Abstract

Machine learning methods offer some alternatives to the conventional approaches to the development of passive and adjustable fluid film bearings. Data-based bearing models typically show an advantage over conventional numerical models in terms of computational speed, and can either replace or supplement them in certain applications. The most promising application of machine learning is to create high-performance models and optimal controllers for fluid film bearings. It covers a range of tasks connected with the rotor trajectory planning, like active vibration and friction reduction, that is the main scope of this work. On-line rotor position assessment considering the measured or estimated loads can also be implemented using fast data-driven models in diagnostics and predictive analytics systems. The work presents an analysis of this approach in terms of the accuracy of solutions, the time required for preparing data, and training the models. The results show that the calculation speed using data-driven models can be increased at least 10 times compared to the numerical models. Two ANN-based models with different structure were analyzed in accuracy and performance. A model consisting from three separate ANNs was introduced in addition to a single-ANN model based on the analysis of the bearing forces nonlinearities and demonstrated better accuracy and the training time reduced by 26%. The calculation speed increased 12 time compared to the reference numerical model. The use of approximation models is demonstrated for the case of active conical bearing with rotor motion control with intellectual DQN controller. Also the applicability of the approach is analyzed regarding the implementation of intellectual and predictive controllers of active bearings.

The study was supported by the Russian Science Foundation grant No. 22-19-00789, https://rscf.ru/en/project/22-19-00789/..

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The Industry 4.0 paradigm implies integration of information technologies and control means into machines and equipment. Based on the data received from them, analytical, predictive models and digital twins are formed for more effective production management.

Bearings are the critical components of rotary machines. Fluid film bearings (FFB) are indispensable in many cases, although the non-linearity of their properties can make it difficult to make their proper design, especially with modern highly loaded machines. Nonlinear models of FFB are used in analysis [1, 2], design [3, 4] and control [5, 6] tasks related to rotor-bearing systems. The calculation of main design parameters of both passive and active FFB is usually performed by solving the Reynolds equation using numerical methods [7,8,9]. Such calculations require significant computational resources to achieve good accuracy. However, the on-board computing facilities of rotary machine control systems almost always have limited performance. The linearization of the dynamic parameters of FFB [7, 10] allows to reduce the amount of calculations while solving the rotor dynamics problems. However, this approach does not consider the nonlinear properties of the lubricant film. This makes it hardly applicable in a number of conditions, such as a significant eccentricity of the rotor position, the presence of cavitation phenomena, and especially in the use of adjustable bearings with rotor motion control systems [11, 12]. Therefore, there is a need for more efficient models providing sufficient accuracy. A possible approach is the use of models based on machine learning methods. These models are created using experimental data and/or physics-based mathematical models of nonlinear objects [5, 10, 13,14,15]. Currently, machine learning methods are widely used in solving a number of different tasks, for example, defect detection [16,17,18] and condition diagnostics [15, 19], as well as control of mechanical systems: rotors, hydraulic systems and manipulators [5, 20, 21].

It is even more important to take into account the nonlinear properties of the lubricant film in the problems of controlling rotor motion parameters in active FFB. Models of mechanical systems are often used for tuning and evaluating the controllers, as well as for training more advanced intelligent controllers [5, 22]. It is also possible to use models directly to solve control problems, for example, using model predictive control (MPC) [13].

This paper analyses the possibilities and advantages of using machine learning for solving modeling and control problems in FFB. The proposed approach to modeling bearing forces makes it possible to obtain solutions to rotor dynamics problems comparable in accuracy, but many times faster than conventional numerical methods.

2 Modeling and Methods

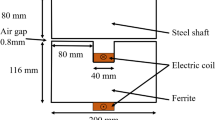

Journal FFB is considered in this work as a well-known and understandable system. Its schematic is shown in Fig. 1.

As a bearing model, we consider the flow of a viscous incompressible fluid in a channel of length l formed by two cylinders, a shaft and a bearing. The bearing with radius \(R=r+h_0\), where r is the shaft radius, \(h_0\) is the radial clearance, is stationary. \(X_1\), \(X_2\), \(V_1\) and \(V_2\) are the rotor displacements and velocities on the abscissa and ordinate axes. \(X_3\) and \(V_3\) are the rotor axial displacement and velocity. In turn, the shaft rotates in the bearing with a constant frequency and angular velocity \(\omega \). Lubricant is supplied from one end of the bearing under pressure \(p_0\). The velocity field is three-dimensional and is characterized by the vector \(V\equiv [(V_1, V_2, V_3)]\). It is convenient to represent the equations describing the motions of the medium in cylindrical coordinates \(\beta _i\), where \(\beta _1,\beta _2,\beta _3\) are the radial, angular, and axial coordinates, respectively.

Cylindrical coordinates are characterized by Lame coefficients: \(H_1=H_3=1,H_2=\beta _1\). The model of a fluid film bearing is based on the Reynolds equation in the form [5]:

where \(u_1=V_3\), \(u_2=\omega \left( r_0+\frac{\beta _1-\beta _1^-}{l}\left( r_1-r_0 \right) \right) +V_1 \cos \left( \frac{\beta _1^ - \beta _2}{r_0}\right) - V_2 \sin \left( \frac{\beta _1^- \beta _2}{r_0}\right) \), \(u_3=V_1 \sin \left( \frac{\beta _1^- \beta _2}{r_0}\right) +V_2 \cos \left( \frac{\beta _1^- \beta _2}{r_0}\right) \) are the components of the fluid velocity vector at the shaft surface, \(\mu \) is viscosity.

The radial clearance function is as follows:

where \(X_i\) are the coordinates of the center of mass of the rotor.

Cavitation is based on the Gumbel hypothesis [5, 23]. The Reynolds equation is solved by the finite differences method [5, 7]. The result of the solution is the pressure field of the lubricant film. The bearing reactions are calculated by integrating the pressure field using the Simpson numerical integration method:

The dynamic model of the rotor system is based on a single-mass oscillatory model. The rotor is represented as a point mass oscillating in the bearing under the influence of gravity, the reaction forces and the imbalance forces. The imbalance forces are modeled as the centrifugal forces. The motion equation of the center mass of rotor in matrix form [24]:

where \(V_1\) ,\(V_2\) is the velocity of the center of the shaft, t is time, \(m_ud\) is imbalance, g is free fall acceleration.

The journal bearing reactions are non-linear and increase significantly at high shaft eccentricities. Also, the calculation results using numerical methods, such as the finite difference method, are sensitive to the size of the computational grid. Figure 2 shows that the lower density grid gives a big calculation error. This phenomenon is most pronounced for the range of eccentricities from 0.9 to 1. Figure 2 demonstrates the stabilization of the calculated results in this area with an increase in the grid dimension from 30\(\,\times \,\)30 to 60\(\,\times \,\)60. However, it leads to an increase in the calculation time.

Numerical solving of Lagrange equations in rotor dynamics problems requires recalculation of the bearing forces at each step so the modeling time can be enormous. Therefore, an alternative approach is the approximation of solutions obtained with numerical methods. Thus, artificial neural networks (ANN) can be used for approximation. A verified numerical model was considered as the reference solution. The Reynolds equation was solved by the finite difference method with a computational grid of 30\(\,\times \,\)30 for low eccentricities and 55\(\,\times \,\)55 for higher eccentricities. A denser grid was used to obtain the sufficient accuracy at higher rotor eccentricities. The obtained bearing forces were used to test the accuracy of the developed approximation models.

The choice of approximation methods is significantly affected by the nature of the initial dependencies. The bearing forces exponentially increase with increasing rotor eccentricity. Also, the compression rate of the fluid film significantly affects their values. The dependence of the fluid film reactions on the compression rate also is strongly nonlinear, see Fig. 3.

As Fig. 3 shows, the dependencies have both relatively linear and substantially non-linear regions. The latter require more values to obtain an approximation with acceptable accuracy. Therefore, as in the case of a finite difference grid when solving the Reynolds equation, it is advisable to use a grid of different density for different regions in the initial dataset for approximation.

3 Results and Discussion

3.1 Approximation of FFB Models

A dataset was generated using the model described in Sect. 2. The model was implemented in Matlab software. The dataset describes the bearing forces \(R_1\) and \(R_2\) for various rotor positions and velocities. A bearing with the following parameters was taken as a test system: the bearing length is 64 mm, the bearing diameter is 40 mm, the clearance is 120 \(\upmu \)m, the rotation speed is 3000 rpm, the lubricant is water at a temperature of 40 \(^\circ \)C.

A polar coordinate system was used for the grid during building the dataset on the bearing forces. Their values were calculated for a uniform distribution of 12 points along the radial (i.e., along the eccentricity of the rotor position) and 40 points along the circumferential (i.e., along the angle of the rotor position in the bearing) coordinates. This distribution was used to collect data at 0-0.9 and 0.9-1 eccentricities to deal with the large nonlinearity at high eccentricity values. The entire eccentricities region was divided into 2 main sections, 0.1-0.5 and 0.5-1, for which different velocity distributions were used. The distributions differed in the boundary values of the velocities, as well as in the number of points in the critical region. The same number of points equal to 80 was used for all sections according to the velocity values, 40 points each for the positive and negative regions. For low eccentricities, we collected the data for the range of velocities from −0.2 m/s to 0.2 m/s, and 70% of all points were located within the range from −0.05 m/s to 0.05 m/s. At high eccentricities, the range was increased to −0.5 m/s to 0.5 m/s, and 50% of all points were located within the range from −0.2 m/s to 0.2 m/s. Thus, the final dataset included 4,700,000 training samples. The dataset input data were the coordinates of the rotor position (\(X_1, X_2\)) and its velocities (\(V_1, V_2\)). Bearing forces values (\(F_1, F_2\)) were the output parameters.

A fully connected ANN was used for training. ANN was with one hidden layer and contained 50 neurons The main evaluation parameters were the network training time, the trajectory calculation time, and the calculation accuracy. The accuracy and the calculation time were compared with those of the reference model based on the numerical solution of the Reynolds equation.

A computer of the following configuration was used for all calculations: Intel Core i5-11600K 3.90 GHz processor, NVIDIA T1000 graphics card, 16 GB of RAM.

Two approaches to the construction of approximation based on ANN were tested in this study. The first is to use a single ANN trained on the entire dataset. The network training time was 5 h 42 min. The second approach was to divide the samples into several parts, based on the nature of the approximate dependence in the corresponding region. In this work, the dataset was divided into 3 parts depending on the eccentricity: 0–0.5, 0.5–0.7, >0.7. Each range was used to train a separate ANN. The training of each ANN was about 1.5 h, which is about 4.5 h in total.

After training ANNs, a number of computational experiments were carried out to check the accuracy of the obtained models. A number of rotor trajectories in the bearing were calculated with two trained and the reference models. The rotor imbalance was a variable value for evaluating the operation of models in different ranges of eccentricities. The calculation results are shown in Fig. 4.

Firstly, the accuracy of the ANNs was tested at small imbalance values which is characterized by small values of velocities and eccentricities, the results are shown in Fig. 4 a. Figure 4 b and c show the rotor trajectories for the imbalance value of 5e−5 and 1e−4, respectively, while the trajectory span is approximately 20% of the radial clearance. After that, the imbalance value was increased to 5e−4 and 10e−4, which gives a span of about 65% of the radial clearance (see Fig. 4 d, e). Also, the operation of the models was tested for the cases when a constant force is applied to the rotor. The force was applied along the \(X_1\) coordinate and was equal to 30N and −40N. The results are shown in Fig. 4 f,g.

Based on the data obtained, when using a single ANN, the rotor trajectories differ significantly from the reference ones in most tests, except for cases with the largest imbalance value. This suggests that the best approximation quality was achieved for data from the region with low non-linearity. In other ranges, the approximation accuracy cannot be considered satisfactory.

When using three ANNs, tests with all imbalance values show a satisfactory accuracy of approximation of the initial data. The model provides correct in- formation about both the steady-state amplitudes of rotor oscillations and the shape of trajectories and transients. At the same time, as in the case of a single ANN, the discrepancy between the trajectories and the reference ones was large during the test with an external load. Although, in the case with three ANNs the discrepancy is less than for a single ANN. The form of the resulting trajectories is similar to the reference model, but their location and amplitude differ.

Thus, the results cannot be assessed as completely satisfactory for any of the tested cases. Only the model based on three ANNs can be considered as limitedly applicable for calculations in systems without complex schemes for loading rotors with external forces.

However, the nature of the results obtained allows us to conclude that the combination of several ANNs for data approximation is a direction that can lead to satisfactory results when it is developed. It is advisable to conduct a more in-depth analysis of the nonlinear properties of the initial data. Probably, dividing them into a larger number of sub-ranges will make it possible to achieve an acceptable modeling accuracy. In addition, the improvement of the results can be achieved by optimizing the approximation methods themselves, e.g., using more complex ANNs of a different architecture and/or increasing the size/number of hidden layers, applying different activation functions, etc. It should be noted that despite the more complex structure of the model consisting of three ANNs, the training time was reduced by 26% compared to the one ANN model. As for another key point, namely the calculation time, the use of a single ANN reduced the estimated time by 12 times in comparison with the reference numerical model.

3.2 Data Driven FFB Models in Control Tasks

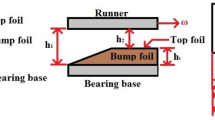

Object models are often used in control tasks to tune controllers. Synthesis of intelligent controllers based on reinforcement learning should be notes particularly since the process of their training implies continuous interaction between the agent and the model of the system. In other cases, for example, in model-predictive control (MPC), an object model is used to predict its response to a planned sequence of control signals. In all the cases noted, sufficient accuracy and high model speed are the essential factors, especially relating to MPC. As mentioned above, the use of machine learning methods can significantly reduce the calculation time in comparison with numerical methods. This also makes it possible to significantly reduce the controller training time. However, it should be noted that achieving high accuracy of such models is a laborious task. The least resource-intensive approach to obtaining data-driven bearing models is to train them using a limited amount of data about the typical ways of the rotor motion in a limited bearing area. Such an approach, for example, was used in one of our previous studies of actively lubricated journal bearing in [13]. In this work such a model was used to synthesize and test several optimal controllers. A similar approach was also used in [22], where an intelligent controller based on a DQN agent was trained to control the position of a rotor in adjustable conical bearings. The bearings were equipped with the axially displaceable sleeves for influencing the type of the rotor motion by changing the average fluid film thickness. ANN was also used to calculate the bearing forces. However, in contrast to this work, the original dataset included a limited number of precalculated rotor trajectories. The trajectories were obtained for different values of the axial dis placement of the rotor in bearings. An example of a calculation with such a model is shown in Fig. 5 [22].

The tests shown in Fig. 5 presented a simulation of occurrence of a malfunction in a rotary machine associated with an increase in rotor imbalance. The imbalance increased uniformly over 5 s, the timing of the presented trajectories is shown in the legend of Fig. 5. As can be seen in the passive system (Fig. 5 b), this leads to an increase in the oscillations amplitude, while in an adjustable bearing (Fig. 5 a) it tends to restrain the growth of this parameter. In one of the presented results, the rotor trajectories at the final moment of time cross the bearing boundaries. In a physical system it would mean the contact of the rotor with the bearing and would lead to the occurrence of shock processes and, probably, chaotic oscillations. The continuation of the calculation indicates a significant approximation error near the boundaries of the training dataset. This phenomenon is strongly manifested in the region of high eccentricities and at the boundary of the control action. It can be concluded that the use of this modeling method imposes significant restrictions on the range of control actions, as well as on the possibility of numerical evaluation of controllers. However, they can be used for preliminary training and qualitative assessment in a strictly defined operating range.

The proposed approach to modeling in this work allows developing models that can calculate the bearing forces for any rotor position and at its different velocities. This makes such a model more flexible with respect to the range of control actions, and also increases the accuracy of the qualitative and quantitative assessment. In addition, such models are more versatile in their application. For training intelligent controllers with reinforcement learning methods, the speed of computing on approximation models allows reducing the training time by at least 10 times while maintaining the accuracy of the results. Implementation of MPC may additionally require reducing the order of approximating models to further improve their performance. In this case, it will be necessary to find a balance between the accuracy and speed of the model.

The disadvantage of the presented approximation approach is the need for preliminary generation of a significant amount of data describing all the nonlinear bearing forces properties with sufficient quality. In addition, in adjustable bearings the fluid film forces are also affected by controlled parameters (gap shape, lubricant supply pressure, its viscosity in the case of magnetorheological fluids, etc.) in addition to the rotor position and velocities. In some cases, like in [22], the controller impact is described by a single parameter. However, in other cases more of them may be required. Adding each parameter to a dataset multiplies its dimension and, accordingly, the generation time. The generation time can be reduced by accelerating the initial calculation methods, but in this case, the accuracy of the data decreases.

Additionally, time is also spent on training approximation models. Reducing these time costs while meeting the requirements for the accuracy of the models is possible by choosing the most effective training methods and optimizing their parameters. It also should be noted that if the parameters of the bearing change during its designing, the above actions for approximating the models will have to be repeated, which further reduces the process flexibility.

4 Conclusion

An approach to modeling the fluid film bearings forces by approximation of their conventional numerical models with artificial neural networks (ANNs) was studied in this work. As the results show, such approximation models are able to exceed the numerical models in calculation speed at least an order of magnitude. However, obtaining such models is associated with a number of limiting factors. The strong non-linear dependence of bearing forces in on the rotor eccentricity and its radial velocity require generating a significant amount of data by the initial numerical model to provide the appropriate accuracy of approximation. A denser computational grid also should be used in numerical model for the same purpose. These factors make the generation of the initial dataset a time-consuming task. It should be considered when making decisions on applying of ANNs to such approximation tasks.

The speed and accuracy of the ANN-based approximation models also depends on their structure. Two different model structures have been tested in this work using the trajectories method. The model based on the combination of three separate ANNs showed better accuracy compared to the single-ANN model, as well as the reduction in the training time by 26%. The three-ANN bearing model also exceeds the reference numerical model by 12 times in calculation speed. However, its accuracy was still insufficient in some scenarios, like adding the radial force to the rotor, to obtain adequate solutions to rotor dynamics problems. So, the further improvement in the model and/or data structure is required. The described approach is mostly applicable to the tasks where a lot of calculations of rotor dynamic behavior is required. The ANN-based models were successfully utilized for training intelligent controllers of fluid film bearings. Using them instead of conventional numerical models reduces the controller training time. Fast approximation models are also suitable for model predictive controllers for active bearings, where fast on-line response analysis is required, as well as for predictive systems for monitoring and diagnostics of fluid film bearings.

References

Tala-Ighil, N., Fillon, M.: A numerical investigation of both thermal and texturing surface effects on the journal bearings static characteristics. Tribol. Int. 90, 228–239 (2015)

Gropper, D., Harvey, T.J., Wang, L.: Numerical analysis and optimization of surface textures for a tilting pad thrust bearing. Tribol. Int. 124, 134–144 (2018)

Kumar, V., Sharma, S.C., Jain, S.C.: On the restrictor design parameter of hybrid journal bearing for optimum rotordynamic coefficients. Tribol. Int. 22, 356–368 (2006)

Cui, S., Zhang, C., Fillon, M., Gu, L.: Optimization performance of plain journal bearings with partial wall slip. Tribol. Int., 106–137 (2020)

Kazakov, Y.N., Kornaev, A.V., Shutin, D.V., Li, S., Savin, L.A.: Active fluid-film bearing with deep q-network agent-based control system. J. Tribol. 144, 1–12 (2022)

Breńkacz, Ł., Witanowski, Ł., Drosińska-Komor, M., Szewczuk-Krypa, N.: Research and applications of active bearings: a state-of-the-art review. Mech. Syst. Signal Process. 151, 107423 (2021)

Kornaev, A.V., Kornaeva, E.P., Savin, L.A., Kazakov, Y.N., Fetisov, A., Rodichev, A.Y., Mayorov, S.V.: Enhanced hydrodynamic lubrication of lightly loaded fluid-film bearings due to the viscosity wedge effect. Tribology International, vol. 160. 107027 (2021)

Peixoto, T.F., Cavalca, K.L.: Thrust bearing coupling effects on the lateral dynamics of turbochargers. Tribol. Int. 145, 106166 (2020)

Momoniat, E.: A reynolds equation modelling coriolis force effects on chemical mechanical polishing. Int. J. Non-Linear Mech. 92, 111–117 (2017)

Iseli, E., Schiffmann, J.: Prediction of the reaction forces of spiral-groove gas journal bearings by artificial neural network regression models. J. Comput. Sci. 48, 101256 (2021)

Chasalevris, A., Dohnal, F.: Vibration quenching in a large scale rotor-bearing system using journal bearings with variable geometry. J. Sound Vib. 333, 2087–2099 (2014)

Santos, I.F.: Controllable sliding bearings and controllable lubrication principles-an overview. Lubricants 6, 1–16 (2018)

Li, S., et al.: Active hybrid journal bearings with lubrication control: towards machine learning. Tribol. Int. 175. 107805 (2022)

lmqvist, A.: Fundamentals of physics-informed neural networks applied to solve the reynolds boundary value problem. Lubricants 9, 1–9 (2021)

Kornaev, A.V., Kornaev, N.V., Kornaeva, E.P., Savin, L.A.: Application of artificial neural networks to calculation of oil film reaction forces and dynamics of rotors on journal bearings. Int. J. Rotating Mach. 2017, 1–11 (2017)

Kumar, A., Gandhi, C.P., Zhou, Y., Kumar, R., Xiang, J.: Improved deep convolution neural network (CNN) for the identification of defects in the centrifugal pump using acoustic images. Applied Acoustics, vol. 167. 107399 (2020)

Misra, S., et al.: Fault detection in induction motor using time domain and spectral imaging-based transfer learning approach on vibration data. Sensors 22, 1–22 (2022)

Chen, H.Y., Lee, C.H.: Vibration signals analysis by explainable artificial intelligence (XAI) approach: application on bearing faults diagnosis. IEEE Access 8, 134246–134256 (2020)

Kornaeva, E.P., Kornaev, A.V., Kazakov, Y.N., Polyakov, R.N.: Application of artificial neural networks to diagnostics of fluid-film bearing lubrication. In: IOP Conference Series: Materials Science and Engineering 734, pp. 1–9 (2020)

Yeo, S., Naing, Y., Kim, T., Oh, S.: Achieving balanced load distribution with reinforcement learning-based switch migration in distributed SDN controllers. Electronics 10, 1–10 (2021)

Kim, J.B., Lim, H.K., Kim, C.M., Kim, M.S., Hong, Y.G., Han, Y.H.: Imitation reinforcement learning-based remote rotary inverted pendulum control in openflow network. IEEE Access 7, 36682–36690 (2019)

Kazakov, Y.N., Kornaev, A.V., Shutin, D.V., Kornaeva, E.P., Savin, L.A.: Reducing rotor vibrations in active conical fluid film bearings with controllable gap. Nonlinear Dyn. 18, 863–873 (2022)

Hori, Y.: Hydrodynamic lubrication. Hydrodynamic Lubrication, 1–231 (2006)

Friswell, M.I., Garvey, S.D., Lees, A.W.: Rotor dynamics: modeling and analysis modeling and analysis of rotating machines, 1–544 (2010)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Kazakov, Y., Stebakov, I., Shutin, D., Savin, L. (2024). Application of Machine Learning in Simulation Models and Optimal Controllers for Fluid Film Bearings. In: Chu, F., Qin, Z. (eds) Proceedings of the 11th IFToMM International Conference on Rotordynamics. IFToMM 2023. Mechanisms and Machine Science, vol 139. Springer, Cham. https://doi.org/10.1007/978-3-031-40455-9_18

Download citation

DOI: https://doi.org/10.1007/978-3-031-40455-9_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-40454-2

Online ISBN: 978-3-031-40455-9

eBook Packages: EngineeringEngineering (R0)