Abstract

In this paper, the microwave absorbing and resonance properties of solid solutions based on BiFeO3 and Pb(Fe0.5Nb0.5)O3 and PbTiO3 modified with GeO2 are studied. The choice of these systems is justified by the high microwave absorbing properties of the components separately and the prospects for their applications in microwave technology. A method for studying cylindrical material samples on a microstrip line using a network analyzer is briefly described. The measurements were carried out in the frequency range of 300–26.5 GHz. Studies have shown that with an increase in the porosity of the material, its microwave absorbing properties increase, while the resonant characteristics, presumably, worsen. Materials with a low content of bismuth ferrite have the best microwave absorbing properties. The results obtained will help in the development of materials with controlled microwave absorbing properties for applications as microwave absorbing coatings, microwave substrates, resonator and filter materials.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Microwave absorption

- Microwave absorbing properties

- Lead ferroniobate (PFN)

- Bismuth ferrite (BFO)

- Multiferroic

1 Introduction

Highly effective microwave absorbing materials (MAMs) allow solving a number of problems related to the environmental protection of biological objects from the harmful effects of electromagnetic radiation, suppression of interference to communications, ensuring the electromagnetic compatibility of microwave electronic equipment, preventing information leaks over a radio channel, etc. Of particular interest is the development of stealth technology.

Generally, microwave absorbing materials consist of a matrix and conductive/dielectric/magnetic fillers. Among the fillers that could provide an acceptable level of performance in a wide frequency range, ferrites can be distinguished. Unlike other MAMs, ferrite materials can demonstrate high performance in the frequency range from tens of MHz to tens of GHz. For example, in the review paper [1] there are 5 types of absorbing materials (all based on a magnetic subsystem):

-

(i)

ferrites;

-

(ii)

materials based on metal powder with ferromagnetic properties;

-

(iii)

materials based on nanoscale composites with ferrites;

-

(iv)

fiber magnetic materials;

-

(v)

materials based on carbonyl iron.

Many papers report that permeability is one of the main factors determining the microwave absorbing properties of a material. Magnetization saturation, magneto-crystalline anisotropy constant and internal strain are the main parameters that affect the permeability.

Fiber materials are given special attention when looking for high absorption values. For example, the review paper [2] notes relatively high absorption rates for carbide, nitride, oxide, and multicomponent nanofibers. The microwave absorbing properties of carbon nanotubes and conductive polymer fibers are also noted separately.

Conventional materials such as ferrites, carbon nanotube materials, and carbon fibers exhibit satisfactory microwave suppression performance under room temperature conditions. However, they are not suitable for high temperature applications due to their poor oxidation stability or low Curie temperature.

Recently, more and more attention has been paid to the study of the prospects for the use of functional materials, such as ferroelectrics, ferromagnets, and multiferroics in the field of microwave electronics, in particular, as MAMs.

There are many studies of the electrical and magnetic properties of ceramics based on BiFeO3 in the microwave range. Rare-earth elements such as samarium [3] can be used as alloying components to improve the magnetic properties of bismuth ferrite. In other papers, for example [4], the properties of bismuth ferrite, modified with chromium and neodymium, are studied, which demonstrates a high level of microwave absorption in the frequency range of 10–10.5 GHz. In addition, much attention is paid to composites based on bismuth ferrite [5].

Along with BiFeO3, a promising material for use in microwave electronics is Pb(Fe0.5Nb0.5)O3 [6]. The authors in [7] demonstrated satisfactory microwave absorbing properties of this material, and in the papers [8, 9], the properties of solid solutions (SSs) Pb(Fe0.5Nb0.5)O3 with Pb(Fe2/3W1/3)O3 and CuMnFeO4 and the prospects for the use of these compositions as an MAMs are also considered.

Based on the foregoing, it can be concluded that there are two approaches to improve the absorbing properties of a material associated with the complication of its microstructure:

-

(i)

the development of composites based on one material;

-

(ii)

the modification of the composition with alloying components, or other compositions of a similar structure.

In order to achieve high absorption rates, we chose the second approach. Thus, in this work, we study the microwave absorbing properties of BiFeO3, Pb(Fe0.5Nb0.5)O3, and PbTiO3 SSs. In addition, we also paid attention to the resonance properties of the studied materials.

2 Materials

The objects of study were samples of the SSs of the binary system (1 − x)BiFeO3 − xPb(Fe0.5Nb0.5)O3 (BFO – PFN) with x = 0.3 (SS-1), x = 0.95 (SS-2) and the ternary system (0.5 − y)BiFeO3 – 0.5Pb(Fe0.5Nb0.5)O3 – yPbTiO3 (BFO – PFN – PT) with y = 0.2 (SS-3). GeO2 (G) was chosen as a modifier, which was added to various compositions in ratio of 0.5% and 1% of the total mass in order to obtain a more perfect crystalline and grain structure. Previously, samples of the SS of the ternary system PbTiO3 – PbZrO3 – PbMg1/3Nb2/3O3 (PZT – PMN) [10] were prepared using the same method; in addition to improving the structure, a higher temperature stability of some characteristics of the composition was also achieved.

The material was made in the form of cylindrical columns with a diameter of 12 mm using conventional ceramic technology [11]. During the synthesis and sintering of samples, various process conditions were used, while for each composition, both the synthesis and sintering temperatures and the number of synthesis stages were varied. In the future, we will use conditional abbreviations, which are presented in Table 1.

Thus, within the framework of this study, 10 groups of samples were selected:

-

(i)

3 groups of SS-1 with different mass fractions of GeO2 and manufactured under similar process conditions;

-

(ii)

3 groups of SS-2, modified with 0.5% GeO2, fabricated under different process conditions;

-

(iii)

4 TP3 groups with different mass fractions of GeO2, manufactured under different process conditions;

To conduct radiophysical studies, cylindrical samples of various heights and 12 mm in diameter were made. The height variation made it possible to assess the degree of influence of this parameter on the results obtained.

During the preparation of the samples, it was suggested that a gradient of structural inhomogeneities of the material arises due to the possible segregation of lead [12]. At the same time, we have previously demonstrated the dependence of the microwave absorbing properties of a material on the phase composition of the material [13]. In this regard, it was decided to study several samples from each group: sections of the upper, middle and lower parts of the column.

3 Methods

As part of the radiophysical studies descriptions, the elements of the scattering parameters matrix (S-parameters) will be mentioned, so it is necessary to briefly explain their essence. The matrix of S-parameters for a quadripole (two-port device) consists of four coefficients of electromagnetic waves power ratios: S11 and S22 are the reflection coefficients for the first and second ports (the power ratio of the reflected wave to the incident wave); S12 and S21 are the transmission coefficients for the first and second ports (the power ratio of the transmitted wave to the incident wave) [14].

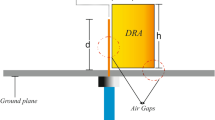

Radiophysical measurements were performed using a vector network analyzer (VNA) P9375A “Keysight” with an operating frequency range of 300–26.5 GHz. To connect the measuring cell with the VNA measuring cables, microwave adapters of the PC 3.5 standard with a limiting operating frequency of 26.5 GHz were used.

To study the microwave absorbing properties of the material, a measuring cell was used, which is a straight segment of a microstrip line (MSL) on a substrate made of glass fiber reinforced epoxy material (FR4), with coaxial connectors of the SMA 3.5 standard at both ends. The operating frequency range of the connectors is up to 18 GHz. During the measurements, the samples were located in the center of the cell, on the surface of the MSL, and the frequency dependences of the coefficients of the scattering matrix were recorded.

The contact quality of MSL coaxial connectors and VNA microwave cables, as well as the quality of manufacturing of the measuring cell, can be estimated by analyzing the dependences of the S-parameters on the frequency of an empty measuring cell (Fig. 1).

Periodic dips and small ripples of the reflection coefficient are associated with the interference of waves reflected from the coaxial connectors of the MSL and the interference of small reflections from the junctions of the coaxial junctions with the measuring cables and connectors of the measuring cell, respectively. The bandwidth with a satisfactory degree of matching (the level of reflection coefficients does not exceed −20 dB) is about 7 GHz. Therefore, the reliability of measuring the level of reflection and transmission coefficients is limited from above by a frequency of 7–8 GHz. Although signal level information may not be accurate, measurements and calculations are still carried out over the entire available frequency range in order to evaluate microwave absorbing and resonant properties at a qualitative level.

The absorption coefficient of the material is defined by the equation:

where, di is the scattering coefficient of the MSL with the i-th sample, d0 is the scattering coefficient of the empty MSL. The scattering coefficients are calculated by the following equation:

The absorption coefficient in our case indicates what part of the energy was dissipated when the sample was introduced into the measuring cell. It consists of three main contributions:

-

(i)

energy absorbed by the sample;

-

(ii)

energy reflected into the surrounding space due to the presence of the sample;

-

(iii)

energy absorbed by the MSL substrate.

The third contribution may arise due to the fact that the electromagnetic wave reflected by the sample can rush into the MSL substrate.

When analyzing the dependences of S-parameters on frequency, we pay attention to the transmission coefficient, while trying to detect resonant dips. Their presence alone does not provide much useful information, however, if we have two samples of the same shape but different composition, in which resonant dips are observed, we can compare some parameters of the samples and materials. In particular, this makes it possible to compare the average value of the permittivity by the dip position in the frequency domain (with a decrease in the permittivity, the minima shift to higher frequencies).

The method for calculating the absorption coefficient makes it possible to compare the level of absorption of electromagnetic waves in the microwave range in various materials with similar electrical parameters. The method for measuring and calculating the absorption coefficient is described in detail in the works [13, 15]. In particular, the analysis of the frequency dependences of the absorption coefficient makes it possible to estimate the absorption band width of a given system. While comparing the measurement results of various materials, one can say, which composition introduces large losses into the system.

It is known that structural inhomogeneities in composite materials, as well as in porous ceramics, can serve as one of the main factors affecting the properties of materials in the microwave range [16]. Therefore, the samples’ degree of porosity of the was estimated.

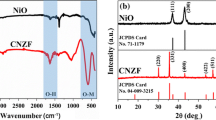

To determine the samples’ degree of porosity, the density of the samples was first measured by hydrostatic weighing in octane, then the crystal structure of the objects was studied by X-ray powder diffraction (XRD). According to the data of X-ray analysis, the X-ray density of the material was calculated, after which the relative density was calculated. This parameter is calculated as the ratio of the measured density to the X-ray density, and shows how the actual density of the material differs from the expected density of a defect-free single crystal of this material, taking into account the measured parameters of the crystal lattice.

4 Results and Discussion

Since we had 3 solid solutions with radically different compositions at our disposal, it is proposed to compare all three compositions with each other for the presence of their own resonances in cylindrical samples. A comparison of their amplitude-frequency response (AFR) will also possibly show, which of the compositions has the highest dielectric permittivity in the microwave range. The calculation of the absorption coefficient will reveal the composition with the widest microwave absorption band.

For SS-1 samples, it is required to analyze the dependence of resonant and absorbing properties on frequency, when adding a small amount of GeO2. Since various process conditions were used in the manufacture of SS-2 samples, we analyzed the measurement results and compared their characteristics separately. The SS-3 samples were investigated comprehensively, as not only the composition varied, but also the manufacturing conditions.

It makes sense to additionally assess the degree of homogeneity of the synthesized compositions. Heterogeneity could occur at the stage of synthesis and sintering of cylindrical columns. Since the samples were made by cutting cylindrical columns, it is possible to assess the degree of homogeneity of the material after sintering by comparing the samples’ characteristics of the of the upper and lower column parts.

4.1 Study of the SS-1 Samples Characteristics

In the group of SS-1 samples without a modifier, there was 1 sample of the lower part of the first column and 3 samples of the second column, its lower, middle and upper parts. S-parameters and absorption coefficients of these samples are shown in Fig. 2.

S-parameters (a) and absorption coefficients (b) of SS-1 samples without GeO2 of various column sections (low. 1 is the lower part of the first column; up. 2, mid. 2, low. 2 are the upper, middle and lower parts of the second column, respectively). The resonant dips of the transmission coefficient are highlighted by a circle

The resonant dips of the edge sections are grouped in the frequency range of 5–6 GHz, while the resonant frequency of the sample of the second column middle part is located near the frequency of 6.5 GHz. This feature is most likely related to the lower relative density of the middle sample (Table 2).

During the measurement process, at the stage of statistics collection, it was found that the level of the transmission coefficient in the resonance region varied from −30 to −20 dB from measurement to measurement. This is probably due to slight differences in the arrangement of samples on the MSL. We ask the reader not to focus on the significant differences in the height of the samples yet. Further it will be shown that differences in height do not have a big impact on their characteristics.

Resonant dips of the transmission coefficient are also observed in SS-1 samples with a mass fraction of GeO2 0.5% (Fig. 3).

These minima are located in the frequency range of 6–7 GHz and have a higher relative power level. It is worth recalling here that the measurements of the samples in this series, as well as the previous one, were repeated many times to accumulate statistics and evaluate the effect of sample positioning on the MSL. If in the previous case a variation in the power level of the resonant dip was noted depending on the location of the sample in the measuring cell from −20 to −30 dB, then a similar pattern takes place here, but the coefficient level is never higher than −20 dB. We assume that this feature may be associated with the presence of GeO2 in the composition, since all other parameters of the samples either do not differ, or their differences do not affect the properties in the microwave range.

On average, all features for all samples of this group approximately coincide in frequency, while all samples have approximately the same relative density (Table 3). This is also facilitated by a relatively small error in geometric parameters relative to the average value.

The SS-1 samples with a 1% GeO2 mass fraction have similar features of the S-parameter dependences on frequency with the previous ones. Resonance dips are also located in the frequency range of 6–7 GHz (Fig. 4).

Despite significant differences in height (Table 4), the transmission, reflection, and absorption spectra approximately coincide. We assume that this may be due to the fact that the relative density of all three samples is practically the same.

Comparing all 3 series of samples, it can be seen that the addition of a small amount of GeO2 to the composition does not affect its absorbing properties in the measured range, however, there is an assumption about the deterioration of the resonance properties.

4.2 Study of the SS-2 Samples Characteristics

In contrast to the SS-1 samples, the SS-2 samples do not exhibit resonant behavior in the studied frequency range (there are no resonant dips in the frequency dependences of the S-parameters (Fig. 5)).

Despite small differences in the relative densities and thicknesses of the samples, the frequency dependences of the S-parameters and the absorption coefficient are in good agreement with each other (possibly, the different thickness of the samples compensates for the difference in relative density (Table 5)).

The characteristics of SS-2 samples, fabricated according to process conditions 4, as well as in the previous series, practically do not differ from each other (Fig. 6).

The relative densities of these samples are very similar to each other, but the thickness varies over a fairly wide range (Table 6). As can be seen from the graphs, the thickness of the samples does not significantly affect their characteristics.

SS-2 samples, fabricated according to process conditions 5 are relatively well matched both in density and thickness (Table 7). Their characteristics also differ to a small extent (Fig. 7).

As it was seen earlier, SS-2 manufactured by different process conditions have different relative densities: samples that have passed 2 stages of synthesis and 1 stage of sintering at high temperature (1000 ℃) on average have a relative density of 93.5%. The elimination of one synthesis step reduced the average relative density to 92.2%. Lowering the sintering temperature to 950 ℃ in the presence of an additional synthesis step also reduced the relative density to 86.8%. As shown earlier in this work, the relative density can significantly affect the characteristics of samples in the microwave range. Figure 8 shows the absorption properties of the above FRs in comparison with each other.

It can be seen from the figure that an increase in relative density slightly reduces the overall level of the absorption coefficient. This may be due to a decrease in the total number of structural inhomogeneities present in the material. At the same time, all samples had different heights, however, the study shows that in most cases, the height of the samples has little effect on their properties.

The study of the absorbing properties of SS-2 shows that a relatively high level of the absorption coefficient of SS-1 samples at a frequency of 6.3 GHz is mainly associated with the occurrence of resonance in the sample (Fig. 9). The characteristics of SS-1 and SS-2 differ significantly up to 9 GHz, and in the region of higher frequencies they approximately coincide. Most likely, this is due to the imperfection of the MSL, which we discussed in the chapter devoted to methods.

4.3 Study of the SS-3 Samples Characteristics

Previously, we found that the process conditions for the manufacture of the material and the presence of impurities in them affect the relative density. This, in turn, is one of the factors that determine the electrical properties of the material in the studied frequency range. In our samples, there are series of samples of different column sections, but with approximately the same relative densities. Such samples demonstrate similar characteristics, both transmitting and reflecting, and absorbing. Therefore, we will not further focus on cuts, but will indicate only relative densities.

Let us consider the characteristics of SS-3 samples with 0.5% GeO2, fabricated according to process conditions 6 (Fig. 10).

In this series, we had 2 samples with approximately the same relative density, but with different heights (Table 8).

As it can be seen from Fig. 10, the characteristics of these samples are practically the same. This confirms our earlier assumption that the relative density of the material has a much greater effect on the properties of the samples in the microwave range than their geometric parameters. This somewhat softens the requirements for machining, thereby simplifying future studies.

Samples of SS-3 with 0.5% GeO2, fabricated according to process conditions 7, also have characteristics similar to each other (Fig. 11).

This series of samples has not only similar relative densities, but also heights (Table 9).

Similar results were obtained for SS-3 samples with 1% GeO2, fabricated according to process conditions 8 (Fig. 12 and (Table 10).

The results of measuring and calculating the parameters of SS-3 samples with 1% GeO2, manufactured according to process conditions 9 (Fig. 13) with strengthen the statistics obtained at the previous stages: small fluctuations in the samples height (Table 11) affect their parameters insignificantly.

The absorbing properties of all samples practically do not differ, which confirms the hypothesis that the presence of a small amount of GeO2 does not affect the absorbing properties of this material in the microwave range. Differences in relative density of all samples of current SS were very small, so they also did not affect the final properties.

5 Additional Comparisons

As a complement to this study, we compared the characteristics of the fabricated materials with the characteristics of materials of a completely different structure and chemical composition. This made it possible to form an idea of the properties of the obtained materials at a qualitative level.

Samples SS-2, as well as samples SS-3, do not exhibit resonant properties in the studied frequency range. Therefore, we compared their absorbing characteristics with industrial absorber materials of various compositions (Fig. 14). For comparison, samples of the same shape as the studied samples were made from rubber and an industrial absorber, which included epoxy resin and more than 50% carbonyl iron. For this comparison, we do not take into account the SS-1 samples, since their absorbing properties largely depend on the resonance that arises in them.

SS-3 samples have a relatively high level of absorption (more than 50%) in the frequency range of 3–6 GHz, while the absorption band of the industrial absorber in this configuration is located in the range of 5.5–7.5 GHz. The absorption level of the SS-2 samples is slightly lower and the high absorption band is significantly narrower. The rubber sample introduces practically no losses into the system. At some frequencies, the absorption coefficient is negative. This means that the match of the system at these frequencies has improved after the application of the sample.

Since the SS-1 samples have distinct resonant dips, we compared their characteristics with those of an industrial dielectric resonator. It has a cylindrical shape and is similar to the samples we are considering. The resonator material is a ferroelectric ceramic based on BaTiO3. The exact composition of the resonator material is unknown; X-ray studies have not been carried out at the current stage. In this work, it is sufficient to know only the spectra of the transmission, reflection, and absorption coefficients of a given resonator. SS-1 samples without GeO2 were taken as samples for comparison, since they had the most distinct resonant dips. The results are presented in Fig. 15.

Like the samples, the resonator was placed at the center of the MSL. This comparison is not entirely correct, due to the fact that the dielectric resonator has a different diameter. Despite this, we can at least estimate the level of losses in the resonator and understand what we should strive for when developing such devices.

It can be seen from the figure that the level of absorption in the resonator is significantly lower than in our sample. Also, judging by the width of the resonant dip, our sample has a much lower quality factor. The lower level of the transmission coefficient at the resonant frequency in our sample, potentially, indicates a higher power of the frequency-stabilized signal when using the sample in circuits for the formation of highly stable microwave oscillations. However, we do not take this fact into account due to 3 reasons: (i) we do not have information on how the characteristics of this sample will behave in another system; (ii) while manufacturing the sample, the goal was not to obtain high-quality resonances; (iii) no preliminary simulation was carried out.

6 Conclusions

The study showed that samples of the composition 0.7BiFeO3–0.3PbFe0.5Nb0.5O3 have the best resonant properties, while the resonant dips of other compositions are either absent in this frequency range or poorly distinguishable. Due to the large difference in the frequency response of all three compositions, it is not possible to evaluate the differences in the permittivity.

The accumulated measurement statistics show that if the samples do not differ in diameter and composition, then their height does not significantly affect both the resonant and microwave absorbing properties. This reduces the time for preparing samples for measurements, and therefore speeds up research.

An analysis of the dependences of S-parameters and reflection coefficient on frequency for materials of the same composition but different relative density showed that one of the factors that significantly affect the characteristics of multiferroic ceramics in the microwave range is the degree of porosity. The statistics obtained during the study is not enough to judge how the relative density affects the resonant properties of cylindrical samples. Probably, in more porous samples, the resonant features are shifted to a higher frequency region, but the method we use does not allow us to accurately determine how porosity affects the level of resonant dips.

In general, modification with a small amount of germanium does not significantly affect the microwave absorbing properties. This suggests that either the grain structure of the material changed insignificantly, or the grain structure changed, but this did not affect the properties we measured, and hence the electromagnetic parameters of the material, such as dielectric and magnetic permeability. To clarify this issue, microstructural studies are required.

Comparison of samples of the composition under study with some materials of the microwave-electronic industry showed the prospects for the use of solid solutions of the composition 0.7BiFeO3–0.3PbFe0.5Nb0.5O3 as materials for dielectric resonators or filters. The SSs of the compositions 0.05BiFeO3–0.95PbFe0.5Nb0.5O3 and 0.3BiFeO3–0.5Pb(Fe0.5Nb0.5)O3–0.2PbTiO3 demonstrate good absorbing properties; therefore, there are prospects for their application as microwave absorbing coatings.

Anyway, for more accurate assessments of these compositions applicability in the field of microwave electronics, it is necessary to determine their spectra of complex dielectric and magnetic permeabilities, which within the framework of this system is possible only with the use of simulation.

References

Wei H, Zhang Z, Hussain G, Zhou L, Li Q, Ostrikov KK (2020) Appl Mater Today 19:100596

Huang W et al (2020) Ceram Int 46(17):26441

Palaimiene E, Macutkevic J, Karpinsky DV, Kholkin AL, Banys J (2015) Appl Phys Lett 106(1):012906

Yousaf M et al (2022) J Colloid Interface Sci 608:1868

Rusly SNA et al (2020) Ceram Int 46(1):737

Alvarez G, Font R, Portelles J, Zamorano R, Valenzuela R (2007) J Phys Chem Solids 68(7):1436

Khuchua NP (1966) Proc Int Meet Ferrol 2:161

Shevchuk YA, Gagulin VV, Korchagina SK, Ivanova VV (2001) Inorg Mater 37(8):836

Fedii AA, Kalganov DA, Filonenko EM, Yaroshenko FA, Bezborodova PA, Lupitskaya YA (2021) Phys Solid State 63(11):1774

Reznitchenko LA et al (2009) Inorg Mater 45(2):173

Okazaki K (1969) Ceramic engineering for dielectrics. Zinatne, Tokyo

Shut VN (1996) Semiconductors–Ferroelectrics, Proceedings of the 7th international seminar on physics of semiconductors–ferroelectrics vol 6. p 199 (In Russian)

Astafev P, Pavelko A, Lerer A, Reizenkind J, Noykin Y, Reznichenko L (2022) Curr Comput-Aided Drug Des 12(4):551

Robert EC (2001) Foundations for microwave engineering, 2nd edn. Wiley, Hoboken, NJ, USA

Reizenkind YA, Kleshchenkov AB, Lerer AM, Noikin YM (2021) Proceedings of the international symposium: physics of lead-free piezoactive and related materials. Modeling of eco-systems (Analysis of Current State and Prospects of Development), vol 2. Rostov-on-Don, Russia, p 280 (In Russian)

McNeal MP, Jang SJ, Newnham RE (1998) J Appl Phys 83(6):3288

Acknowledgement

The study was carried out on the equipment of the Shared Research Facility Center of SFedU, Research Institute of Physics with the financial support of the Ministry of Science and Higher Education of the Russian Federation (State task in the field of scientific activity, scientific project No. (0852-2020-0032)/(BAZ0110/20-3-07IF)).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Astafev, P., Zhidel, K., Reizenkind, J., Pavlenko, A., Shilkina, L., Reznichenko, L. (2023). Microwave Absorbing Properties of Modified Solid Solutions Based on Bismuth Ferrite and Lead Ferroniobate with Different Degrees of Porosity. In: Parinov, I.A., Chang, SH., Soloviev, A.N. (eds) Physics and Mechanics of New Materials and Their Applications. Springer Proceedings in Materials, vol 20. Springer, Cham. https://doi.org/10.1007/978-3-031-21572-8_17

Download citation

DOI: https://doi.org/10.1007/978-3-031-21572-8_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-21571-1

Online ISBN: 978-3-031-21572-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)