Abstract

The propose of study is a convert the capture of solar energy into thermal energy as one of the renewable energies. Surface-selective hot water collectors with an area of 225 m2 are used to collect solar energy. This energy captured by the collectors is transferred by technologically modified water, which transfers the heat in the technical room with the help of an exchanger. On the other side of the exchanger is water in which energy is stored. Water with a volume of 160 m3 is stored in three different sizes of thermal tank storage. The smallest thermal tank storage with a volume of 24 m3. This thermal tank storage was measuring during 2 years which charging and discharging cycles took place. In the first year, there were large heat losses through evaporation from the water surface. And in the second year of research, the water surface was covered, which helped to eliminate heat losses and extend the accumulation period.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

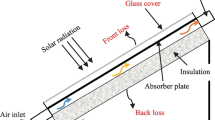

1 Introduction

In Slovakia and similarly situated countries, the demand for heat in the heating season is 10 times higher than in the non-heating season. Paradoxically, at the same time when solar radiation reaches its maximum, the need for heat for heating is the lowest. From May to August, solar radiation in our country is most intense [1]. In this summer season, there is no need to use another fossil source, but you can heat and heat hot drinking water directly. However, during the non-heating period, there is a minimal demand for heat, which is also a problem, Fig. 1. This heat captured during the summer needs to be accumulated in order to reduce energy consumption in the heating season [2].

Energy production and energy demand in year [2].

2 Thermal Energy Tank Storage

2.1 Thermal Energy Tank Storage Measured

Surface-selective hot water collectors with an area of 225 m2 are used to collect solar energy. This energy captured by the collectors is transferred by technologically modified water, which transfers the heat in the technical room with the help of an exchanger. On the other side of the exchanger is water in which energy is stored. Water with a volume of 160 m3 is stored in three different sizes of thermal tank storage, Fig. 2. Different sizes of thermal tanks allow them to be used for different purposes and at different times. The structure of the thermal tank storage is made of reinforced concrete with thermal insulation and they are stored under the floor of the hall. Collectors are also installed on the roof of the hall.

2.2 Thermal Energy Tanks Storage in Different Types

We can divide the thermal tank storage according to the media in which the energy is accumulated into sensible heat and latent heat. Performance, efficiency and other parameters can be divided according to media, method of accumulation and use. But we basically divide them into thermal and chemical accumulation, Fig. 3 [3].

Types of tanks [3].

We will not discuss chemical energy that comes from fossil fuels because it is not a renewable resource. Thermal storage tanks are used today. These thermal tanks storage can be divided into sensible heat and latent heat storage tanks. Latent heat is generated when the state changes. E.g. when switching from ice to water, just as much energy is needed as heating the water to 80 °C. Sensible heat represents the behavior of the temperature during the supply and consumption of energy. Sensible heat is derived according to the Eq. (1) [4] (Table 1)

The heat in the QSp storage tank depends on the weight of the medium (m), the heat capacity (c) and the temperature difference. If we have a 200 L tank and needed to heat it from 10 °C to 60 °C, the energy needed would be:

According to these values, water availability and specific heat were selected as the medium [5].

3 Measuring

Were collected data took place for 2 years. During these 2 years, the water temperatures in the thermal tank storage and in the ground near the reservoirs were recorded to find out if there is heat loss to the environment, Fig. 4.

A total of 27 temperature sensors are located in all 3 thermal tank storage and the ground. These sensors recorded temperatures for two years, which gave us the graphic representation in Fig. 4. In Fig. 4, the color-coded temperature curves according to location correspond to the colors according to Fig. 5.

4 Comparison AN1 Tank Between Seasons

So far, the thermal tank storage AN1 with a volume of 24 m3, which is the smallest of them, has been investigated. This tank showed heat losses caused by evaporation. This graphic representation is the course of measurement over two years, Fig. 6.

4.1 Accumulation Tank Without Cover

Evaporation through the water surface caused large heat losses in the first year, which are graphically shown in Fig. 7.

The real measurement data shows us how quickly the energy was discharged from the reservoir. The discharge process is quadratic without energy consumption, Fig. 7.

The graphic percentage representation is from the maximum medium temperature of 67 ℃ to the initial temperature of 18 ℃, which corresponds to the ambient temperature. The discharge took place in 85 days. The effectiveness of such discharge is very low, as it would only be enough for a short time, Fig. 8.

4.2 Accumulation Tank with Cover

In the second year, we improved the AN1 research thermal tank storage by covering the water surface. The covering consisted of thermal insulation made of polystyrene with a thickness of 20 mm. It can be proven from the collected temperature values that the discharge is not so fast. This discharge passes at a certain temperature from quadratic to linear discharge, Fig. 9.

In the second year, the tank was charged up to a temperature of 73 ℃, but 100% of the temperature value for comparison between the first and second year was set to 67 ℃ from the first year. So 100% is 67 ℃ and 73 ℃ is 108,11%. For the second year, therefore, the covered water surface shows a more effective solution for long-term energy accumulation. Comparing the first and second years, in the third week the temperature before covering was 34 ℃, and after covering it was 46 ℃. In the second year, the tank was discharged to the original temperature of 18 ℃, which was 183 days, Fig. 10.

5 Conclusion

This research pointed out how to prevent heat losses, eliminate them and thereby increase the efficiency of the accumulation. In the future, we will focus on examining physical processes such as heat loss, stratification, etc.

References

Riahi L, Martinez C (2019) District energy in cities. UNEP. http://www.districtenergyinitiative.org

Trier D, Bava F, Kok Skov C, Stendorf Sorensen S (2018) Solar district heating trends and possibilities. Helsinge, Denmark

Ladener H, Späte F (2001) Solaranlagen (Staufen bei Breisgau). ISBN 80-247-0362-9

Understanding renewable energy systems. Carl Hanser Verlag Gmbh Co KG (2005). ISBN 1-84407-136-7

Technology roadmap energy-efficient buildings: heating and cooling equipment. International Energy Agency – IEA 9 rue de la Fédération, 75015 Paris, France, Printed in France by Corlet (2011)

Acknowledgements

The article was created with the support of the project Hungary-Slovakia-Romania-Ukraine ENI CBC Programme 2014–2020 HUSKROUA/1702 New Energy Solutions in Carpathian area.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Gorás, M., Vranay, F. (2024). Accumulation of Thermal Energy in the Thermal Tank Storage with the Help of the Sun. In: Blikharskyy, Z., Koszelnik, P., Lichołai, L., Nazarko, P., Katunský, D. (eds) Proceedings of CEE 2023. CEE 2023. Lecture Notes in Civil Engineering, vol 438. Springer, Cham. https://doi.org/10.1007/978-3-031-44955-0_13

Download citation

DOI: https://doi.org/10.1007/978-3-031-44955-0_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-44954-3

Online ISBN: 978-3-031-44955-0

eBook Packages: EngineeringEngineering (R0)