Abstract

Development of civilization and industry inevitably brings increasing levels of pollution to the natural environment. This forces the activity aimed on the one hand at limiting the amount of pollutants introduced into water and air and on the other hand at effective removal of polluting substances already present in the natural environment. One of the methods for the removal of pollutants is adsorption, and one of the best adsorbents is activated carbon. Activated carbons are microcrystalline materials which show a well-developed surface area and porous structure, so they can be used for removal of pollutants from liquid and gas phase. Thanks to their unique sorption properties, activated carbons have been used in many areas of industry. Wider and wider range of their application cause increasing demands for these materials and stimulate the search for new precursors. Thanks to their unique sorption properties, activated carbons have been used in many areas. Widening panoply of their applications caused increasing demands for these materials and stimulated the search for their new precursors. One of them is plants, which are materials left after supercritical extraction. The present paper provides an overview of reports on adsorption of pollutants from gas phase (NO2) for biomaterials obtained from the residues after supercritical extraction of raw plants.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Biocarbons

- Physicochemical properties

- Physical and chemical activation

- Conventional heating

- NO2 adsorption

An alternative method for biowaste utilization has been proposed.

The activated biocarbons have been used for NO2 adsorption.

The capacity of biocarbons to adsorb nitrogen dioxide was primarily dependent on the conditions of the adsorption process.

1 Introduction

Today, we live in a time of dynamic civilization and technological development, which have enabled people to make their professional and private lives easier. Unfortunately, this progress brings positive and negative consequences. One of the negative effects of human activity is the increase in air, water and soil pollution [1,2,3]. According to the World Health Organization, 80% of the world's population live in areas where air pollution concentrations exceed acceptable standards. This is influenced by both natural and anthropogenic factors [4].

Pollutants in the atmosphere have a significant impact on human health, the condition of ecosystems or climate change [5, 6]. In addition, atmospheric pollutants are difficult to abate because they cannot be confined to a certain area, as they have the potential to spread widely. Toxic gases emitted into the earth's atmosphere mainly include nitrogen, sulfur and carbon oxides, volatile organic compounds and hydrogen sulfide. These compounds contribute to the destruction of the ozone layer and are responsible for the formation of smog and the greenhouse effect [7,8,9,10].

Porous carbon materials, e.g., activated carbons, activated fibers, carbon blacks and mesoporous carbons, are very popular among a wide group of materials used in adsorption of gas pollutants [11, 12]. Carbon adsorbents should be characterized by high sorption capacity, short duration of sorption processes, no toxic by-products and relatively low production cost. These requirements make that activated carbons are one of the most popular carbon materials used in adsorption process [13, 14].

The growing demand for activated carbons and increasing requirements in the field of environmental protection have resulted in a search for new activated carbons precursors [15,16,17,18] and methods of their production [19,20,21]. An interesting group of precursors may be the residues after supercritical extraction of raw plants. In the literature, you can find a huge number of reports on the use of the supercritical extraction process to obtain natural substances contained in herbal plants. This process allows the extraction of natural dyes, flavors and fatty acids, which are the valuable raw materials for the food, cosmetic and pharmaceutical industries [22,23,24]. The raw materials subjected to the supercritical extraction process are mainly hop cones, rape seeds and sunflower seeds, as well as herbs such as nettle, marigold and camomile. The use of these materials for the production of carbon adsorbents can be an excellent alternative for their disposal, because today the main method of dealing with post-extraction wastes is their incineration. Obtaining cheap adsorbents from this type of precursors will allow to obtain activated carbons with interesting physicochemical properties and good sorption properties against gaseous pollutants [24,25,26,27,28].

This paper is a review of the reports on the possibility of removal of gaseous NO2 with the use of activated carbons obtained from residues after supercritical extraction of camomile, marigold and hops.

2 Biocarbons Obtained from the Residues After Supercritical Extraction of Camomile Flowers

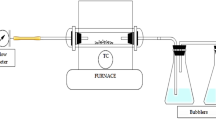

Adsorbents were obtained by physical activation of the residues after supercritical extraction of camomile flowers. Physicochemical and sorption properties toward NO2 of the biocarbons were determined [29]. The starting raw material in the form of powder was subjected to carbonization process at two temperature variants, at 500 or 700 °C (C5 and C7). The process was performed in a tube furnace in nitrogen atmosphere. The biochars were then subjected to physical activation (A) with CO2 in the same tube furnace. Two activation temperatures were applied, of 700 or 800 °C (A7 and A8), and the samples were thermostated for 60 min. As a result of the physical activation of starting material, four biocarbons were obtained for which physicochemical characterization was carried out. All the adsorbents obtained were characterized by: low-temperature nitrogen adsorption, pH of water extracts of the adsorbents and the contents of acidic and basic oxygen functional groups on the surface of activated carbons by the Boehm method [30].

According to the results presented in Table 1, physical activation of the residues after supercritical extraction of camomile flowers leads to the production of mesoporous carbon adsorbents with a surface area in the range 9–104 m2/g. It has been shown that raising the activation temperature by 100°C leads to an enhancement of the textural parameters of the biocarbons and an increase in the proportion of micropores in the sample structures. However, the surface area of the samples obtained by physical activation of the residues after supercritical extraction of camomile flowers is much lower than that of commercial products [31, 32].

Chemical character of the obtained biocarbons was determined by Boehm titration. Moreover, the acid–base properties of the samples were confirmed by measurement of pH of the water extracts of these biocarbons (Table 1). The results of determination of the content of oxygen functional groups clearly indicated that the carbonization and activation processes with CO2 lead to the production of biocarbon adsorbents with only basic functional groups on their surface [33, 34]. The largest amount of this type of group was produced for sample obtained by carbonization at 700 °C, followed by activation at 800 °C. Results of the Boehm titration for samples C5A7, C7A7, C5A8 and C7A8 are confirmed by the pH values of the samples water extracts that fall in the range 10.4–11.0.

The obtained biocarbons were tested as adsorbents of the gas pollutant, NO2. Four variants of adsorption were used during the research [35]. The process of adsorption was carried out in dry (D) or wet (W, 70% humidity) conditions. Moreover, in order to check the effect of moisture content on the sorption abilities of the samples studied, they were subjected to prehumidization (M) with humid air (70% humidity) for 30 min. After this time, the adsorption tests were made in dry (MD) and wet (MW) conditions [36]. The effectiveness of NO2 removal was observed to depend on the carbonization/activation temperature and conditions of adsorption. The sorption capacity of sample varied from 2.0 to 59.1 mg/g. The most effective adsorbent was sample C7A8 obtained by carbonization at 700 °C and activation at 800 °C, which was able to absorb between 19.1 and 57.1 mg NO2/gads, depending on the adsorption variant. Sorption capacities of the biocarbon samples obtained were significantly dependent on the adsorption conditions. As indicated by the data from Fig. 1, prehumidization of the carbon adsorbent bed for 30 min prior to adsorption, conducted in dry (MD) and wet (MW) conditions, has a beneficial effect on the adsorption capacity. Only for samples C5A7 and C7A7, the relation is different.

NO2 breakthrough capacities of the samples obtained from the residues after supercritical extraction of camomile flowers [29]

Another observation following from the data collected in Fig. 1 is that the effectiveness of NO2 removal by the biocarbons studied increases with increasing temperature of carbonization. The effect of the activation temperature was slightly more varied. In the case of samples C5A7 and C5A8, it was observed that the increase in activation temperature was accompanied by a slight decrease in the NO2 removal efficiency when the adsorption test was carried out under MD and MW conditions. An inverse relationship was observed for analogous samples obtained from the residues after supercritical extraction of camomile flowers subjected to carbonization at 700 °C.

The work showed that the residues after supercritical extraction of camomile flowers can be cheap and easily available precursor for obtaining biocarbons with good sorption capacity toward nitric(IV) oxide. The obtained results indicate a significant influence of the conditions of the adsorption process on the obtained sorption capacities. It has been shown that, despite the low specific surface area, the samples show high sorption capacity toward NO2, especially when the adsorption process was carried out in mix-dry and mix-wet conditions. The biomaterials obtained by physical activation with CO2 show not well-developed porous structure and surface area, so further studies should be aimed at optimization of textural parameters.

3 Biocarbons Obtained from the Residues After Supercritical Extraction of Marigold Flowers

Next precursor was the residues after supercritical extraction of marigold flowers [37]. The starting material (M) was subjected to carbonization process that was carried out in a quartz tubular reactor heated by horizontal furnace, under a stream of nitrogen. The samples were heated from room temperature to the final carbonization temperature of 500 (M5) and 700 °C (M7) and kept at the maximum temperature for 60 min and then cooled down in inert atmosphere. Carbonization products were next subjected to physical activation (A). This process was carried out at temperature of 700 (A7) or 800 °C (A8) under a stream of carbon dioxide for 60 min.

The elemental analysis (Table 2) showed that the obtained carbon materials are characterized by higher content of elemental carbon and mineral substances than the initial material. Biocarbons showed higher content of Ndaf relative to the precursor, which may follow from the presence of heterocyclic nitrogen groups resistant to the effect of high temperatures. The content of sulfur in the carbon adsorbents obtained is similar, irrespective of the activation temperature. The changes in content of oxygen and hydrogen were more complex. Unfortunately, as was the case with camomile, the physical activation of the residues after supercritical extraction of marigold flowers also does not permit effective development of surface area. The surface area of the samples varies from 2 to 206 m2/g. The most developed surface area and porous structure showed sample M5A8, obtained by activation of biochar M5 at 800 °C. The textural parameters of the activated carbons discussed in [29, 37] indicate that the physical activation of the residues after supercritical extraction of raw plants should be carried out at a temperature not lower than 800 °C. Nevertheless, the results presented in Fig. 2 prove that the textural parameters of activated carbons depend on type of precursor and activation conditions. Each of starting materials requires an individual approach in determining the most optimal production procedure. According to the results collected in Table 2, the precursor used in the studies shows acidic character of surface. Interestingly, the processes of both carbonization and activation, irrespective of their temperatures, result in removal of acidic groups and a considerable increase in the basic groups. The number of basic oxygen groups on the surface depends to a significant degree on the temperature of carbonization and activation. With increasing temperature of carbonization and activation, the number of basic groups increases. The strongly basic character of the surfaces of activated carbons obtained is probably a consequence of the fact that the activator applied (CO2) and the high temperature of activation are favorable for generation of basic groups [38].

The study has shown that the effectiveness of gas pollutants (NO2) removal depends first of all on the conditions of adsorption. The samples were tested in two variants: in dry conditions (D) and after pre-humidification of activated carbon’s bed by the air of 70% humidity for 30 min-mix-dry conditions (MD). The most effective adsorbent in dry conditions was sample M7A8 whose sorption capacity of 29.2 mg/g was about twice higher than that of the other samples. Also in mix-dry conditions, this sample showed very good sorption capacity. The most effective adsorbent in mix-dry conditions was, however, sample M5A7, whose sorption capacity reached over 102.1 mg NO2/gads, which was over 6 times greater than in the dry conditions (16.3 mg/g). For the other carbon samples studied, preliminary wetting with humid air resulted in only twice increased sorption capacity.

In turn, in the work [39], the residues after supercritical extraction of marigold flowers were carbonized at 600 °C in a nitrogen atmosphere for 60 min. The biochar (M6) was next subjected to physical activation at temperature of 700 (A7) and 800 °C (A8) under a stream of carbon(IV) oxide for 60 min. The processes of carbonization and activation were carried out in a quartz tubular reactor heated by horizontal furnace. Biocarbons obtained were characterized by elemental analysis, low-temperature nitrogen sorption and content of surface oxygen functional groups. Biocarbons were tested for the removal of NO2 from the gaseous phase in dry, mix-dry, wet and mix-wet conditions (Table 3). All biocarbons are characterized by a higher content of elemental carbon than the starting material [29]. The highest content of elemental carbon was found in sample M6A8 obtained by activation of biochar M6 at 800 °C. Each of the activation products showed a very high mineral admixture content, as the contribution of ash varies from 27.2 to 32.7 wt%. The physical activation of the residues after supercritical extraction of marigold flowers does not permit effective development of their surface area. The BET surface area of the bicarbons varies from only 44 to 57 m2/g. The data characterizing the acid–base nature indicated that the surfaces of the studied materials show basic character as there are no functional groups of acidic nature. As indicated by the data presented in Table 3, the efficiency of nitrogen dioxide removal depends first of all on the conditions under which the adsorption test was carried out. The highest sorption capacities were measured in wet as well as mix-wet conditions. High sorption capacities in these conditions are related to water film formation on the carbonaceous adsorbent’s surface, which favors the capture and bonding of NO2 molecules or even nitric acid formation [40].

The studies summarized in the articles [29, 37, 39] confirmed that it is necessary to optimize the process of producing biocarbons from the residues after supercritical extraction of raw plants.

4 Biocarbons Obtained from the Residues After Supercritical Extraction of Hops

In the next stage of the research, residues left after supercritical extraction of hops were used as a precursor for the production of biocarbons [41]. The production of hop has been continuously developing along with beer industry [42]. Although it is mostly used for beer production, the properties of hop have made it an attractive raw product for medicine, pharmacy or in cosmetic and food industry [43,44,45]. On industrial scale, extract from hop is obtained by supercritical CO2 extraction [46]. This type of plants extraction leaves much waste that has to be utilized, and one of the methods proposed for their utilization is production of carbon adsorbents.

The precursor (H) was at first subjected to carbonization process in a traditional resistance pipe furnace at 500 for 1 h. Carbonization product was next subjected to physical activation (A) with carbon(IV) oxide at 800 °C for 1 h. The final product of activation was divided into two parts. One of them was washed distilled water (H5AH2O), while the second part of the biocarbon (H5AHCl) was subjected to demineralization with HCl and H2O.

According to the data in [41], the ash content in the activated biocarbons varies from 5.3 to 32.2 wt% (Table 4). Due to the ash components, may block some pores in the activated carbon structure, thus reducing their surface area. That is why we introduced the process of washing of the carbon material with a 5% HCl solution and/or distilled water. Sample H5AH2O has a half-reduced content of ash than sample H5A. On the other hand, sample H5AHCl, washed with HCl solution and distilled water, has over sixfold lower content of ash than biocarbon H5A and threefold lower content of ash than sample H5AH2O. Biocarbon H5AHCl shows the most developed surface area and porous structure and is the only sample whose SBET exceeds 1000 m2/g. The surface area of the biocarbons obtained depends significantly on the variant of sample washing after activation. Washing with HCl causes unblocking of pores in the biocarbon structure and improves its textural properties [47]. It is evident from the data presented in Table 4 that the surfaces of samples H5A and H5AH2O show basic character. On the other hand, the washing at first with HCl solution and then with distilled water favors generation of acidic functional groups. This change in acid-base characteristics is due to the fact that HCl removes a considerable amount of mineral substance, which is usually basic in nature.

According to the data from Table 4, the effectiveness of removal of NO2 depends considerably on the conditions of adsorption. For all biocarbons, the sorption capacities toward NO2 were higher when adsorption took place in the presence of steam. The highest sorption capacity toward NO2 showed sample H5A which has a relatively high content of mineral substance whose presence may be conducive to adsorption of gas pollutants such as nitrogen(IV) oxide [48]. The other two samples showed much lower sorption capacities toward NO2. It should be mentioned that the highest effectiveness of NO2 removal by sample H5A is beneficial from the ecological and economic points of view as washing is related to additional cost and use of large volumes of water.

The curves in Fig. 3 illustrating changes in NO2 upon adsorption in dry and wet conditions suggest that the process of NO2 removal for the samples takes place according to the similar mechanism. For all samples, the concentration of NO2 was equal to zero for a certain period of time, and only after the breakthrough, a gradual increase in NO2 concentration was observed. A similar course of the curves was observed in the case of samples obtained by physical activation of the residues after supercritical extraction of camomile and marigold flowers [29, 37]. The results in work [41] confirmed the beneficial influence of the mineral substance content in the adsorbents on their sorption capacity toward nitrogen(IV) oxide.

In the next stage of the research, an attempt was made to obtain carbon adsorbents with a strongly developed surface area and microporous structure, as well as high sorption capacity toward NO2. The method allowing production of such adsorbents is chemical activation by a series of activating agents such as: NaOH, KOH, K2CO3, H3PO4 and ZnCl2 as it gives biocarbons of highly developed surface area and pore size distribution needed [49,50,51].

The residues left after supercritical extraction of hops (H) were divided into two parts [52]. One of them was impregnated with Na2CO3 solution (weight ratio Na2CO3:precursor 2:1—sample H2:1 or 3:1—sample H3:1) and subjected to chemical activation at 700 °C and kept for 45 min. The second part was first subjected to pyrolysis (HP) at 500 °C for 1 h. Pyrolysis product was next subjected to chemical activation with Na2CO3. Chemical activation by Na2CO3 was performed at 750 °C with an alkali/biochar weight ratio of 2:1—sample HP2:1 or 3:1—sample HP2:1 in nitrogen for 45 min. Chemical activation and carbonization were carried out in a quartz tubular reactor heated by horizontal laboratory furnace. After the activation process, the final products were subjected to two-step washing procedure, first with a hot 5% solution of HCl and later with demineralized water until free of chloride ions.

According to the results presented in Table 5 and Fig. 4, the chemical activation of the residue after supercritical extraction of hop allows for a much more effective development of the surface area and the porous structure compared by physical activation of residues after supercritical extraction of raw plants. The surface area of the products varies in the range 897–1095 m2/g. The textural parameters of the biocarbons depend on the weight ratio of the activating agent to the precursor or biochar. It should be noted that the surface areas of all activated biocarbons obtained in work [52] were larger than those of many commercial products available on the market [31]. Although obtained by different procedures, all the biocarbons obtained have similar acid–base properties. The highest total content of surface oxygen groups was found on sample H3:1, obtained by chemical activation of precursor by Na2CO3, at the alkali:biochar ratio of 3:1. The lowest total content of functional groups was on the surface of sample H2:1, on which only acidic functional groups were found. For the other activated biocarbon samples also, the acidic surface functional groups were dominant over the basic ones. Analysis of the effect of the variant of activation showed that the activation of the precursor favors the generation of a greater number of groups of acidic character and a smaller number of those of basic character in comparison to their number on the samples obtained by chemical activation of the biochar.

Each sample of activated biocarbon obtained was tested as adsorbent of NO2 in dry and wet conditions. The results of the adsorption tests showed that biocarbons obtained are characterized by very good sorption capacity toward nitric(VI) oxide. Sorption capacity of the biocarbons in dry conditions is from 65.8 to 77.2 mg NO2/gads and in wet conditions from 67.3 to 155.3 mg NO2/gads. Comparison of the textural parameters with sorption capacities toward NO2 reveals the effect of the degree of surface area development on the biocarbons adsorption capacity of this toxic gas. The higher capacities (especially in wet conditions) observed for samples H3:1 and HP3:1 are most probably related to better developed porous structure of these samples. However, the sorption capacity depends also on the type of porous structure and mean pore size. According to literature, the adsorbents with mesopores of the sizes from the range of 5–10 nm are more effective in removal of gas pollutants [53].

The curves showing changes in the NO2 concentration during the processes of adsorption in dry and wet conditions (Fig. 5) are similar for all biocarbon samples studied, so it can be assumed that the sorption on these samples takes place according to similar mechanism. However, the character of the desorption section of the isotherms (Fig. 5) revealed significant differences between the samples. After cutting off the inflow of NO2 to the adsorbent bed, for samples H3:1 (dry conditions) and HP3:1 (dry and wet conditions), the concentration of NO2 was maintained at a high level even after 30 min of washing with a flux of pure air, which proved weak bonding of nitrogen(IV) oxide in the porous structure of the adsorbent. It is worth pointing out that in the case of samples obtained by physical activation of the residues after supercritical extraction of camomile/marigold flowers and hops, an inverse relationship was observed [29, 37]. A rapid decrease in NO2 concentration after cutting off its flow to the adsorbent bed suggests that the majority of adsorbed NO2 has been permanently bound in the porous structure of the activated carbons, so it underwent chemisorption.

NO2 breakthrough curves for biocarbons studied in dry and wet conditions [52]

Based on the literature data [40, 54], it can be expected that adsorption of NO2 in dry conditions takes place according to the following mechanism:

where –C* represents a carbon active site and –C(O) carbon oxygen complexes. Generally speaking, oxidation process of the carbons surface occurs, according to reactions:

During adsorption in wet conditions, the reaction of nitrogen dioxide with water can lead to formation of nitric acid or a mixture of nitric and nitrous acids:

which increases the sorption capacity toward NO2 for the biocarbon samples studied.

5 Conclusion

This paper presents the results of research on the preparation of biocarbons from the residues after supercritical extraction of hops, camomile and marigold flowers. Biocarbons were synthesized based on two methods: physical and chemical activation. Carbon adsorbents were subjected to physicochemical characteristics and evaluation of sorption capacity toward NO2.

-

1.

It was found that the textural parameters of biocarbons depend on the method of activation and the starting material used for the research. The most favorable textural parameters were demonstrated by the samples obtained by activation of residues after supercritical extraction of hops, in particular the adsorbents obtained by chemical activation of this precursor.

-

2.

The textural parameters of adsorbents obtained by physical activation depend on the carbonization and activation temperature. In addition, the surface area of the biocarbons obtained from the residues after supercritical extraction of hops depends significantly on the variant of sample washing after activation. Washing with HCl causes unblocking of pores in the biocarbon structure and improves its textural properties

-

3.

Physical activation of the residues after supercritical extraction of hops, camomile and marigold flowers leads to the obtaining of activated carbons with a clearly basic surface character. On the other hand, adsorbents obtained by chemical activation have clear advantage of acidic surface character.

-

4.

The study has also shown that the effectiveness of NO2 removal depends first of all on the conditions of adsorption. The presence of water vapor and the previous wetting of the biocarbon bed had a beneficial effect on the sorption capacity obtained.

-

5.

Poorly developed specific surface and a mineral substance in the structure of biocarbons obtained by physical activation of the residues after supercritical extraction of raw plants does not compromise their usefulness in the removal of gaseous pollutants.

References

G.Z. Guo, Y. Yu, K.C.S. Kwok, Y. Zhang, Air pollutant dispersion around high-rise buildings due to roof emissions. Build. Environ. 219, 109215 (2022). https://doi.org/10.1016/j.buildenv.2022.109215

N. Elfikrie, Y.B. Ho, H. Juahir, E.S.S. Tan, Occurrence of pesticides in surface water, pesticides removal efficiency in drinking water treatment plant and potential health risk to consumers in Tengi River Basin. Malaysia. Sci. Total Environ. 712, 136540 (2020). https://doi.org/10.1016/j.scitotenv.2020.136540

B. Mohammed, T. Mohammed, E. M’hammed, A. Tarik, Physiological and physico-chemical study of the effect of chromium VI on the nutritional quality of maize (Zea mays. L). Procedia Comput. Sci. 191, 464–468 (2021). https://doi.org/10.1016/j.procs.2021.07.058

S. Jones, N. Richardson, M. Bennett, S.R. Hoon, The application of magnetic measurements for the characterization of atmospheric particulate pollution within the airport environment. Sci. Total Environ. 502, 385–390 (2015). https://doi.org/10.1016/j.scitotenv.2014.09.010

D. Landau, L. Novack, M. Yitshak-Sade, B. Sarov, I. Kloog, R. Hershkovitz, I. Grotto, I. Karakis, Nitrogen Dioxide pollution and hazardous household environment: what impacts more congenital malformations. Chemosphere 139, 340–348 (2015). https://doi.org/10.1016/j.chemosphere.2015.06.091

Y. Dai, X. Cai, J. Zhong, A. Mazzeo, A.R. MacKenzie, Chemistry, transport, emission, and shading effects on NO2 and Ox distributions within urban canyons. Environ. Pollut. 315, 120347 (2022). https://doi.org/10.1016/j.envpol.2022.120347

Y. Zhao, S. Su, Y. Xing, L. Yu, S. Cui, D. Jiang, Z. Xiao, The green bonus: carbon reduction effect of sulfur dioxide emissions trading pilot scheme. Front. Environ. Sci. (2022). https://doi.org/10.3389/fenvs.2022.917887

X. Zhang, B. Gao, A.E. Creamer, C. Cao, Y. Li, Adsorption of VOCs onto engineered carbon materials: a review. J Hazard. Mater. 338, 102–123 (2017). https://doi.org/10.1016/j.jhazmat.2017.05.013

M. Ligaray, C.M. Futalan, M.D. de Luna, M.-W. Wan, Removal of chemical oxygen demand from thin-film transistor liquid-crystal display wastewater using chitosan-coated bentonite: isotherm, kinetics and optimization studies. J. Cleaner Prod. 174, 145–154 (2018). https://doi.org/10.1016/j.jclepro.2017.12.052

M. Marciniak, J. Goscianska, M. Norman, T. Jesionowski, A. Bazan-Wozniak, R. Pietrzak, Equilibrium, kinetic, and thermodynamic studies on adsorption of rhodamine B from aqueous solutions using oxidized mesoporous carbons. Materials 15, 5573 (2022). https://doi.org/10.3390/ma15165573

Y. Li, Q. Dua, T. Liua, X. Peng, J. Wang, J. Sun, Y. Wang, S. Wu, Z. Wang, Y. Xia, L. Xia, Comparative study of methylene blue dye adsorption onto activated carbon, graphene oxide, and carbon nanotubes. Chem. Eng. Res. Des. 91, 361–368 (2013). https://doi.org/10.1016/j.cherd.2012.07.007

A. Bazan-Wozniak, J. Cielecka-Piontek, A. Nosal-Wiercińska, R. Pietrzak, Adsorption of organic compounds on adsorbents obtained with the use of microwave heating. Materials 15, 5664 (2022). https://doi.org/10.3390/ma15165664

E.L. da Silva, M. Torres, P. Portugau, A. Cuña, High surface activated carbon obtained from Uruguayan rice husk wastes for supercapacitor electrode applications: correlation between physicochemical and electrochemical properties. J. Energy Storage 44, 103949 (2021). https://doi.org/10.1016/j.est.2021.103494

I. Enniyaa, L. Rghioui, A. Jourania, Adsorption of hexavalent chromium in aqueous solution on activated carbon prepared from apple peels. Sustain. Chem. Pharm. 7, 9–16 (2018). https://doi.org/10.1016/j.scp.2017.11.003

J. Saleem, U.B. Shahid, M. Hijab, H. Mackey, G. McKay, Production and applications of activated carbons as adsorbents from olive stones. Biomass. Convers. Biorefin. 9(4), 775–802 (2019). https://doi.org/10.1007/s13399-019-00473-7

J. McGinley, M.G. Healy, P.C. Ryan, P.-E. Mellander, L. Morrison, J.H. O’Driscoll, A. Siggins, Batch adsorption of herbicides from aqueous solution onto diverse reusable materials and granulated activated carbon. J. Environ. Manage. 323, 116102 (2022). https://doi.org/10.1016/j.jenvman.2022.116102

G. Tang, L. Zhang, X. Zhu, X. Zhu, The preparation of activated carbon from walnut shell bio-oil distillation residues. New Carbon Mater. 34, 434–440 (2019). https://doi.org/10.1016/j.carbon.2019.10.091

O. Baytar, Ö. Şahin, C. Saka, Sequential application of microwave and conventional heating methods for preparation of activated carbon from biomass and its methylene blue adsorption. Appl. Therm. Eng. 138, 542–551 (2018). https://doi.org/10.1016/j.applthermaleng.2018.04.039

W. Ao, J. Fu, X. Mao, Q. Kang, C. Ran, Y. Liu, J. Dai, Microwave assisted preparation of activated carbon from biomass. Renew. Sustain. Energy Rev. 92, 958–979 (2018). https://doi.org/10.1016/j.rser.2018.04.051

M.J. Puchana-Rosero, M.A. Adebayo, E.C. Lima, F.M. Machado, P.S. Thue, J.C.P. Vaghetti, M. Gutterres, Microwave-assisted activated carbon obtained from the sludge of tannery-treatment effluent plant for removal of leather dyes. Colloids Surf. A Physicochem. Eng. Asp. 504, 105–115 (2016). https://doi.org/10.1016/j.colsurfa.2016.05.0

E. Uquichea, N. Cirano, S. Millao, Supercritical fluid extraction of essential oil from Leptocarpha rivularis using CO2. Ind. Crop. Prod. 77, 307–314 (2015). https://doi.org/10.1016/j.indcrop.2015.09.001

A. Rai, B. Mohanty, R. Bhargava, Supercritical extraction of sunflower oil: a central composite design for extraction variables. Food Chem. 192, 647–659 (2016). https://doi.org/10.1016/j.foodchem.2015.07.070

S. Millao, E. Uquiche, Extraction of oil and carotenoids from pelletized microalgae using supercritical carbon dioxide. J. Supercrit. Fluid. 116, 223–231 (2016). https://doi.org/10.1016/j.supflu.2016.05.049

M.M.R. de Melo, A.J.D. Silvestre, C.M. Silva, Supercritical fluid extraction of vegetable matrices: applications, trends and future perspectives of a convincing green technology. J. Supercrit. Fluid. 92, 115–176 (2014). https://doi.org/10.1016/j.supflu.2014.04.007

S. Zhao, D. Zhang, Supercritical fluid extraction and characterisation of Moringaoleifera leaves oil. Sep. Purif. Technol. 118, 497–502 (2013). https://doi.org/10.1016/j.seppur.2013.07.046

L. López-Hortas, P. Rodríguez, B. Díaz-Reinoso, M.C. Gaspar, H.C. de Sousa, M.E.A. Braga, H. Domínguez, Supercritical fluid extraction as a suitable technology to recover bioactive compounds from flowers. J Supercrit Fluids. 188, 105652 (2022). https://doi.org/10.1016/j.supflu.2022.105652

H.H. Rassem, A.H. Nour, R.M. Yunus, Y.H. Zaki, H.S.M. Abdlrhman, Yield optimization and supercritical CO2 extraction of essential oil from jasmine flower. Indones. J. Chem. 19, 479–485 (2019). https://doi.org/10.22146/ijc.39710

A. Bazan, P. Nowicki, R. Pietrzak, Removal of NO2 by adsorbents made of a residue from supercritical extraction of chamomile. Przem. Chem. 95(4), 856–860 (2016). https://doi.org/10.15199/62.2016.4.29

H.P. Boehm, Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon 32, 759–769 (1994). https://doi.org/10.1016/0008-6223(94)90031-0

N.M.A. Al-Lagtah, A.H. Al-Muhtaseb, M.N.M. Ahmad, Y. Salameh, Chemical and physical characteristics of optimal synthesised activated carbons from grass-derived sulfonated lignin versus commercial activated carbons. Micropor. Mesopor. Mat. 225, 504–514 (2016). https://doi.org/10.1016/j.micromeso.2016.01.043

Z. Ioannou, C. Karasavvidis, A. Dimirkou, V. Antoniadis, Adsorption of methylene blue and methyl red dyes from aqueous solutions onto modified zeolites. Water Sci. Technol. 67(5), 1129–1136 (2013). https://doi.org/10.2166/wst.2013.672

P. Nowicki, The effect of mineral matter on the physicochemical and sorption properties of brown coal-based activated carbons. Adsorption 22(4–6), 561–569 (2016). https://doi.org/10.1007/s10450-015-9729-x

J. Kazmierczak-Razna, P. Nowicki, R. Pietrzak, Characterization and application of bio-activated carbons prepared by direct activation of hay with the use of microwave radiation. Powder Technol. 319, 302–312 (2017). https://doi.org/10.1016/j.powtec.2017.06.062

P. Nowicki, J. Kazmierczak, R. Pietrzak, Comparison of physicochemical and sorption properties of activated carbons prepared by physical and chemical activation of cherry stones. Powder Technol. 269, 312–319 (2015). https://doi.org/10.1016/j.powtec.2014.09.023

R. Pietrzak, T.J. Bandosz, Activated carbons modified with sewage sludge derived phase and their application in the process of NO2 removal. Carbon 45(13), 2537–2546 (2007). https://doi.org/10.1016/j.carbon.2007.08.030

A. Bazan, P. Nowicki, R. Pietrzak, Removal of NO2 by carbonaceous adsorbents obtained from residue after supercritical extraction of marigold. Adsorption 22, 465–471 (2016). https://doi.org/10.1007/s10450-015-9709-1

P. Nowicki, R. Pietrzak, H. Wachowska, Comparison of physicochemical properties of nitrogen-enriched activated carbons prepared by physical and chemical activation of brown coal. Energy Fuels 22, 4133–4138 (2008). https://doi.org/10.1021/ef800251w

A. Bazan-Wozniak, P. Nowicki, R. Wolski, R. Pietrzak, Activated bio-carbons prepared from the residue of supercritical extraction of raw plants and their application for removal of nitrogen dioxide and hydrogen sulfide from the gas phase. Materials 14, 3192 (2021). https://doi.org/10.3390/ma14123192

A.M. Ebrahim, T.J. Bandosz, Effect of amine modification on the properties of zirconium–carboxylic acid based materials and their applications as NO2 adsorbents at ambient conditions. Microporous Mesoporous Mater. 188, 149–162 (2014). https://doi.org/10.1016/j.micromeso.2014.01.009

A. Bazan-Wozniak, P. Nowicki, R. Pietrzak, The effect of demineralization on the physicochemical and sorption properties of activated bio-carbons. Adsorption 25(3), 337–343 (2019). https://doi.org/10.1007/s10450-019-00009-5

S.F. Turner, C.A. Benedict, H. Darby, L.A. Hoagland, P. Simonson, J.R. Sirrine, K.M. Murphy, Challenges and opportunities for organic hop production in the United States. Agron. J. 103(6), 1645–1654 (2011). https://doi.org/10.2134/agronj2011.0131

J.S. Bland, D. Minich, R. Lerman, G. Darland, J. Lamb, M. Tripp, N. Grayson, Isohumulones from hops (Humulus lupulus) and their potential role in medical nutrition therapy. PharmaNutrition 3, 46–52 (2015). https://doi.org/10.1016/j.phanu.2015.03.001

A. Formato, M. Gallo, D. Ianniello, D. Montesano, D. Naviglio, Supercritical fluid extraction of α and β-acids from hops compared to cyclically pressurized solid–liquid extraction. J. Supercrit. Fluid 84, 113–120 (2013). https://doi.org/10.1016/j.supflu.2013.09.021

V. Sanz, M.D. Torres, V.J. López, H. Domínguez, What is new on the hop extraction? Trend Food Sci. Tech. 93, 12–22 (2019). https://doi.org/10.1016/j.tifs.2019.08.018

A. Capuzzo, M.E. Maffei, A. Occhipinti, Supercritical fluid extraction of plant flavors and fragrances. Molecules 18, 7194–7238 (2013). https://doi.org/10.3390/molecules18067194

A. Bazan-Wozniak, J. Cielecka-Piontek, A. Nosal-Wiercińska, R. Pietrzak, Activation of waste materials with carbon(IV) oxide as an effective method of obtaining biochars of attractive sorption properties towards liquid and gas pollutants. Materials 15, 8000 (2022). https://doi.org/10.3390/ma15228000

A. Bazan-Wozniak, P. Nowicki, R. Pietrzak, The influence of activation procedure on the physicochemical and sorption properties of activated carbons prepared from pistachio nutshells for removal of NO2/H2S gases and dyes. J. Clean. Prod. 152, 211–222 (2017). https://doi.org/10.1016/j.jclepro.2017.03.114

M. Kılıç, E. Apaydın-Varol, A.E. Pütün, Preparation and surface characterization of activated carbons from Euphorbia rigida by chemical activation with ZnCl2, K2CO3, NaOH and H3PO4. Appl. Surf. Sci. 261, 247–254 (2012). https://doi.org/10.1016/j.apsusc.2012.07.155

A. Elmouwahidi, E. Bailón-García, A.F. Pérez-Cadenas, F.J. Maldonado-Hódar, F. Carrasco-Marín, Activated carbons from KOH and H3PO4-activation of olive residues and its application as supercapacitor electrodes. Electrochim. Acta 229, 219–228 (2017). https://doi.org/10.1016/j.electacta.2017.01.152

K.Y. Foo, B.H. Hameed, Preparation and characterization of activated carbon from pistachio nut shells via microwave-induced chemical activation. Biomass Bioenerg. 35, 3257–3261 (2011). https://doi.org/10.1016/j.biombioe.2011.04.023

A. Bazan-Wozniak, P. Nowicki, R. Pietrzak, Production of new activated bio-carbons by chemical activation of residue left after supercritical extraction of hops. Environ. Res. 161, 453–463 (2018). https://doi.org/10.1016/j.envres.2017.11.041

M. Florent, M. Tocci, T.J. Bandosz, NO2 adsorption at ambient temperature on urea-modified ordered mesoporous carbon. Carbon 63, 283–293 (2013). https://doi.org/10.1016/j.carbon.2013.06.081

P. Nowicki, R. Pietrzak, Effect of ammoxidation of activated carbons obtained from sub-bituminous coal on their NO2 sorption capacity under dry conditions. Chem. Eng. J. 166(3), 1039–1043 (2011). https://doi.org/10.1016/j.cej.2010.11.101

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bazan-Wozniak, A. (2023). Study of Biocarbons Derived from the Residues After Supercritical Extraction of Raw Plants from Adsorption of Gaseous NO2—Mini Review. In: Fesenko, O., Yatsenko, L. (eds) Nanoelectronics, Nanooptics, Nanochemistry and Nanobiotechnology, and Their Applications . NANO 2022. Springer Proceedings in Physics, vol 297. Springer, Cham. https://doi.org/10.1007/978-3-031-42708-4_2

Download citation

DOI: https://doi.org/10.1007/978-3-031-42708-4_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-42707-7

Online ISBN: 978-3-031-42708-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)