Abstract

Mediatorless, two-chambered microbial fuel cells were developed using activated sewage sludge as the source of exoelectrogenic microorganisms with wastewater from two Nigerian traditional food processing activities (locust Bean Processing and Sorghum processing) as the energy source. The fuel cells were operated in batch mode, with aerobic, instead of anaerobic anode chamber. Carbon felt rolled into cylindrical shapes were used for both electrodes and a Nafion® 117 (Dupont Co., USA) proton exchange membrane was used. The highest voltage (172.3 mV) was reached using Locust bean wastewater as the anolyte. A directly proportional relationship was observed between current density and power generation. These initial results demonstrate that wastewater from traditional food processing activities can be used for power generation in a mediatorless microbial fuel cell with an aerobic anode chamber.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nigeria is a country known for its diverse cultures and cuisines [1, 2]. The west African country, with a population of over 210 million (2021 est.) [3], has over 250 ethnic groups (2018 est.) [3]. These ethnic groups each have their own distinct cultures, traditions and cuisines.

Iru (Yoruba), also referred to as Ukpehe in Igala land and dadawa in the northern part of the country, is a condiment often used in the preparation of traditional dishes by many ethnic groups in Nigeria. The condiment is made from the fermentation of whole locust beans. However, iru is not the only condiment gotten from this process. Other oil seeds such as soybean, melon seed, castor oil seed and mesquite bean are fermented to yield other condiments [4].

Ogi or akamu also known as pap is a fermented cereal pudding, enjoyed by many Nigerians, which has a custard-like consistency. It can be made from the wet milling of various cereals like maize, millet or sorghum. After milling, it is allowed to settle and the water is decanted off and disposed of.

The making of these two products generates wastewater. This water is either poured on the ground, in gutters, or water bodies.

This wastewater, however, can be kept out of the environment by using it to produce energy in a process that could also produce electricity [5].

In 2016, Nigeria emitted 120.37 megatons of CO2 [3]. This figure can be drastically reduced if the country looks towards renewable sources of energy instead of relying on less sustainable sources.

A Microbial Fuel Cell (MFC) is a device that produces electrical current from the microbial degradation of a chosen substrate [6]. If practicalized, MFCs will be a beneficial source of renewable energy as not only can they produce electricity sustainably, they are also invaluable in the treatment of wastewater [5, 7, 8].

MFCs are commonly dual chambered. They have an anodic chamber that contains an anolyte as well as an anode and a cathodic chamber that contains a catholyte and the cathode [9]. These chambers are kept separate by a Proton Exchange Membrane (PEM) which is selectively permeable and prevents the anolyte and catholyte from mixing but serves as a route for protons to migrate from the anodic chamber to the cathodic chamber [9, 10]. The two chambers are also connected by a wire running from the anodic chamber to the cathodic chamber.

The anolyte refers to organic substrates which serve as fuel to the MFC by providing microorganisms present in the anodic chamber with nutrients for their growth [11]. These microorganisms can be referred to as electroactive microorganisms (EAMs), exoelectrogens, electrogens, electro-active bacteria, or anode respiring bacteria. They degrade the feedstock, producing electrons and protons as a by-product. The electrons pass from the anodic chamber to the cathodic chamber through the external wire, creating a current in the process while the protons move from the anodic chamber to the cathodic chamber through the proton exchange membrane where they react with oxygen to produce water.

Typically, the anodic chamber is kept anaerobic because many MFCs use microorganisms that are obligate anaerobes and are unable to survive in the presence of oxygen [12].

In this study, we used both wastewater from the production of iru (Locust Bean Wastewater, LBWW) and wastewater from the production of pap (Sorghum Wastewater, SWW) as the anolytes in an MFC, and return activated sewage sludge (RAS) as the inoculum. A number of studies have already been carried out on the use of different fuels, configurations, consortia of microorganisms, aerobic and anaerobic anode chambers as well as the effects of pH., temperature, magnetic fields, etc., on electricity generation using MFCs. However, no research has been done in relation to what is obtainable in rural communities in Africa. To this effect, this study was carried out using materials from a village in Nigeria (Abocho, Dekina, Kogi state) to determine the possibility of using MFCs in rural settings.

2 Materials and Methods

2.1 Inoculum

Return Activated Sludge was obtained from Wupa Wastewater Treatment Plant (WWTP), Abuja Nigeria. The sludge was collected in sterile sample collection containers and transported on ice to the laboratory. In the Laboratory, it was stored at 4 ℃ for use as the inoculum in subsequent experiments.

2.2 Physicochemical Analysis

The COD, BOD, Total Suspended Solids, Total Dissolved Solids and pH were analyzed by standard methods (Table 1).

2.3 Microbial Fuel Cell Coupling and Operation

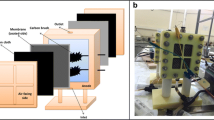

The H-type MFC reactor used in the study was purchased from Huirong E-commerce Co., Ltd., (Hebei, China). Each reactor was assembled by placing a pre-treated Nafion® 117 (Dupont Co., USA) proton exchange membrane between each chamber and holding them together with a clamp. Each chamber contained carbon felt folded cylindrically attached to the external system with copper wires.

The anode chambers were filled with either LBWW, SWW or Distilled Water (DW), as a control.

The cathode chambers were always filled with a sodium percarbonate catholyte (5 g/L) prepared according to Forrestal et al. [13]. The initial pH of all solutions was adjusted to 7.0 and all MFCs were operated at room temperature.

Microorganisms of interest were first immobilized on the anode by filling the anode chamber with 97 mL of the individual anolytes and 3 mL of the RAS inoculum. The system was then run until maximum Open Current Voltage (OCV) was achieved and then the voltage dropped (17 days).

After the immobilization step, the anode chambers were filled with 100 mL of either LBWW, SWW or DW.

2.4 Data Acquisition and Calculations

A multimeter (PeakTech® 2010DMM) was used to measure the voltage across a 1 KΩ resistor and the Open Current Voltage (OCV) of each cell.

The current (I) in amperes (A) was calculated using Ohm’s law:

where V is the potential drop in volts (V) across the external load resistor (R) in Ohms (Ω).

The power output (P) in watts (W), was calculated using the formula:

and the power density (PD) in (W m−2) using the formula:

where A (m2) is the area of the anode.

3 Results and Discussion

3.1 Open Current Voltage

Following the immobilization period, which lasted approximately 17 days, the anode chambers of all MFCs were filled with either LBWW, SWW or DW. No electricity was generated in the MFC with DW as the anolyte (control).

However, the LBWW MFC achieved a maximum voltage of 172.3 mV and the SWW achieved a maximum voltage of 112.4 mV.

From Fig. 1, two peaks can be observed in the graph for both nutrient sources. This is believed to be due to the presence of different types of microorganisms in the inoculum. The initial rise in the open current voltage indicates that the exoelectrogens and other microorganisms are using up glucose as their primary energy source. The number of exoelectrogens, as well as other microorganisms, increase and so, there is a further increase in open current voltage. At the peak, these exoelectrogens have utilized all the glucose present. Due to this, they begin to compete for available nutrients. Their number begins to drop, and consequently, the open current voltage does as well. At this point, the other microorganisms in the anolyte begin to use more complex sugars as their energy source. This results in the production of glucose, which the exoelectrogens then use as their energy source, producing electrons in the process. The open current voltage rises again, only for it to permanently fall after all nutrients have been utilized (Fig. 1).

3.2 Extended Performance of the Microbial Fuel Cells Under an External Resistance

Once it was established that a microbial fuel cell using a mixed inoculum obtained from activated sewage sludge could indeed generate an electrical current, the performance of the MFC was monitored during prolonged operation using Locust Bean Wastewater and Sorghum Wastewater as nutrient sources and carbon felt as both the anode and cathode. The cell was operated over an external resistance of 1 kΩ. The potential difference across the external resistance (Fig. 2) reached a maximum of approximately 28 h after the start of the experiment in the case of LBWW and after approximately 44 h for SWW. The potential difference fell to 0 mV after 72 h of running the LBWW MFC and 76 h of running the SWW MFC. Removal of the wastewater, in both cases, and replacement with fresh wastewater restored the potential difference to the maximum. This indicates that the drop in potential difference was due to the exhaustion of nutrients available in the media.

3.3 Effect of Anolyte on Electricity Generation

From Figs. 1, 2 and 3, it is clear that an MFC using LBWW as the anolyte, with all things being equal, will produce higher power than an MFC which uses SWW as the anolyte. This can be due to the fact that LBWW contains higher amounts of nutrients which exoelectrogens can use as an energy source in the process of the current generation. These nutrients may be found in the higher number of dissolved and suspended solids.

3.4 Relationship Between Current Density and Power Generation

From Fig. 4, we can see that regardless of the feedstock used as the anolyte, current density and power generation are directly proportional. This means that as the current density increase, so also does the power generated by the MFC and to generate greater power, the current density must be increased.

4 Conclusion

This study shows that LBWW is a more feasible anolyte for MFCs which may be operated in rural areas in Nigeria. With an LBWW powered MFC, higher voltages are achieved, more power is produced, and a higher current density can be observed.

Since the process of making the anode chamber anaerobic may not be cost-effective, in rural areas, this study was carried out with an anode chamber that began as aerobic. No oxygen was sparged into the chamber, and there was no shaking of the anode chamber to introduce oxygen. This means that during the course of the experiment, the oxygen concentration changed, therefore altering the active microbial communities.

References

Babani, S.I., Ogbaga, C.C., Okolo, D., Mangse, G.: Bioactive compound and rubisco analyses of leaf and seed extracts of Sesamum indicum. In: 2019 15th International Conference on Electronics Computer and Computation (ICECCO), pp. 1–6. IEEE, USA (2019)

Ogbaga, C.C., Maishanu, R.A., Okolo, D.: Characterisation of the Rubisco Content and Bioactive Compound Analysis of Leaf and Seed Extracts of Tamarindus indica. In: 2019 15th International Conference on Electronics Computer and Computation (ICECCO), pp. 1–6. IEEE, USA (2019)

Mohan, S., Saravanan, R., Raghavulu, S.V., Mohanakrishna, G., Sarma, P.: Bioelectricity production from wastewater treatment in dual chambered microbial fuel cell (MFC) using selectively enriched mixed microflora: effect of catholyte. Biores. Technol. 99(3), 596–603 (2008)

Omafuvbe, B.O., Falade, O.S., Osuntogun, B.A., Adewusi, S.R.: Chemical and biochemical changes in African locust bean (Parkia biglobosa) and melon (Citrullus vulgaris) seeds during fermentation to condiments. Pak. J. Nutr. 3(3), 140–145 (2004)

The World Factbook – Nigeria. https://www.cia.gov/the-world-factbook/countries/nigeria/. Accessed 1 Nov 2022

Herrero-Hernandez, E., Smith, T., Akid, R.: Electricity generation from wastewaters with starch as carbon source using a mediatorless microbial fuel cell. Biosens. Bioelectron. 39(1), 194–198 (2013)

Fernández de Dios, M.Á., Del Campo, A.G., Fernández, F.J., Rodrigo, M., Pazos, M., Sanromán, M.Á.: Bacterial–fungal interactions enhance power generation in microbial fuel cells and drive dye decolourisation by an ex situ and in situ electro-Fenton process. Bioresour. Technol. 148, 39–46 (2013)

Lu, N., Zhou, S., Zhuang, L., Zhang, J., Ni, J.: Electricity generation from starch processing wastewater using microbial fuel cell technology. Biochem. Eng. J. 43(3), 246–251 (2009)

Oh, S., Logan, B.E.: Hydrogen and electricity production from a food processing wastewater using fermentation and microbial fuel cell technologies. Water Res. 39(19), 4673–4682 (2005)

Min, B., Cheng, S., Logan, B.E.: Electricity generation using membrane and salt bridge microbial fuel cells. Water Res. 39, 1675–1686 (2005)

Slate, A.J., Whitehead, K.A., Brownson, D.A., Banks, C.E.: Microbial fuel cells: an overview of current technology. Renew. Sustain. Energy Rev. 101, 60–81 (2019)

Zhang, Y., Min, B., Huang, L., Angelidaki, I.: Generation of electricity and analysis of microbial communities in wheat straw biomass-powered microbial fuel cells. Appl. Environ. Microbiol. 75(11), 3389–3395 (2009)

Forrestal, C., Huang, Z., Ren, Z.J.: Percarbonate as a naturally buffering catholyte for microbial fuel cells. Biores. Technol. 172, 429–432 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 ICST Institute for Computer Sciences, Social Informatics and Telecommunications Engineering

About this paper

Cite this paper

Ocheni, S.I., Ogbaga, C.C., Mohammed, S.S.D., Mangse, G. (2022). Generating Bioelectricity from Traditional Food Processing Wastewater Using an Inoculum of Return Activated Sewage Sludge. In: Mambo, A.D., Gueye, A., Bassioni, G. (eds) Innovations and Interdisciplinary Solutions for Underserved Areas. InterSol 2022. Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering, vol 449. Springer, Cham. https://doi.org/10.1007/978-3-031-23116-2_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-23116-2_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-23115-5

Online ISBN: 978-3-031-23116-2

eBook Packages: Computer ScienceComputer Science (R0)