conductivity of the composite system, which makes it suitable for battery and electronic applications. Palladium nanoparticles have remarkable supramolecular and catalytic activity. The dielectric constant and loss values were high at low frequency and the values were decreased with a rise in frequency, besides an increasing trend of both the properties observed with an increase in the dosage of PdNPs. Both these behaviours are due to the high contribution of charge accumulation in the composite assigned to the polarization effect [39].

Dielectric Composites for Other Applications

The high driving voltage requirement of several kilovolts associated with dielectric elastomer actuators (DEAs) directed PVC gel, a kind of electroactive polymer actuator as a promising dielectric material for soft robotics. Moreover, PVC gel exhibited high electrically induced bending deformation as well as amoeba-like creep deformation with high stability and durability. The actuator consists of a PVC gel membrane placed between two electrodes and when an electric field is applied, electrons migrate from cathode to anode through the PVC gel and a layer with high a density of negative charges in gel near the anode is formed. The Maxwell force between this layer and the anode surface led the gel to asymmetric deformation, resulting in creep deformation along the anode. The PVC actuator proposed by Yi et al. displayed a minimum strain of 21%, and maximum output stress of 600 kPa only at a low voltage of 120 V and a continuous actuation of 1 million times, a sign of high durability [1]. PVC gel plasticized with dibutyl adipate (DBA) also showed an efficient electrically induced bending deformation due to the electrochemical formation of the solvent-rich layer and its deformation from the Maxwell stress [40]. There have been reports of the potential application of PVC nanostructure-based ultra-flexible biosensors prepared using the dielectric heating assisted nanoimprint lithography (NIL) method for wearable health monitoring devices [41]. A 6% PVC/PVA blend owing to the extended chain length of the blend showed high conductivity of about 2.59 × 10–6 Scm−1and low tangent loss of 0.9 that is suitable for low k-dielectric materials, gas sensor encapsulation device and other electronic applications [42]. PMMA/PVC/m-SiO2 (hexamethyldisilazane modified silica) composite prepared by Lavina et al. yielded low-k composite dielectric films with electrical dispersion up to a frequency of 1 MHz which is promising for organic microelectronic systems such as OTFT devices. Film with 20 to 35 wt% m-SiO2 exhibited ε′ values lower than that of SiO2 (ε′ = 3.9) and a tan δ < 0.05 [43]. Dielectric behaviour of PVC/lithium triflate polymer electrolytes showed a sharp rise of both real and imaginary parts of dielectric constants towards low frequencies as a result of electrode polarization effects and a decrease in polarization due to the charge accumulation as well as a drop in ε′ and ε″ at high frequencies [44]. The dibutyl phthalate (DBP) plasticized PVC/lithium triflate electrolyte showed much higher ε′ as well as dissipation factor (tan δ) values at room temperature Higher lithium triflate content (40%) was dominated by conductivity and mask any dielectric process [45].

6 Summary and Conclusion

Flexible polymer composites are frequently used in the design of various dielectric applications ranging from portable electronic devices to high-efficiency hybrid electric vehicles. PVC based composites are characterized by excellent insulation properties, flexibility, and mechanical, thermal as well as chemical stability making them a promising candidate as dielectrics. Flexible energy storage materials with high dielectric constant and minimum loss are highly demanded the miniaturization of various electronic gadgets. Various ceramic fillers with high intrinsic dielectric constants have been utilized to enhance the dielectric properties but the high volume requirement and low interfacial interaction results in high dielectric loss and poor flexibility to the composites. The application of low loading nanoparticles owing to their high surface area with homogeneous distribution and structure–property relationship is appropriate and various nanocomposites are designed with different techniques for dielectric applications. Filler type and concentration as well as polymer matrix-nanoparticle interface have a significant impact on the dielectric properties of PVC nanocomposites. The effect of various nanoparticles such as SiO2, Al2O3, ZnO, CuO, PbO, palladium, CNT, clay, GO, etc. on the dielectric properties of PVC composites and their applicability for high voltage cable insulation, energy storage, actuators, sensors, telecommunication systems, and so on are discussed in detail.

Advantages such as high resistance and dielectric breakdown strength as well as low dielectric loss make PVC based nanocomposites suitable for high voltage insulators. High breakdown strength and dielectric constant, both contrary to each other are the key parameters required for high energy capacitors. In this regard, high-k composites have been developed by integrating high dielectric constant nanofiller with a high breakdown voltage of matrix. Composites have various advantages depending on the microstructure and interface between polymer and filler. Even though the desired dielectric properties have been realized in many PVC nanocomposites, achieving high permittivity with low loss at high frequencies is still challenging. Therefore, attention should be given to the PVC-nanofiller interface.

References

Li, Y., Li, Y., Hashimoto, M.: Low-voltage planar PVC gel actuator with high performances. Sens. Actuators B Chem. 282, 482–489 (2019)

Rajesh, K.D., Gaur, M.S., Goyal, P., Tiwari, R.K., Rogachev, A.A., Rogachev, A.V.: Measurement of AC and DC relaxation properties in polyvinyl chloride (PVC) nanocomposites. Measurement 135, 323–332 (2019)

Mazhar, S., Qarni, A.A., Ul, H.Y., Ul, H.Z., Murtaza, I.: Promising PVC/MXene based flexible thin film nanocomposites with excellent dielectric, thermal and mechanical properties. Ceram. Int. 46, 12593–12605 (2020)

Taha, T.A., Hendawy, N., El-Rabaie, S., Esmat, A., El-Mansy, M.K.: Fluorescence and dielectric spectroscopy identification of polyvinyl chloride/NiO nanocomposites. J. Mol. Struct. 1212, 128162 (2020)

Nikam, P.N., Deshpande, V.D.: Dielectric behavior of plasticized PVC/alumina nanocomposites influenced with DC biasing field. Mater. Today: Proc. 5, 2254–2262 (2018)

Zhang, Y., Ding, C., Zhang, N., Chen, C., DI, X., Zhang, Y.: Surface modification of silica micro-powder by titanate coupling agent and its utilization in PVC based composite. Constr. Build. Mater. 307, 124933 (2021)

Akhina H, Arif PM, Gopinathan Nair MR, Nandakumar K, Thomas S (2019) Development of plasticized poly (vinyl chloride)/reduced graphene oxide nanocomposites for energy storage applications. Polym. Test. 73, 250–257

Wu, X., Chen, X., Zhang, Q.M., Tan, D.Q.: Advanced dielectric polymers for energy storage. Energy Storage Mater. 44, 29–47 (2022)

Shanmugasundram H.P.P.V., Jayamani, E., Soon, K.H.: A comprehensive review on dielectric composites: classification of dielectric composites. Renew. Sustain. Energy Rev. 157, 112075 (2022)

Abdel-Gawad, N.M.K., El Dein, A.Z., Mansour, D.E.A., Ahmed, H.M., Darwish, M.M.F., Lehtonen, M.: Multiple enhancement of PVC cable insulation using functionalized SiO2 nanoparticles based nanocomposites. Electr. Power Syst. Res. 163, 612–625 (2018)

Ahmed, R.M., Ibrahiem, A.A., El-Bayoumi, A.S., Atta, M.M.: Structural, mechanical, and dielectric properties of polyvinylchloride/graphene nano platelets composites. Int. J. Polym. Anal. Charact. 26, 68–83 (2020)

Allahbakhsh, A.: PVC/rice straw/SDBS-modified graphene oxide sustainable nanocomposites: Melt mixing process and electrical insulation characteristics. Compos. Part A 134, 105902 (2020)

Uwa, C.A., Abe, B., Nnachi, A.F., Sadiku, E.R., Jamiru, T.: Experimental investigation of thermal and physical properties of nanocomposites for power cable insulations. Mater. Today: Proc. 38, 823–829 (2021)

Thabet, A., Ebnalwaled, A.A.: Improvement of surface energy properties of PVC nanocomposites for enhancing electrical applications. Measurement 110, 78–83 (2017)

Mansour, S.A., Elsad, R.A., Izzularab, M.A.: Dielectric properties enhancement of PVC nanodielectrics based on synthesized ZnO nanoparticles. J. Polym. Res. 23, 85 (2016)

Abdel-Baset, T., Elzayat, M., Mahrous, S.: Characterization and optical and dielectric properties of polyvinyl chloride/silica nanocomposites films. Int. J. Polym. Sci. 1–13 (2016)

Abdelrazek, E.M., Elashmawi, I.S., Hezma, A.M., Rajeh, A., Kamal, M.: Effect of an encapsulate carbon nanotubes (CNTs) on structural and electrical properties of PU/PVC nanocomposites. Phys. B 502, 48–55 (2016)

Abdullah, E.T., Naje, A.N.: AC electrical and dielectric properties of PVC-MWCNT nanocomposites. Indian J. Sci. Technol. 4, 731–735 (2011)

Ciuprina, F., Zaharescu, T., Jipa, S., Plesa, I., Notingher, P.V., Panaitescu, D.: Dielectric properties and thermal stability of γ-irradiated inorganic nanofiller modified PVC. Radiat. Phys. Chem. 79, 379–382 (2010)

Mamunya, Y.P., Levchenko, V.V., Rybak, A., Boiteux, G., Lebedev, E.V., Ulanski, J., Seytre, G.: Electrical and thermomechanical properties of segregated nanocomposites based on PVC and multiwalled carbon nanotubes. J. Non-Cryst. Solids 356, 635–641 (2010)

Abouhaswa, A.S., Taha, T.A.: Tailoring the optical and dielectric properties of PVC/CuO nanocomposites. Polym. Bull. 77, 6005–6016 (2020)

Abdel-Gawad, N.M.K., Mansour, D.E.A., El Dein, A.Z., Ahmed, H.M., Darwish, M.M.F.: Effect of functionalized TiO2 nanoparticles on dielectric properties of PVC nanocomposites used in electrical insulating cables. In: 18th International Middle-East Power Systems Conference, MEPCON 2016 - Proceedings, pp. 693–698 (2017)

Silva, T.F., Soares, B.G., Ferreira, S.C., Livi, S.: Silylated montmorillonite as nanofillers for plasticized PVC nanocomposites: effect of the plasticizer. Appl. Clay Sci. 99, 93–99 (2014)

Abd El-Kader, M.F.H., Awwad, N.S., Ibrahium, H.A., Ahmed, M.K.: Graphene oxide fillers through polymeric blends of PVC/PVDF using laser ablation technique: electrical behavior, cell viability, and thermal stability. J. Market. Res. 13, 1878–1886 (2021)

Elsad, R.A., Mahmoud, K.A., Rammah, Y.S., Abouhaswa, A.S.: Fabrication, structural, optical, and dielectric properties of PVC-PbO nanocomposites, as well as their gamma-ray shielding capability. Radiat. Phys. Chem. 189, 109753 (2021)

Taha, T.A., Azab, A.A.: Thermal, optical and dielectric investigations of PVC/La0.95Bi0.05FeO3 nanocomposites. J. Mol. Struct. 1178, 39–44 (2019)

Thabet, A., Salem, N.: Experimental investigation on dielectric losses and electric field distribution inside nanocomposites insulation of three-core belted power cables. Adv. Ind. Eng. Polym. Res. 4, 19–28 (2021)

Elashmawi, I.S., Alatawi, N.S., Elsayed, N.H.: Preparation and characterization of polymer nanocomposites based on PVDF/PVC doped with graphene nanoparticles. Results Phys. 7, 636–640 (2017)

Afzal, A.B., Akhtar, M.J., Nadeem, M., Hassan, M.M.: Dielectric and impedance studies of DBSA doped polyaniline/PVC composites. Curr. Appl. Phys. 10, 601–606 (2010)

Alghunaim, N.S.: Structural, thermal, dielectric spectroscopic and AC impedance properties of SiC nanoparticles doped PVK/PVC blend. Results Phys. 9, 1136–1140 (2018)

Singh, A.P., Singh, Y.P.: Dielectric behavior of CaCu3Ti4O12: Poly vinyl chloride ceramic polymer composites at different temperature and frequencies. Mod. Electron. Mater. 2, 121–126 (2016)

Hu, J., Zhang, S., Tang, B.: 2D filler-reinforced polymer nanocomposite dielectrics for high-k dielectric and energy storage applications. Energy Storage Mater. 34, 260–281 (2021)

Wang, H., Xie, G., Fang, M., Ying, Z., Tong, Y., Zeng, Y.: Electrical and mechanical properties of antistatic PVC films containing multi-layer graphene. Compos. B 79, 444–450 (2015)

Feng, Y., Qiu, H., Mao, B., Bo, M., Deng, Q.: Preparation of hybrid ceramic/PVC composites showing both high dielectric constant and breakdown strength ascribed to interfacial effect between V2C MXene and Cu2O. Colloids Surf. A 630, 127650 (2021)

Huang, X., Sun, B., Zhu, Y., Li, S., Jiang, P.: High-k polymer nanocomposites with 1D filler for dielectric and energy storage applications. Prog. Mater Sci. 100, 187–225 (2019)

Francis, E., Ko, H.U., Kim, J.W., Kim, H.C., Kalarikkal, N., Varughese, K., Thomas, S.: High-k dielectric percolative nanocomposites based on multiwalled carbon nanotubes and polyvinyl chloride. J. Mater. Chem. C 00, 1–7 (2018)

Peng, C., Feng, Y., Hu, J.: Enhancing high-frequency dielectric properties of beta-SiC filled nanocomposites from synergy between percolation and polarization. Materials 11, 1699 (2018)

Bhavsar, S., Patel, G.B., Singh, B., Singh, F., Singh, N.L.: A comparative study on gamma and carbon ion irradiations induced modification in structural and electrical properties of PVA/H3PO4/SiO2 nanocomposite polymer electrolyte. Radiat. Phys. Chem. 192, 109916 (2022)

Ismail, A.M., El-Newehy, M.H., El-Naggar, M.E., Meera, M.A., Menazea, A.A.: Enhancement the electrical conductivity of the synthesized polyvinylidene fluoride/polyvinyl chloride composite doped with palladium nanoparticles via laser ablation. J. Market. Res. 9, 11178–11188 (2020)

Asaka, K., Hashimoto, M.: Electrical properties and electromechanical modeling of plasticized PVC gel actuators. Sens. Actuators B Chem. 273, 1246–1256 (2018)

Wu, T.Y., Tsai, P.C., Lo, S.C., Li, Y.R., Lee, K.L., Yang, S.Y., Wei, P.K.: Fabrication and applications of ultraflexible nanostructures using dielectric heating-assisted nanoimprint on PVC films. Curr. Appl. Phys. 18, 12–18 (2018)

Raheem, M.A., Roy, A.S., Prasad, M.V.N.A.: Negative thermal coefficient behaviour, dielectric and mechanical properties of poly(vinyl chloride)/poly(vinyl alcohol) blends. Compos. Commun. 1, 38–43 (2016)

Lavina, S., Negro, E., Pace, G., Gross, S., Depaoli, G., Vidali, M., Di Noto, V.: Dielectric low-k composite films based on PMMA, PVC and methylsiloxane-silica: synthesis, characterization and electrical properties. J. Non-Cryst. Solids 353, 2878–2888 (2007)

Ramesh, S., Chai, M.F.: Conductivity, dielectric behavior and FTIR studies of high molecular weight poly(vinylchloride)-lithium triflate polymer electrolytes. Mater. Sci. Eng. B 139, 240–245 (2007)

Ramesh, S., Yahaya, A.H., Arof, A.K.: Dielectric behaviour of PVC-based polymer electrolytes. Solid State Ionics 152–153, 291–294 (2002)

Acknowledgements

The authors acknowledge the financial assistance received from the National Research Foundation of Korea (NRF), ministry of science and ICT (NRF—2021 M1A2A2038115). This research was also supported by basic science research program funded by ministry of education (NRF—2020R1A6A1A03038697).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Vijayakumar, V., Nam, S.Y. (2024). Dielectric Properties of Polyvinylchloride (PVC) Composites and Nanocomposites. In: H, A., Sabu, T. (eds) Poly(Vinyl Chloride) Based Composites and Nanocomposites. Engineering Materials. Springer, Cham. https://doi.org/10.1007/978-3-031-45375-5_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-45375-5_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-45374-8

Online ISBN: 978-3-031-45375-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)