Abstract

Li-ion cells (LIC) are regarded as a very promising technology for energy storage systems due to their high energy density and good cycling stability. However, they still have several shortcomings, especially in terms of safety. Under off-nominal conditions, LIC can experience thermal runaway that can lead to fire and explosion hazards. To understand the triggering conditions of thermal runaway, as well as its consequences, thermal abuse tests on fully charged high-capacity LIC were carried out. Three types of LIC, namely lithium-nickel-manganese-cobalt, super lithium-iron-phosphate, and lithium-nickel-cobalt-aluminum, with nominal capacities of 28, 39, and 42.2 Ah respectively, were selected. Measurements included cell mass loss, gas temperature, vent bursting and thermal runaway delays. The test results showed that the effects of runaway are all the more important as the capacity (energy stored) of the cell is high. With increasing capacity, thermal runaway occurs earlier, and different failure modes can be observed: a slow combustion with diffusion flame, aggressive jet flame containing molten metal particles, up to a fireball ejecting all the contents of the cell.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

More and more everyday life or military equipment is powered, wholly or in part, by lithium-ion batteries (LIB) or accumulators. This technology, considered the most efficient on the market, now supplants all other storage technologies. Compared to other traditional technologies (lead acid, nickel-metal hydride, or nickel-cadmium), they offer many advantages and improvements such as higher energy density, lower self-discharge, no memory effect, quick charging, high voltage, longer service life, low maintenance, and environmentally friendly. On the other hand, Li-ion batteries have drawbacks. They are expensive and sensitive to high temperature, have low self-discharge, and above all they are more fragile, which makes their use, transport, storage, and long-term conservation more complex. The main risk of a lithium-ion cell (LIC), the fundamental unit of a battery, is what is known as thermal runaway (TR). TR is a phenomenon where the cell overheats and overpressures uncontrollably, resulting in violent venting, bursting of the cell housing, possible fire, and explosion with release of flammable and toxic materials. Its triggering can be due to thermal (e.g., high- or low- temperature environments), electrical (e.g., short circuit, overcharge, or overdischarges followed by charge), or mechanical abuse (vibration, shock, and penetration). For lithium-ion batteries, where the cells are packed even more densely, TR is likely to spread from cell to cell through the entire battery in what is termed “thermal propagation”.

Li-ion batteries are the cause of dramatic incidents, including mobile devices (phones, laptops, e-cigarettes, etc.), electric or hybrid vehicles and airplanes. In [1,2,3], representative incidents of LIB failure in recent years are reported. The Federal Aviation Administration database lists more than 400 aviation-related incidents involving Li-ion batteries from January 2006, with a notable increase from 2014 [4].

Research on thermal runaway of LIC caused by the above-mentioned abuses is very active. Nevertheless, the vast majority of these studies have focused on LIC of 18650 type, with a capacity of a few Ah [5,6,7,8,9,10,11,12], and very little on higher capacity cells, of several tens of Ah. To our knowledge, only Peng et al. [13] addressed this topic. This can be explained by the high energy released during thermal runaway and the difficulty of extending the standard normative methods (e.g., those based on oxygen consumption calorimetry) to predict the chemical heat release rate of LIC [14, 15].

In this context, an experimental campaign was carried out with a double objective: on the one hand, to develop a dedicated experiment to trigger the thermal runaway of high-capacity LIC in a controlled, reproducible, representative, and safe way, and on the other hand, carry out open-air tests on three LIC technologies, to study the thermal runaway phenomenon and its consequences on the surrounding environment.

2 Overview of Experiment

2.1 Used Lithium-Ion Cells

The electrochemical high-capacity cells tested in this study are commonly used on board French Navy ships and in the field of solar energy. They belong to three lithium technologies depending on the cathode material used: lithium-nickel-manganese-cobalt (NMC), super lithium-iron-phosphate (SLFP), and lithium-nickel-cobalt-aluminum (NCA). The characteristics of each technology are detailed in [16].

Specifications for each cell type are shown in Table 1. The three types of cells have the same geometric characteristics and comparable masses. The cells are cylindrical and measure 50 mm in diameter and 215 mm in height. They have a safety vent to allow the release of gases that accumulate inside the battery and thus help reduce the effects of thermal runaway, including fires and explosions [17, 18].

Each cell was fully charged to 100% SOC (State Of Charge) using a constant current-constant voltage (CC-CV) Li-ion battery charger (BK precision Model 1900B). SOC of 100% is set because it represents the worst fire scenario. The higher the SOC, the more flammable gases the thermal runaway produces, the higher the rate of heat release and the lower the residual mass after combustion [2, 13, 17, 19,20,21,22,23].

2.2 Experimental Device and Instrumentation

An experimental device has been set up to trigger the thermal runaway of a LIC and to assess its consequences on its surrounding environment (Fig. 1). The device was placed under an extraction hood. It included a cylindrical heating rod, arranged parallel to the LIC, and its regulation system, a metal frame to hold the LIC, and a dummy hollow cell of the same dimensions, placed at 5 mm from the LIC. The frame was designed to ensure, throughout the test, the maintenance of the cells and rod. In most literature studies, such as those by Andersson et al. [7] and Anderson et al. [24], the LIC was exposed to a propane burner flame to initiate the thermal runaway event. For the sake of repeatability and to get closer to real conditions, it was decided here to expose the LIC to a heating rod, 15 mm in diameter and 350 mm long, which can generate an electrical power of 2kW. This technique has already been used by other authors [10, 11, 13].

The experimental device was equipped with seven type K sheathed thermocouples of 1 mm in diameter: one wrapped around the LIC and six (TC1 to TC6) evenly distributed on the dummy cell to measure the temperature of the gas at the surface of the cells. The instrumentation also included: a SARTORIUS brand precision balance with an accuracy of 0.1g to measure the time evolution of cell mass loss and determine the total mass lost during the test; an autonomous unit GRAPHTEC Midi logger GL 840, operating at a frequency of 1 Hz, for the acquisition of measurements; and two standard CCD cameras, with a frame rate of 30 frames per second, to evaluate the volume of flame and to provide a general view of the fire scene.

2.3 Results and Discussion

Six tests were carried out, two per cell technology, for a state of charge of 100%. Tests 1 and 2 relate to the NMC technology, tests 3 and 4 to the SLFP technology, and tests 5 and 6 to the NCA technology.

For all tests, external heating led to the failure and thermal runaway of the LIC. Once the vent is open, white and/or light grey smoke is first observed, which is consistent with the release of flammable electrolyte material from the cell. Thermal runaway of NMC cells is accompanied by swelling of the cell, bursting of the vent and rapid combustion of the flammable gas ejected. For SLFP cells, bursting the vent is not enough to prevent internal pressure build-up and explosive rupture of the cell housing, causing multiple tears and projection of debris. This behavior is even more marked for NCA cells: the explosion is more violent and is accompanied by a large tear of the housing, which can lead to the ejection of the cell content several meters away, as observed for test 6. Figure 2 shows images of the fire, taken just after the thermal runaway for tests 1 to 6. The higher the energy of the cell (NMC < SLFP < NCA), the greater the effects of the thermal runaway in terms of volume and severity of flames, and explosiveness, as summarized by Mikolajczak et al. [23] by: “The more energy a cell has stored, the more energetic a thermal runaway reaction will be”. The NMC cells, which have the lowest energy (28 Ah), generate flames which do not exceed 1 m in length, while they are about 2 m long for SLFP cells (39 Ah), or even more for NCA cells (42.2 Ah). Moreover, the greater violence of the explosion of NCA cells tends to increase the volume of flame and therefore the induced risk.

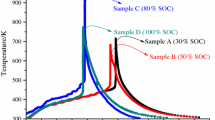

As shown in Fig. 3, thermal runaway of NMC cells occurs later (1944 and 1966 s) than SLFP cells (1562 and 1758 s), which themselves runaway later than NCA cells (1343 and 1391 s). This behavior had already been observed on small format 18650 cells of the LFP and NCA types by Golubkov et al. [9]. Cell technology also conditions the time interval between vent bursting and the onset of thermal runaway. These two phenomena are practically concomitant for NMC cells, whereas they are spaced 155–168 s for SLFP cells and 44–45 s for NCA cells (Fig. 4). Figure 3 presents the time evolutions of the temperature at the surface of the LIC for the six tests. The repeatability of this measurement (tests 1 vs. 2, 3 vs. 4, and 5 vs. 6) up to thermal runaway is excellent. It should be noted that the values obtained for NMC cells, i.e., 146 and 156 ℃, are comparable to those given by other authors for 18650 cells using the same technology [9, 11, 13]. Beyond runaway, the temperature of the gas at the surface depends on the behavior of the flame which envelops the cell, which explains the significant fluctuations observed and limits the interpretation of the results. The curve relating to test 6 is close to a Dirac peak, the bursting of the cell having undoubtedly separated the thermocouple from it.

Figure 4 presents the time evolution of the cell mass loss, using as the origin of time the moment of vent bursting for each test. There is good repeatability of test results using the same technology. Test 5 shows a final mass loss much lower than that of test 6, but if we add to this the mass of the debris projected on the ground by the explosion of the cell, more than 400 g, the results are comparable.

The dynamics of mass loss are also well reproduced, and therefore the combustion regimes of the cells, alternating slow combustion and strong combustion, with or without explosion. The sudden drop observed on the mass loss curve of test 6 results, as before, from the ejection of a large part of the cell contents, including the cell windings, which was not the case for test 5. This phenomenon has also been reported by Mikolajczak et al. [23] and Abbott et al. [25] for small format lithium-ion cells.

The time evolution of the average gas temperature obtained from the six thermocouples of the target cell is plotted in Fig. 4 for each test. Obviously, the thermal response of the target cell depends not only on the technology of the LCI, but also on how the LCI fails. For the same technology, the flame generated by the thermal runaway of the LCI can wrap the target cell or not, leading to very different temperature levels. These results show the need to carry out abuse tests in a confined environment for which temperature homogenization is expected. In addition, the use of a containment enclosure should make it possible to determine, via an energy balance equation, the heat released by the thermal runaway of a LCI, and to study the thermal propagation from cell to cell in battery modules (Fig. 5).

3 Conclusion

In this paper, a series of thermal abuse tests on high-capacity lithium-ion cells (between 28 and 42.2 Ah) were conducted. Three cell technologies were considered, NMC, SLFP and NCA, and for each of them, two abuse tests were carried out. An original experimental device has been developed, using an external heating element to produce failure and thermal runaway of the fully charged cells. Measurements included cell mass loss, vent bursting and thermal runaway delays. The external heating technique has proven to be safe and reproducible. It made it possible, in all cases, to cause the failure and thermal runaway of the cell. The results obtained for the two cells of each technology are quantitatively comparable. As also stated by other authors for small format 18650 cells, the chemistry of the cell conditions the physical phenomena induced by its failure. The more energy a cell has stored (NCA > SLFP > NMC), the greater the effects of thermal runaway, e.g., thermal runaway occurs earlier, and the failure modes differ, going from a slow combustion with diffusion flame to an aggressive jet flame containing molten metallic particles, or even a fireball ejecting the entire contents of the cell.

The location of the flame zone was unpredictable due to tears in the cell housing, which led to great variability in gas temperature measurements. This preliminary campaign, although it has a limited quantitative scope as to the consequences of a lithium-ion cell fire, in particular the rate of heat release, nevertheless highlighted the need to conduct abuse tests in a dedicated confined environment. Thermal abuse tests on a single cell, but also on a group of cells and battery packs are planned in the short term, as well as gas analysis to monitor effluent markers such as hydrofluoric acid.

References

Ouyang, D., Chen, M., Huang, Q., Weng, J., Wang, Z., Wang, J.: A review on the thermal hazards of the lithium-ion battery and the corresponding countermeasures. Appl. Sci. 9(12), 2483 (2019)

Sun, P., Bisschop, R., Niu, H., Huang, X.: A review of battery fires in electric vehicles. Fire Technol. 56, 1361–1410 (2020)

Quintiere, J.G., Crowley, S., Walters, R.N., Lyon, R.E., Blake, D.: Fire hazards of lithium batteries, DOT/FAA/TC-TN15/17. Federal Aviation Administration (2016)

FAA Homepage, https://www.faa.gov/hazmat/resources/lithium_batteries/incidents, last accessed 2023/01/20

Wang, Q., Sun, J., Guanquan, C.: Lithium ion battery fire and explosion. In: Fire Safety Science—Proceedings of the 8th International Symposium, pp 375–382. International Association for the Fire Safety Science, Beijing, China (2005)

Williams, F.W., Back, G.G.: Lithium battery fire tests and mitigation. Report NRL/FR/6104-14-10, 262. Naval Research Laboratory, Washington DC 20375-5320 (2014)

Anderson, J., Larsson, F., Andersson, P., Mellander, B.-E.: Thermal modeling of fire propagation in lithium-ion batteries. In: Proceedings of the 24th International Technical Conference on the Enhanced Safety of Vehicles (ESV), Gothenburg, Sweden (2015)

Wang, Q., Mao, B., Stoliarov, S.I., Sun, J.: A review of lithium ion battery failure mechanisms and fire prevention strategies. Prog. Energy Combust. Sci. 73, 95–131 (2019)

Golubkov, A.W., et al.: Thermal-runaway experiments on consumer Li-ion batteries with metal-oxide and olivin-type cathodes. Royal Soc. Chem. Adv. 4, 3633–3642 (2014)

Said, A., Lee, C., Stoliarov, S.I., Marshall, A.W.: Comprehensive analysis of dynamics and hazards associated with cascading failure in 18650 lithium ion cell arrays. Appl. Energy 248, 415–428 (2019)

Li, H., Chen, H., Zhong, G., Wang, Y., Wang, Q.: Experimental study on thermal runaway risk of 18650 lithium ion battery under side-heating condition. J. Loss Prevention Indust. 61, 122–129 (2019)

Finegan, D.P., et al.: Modelling and experiments to identify high-risk failure scenarios for testing the safety of lithium-ion cells. J. Power Sources 417, 29–41 (2019)

Peng, Y., et al.: A comprehensive investigation on the thermal and toxic hazards of large format lithium-ion batteries with LiFePO4 cathode. J. Hazard. Mater. 381, 120916 (2020)

Ditch, B., de Vries, J.: Flammability characterization of lithium-ion batteries in bulk storage. Research Technical report, FM Global, Norwood, MA (2013)

Somandepalli, V., Biteau, H.: Cone calorimetry as a tool for thermal hazard assessment of Li-Ion cells. SAE Internat. J. Alternative Power. 3(2), 222–233 (2014)

Battery University Homepage, https://batteryuniversity.com/learn/article/types_of_battery_cells, last accessed 2023/01/20

Coman, P.T., Rayman, S., White, R.E.: A lumped model of venting during thermal runaway in a cylindrical Lithium Cobalt Oxide lithium-ion cell. J. Power Sources 307, 56–62 (2016)

Yao, X.-Y., Kong, L., Pecht, M.G.: Reliability of cylindrical Li-ion battery safety vents. IEEE Access 8, 101859–101866 (2020)

Li, H., Duan, Q., Zhao, C., Huang, Z., Wang, Q.: Experimental investigation on the thermal runaway and its propagation in the large format battery module with Li(Ni1/3Co1/3Mn1/3)O2 as cathode. J. Hazard. Mater. 375, 241–254 (2019)

Ribière, P., Grugeon, S., Morcrette, M., Boyanov, S., Laruelle, S., Marlair, G.: Investigation on the fire-induced hazards of Li-ion battery cells by fire calorimetry. Energy Environ. Sci. 5, 5271–5280 (2012)

Larsson, F., Andersson, P., Blomqvist, P., Mellander, B.-E.: Toxic fluoride gas emissions from lithium-ion battery fires. Sci. Rep. 7, 10018 (2017)

Lecoq, A., Eshetu, G.G., Grugeon, S., Martin, N., Laruelle, S., Marlair, G.: Scenario-based prediction of Li-ion batteries fire-induced toxicity. J. Power Sources 316, 197–206 (2016)

Mikolajczak, C., Kahn, M., White, K., Long, R.T.: Lithium-ion batteries hazard and use assessment. Final Report, The Fire Protection Research Foundation, Quincy, MA (2011)

Andersson, P., Blomqvist, P., Lorén, A., Larsson, F.: Investigation of fire emissions from Li-ion batteries. SP Report 2013:15, SP Technical Research Institute of Sweden, Borås, Sweden (2013)

Abbott, K.C., Gill, J., Buston, J.E.H.: Smoke, sparks, flames or explosions? An experimental study into how Lithium-ion cell failure varies in open field. Hazards 31—IChemE: Symposium Series No. 168 (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Pizzo, Y. et al. (2024). Thermal Runaway Experiments on High-Capacity Lithium-Ion Cells. In: Ali-Toudert, F., Draoui, A., Halouani, K., Hasnaoui, M., Jemni, A., Tadrist, L. (eds) Advances in Thermal Science and Energy. JITH 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-43934-6_12

Download citation

DOI: https://doi.org/10.1007/978-3-031-43934-6_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-43933-9

Online ISBN: 978-3-031-43934-6

eBook Packages: EngineeringEngineering (R0)