Abstract

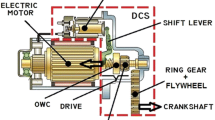

With the continuous development of automobile technology, the performance requirements of automobile engines are getting higher and higher. Low-noise, low-vibration gear systems are increasingly used in engine timing valve mechanisms and other power transmission mechanisms. However, the technical research, development and application of the domestic timing chain system in the engine timing chain system is still in its infancy, and its independent design and research and development capabilities are insufficient. The basic time chain system design techniques are all foreign chain systems that have existed for a long time. This article focuses on the design of automobile engine timing chain system and the wear experiment. First, use the literature research method to explain the layout position of the timing chain system in the whole machine and the type of wear, and then design the automobile engine timing chain system. In the wear test of the designed chain, the result obtained is that the maximum elongation of the center distance is 0.770 mm, and the total center distance wear elongation is ε = 0.33%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fan, C.Y., Shu-Xin, X.U., Wang, H.J., et al.: Wear and limiting condition of three-axial timing chain system. J. Jilin Univ. (Eng. Technol. Ed.) 47(1), 122–128 (2017)

Nayak, N., Rane, S., Anarghya, A., et al.: Wear study and EHD lubrication analysis on connecting rod big end bearings of off-highway application engine. Lubr. Sci. 32(5), 218–229 (2020)

Becker, A., Meffert, D., Sauer, B.: Friction and wear investigations on single chain joints. Forsch. Ingenieurwes. 83(1), 53–63 (2019). https://doi.org/10.1007/s10010-019-00297-x

Li, Q.,Guo, J., Hu, J., et al.: Design and test analysis of bionic subsoiler tip. Paper Asia (7), 42–46 (2018)

Wang, M., Ge, Q., Jiang, H., Yao, G.: Wear fault diagnosis of aeroengines based on broad learning system and ensemble learning. Energies 12(24), 4750 (2019)

Dong, C., Meng, F., Feng, Z., et al.: 58799 Dynamic simulation and analysis of automotive engine’s timing silent chain system (multibody system analysis). Opt. Eng. 45(10), 514–518 (2017)

Kováiková, P., Dubec, A., Kotialiková, D., et al.: Examination of surface wear on the timing chain tensioner depending on the engine oil contamination. Manuf. Technol. 20(4), 463–467 (2020)

Jung, T., Park, Y., Kim, Y.J., Cho, C.: Integrated approach to an optimal automotive timing chain system design. Int. J. Automot. Technol. 18(6), 1037–1045 (2017). https://doi.org/10.1007/s12239-017-0101-x

Kumar, J.S., Giridharan, S., Kannan, T., et al.: Study and overview about process failure mode and effects analysis on automotive timing chain. Int. J. Autom. Mech. Eng. 2(5), 17–21 (2019)

Lee, S., Son, C., Kim, S.-Y., Lee, C.-H.: Timing system development for RAON operation. J. Korean Phys. Soc. 76(7), 551–559 (2020). https://doi.org/10.3938/jkps.76.551

Bazhenov, Y.V., Kalenov, V.P.: The forecasting of the residual resource of electronic engine control system. Russ. Automob. Highw. Ind. J. 2(54), 52–59 (2017)

Nam, K.H., Kim, Y.J., Ye, S.M., et al.: Salinity affects metabolomic profiles of different trophic levels in a food chain. Sci. Total Environ. s 599–600(dec.1), 198–206 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Tang, S. et al. (2023). Design of Automobile Engine Timing Chain System Under Artificial Intelligence Technology. In: Abawajy, J.H., Xu, Z., Atiquzzaman, M., Zhang, X. (eds) Tenth International Conference on Applications and Techniques in Cyber Intelligence (ICATCI 2022). ICATCI 2022. Lecture Notes on Data Engineering and Communications Technologies, vol 170. Springer, Cham. https://doi.org/10.1007/978-3-031-29097-8_68

Download citation

DOI: https://doi.org/10.1007/978-3-031-29097-8_68

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-29096-1

Online ISBN: 978-3-031-29097-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)