Abstract

European coal production underwent a period of dramatic increase from the early nineteenth century to 1913. A consensus exists, however, for a depiction of the coal industry as, to a high degree, technologically stagnant throughout the long nineteenth century. Macro-inventions, or general-purpose technologies, in fact, appeared at either end of the period. Steam power to drive water pumps and shaft elevators was introduced in the eighteenth century, while the application of mechanical power to different tasks and the electrification of mines were advances that became pervasive in the twentieth century. In the interregnum, therefore, the increase in European coal production would have mainly been the result of adding more labor rather than developing new technology. This paper aims to revise this interpretation. First, long-term series of labor productivity and fatality rates data are presented for the four main coal-producing European nations, Great Britain, Belgium, France, and Germany. Second, a link between improvements in Europe both in productivity and safety in conjunction with a series of “small-scale” technological innovations is proposed. These technologies, which emerged and diffused to affect different aspects of mining production, did not involve huge investments in labor-replacing capital. They were, for the most part, complementary to labor and closely related to questions of safety. A comparison of both estimates, labor productivity and safety, for the European countries is also established with those of the United States, a latecomer to the exploitation of coal resources.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

16.1 Introduction

The fuel of the European Industrial Revolution was coal. Data for eight European countries compiled by Kander et al. (2013, pp. 131–132) show that coal consumption per capita grew sevenfold between 1820 and 1910. More than four-fifths of Western Europe’s energy supply came from coal on the eve of World War I (Kander et al. 2013, p. 132). Britain was the leader in coal exploitation, in large measure due to its development of coking and pumping technologies (Allen 2009).Footnote 1 However, although in the second half of the nineteenth century Britain still produced more coal than the rest of Continental Europe combined, a few countries became large-scale producers. Between the early 1830s (a point when statistical sources on coal improved for some of the major producing nations) and 1913, coal production in Britain and Belgium grew by a factor of 9, and a factor of 20 in France. While in Germany (Prussia), between 1850 and 1913, coal production grew by a factor of 41 (See Table 16.1). In 1913, these four countries accounted for 86.6 percent of the European output, according to data collected by Mitchell (1992) (See Table 16.2).

The different parts of Europe from which coal was won tended to be highly localized. In a broad geological sense, much of Europe’s coal formed a discontinuous belt from coalfields in the North and the Midlands of Britain to Silesia, via the Nord and Pas-de-Calais coalfields in France, central Belgium, and the Ruhr. Other important coalfields included those in South Wales, the Loire Valley, and the Saar-Lorraine (e.g. Pounds and Parker 1957; Wrigley 1961; Leboutte 1997). It is true that, for example, France had many scattered coal basins throughout the country, but most of them were of little importance. The actual availability of coal has been one of the main topics in the discussion about the causes of the European Industrial Revolution.Footnote 2 It has been argued that coal could have been transported, as indeed it was to non-producing regions and countries. In spite of the uneven advance of coal across Europe over the nineteenth century (Kander et al. 2013, p. 137; Henriques and Sharp 2021), national and international coal markets became more integrated, especially up to the turn of the century, reflecting a decline in transaction costs (Murray and Silvestre 2020).

A stronger consensus, however, exists for another of the main topics involving coal: the coal industry has been depicted as, to a large extent, technologically stagnant, and unable to make significant gains in productivity throughout the long nineteenth century. Far-reaching macro-inventions, or general-purpose technologies, in fact, appeared at either end of the period. On the one hand, steam power to drive water pumps and shaft elevators was introduced in the eighteenth century. The Newcomen engine, mainly but not exclusively, was first adopted in Britain and then in the main Continental European coalfields (e.g. Pounds and Parker 1957, pp. 81–82; Wrigley 1961, pp. 14, 27; Leboutte et al. 1998, p. 46; Allen 2009, pp. 161–163; Mokyr 2009, pp. 269–270; Kander et al. 2013, p. 165).Footnote 3

On the other hand, the application of mechanical power to different tasks pertaining to coal extraction and (horizontal and vertical) transportation of coal, miners, and equipment, as well as the electrification of mines, although in some cases introduced during the period being studied (or earlier), were advances that, with some exceptions, did not become pervasive until the twentieth century. For example, coal-cutting machines, at first usually powered by compressed air and later by electricity, diffused slowly because of problems of motive power, maintenance, and reliability, not to mention the geological conditions of mines, safety issues, and the reorganization of labor. On the eve of World War I, 8 percent of coal was mechanically cut in Britain (although 20 percent in Scotland), 10 percent in Belgium, and below 3 percent in the Ruhr (Bézy 1951, p. 39; Milward and Saul 1973, p. 187; Greasley 1990, p. 883; Scott 2006, p. 27; Jopp 2016, p. 1117).Footnote 4 As a consequence of the adoption of more productive coal-cutting machines, another sweeping innovation, the conveyor (as a replacement for wagons and rails), was first used in Britain in 1902. By 1928, only 11.8 percent of British coal was face conveyed (Scott 2006, p. 27). In Continental Europe, the expansion of conveyors first began in Germany (Rice and Hartmann 1939, p. 167).

Drilling may have required less energy than coal cutting and, consequently, may have been more diffused. But, again, compressed air technology, even if well established by the 1880s, had its limitations (e.g. Lamb 1976, p. 165; Hickey 1985, p. 112; Church 1986, p. 344; McIvor and Johnston 2007, p. 34). The use of steam and compressed air for transportation purposes, although it gradually became more prevalent, also suffered from limitations in power transmission and safety (e.g. Hay 1924; Poole 1924). Electric locomotives appeared or began to consolidate only at the end of the period. Similarly, some portable electric lights appeared in the final years of the century, but (perhaps) the most successful early electric lamp did not materialize until 1912, in Germany (Maurice 1937, p. 367). While (safer) electric detonators were beginning to appear by the end of the nineteenth century (Guttmann 1895a, p. 333).

In the interregnum, therefore, the dramatic increase in European coal production would have mainly been the result of adding more labor rather than developing new technology. References, usually brief, to the illumination and ventilation of mines, the use of explosives, or better transport systems are actually not uncommon in the economic and social history literature. However, as epitomized by Milward and Saul (1973, p. 187), in the nineteenth-century coal industry, “Like house building, the industrial revolution to a major degree passed it by.” And, as more recently argued by Stewart (2003, p. 518) with regard to mining in general, “real productivity gains would have to await the substitution of capital for labor in the drilling, boring, and movement of ore underground.” For the particular case of Britain, Wrigley (2016, p. 42) concludes, “It is an interesting irony of the period during which the English economy was transformed by the energy derived from coal that manpower productivity in the coalmining industry barely changed….” Similar arguments can be found in Benson (1989, p. 7), MacRaid and Martin (2000, p. 29), Ó Gráda (2016, p. 230), and the works cited therein. Thus the question is posed by Clark and Jacks (2007, p. 47): “Might the absence of an ‘unceasing flow of technical advances’—safety lamps, gunpowder in shaft excavating, improved winding gearing, ventilation systems, and so on—have driven up costs in the nineteenth by hundreds of percent?”Footnote 5

Studies of coal mining productivity at national or regional levels tend to share two characteristics. First, they usually focus on the late-nineteenth and early-twentieth centuries, a period of stagnant or even decreasing productivity (an issue to which I will return below), thus overlooking the dynamics of a longer-term evolution (e.g. Lamb 1976, esp. p. 155; Greasley 1990; Burghardt 1995, p. 382; Scott 2006; Broadberry and Burhop 2007; Burhop 2008; Burhop and Lübbers 2009). However, Clark and Jacks’ (2007) estimates focus attention on the early English Industrial Revolution, between 1700 and 1869, showing a very modest productivity growth.Footnote 6 Longer-term analyses include Mitchell (1984, esp. p. 317), Church (1986, esp. pp. 470–496), and Jopp (2017).Footnote 7 Second, these studies predominantly refer to Britain and Germany, specifically the Ruhr area.Footnote 8 While granting less coverage to other major producing countries such as Belgium and France. Exceptions would include Wibail (1914), de Bivort de La Saudée (1939), Bézy (1951), and Wauthelet (1997).

This essay aims to revise the interpretation of the European coal industry as, in essence, technologically stagnant. In the next section, long-term series of labor productivity and fatality rates data are presented for the four main coal-producing European nations, Britain, Belgium, France, and Germany. The measurement of productivity used, although elementary, suggests a less bleak picture, with marked increases, notably in Continental Europe, up to approximately the late 1880s, or a little earlier in the case of Britain. The consideration of safety responds to the key fact that the capital introduced into mines was, for the most part, complementary to labor and closely related to questions of safety. Fatality rates show a considerable decline up to the turn of the century. A comparison of both estimates, labor productivity and the fatality rate, is established between the European countries and the United States, a latecomer to the exploitation of coal resources. Between 1850 and 1913, however, production in the United States grew by a factor of 68 (see Table 16.1). While its share of world production raised fourfold, to reach almost 40 percent of the world total (see Table 16.3).

Section 16.3 proposes a link between “small-scale” technological advances and improvements both in productivity and safety, as previously argued by Murray and Silvestre (2015) for the case of safety. Although no new large-scale technology appeared, or entered mainstream use, over the period, a series of relatively small-scale technologies emerged and diffused, within and between countries, to affect different aspects of mining production. Unlike the later mechanization of coal extraction and transportation, technologies in mine construction, working methods, transport, lighting, ventilation, and explosives did not tend to involve large scale investments in labor-replacing capital (e.g. Lamb 1976, p. 219; Mokyr 2010, p. 45; Murray and Silvestre 2015).Footnote 9 These methods permitted much more work without interruptions due to serious accidents, as well as an increase in job-specific human capital. The consequences of the aforementioned small-scale innovations have largely been overlooked, especially in the economic history literature.Footnote 10

16.2 Labor Productivity and Fatality Rates in the Long-Term

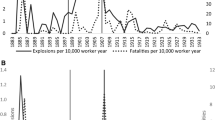

Figures 16.1, 16.2, 16.3, 16.4, and 16.5 report (mostly) annual estimates of labor productivity and fatality rates for the four major European producing countries and the United States. Data for Prussia rather than Germany are used, since official statistics of accidents for the whole country seem not to have been published (Wright 1905, p. 326; Horton 1913, p. 66). Most German production occurred within the boundaries of Prussia, however. The collection of European data by labor statistician Carroll Wright (1905) was the starting point.Footnote 11 Wright (1905) was also used as a guide in order to check values and extend some series forward, as he included an exhaustive list of primary sources, i.e. government publications. The database was completed using secondary literature, particularly in the cases of Britain and Germany. The main US data (in Fig. 16.5) are taken entirely from (Gavin) Wright (2006) and Aldrich (1997a). The list of sources used for each period is included in the Notes to Figs. 16.1, 16.2, 16.3, 16.4, and 16.5. Supporting data reported in Tables 16.4, 16.5, and 16.6 are mainly taken from US official publications.

Labor productivity and the fatality rate in coal mining, Great Britain, 1800–1913. (Notes: Production includes coal extracted from open quarries. The records do not generally distinguish between bituminous and anthracite, but only small amounts of the latter were produced. The fatality rate for 1813 and 1842 refers to the North-East coalfield only. Sources: Productivity, 1800, 1816 and 1820: Mitchell (1984, p. 317); 1831 and 1841: Church (1986, p. 472). Production, 1851–1913: Church (1986, p. 86). Workers, 1851–1913: Wright (1905, p. 416) and Church (1986, pp. 304–305). Fatality rate, 1813 and 1942: Hair (1968, pp. 553, 559–560). Fatalities, 1851–1903: Wright (1905, p. 444); 1904–1913: data compiled by Arthur McIvor, originally taken from Board of Trade, Abstract of Labour Statistics (various years). See also Murray and Silvestre (2015) for the sources used for cross reference purposes)

Labor productivity and the fatality rate in coal mining, Belgium, 1833–1913. (Sources: Production, 1833–1903: Wright (1905, pp. 113–114); 1904–1913: Ministère de l’Intérieu (1904–1913). Workers, 1833–1903: Wright (1905, p. 118); 1904–1913: Ministère de l’Intérieu (1904–1913). Fatalities, 1833–1903: Wright (1905, p. 141); 1904–1913: Ministère de l’Intérieu (1904–1913). See also Murray and Silvestre (2015) for the sources used for cross reference purposes, as well as Feldman and Tenfelde (1990, pp. 396–400))

Labor productivity and the fatality rate in coal mining, France, 1834–1913. (Notes: Small amounts of anthracite and lignite were produced, and usually reported separately. Production of bituminous, anthracite, and lignite combined are included here. Sources: Production, 1833–1903: Wright (1905, pp. 184–185); 1904–1913: Ministère des Travaux Publics (1904–1913). Workers, 1833–1903: Wright (1905, p. 197); 1904–1913: Ministère des Travaux Publics (1904–1913). Fatalities, 1833–1903: Wright (1905, pp. 209–210) and, for 1859, Conus and Escudier (1997a); 1904–1913: Ministère des Travaux Publics (1904–1913). See also Murray and Silvestre (2015) for the sources used for cross reference purposes, as well as Feldman and Tenfelde (1990, pp. 396–400))

Labor productivity and the fatality rate in coal mining, Prussia, 1852–1913. (Notes: Steinkohle (hard coal). Sources: Production and workers: Fischer (2011). Fatalities, 1852–1903: Wright (1905, p. 326); 1904–1911: Horton (1913, p. 66); 1912: US Bureau of Labor Statistics (1916, p. 65); 1913: Rice and Hartmann (1939, p. 257). See also Wright (1905) and Murray and Silvestre (2015))

Productivity is simply defined in terms of output per worker. As for the numerator, Figs. 16.1, 16.2, 16.3, 16.4, and 16.5 refer to the types of coal considered.Footnote 12 Both under and above ground work were considered when forming the denominator. Under ground work normally comprised three broad actions: hewing, transportation (of coal and miners), and development and maintenance (for example, roofing). Above ground work included the preparation and transport of coal, working the engines (such as those of pumps and fans), and a wide range of jobs that were necessary for mining operations (e.g. Church 1986, pp. 311–385; McIvor and Johnston 2007, pp. 28–32). The relative number of above ground workers may vary between countries (Aldrich 1997a, p. 65).

More precise measures of productivity, such as output per shift, output per hour, and total factor productivity, have been estimated for some countries, regions, or firms before World War I (e.g. Mitchell 1984; Church 1986; Greasley 1990; Scott 2006; Clark and Jacks 2007; Burhop and Lübbers 2009; Jopp 2016, 2017; Montant 2020). However, given the scarcity of data, these estimates usually refer to relatively short periods or specific dates. Trends, in any case, tend to coincide with simpler measures. Discrepancies may nevertheless emerge, for example, that between Church (1986, pp. 474–480) and Greasley (1990) concerning output per hour at the turn of the century. Table 16.4 reports an international comparison of daily productivity for the 1901–1913 period.

The lack of reliable statistics in Britain before 1872, and especially before 1854, has led to a lively debate (e.g. Mitchell 1984; Church 1986; Minchinton 1990; and the works cited therein). In Fig. 16.1, I took the liberty of, essentially, splicing in Church’s (1986) annual (from the middle of the century) and decennial (1831 and 1841) estimates with Mitchell’s (1984) roughly decennial (1800, 1816, and 1820) estimates. The big jump over the 1820s is remarkable and, to a large extent, possibly determined by, first, the fact that 1800, 1816, and 1820 were depression years (Mitchell 1984, p. 313); and, second, Church’s (1986, pp. 85–88) upward re-estimation of output from 1831 onwards. Furthermore, sparse information on output and the number of workers for the early decades of the nineteenth century points to considerable regional variation (Flinn 1984, pp. 361–366).

The alternative approach by Clark and Jacks (2007) shows modest productivity growth between 1700 and 1860. Nevertheless, the authors’ estimates may have underplayed, to some extent, the role played by the steam engine in mine drainage. Thus, it would not only have been a matter of costs, but also the existence of technological constraints in the use of horses in the deepest mines (Kander et al. 2013, p. 165).Footnote 13 This point was made previously by the mining engineer and colliery manager Robert L. Galloway ([1882] 1969, p. 82). It has also been argued that Clark and Jacks (2007) may have understated improvements such as those in ventilation, which became essential as depth increased (Mokyr 2009, p. 102). (I will return to mine depth below).

The fatality rate, i.e. deaths per 10,000 workers, is used as the measure of safety. Non-fatal accidents may also have been considered, but data are less widespread and much more ambiguous (e.g. Murray and Silvestre 2015, p. 901).Footnote 14 Both below and above ground workers again form the denominator. An alternative measure of safety, deaths per 1000,000 metric tons mined, is reported in Table 16.5, and will be particularly helpful in the Europe-US comparison. Table 16.6 accounts for differences in the number of working days.

As the British expansion of coal started earlier than the systematic record of fatalities, Fig. 16.1 includes estimates of risk for 1813 and 1842 provided by Hair (1968). It must be noted that these fatality rates refer only to the North-East coalfield, for which the available information is more abundant and reliable. The North-East was the most important coalfield, accounting for 30 percent of total output and 23 percent of total employment around 1800, and 22 percent of total output and 20 percent of total employment between 1830 and 1850 (Flinn 1984, pp. 26, 363–365; Church 1986, pp. 10, 189). However, it was also the most dangerous coalfield in terms of explosions, and that in which safety improved the most over the first half of the century thanks to the control of mine gases. In the other British coalfields, the decline in death rates from explosions was probably lower, and the decline in death rates from other causes may have been slight at best. Therefore, “it is probable that all the gassier coalfields showed some improvement, and it is possible that the remaining coalfields showed little or no improvement” (Hair 1968, p. 560).

International, long-term comparisons of productivity and safety are not straightforward. Productivity and risks were, first and foremost, determined by natural conditions, such as geological folding and faulting, thickness and depth of coal seams, the strength of roofs and the presence of gasses, and the resultant mining methods. In broad terms, the US and the Upper Silesian coalfield (the second German coalfield in importance, after the Ruhr) had less difficult conditions than Britain, which in turn had better than or similar conditions to the Ruhr coalfield; while the northern (Nord and Pas-de-Calais) French coalfields and Belgium, in particular, tended to display the most difficult mining conditions (Horton 1913, pp. 88–89; Rice and Hartmann 1939, esp. pp. 55, 88, 94, 255, 312; Pounds and Parker 1957, esp. p. 131; Aldrich 1997a, ch. 2; Scott 2006, p. 23; see also Wrigley 1961, p. 55). Other, sometimes interrelated, factors, such as the number and the length of working days, labor relations, and differences between the US and Europe in the extent of mechanization and government intervention in safety will be (briefly) addressed below. In any case, all of these are limitations to be borne in mind when interpreting the evidence.

In Figs. 16.1, 16.2, 16.3, and 16.4, the series of productivity and accident risk for the main European producing countries reveal largely similar trends. Productivity in Continental Europe increased up to approximately the late 1880s, when it stagnated or even declined slightly. In Prussia, from mid-century, productivity jumped by two-thirds to about 250 tons. From the early 1830s, French and Belgian miner productivity doubled. British increase, up to the early 1880s, was lower. From that point onwards, productivity tended to fall. Therefore, a convergence process occurred among the less productive countries, which came to approach the relatively static British levels of productivity. Prussia caught up with Britain by the early 1890s, while the smaller producers, Belgium and France, increased productivity more gradually. Differences in productivity levels tend to reflect differences in natural disadvantages (see also Table 16.4).

In Britain, several causes acting simultaneously have been proposed so as to understand the generally poor performance from the 1880s to 1913.Footnote 15 It seems that the evolution of geological conditions could be the most determining factor, in the form of higher average depths, exhaustion of thicker seams, and aging of mines, the latter resulting in higher transportation and maintenance costs. Labor-related factors, such as absenteeism and reduction in work effort or hours worked, the latter mainly as a result of legislation, in general, seem to play a minor role in the long-term explanation (Mitchell 1984, 321–326; Church 1986, 470–496; Greasley 1990).

In reality, Figs. 16.1, 16.2, 16.3, and 16.4 may suggest that forces common to all major producing nations contributed to flattened out productivities from the end of the century onwards. As the nineteenth century progressed, worsening mining conditions resulting from the increasing scale of production and the length of time the mines were in operation have also been emphasized for Continental European countries (Wibail 1914, pp. 11–12; de Bivort de La Saudée 1939, p. 23; Gillet 1984, p. 17; Leboutte et al. 1998, 49). Thus, for example, in Belgium the average depth was 210 meters in 1838, 361 meters in 1856 (in the west of Mons), and 437 meters in 1866 (in the same area) (Pounds and Parker 1957, p. 131). In the Ruhr coalfield, the average depth was 134 meters in 1850, 172 meters in 1861, and 523 meters in 1913 (Jopp 2011, p. 82). A similar process occurred in France (Lamb 1976, p. 182). To the best of my knowledge, the effect of labor-related factors in Continental Europe is also not clear-cut. Regardless of which, in all the major coal-producing nations, including Britain, the labor movement strengthened and the incidence of strikes tended to rise from approximately the late 1880s onwards (Feldman and Tenfelde 1990, esp. pp. 25–27, 133, 226, 275–278; see also Hickey 1985, pp. 170–171; Parnell 1994 pp. 22–23; Wauthelet 1997).

Safety improved markedly throughout the period being studied. In Britain, Belgium, and France (Figs. 16.1, 16.2, and 16.3; Table 16.5) the risk of a fatal accident declined at least from when there are systematic records, from midway through the century, whereas in Prussia such a decline began later but was still evident from the mid-1880s (Fig. 16.4; Table 16.5). Belgian and French data compiled by Leboutte (1991) and Conus and Escudier (1997b), respectively, show that, as also probably happened in Britain, the decline could have started in earlier decades. Turning to the Figures presented here, in British and French mines the risk of mortality dropped by about 75 percent, from roughly around 40 per 10,000 in the middle of the century to just over 10 per 10,000 by the early 1910s.Footnote 16 In Belgium, the risk of death fell by two-thirds, from about 30 to 10 deaths per 10,000 workers. This is remarkable given the dangerous geological conditions of Belgian mines. Death rates in Prussia at the end of the period, although uneven, were uniquely high in Europe (see also Leboutte 1989; Martin 2009). Overall, declining trends in European countries applied to death rates from different causes, such as explosions and cave-ins, which were usually the most destructive (e.g. Hall and Snelling 1907; Murray and Silvestre 2015).

While the fundamental argument of this essay is that new technologies were hugely important in explaining trends in productivity and safety, the emphasis on technology alone as the causal agent in improvements cannot be entirely accurate. It has been proposed that, in general, regulation and technological change are interrelated; to put it simply, newer and better technologies may be adopted as a response to regulatory incentives (Pouliakas and Theodossiou 2013, p. 195), a point that has actually been made regarding the adoption of more productive and safer technologies and methods in European coal mining in the nineteenth century (e.g. Lamb 1976, p. 252; Leboutte 1989, p. 88; Singleton 2016, p. 111). Over this period government action included mine inspection laws that aimed to prompt mine owners into making collieries safer under threat of legal sanctions. In Britain, for example, mining was one of the first industries to be regulated (Singleton 2016, p. 109).

However, the British case indicates little direct effect of legislation on actual safety conditions (e.g. Bartrip and Burman 1983; McIvor and Johnston 2007, esp. p. 47; Mills 2010). Public intervention in the nineteenth-century coal industry was complex to design and implement, with the interests of several groups at stake (e.g. Mills 2010). The evidence for other European countries seems to be mixed (e.g. Lamb 1976, esp. pp. 244–252; Reid 1981; Leboutte 1989, 1991; Conus and Escudier 1997b; Murray and Silvestre 2015), though the Belgian record above all has received considerable attention, as mentioned above. In the words of Jevons ([1915] 1969, p. 375): “[It] reflects credit upon the mine engineers and the legal regulation for the protection of the workers”.

In any case, it appears from the secondary literature that detailed and rigorous government regulation in Europe tended to occur after the onset of the decreasing trend in the risk of fatal accident. As an example, mainly from the 1880s onwards, government-appointed commissions collected evidence that helped to delineate revisions of already existing safety regulations regarding explosion risks, acknowledging coal dust as a factor; and the Courrières disaster in 1906 reinvigorated research on the prevention of explosions (Murray and Silvestre 2021). Two further determinants that may have contributed to an improvement in safety were accident insurance systems, which, when well-designed, provided incentives to reduce workplace dangersFootnote 17; and stronger unions, which took up the cause of mine safety.Footnote 18 But, again, these were factors that tended to appear toward the end of the period being studied.

It is worth comparing Europe with the United States. The abundance of wood delayed the latter’s transition to coal (Wright 2015). The anthracite coalfields of Pennsylvania were fully opened in the 1830s (Chandler 1972; Aldrich 1997b). But anthracite was overtaken by bituminous coal, the extraction of which expanded rapidly after the Civil War. Output and employment, even if they fluctuated, grew considerably until the early 1920s (e.g. Dix 1977, p. xiii; Fishback 1992, pp. 19–21; Matheis 2020; see also Table 16.1).

Figure 16.5 shows that productivity levels in the United States were higher than in Europe (as shown in the previous figures). At the end of the period (three-year average around 1912) productivity in anthracite US mining was approximately 2–3 times higher than in Europe.Footnote 19 Productivity in US bituminous mining, by comparison, was approximately 2.5–4.5 times higher.Footnote 20 Daily productivity per underground worker reported in Table 16.4 provides largely similar estimates (with respect to bituminous coal in the United States). As explained above, natural conditions tended to be more advantageous in the United States than in Europe. Mark Aldrich (1997a, pp. 42–43) demonstrates that in the United States, less difficult, and therefore cheaper, access to coal, and more expensive labor and capital, together with the abundance of timber (for roof control), led to room-and-pillar working methods being preferred to longwall mining. Room-and-pillar methods yielded quicker returns and higher labor productivity than longwall techniques, which however spread from the 1830s onwards first in Britain and then in Continental Europe (Aldrich 1997a, pp. 44, 63; see also Church 1986, p. 336). (I will return to this issue in the next section). The mechanization of coal extraction and transportation also spread faster in the United States, notably in bituminous mines. The use of coal cutting machines, first introduced in the 1870s, accelerated in the early decades of the twentieth century. In 1915, 55.3 percent of the total national coal was mechanically cut; the percentages were higher in the four main producing states (in 1900): Illinois, Ohio, Pennsylvania, and West Virginia (Dix 1977, p. 20). The application of mechanical power to the transportation of coal, including locomotives, also accelerated in the same period (Rice and Hartmann 1939, p. 161; Dix 1977, p. 28).

The inverse in US mining was that, for a number of reasons, the predominant room-and-pillar methods tended to not only be more productive but also more dangerous (Aldrich 1977a, pp. 63–65). Safety was also costly to miners (Boal 2018). In addition to this, the mechanization of different tasks, although often leading to increasingly less hazardous working environments, may also have brought their own risks at first (Rice and Hartmann 1939, pp. 50–51, 268; Aldrich 1997a, pp. 58–60). Furthermore, in many respects, state intervention in the United States may not have been as relevant to the reduction of risks as interventions in European countries toward the end of century probably were (Fishback 1986, 1987, 1992, ch. 7; Aldrich 1995, 1997a, esp. pp. 67–75; compare with Boal 2018, p. 135). As an example, an expedition of three well-respected European experts made recommendations on the backward state of safety in the United States (Watteyne et al. 1908).Footnote 21 In short, safety deteriorated as production increasingly intensified. Figure 16.5 shows that the fatality rate (per 10,000 workers) in bituminous mining worsened from the 1880s onwards, while it did so in anthracite mining from the 1880s or 1890s onwards.Footnote 22 Table 16.5 provides a combined rate, including both bituminous and anthracite mining. Whereas Table 16.6, for selected countries, reports a contemporary estimate that accounts for both differences in the number of days worked and the actual number of miners working underground. Table 16.5 consists of the safety rate on the basis of employees (Panel A) and also of production (Panel B). This complementary rate, however, is much more favorable to the United States as a result of its greater capacity for production.Footnote 23

16.3 Small-Scale Technologies in Europe: A Brief Review

In the virtual absence of large-scale technologies, I focus on small-scale innovations that may have contributed to the improvement of both productivity and safety throughout the long nineteenth century.Footnote 24 Mokyr’s (1990, p. 13) definition of “micro-inventions” as “small, incremental steps that improve, adapt, and streamline existing techniques already in use,” and Engerman and Rosenberg (2016, p. 442) references to the incremental, rather than discontinuous, nature of certain innovations and the “learning by using” process, are helpful here.Footnote 25

It may be added that, although technologies appeared to manage discrete problems of coal mining, the effectiveness of each sometimes depended on others, as in the case of the interaction between lighting, ventilation, and explosives. Improvements in these three particular areas were, in large part, the response to explosions provoked by methane gas (firedamp) and, sometimes, its interaction with coal dust. As stated above, together with landslides and cave-ins, explosions tended to be the most important determinant in the high numbers of death and injuries to coal miners. Moreover, although statistically infrequent, explosions often caused further costs derived from the interruption of the mining activity and the destruction of the capital stock, as well as, from a certain time onwards, workers’ compensation schemes. Explosions were certainly feared, as reflected in the press and folklore around mining communities.

An essential part of the success of innovations was their smooth national and international diffusion. The results of research appeared in government publications, privately-issued memoirs, and the mining press continent-wide.Footnote 26

The works of boring for prospecting purposes, shaft sinking, and road construction were the first steps in the mining process. Prospecting actually started with geological research. In Britain, from the late eighteenth century onwards, the reliance on geology grew along with its practical, local-based approach, which was close to the mining industry (Veneer 2006; Mokyr 2009, p. 140). Geological and related knowledge expanded and systematized across Europe as the century progressed (Ranestad and Sharp 2021). A key advance was the identification of flooding risks (e.g. Conus and Escudier 1997b, p. 53). Boring technology, albeit slowly, improved throughout the entire period. Several innovations, such as the application of steam power, the use of water to lubricate the chisel, the possibility of using ropes (instead of rods), and diamond core drilling, were introduced or consolidated in the middle decades of the nineteenth century (Lupton 1893, pp. 51–79; Brown 1924a, pp. 27–28; Church 1986, p. 313). Given the depth of European mines, sinking vertical shafts was, by far, the most common way of accessing coal.Footnote 27 Sinking technology evolved considerably in order to overcome difficulties such as the presence of water and firedamp (Jevons ([1915] 1969, pp. 181–201; Church 1986, pp. 315–318). For example, the use of just one compartmentalized shaft was often replaced with the construction of two separate shafts, an improvement that reduced the number of fires and explosions. The downcast shaft carried fresh air into the mine from above, and the upcast shaft carried warmer stale air and firedamp to the surface. Underground, main, and secondary, roads (and pillars) permitted access to the seams, and sustained transportation, ventilation, and water drainage. Different techniques across countries were developed over time to avoid landslides and cave-ins (e.g. Leboutte 1991, pp. 727–730).

As explained above, in Europe room-and-pillar mining tended to be replaced with longwall mining as the nineteenth century advanced (see also Jevons ([1915] 1969, pp. 202–209; Lamb 1976, pp. 176–177; Mitchell 1984, pp. 71–75; Church 1986, pp. 328–340; Weisbrod 1990, p. 140; Burghardt 1995, pp. 80–86; Mills 2010, pp. 117–118). In room-and-pillar methods the miners worked in the midst of the vein (the room), removing some coal and leaving great blocks of it to hold up the roof (the pillars). In longwall methods many miners worked on a long face. The removed stone, slate, or other scrap materials were packed in their wake, forming the gob or goaf that held up the roof. In terms of safety, longwall methods were frequently necessary at great depths, and more suitable to larger spaces. For example, longwall mining required less ventilation and was less subject to roof and wall collapses (e.g. Murray and Silvestre 2015).

Transport in the mining process involved the movement of coal from the face to haulage roads and shaft bottom, and then to the surface, and the movement of miners and equipment between surface and work site (Church 1986). At the beginning of the nineteenth century, women and children were typically employed to drag baskets of coal or push wheeled tubs. As women and children began leaving mines, they tended to be replaced with ponies, as well as mules or horses. Moreover, a number of procedures were created to enable the tubs to be moved with a minimum of effort, such as slopes and supplementary rails carrying counterweights. Later, different devices such as endless ropes powered by steam engines pulled the tubs toward shafts (e.g. Poole 1924, pp. 89–100; Mitchell 1984, pp. 77–79; Church 1986, pp. 367–369). From the 1830s and 1840s onwards, usually steam-operated, winding apparatus that substituted early systems based on baskets, or ladders, included, first in Prussia, stronger wire ropes that replaced hemp ropes; guided shaft cages and protected shafts to avoid impacts from oscillation; and, more commonly in Continental Europe, ratchets on which the cage would be caught in the guiding rail should the central rope break (Galloway [1882] 1969, pp. 211–219, 259; Brown 1924b; Lamb 1976, pp. 170–172; Leboutte 1991, p. 727; Conus and Escudier 1997b, p. 58). In Britain, in the case of overwinding, safety hooks which disengaged the cage tended to be preferred (Abel 1889, p. 112).

The fundamental challenge of lighting in coal mines was to keep the source of the light away from the ambient methane that formed naturally with coal. Certain concentrations of gas would explode in the presence of an open flame, such as that of a candle. The problem with other kinds of illumination, such as reflecting the sun’s rays from a mirror or generating sparks from striking a flint, was that they yielded very little light (e.g. Smyth 1890, pp. 190–192). The earliest safety lamps, including the best known by Sir Humphry Davy (1815), appeared in Britain early on in the nineteenth century. All worked on roughly the same principle: metal screens shielded the flame from the methane, producing relatively little light but more safely than open flames. Safety lamps were also used to detect the presence of firedamp. In its presence, flames became blue and elongated. The earliest safety lamps, designed to work in still air, however, became obsolete when mechanical ventilators created a continuous current along the galleries that extinguished the flames.Footnote 28 The first generation of safety lamps was a great step forward, although they remained problematic (e.g. Galloway ([1882] 1969, p. 268; Church 1986, pp. 325–326; James 2005; Mills 2010, p. 16).

Thus, although these lamps became widely used until the century was well advanced, newer lamps, or modified versions of old ones, provided by many inventors appeared elsewhere (e.g. Hardwick and O’Shea 1915, p. 620; Trotter 1982, ch. 1). For example, the Mueseler lamp was invented in 1831. Endorsement by a Belgian government commission followed by a government mandate requiring those lamps in 1851 led to its widespread adoption in that country’s mines (e.g. Leboutte 1991, pp. 722–723). The Mueseler lamp was also used in coalfields in other countries, at least until their limitations were demonstrated (Dickinson 1884; Abel 1889, pp. 88–89). This pattern was very common. Testing was continuous, because balancing all desired attributes in a safety lamp was difficult. A key issue was their capacity to detect firedamp at low concentrations, as the interaction of firedamp with coal dust could reduce the minimum level of concentration needed for ignition (Murray and Silvestre 2021). Another area of interest for research before electrification concerned lamp fuels. But perhaps the most remarkable characteristic of research on safety lamps was scope: the sheer numbers of lamps that were tested and the number of laboratories, governmental and private, built to test them throughout Europe (e.g. Heinzerling 1891; Hardwick and O’Shea 1915; Paul et al. 1924). As an example, among many others, a Royal Commission on accidents in mines appointed by the British government examined more than 250 safety lamps from Britain, Belgium, France, and Germany (Great Britain. Parliament. House of Commons Papers 1886, esp. p. 69).

The (to some extent) inaccuracy of lamps in detecting firedamp gave rise to the need for new ventilation systems to clear the air and new explosives to be used in the presence of small amounts of gas. In the mid-nineteenth century, apart from natural ventilation, the baseline method placed a furnace near the bottom of an upcast shaft. The hot air rose, drawing stale air out of the galleries toward the shaft and sending it upwards (e.g. Hinsley 1969). Many variations and improvements were developed, such as compound ventilation by Mr. Buddle (Moss 1924).Footnote 29 An alternative method was to produce steam (e.g. Atkinson 1892, pp. 55–65). A boiler could be built on the surface, to force steam downwards through a pipe that heated air in the shaft; or a boiler at the bottom of the shaft might either release steam or force it upwards. Furnaces and boilers, even in their most advanced forms, were relatively inexpensive, though at the same time often inefficient and unsafe. Efforts in Britain and Belgium to increase efficiency of steam jets proved futile, at least until the steam injector was developed in Germany in the early 1870s.

The ultimate successor of these (and other) technologies was the mechanical ventilator. These machines became more efficient over time. They were typically powered by steam engines, although attempts to provide underground ventilation through water-powered ventilators date as far back as the early seventeenth century. A mid-nineteenth century technology used steam to operate an air pump. A plunger worked like a piston and a so-called bell like a cylinder in a conventional steam engine. Horizontal ventilators enjoyed some popularity. The Archimedes’ screw principle may also have been applied. (e.g. Galloway [1882] 1969, pp. 253–254; Lupton 1893, pp. 214–217). By the early 1850s, inventors had produced ventilation machines that worked on different principles, which were subject to continual testing (e.g. Jicinsky 1905; Cory 2005, ch. 1).

Over the second half of the century the coal-producing nations engaged in further, related, research, often, as in the case of lamps and explosives, promoted by governmental commissions. Ventilation was also an active research area of mine safety. The desire to solve problems was decidedly strong in Belgium due to the widespread prevalence of firedamp (e.g. Decamps 1888–1889, pp. 92–93). Eventually the most effective technologies involved centrifugal fans, first developed there in 1841 (e.g. Hinsley 1969, p. 32). Rather than a set of rotary blades as in a common window fan, the typical arrangement for a centrifugal fan fixed blades onto a cylinder, which spun so as to direct the air flow across the axis of the cylinder rather than parallel to it. Centrifugal fans reversed the action of a waterwheel: rather than the fluid rotating the wheel to generate power, the power source rotated the wheel to push the fluid along. This simple description belies a host of technical problems, however, that needed to be resolved.

Some ventilation technologies gained popularity only within a certain region, while others were, albeit temporarily, adopted internationally. An excellent example of the international diffusion of a superior design was the machine patented in 1858 by the French-born engineer Théophile Guibal, who settled in Belgium (e.g. Arnould 1877, p. 121; Atkinson 1892, pp. 67–72, 94–95; Church 1986, p. 323). The shares of mines ventilated by mechanical fans had reached high numbers in European coalfields at the end of the period being studied.Footnote 30

Explosive materials were another technology that needed careful introduction into mines. Properly employed they could be a partial substitute for labor, in the digging of shafts and roads, and the releasing of coal from rock strata, but learning to use them took time and a willingness to experiment (Guttmann 1895a, b; Marshall 1915; see also Church 1986, pp. 340–341). By the early nineteenth century, gunpowder was used in some places. Methods of applying gunpowder in the actual winning of coal (as distinct from constructing a mine), in reality, changed little into the nineteenth century (e.g. Lupton 1893). The miner used a tool with a threaded head to drill a long and narrow hole into the coal, near the floor of the gallery so that the coal would be less likely to fall and shatter. He poured gunpowder into the hole and led a train of powder back to an acceptably safe waiting place. After lighting his end of the trail, he waited for the blast.

However, sources of potential improvement encompassed two types of explosive technologies: first, new kinds of explosives, and second, new ways to transmit the charge to the explosive material. In a parallel with safety lamps, it was critical to prevent energy that was intended for the explosive charge from contacting ambient explosive materials. The nature of those ambient materials, especially firedamp and coal dust, engaged the minds of some of Europe’s best-known scientists and engineers (Murray and Silvestre 2021).

Safety fuses, for example, to keep sparks from the firedamp and coal dust developed in Europe from the 1830s onwards. Innovations included the use of potassium chlorate (KClO3), the wrapping with a cable of jute and string, (then) metal or gutta-percha cases, as well as fuses that reached the charge more quickly (which enabled several shots to be fired at once); a sparkless fuse was patented in 1886 (e.g. Marshall 1915, p. 28; Crankshaw 1924). Developments in the explosive materials themselves also occurred over broad swathes of Europe (e.g. Leboutte, p. 724). At first, questions of stability limited the diffusion of new explosives (Guttmann 1895b, pp. 225–226). Not until the 1860s, when Alfred Nobel combined the extremely unstable compound nitroglycerin with diatomaceous earth to create dynamite, was a nitroglycerin-based compound stable enough to be widely used (Marshall 1915, pp. 31–32). Further developments included carbonite (a mixture of nitroglycerin, saltpeter, and flour), and ammonium nitrate (NH4NO3)-based explosives. At the end of the century, for example, improved management of the instability of potassium chlorate led to the British development of cheddite, which became widely used in French and German mines as well as those in Britain (Marshall 1915, pp. 31–36). Before widespread adoption, new explosives and detonating materials were extensively tested, usually by governmental commissions which appointed permitted lists in some countries or required specifications in others (e.g. Rice 1914, p. 555; Murray and Silvestre 2021).

16.4 Conclusions

The production of coal in Europe throughout the long nineteenth century grew dramatically. Economies of scale and increasing populations and incomes per capita have been proposed as the main contributing factors to this expansion, whereas there would have been few signs of a technological revolution (Clark and Jacks 2007, esp. pp. 39, 68–69). However, in the major European producing countries, increased demand seems to have been compatible with a series of small-scale technological innovations, beyond any new large-scale or general-purpose technologies, which may have contributed to the gain in labor productivity and safety. These innovations did not involve huge investments in labor-replacing capital (with the partial exception of explosives). Instead, the technologies were complementary to labor, as well as reducing accident-related interruptions and increasing job-specific human capital.

In terms of productivity, the Continental European nations exhibited a tendency toward convergence with Britain, the stagnating leader. In terms of safety, in three of the four major European producing nations the fatality rate fell to reach a plateau around 10 per 10,000 workers at the end of the period. The exception was Prussia, which along with other newer producing nations, such as the United States, tended to display worse safety records (Leboutte 1989, p. 85). However, a key difference between the Prussian and US safety trends was the opposing direction of their respective evolutions. In fact, in Europe, with the exception of the early Prussian case, increasing productivity and decreasing risk of fatal accident seem to have gone hand-in-hand. Intuitively, it might seem if workers were intent on extracting ever greater amounts of coal from ever more inaccessible deposits, the two variables would be positively rather than negatively related.

In any case, flattened out productivities and safety rates at the end of the period suggest that pre-World War I technological improvements presented decreasing returns as a result of mines becoming older and natural conditions worsening (Lamb 1976, p. 151; Mitchell 1984, p. 323; Church 1986, p. 482; Leboutte et al. 1998, p. 49: Jopp 2011, p. 82). New, and large, increases in, for example, productivity had to wait until the—it may be said—delayed mechanization and rationalization of the European coal industry that, with some national or regional variations, would take place in the Interwar period (Rice and Hartmann 1939, pp. 311–312; Greasley 1990; Scott 2006; Jopp 2016, 2017; Montant 2020, p. 98).

Notes

- 1.

See also Otojanov et al. (2020).

- 2.

- 3.

See also, for example, Otojanov et al. (2020).

- 4.

- 5.

Quotation marks in “unceasing flow of technical advances” are used by the authors, referring to Flinn (1984).

- 6.

The authors also review previous literature, including the cliometric account of coal in the British Industrial Revolution.

- 7.

- 8.

The Ruhr accounted for about 48 percent of German coal in 1880 and about 58 percent in 1913 (Burhop and Lübbers 2009, p. 503).

- 9.

The causes and effects of mechanization were actually varied. For Britain, see, for example, Jevons ([1915] 1969, pp. 212–213), who summarizes the general report of the Royal Commission of Coal Supplies, 1905. See also Melling (1996), McIvor and Johnston (2007, pp. 36–38), and the works cited therein. For Germany, see, for example, Spencer (1984, p. 94) and Jopp (2017, pp. 944–945). For the United States, see, for example, Rice and Hartmann (1939, p. 152) and Boal (2017).

- 10.

- 11.

On Carroll Wright’s work, see Leiby (1960).

- 12.

See also Murray and Silvestre (2020, pp. 673–674).

- 13.

- 14.

Chronic occupation-related diseases are studied in works such as that of McIvor and Johnston (2007).

- 15.

- 16.

In Britain, the spike in 1866 is associated with the explosion at the Oaks Colliery, which killed 334 men. A second explosion killed 27 members of a rescue team (e.g. Harvey 2016). In France, the spike in 1906 is associated with the explosion at the Courrières works in the Nord and Pas-de-Calais coalfields, which killed around 1100 miners (e.g. Neville 1978).

- 17.

Although see Guinnane and Streb (2015) on the limited success of the first compulsory German industrial accident insurance.

- 18.

- 19.

- 20.

- 21.

- 22.

The spike in the bituminous fatality rate in 1907 is associated with the explosion at the Monongah mine, which officially killed 362 miners (McAteer 2014).

- 23.

The coefficient of correlation between the two rates is 0.985 for Britain (1851–1913), 0.967 for Belgium (1851–1913), 0.966 for France (1853–1913), 0.523 for Prussia (1852–1912), and 0.707 for the United States (1870–1913).

- 24.

- 25.

- 26.

- 27.

Sometimes, outcrops permitted access to coal horizontally or by means of slopes.

- 28.

Moreover, miners, rather than returning to central lighting stations, could try relighting the lamp on the spot and risk an explosion of undetected firedamp.

- 29.

Swinging doors and road partitions or air pipes permitted fresh air to be directed where needed.

- 30.

Own unpublished data.

References

Abel FA (1889) Mining accidents and their prevention. Scientific Publishing Company, New York

Adams WW (1920) A miner’s yearly and daily output of coal. Mon Labor Rev 11:522–530

Aldrich M (1995) “The needless peril of the coal mine”: the Bureau of Mines and the campaign against coal mine explosions, 1910–1940. Technol Cult 36:463–518

Aldrich M (1997a) Safety first: technology, labor, and business in the building of American work safety, 1870–1939. Johns Hopkins University Press, Baltimore and London

Aldrich M (1997b) The perils of mining anthracite: regulation, technology and safety, 1870–1945. Penn Hist: J Mid-Atlantic Stud 64:361–383

Allen RC (2009) The British industrial revolution in global perspective. Cambridge University Press, Cambridge

Arnould G (1877) Mémoire historique et descriptif: bassin houiller du Couchant de Mons. Hector Manceaux, Mons

Atkinson AA (1892) A key to mine ventilation. Colliery Engineer Co, Scranton

Bartrip PWJ, Burman SB (1983) The wounded soldiers of industry: industrial compensation policy, 1833–1897. Clarendon Press, Oxford

Benson J (1989) British coalminers in the nineteenth century: a social history. Longman, London and New York

Bézy F (1951) Les phases de la conjoncture au sein de la firme: Les agencements cycliques des coûts de production dans un charbonnage belge, 1836–1939. Bulletin de l'Institut de Recherches Économiques et Sociales 17:29–74

Boal WM (2009) The effect of unionism on accidents in US coal mining, 1897–1929. Ind Relat 48:97–120

Boal WM (2017) The effect of unionization on productivity: evidence from a long panel of coal mines. Ind Lab Relat Rev 70:1254–1282

Boal WM (2018) Work intensity and worker safety in early twentieth-century coal mining. Explor Econ Hist 70:132–149

Broadberry S, Burhop C (2007) Comparative productivity in British and German manufacturing before World War II: reconciling direct benchmark estimates and time series projections. J Econ Hist 67:315–349

Brown EOF (1924a) The history of boring and sinking. In: The Mining Association of Great Britain (ed) Historical review of coal mining. Fleetway Press, London, pp 26–41

Brown EOF (1924b) The history of winding. In: The Mining Association of Great Britain (ed) Historical review of coal mining. Fleetway Press, London, pp 170–182

Burghardt U (1995) Die Mechanisierung des Ruhrbergbaus, 1890–1930. CH Beck, Munich

Burhop C (2008) The level of labour productivity in German mining, crafts, and industry in 1913: evidence from output data. Eur Rev Econ Hist 12:201–219

Burhop C, Lübbers T (2009) Cartels, managerial incentives, and productive efficiency in German coal mining, 1881-1913. J Econ Hist 69:500–527

Chandler AD (1972) Anthracite coal and the beginning of the industrial revolution in the United States. Bus Hist 46:141–181

Church R (1986) The history of the British coal industry, vol 3. 1830–1913, Victorian pre-eminence. Clarendon Press, Oxford

Clark G, Jacks D (2007) Coal and the industrial revolution, 1700–1869. Eur Rev Econ Hist 11:39–72

Conus MF, Escudier JL (1997a) Les transformations d’une mesure: la statistique des accidents dans les mines de charbon en France, 1833–1988. Histoire et Mesure 12:37–68

Conus MF, Escudier JL (1997b) Sécurité et transformations du système productif: application a l’industrie française du charbon (1817–1988). Enterprises et Historie 17:49–71

Cory WTW (2005) Fans & ventilation. Elsevier, Amsterdam

Crankshaw HM (1924) History of explosives used in coal mining. In: The Mining Association of Great Britain (ed) Historical review of coal mining. Fleetway Press, London, pp 82–88

De Bivort de La Saudée E (1939) Des rythmes séculaires d’expansion des industries houillères européennes dans leurs rapports avec les prix et les coûts de production. Bulletin de l’Institut de Recherches Économiques 11:3–38

Decamps G (1888–1889) Mémoire historique sur l’origine et les développements de l’industrie houillère dans le basin du Couchant de Mons. Mémoires et Publications de la Société des Sciences, des Arts, et des Lettres du Hainaut Series 5, 1, pp 7–274

Dickinson J (1884) On the Marsaut safety lamp. T Manchester Geol Soc 17:185–195

Dix K (1977) Work relations in the coal industry: the hand-loading era, 1880–1930. West Virginia University, Morgantown

Engerman SL, Rosenberg N (2016) Innovation in historical perspective. In: Diebolt C, Haupert M (eds) Handbook of cliometrics. Springer, Heidelberg, pp 433–445

Fay AH (1916) Coal-mine fatalities in the United States, 1870–1914. Statistics of coal production, labor, and mining methods, by states and calendar years. US Bureau of mines bulletin no 115. GPO, Washington, DC

Feldman GD, Tenfelde K (eds) (1990) Workers, owners and politics in coal mining: an international comparison of industrial relations. Berg, New York, Oxford and Munich

Fernihough A, O’Rourke KH (2014) Coal and the European industrial revolution. University of Oxford Discussion Papers in Economic and Social History no 124

Fischer W (2011) Steinkohle Königreich Preußen (1850–1914). In: Germany’s mining production statistics from 1850 to 1914. GESIS data archive https://dbk.gesis.org/dbksearch/sdesc2.asp?no=8448&db=e&doi=10.4232/1.10308. Accessed 15 June 2020

Fishback PV (1986) Workplace safety during the progressive era: fatal accidents in bituminous coal mining, 1912–1923. Explor Econ Hist 23:269–298

Fishback PV (1987) Liability rules and accident prevention in the workplace: empirical evidence for the early XXth century. J Leg Stud 16:305–328

Fishback PV (1992) Soft coal, hard choices: the economic welfare of bituminous coal miners, 1890–1930. Oxford University Press, New York and Oxford

Flinn MW (1984) The history of the British coal industry, vol 2. 1700–1830, The industrial revolution. Clarendon Press, Oxford

Foreman-Peck J (2006) A model of later-nineteenth century European economic development. In: Dormois JP, Lains P (eds) Classical trade protectionism 1850–1914. Routledge, London and New York, pp 318–341

Fouquet R (2008) Heat, power and light: revolutions in energy services. Edward Elgar, Cheltenham and Northampton

Galloway RL ([1882] 1969) A history of coal mining in Great Britain. David & Charles Reprints, Newton Abbot

Gillet M (1984) Histoire sociale du Nord et de l’Europe du Nord-Ouest. Recherches sur les XIXe et XXe siècles. Université de Lille, Lille

Greasley D (1990) Fifty years of coal-mining productivity: the record of the British coal industry before 1939. J Econ Hist 50:877–902

Great Britain Parliament. House of Commons Papers (1886) Final report of her Majesty’s commission appointed to inquire into accidents in mines. Eyre and Spottiswoode, London

Guinnane T, Streb J (2015) Incentives that (could have) saved lives: government regulation of accident insurance associations in Germany, 1884–1914. J Econ Hist 75:1196–1227

Guttmann O (1895a) The manufacture of explosives, vol 1. Whittaker & Co, London

Guttmann O (1895b) The manufacture of explosives, vol 2. Whittaker & Co, London

Hair PEH (1968) Mortality from violence in British coal-mines, 1800–50. Econ Hist Rev, 2nd ser 21:545–561

Hall C, Snelling WO (1907) Coal mine accidents: their causes and prevention. A preliminary statistical report. US Geological Survey Bulletin no 333. GPO, Washington, DC

Hardwick FW, O’Shea LT (1915) Notes on the history of the safety-lamp. T Instit Mining Eng 51:548–724

Harvey B (2016) The Oaks colliery disaster of 1866: a case study in responsibility. Bus Hist 58:501–531

Hay D (1924) The development of mechanical and electrical power in collieries since 1850. In: The Mining Association of Great Britain (ed) Historical review of coal mining. Fleetway Press, London, pp 195–203

Healey RG (2007) The Pennsylvania anthracite coal industry, 1860–1902: economic cycles, business decision-making and regional dynamics. University of Scranton Press, Scranton and London

Heinzerling C (1891) Schlagwetter und Sicherheitslampen: Entstehung und Erkennung der Schlagenden Wetter und Konstruktion der Wichtigeren Typen der Sicherheitslampen. Verlag der J.G. Cotta’schen Buchhandlung, Stuttgart

Henriques ST, Sharp PR (2021) Without coal in the age of steam and dams in the age of electricity: an explanation for the failure of Portugal to industrialize before the Second World War. Eur Rev Econ Hist 25:85–105

Hickey SHF (1985) Workers in Imperial Germany: the miners of the Ruhr. Oxford University Press, Oxford

Hinsley FB (1969) The development of coal mine ventilation in Great Britain up to the end of the nineteenth century. T Newcomen Soc 42:25–39

Holmes R (2008) The age of wonder: how the romantic generation discovered the beauty and terror of science. Pantheon Books, New York

Horton FW (1913) Coal-mine accidents in the United States and foreign countries. Department of the Interior. US Bureau of Mines, GPO, Washington, DC

James FAJL (2005) How big is a hole?: the problems of the practical application of science in the invention of the miners’ safety lamp by Humphry Davy and George Stephenson in late Regency England. T Newcomen Soc 75:175–227

Jevons HS ([1915] 1969) The British coal trade. Augustus M Kelley, Publishers, New York

Jicinsky J (1905) Manuel de la ventilation des mines. Librairie Polytechnique, Paris

Jopp TA (2011) The hazard of merger by absorption: why some Knappschaften merged and others did not, 1861 to 1920. J Bus Hist 56:75–101

Jopp TA (2016) How technologically progressive was Germany in the interwar period? Evidence on total factor productivity in coal mining. J Econ Hist 76:1113–1151

Jopp TA (2017) Did closures do any good? Labour productivity, mine dynamics, and rationalization in interwar Ruhr coal mining. Econ Hist Rev 70:944–976

Kander A, Malamina P, Warde P (2013) Power to the people: energy in Europe over the last five centuries. Princeton University Press, Princeton

Lamb GJ (1976) Coal mining in France, 1873 to 1895. Dissertation, University of Illinois

Leboutte R (1989) Pour une histoire des catastrophes charbonnières aux XIXe-XXe siècles. Bulletin du Département d’historie économique et sociale, Université de Genève 19:73–101

Leboutte R (1991) Mortalité par accident dans les mines de charbon en Belgique aux XIXe-XXe siècles. Revue du Nord 73:703–736

Leboutte R (1997) Vie et mort des bassins industriels en Europe, 1750–2000. Éditions L’Harmattan, Paris

Leboutte R, Puissant J, Scuto D (1998) Un siècle d’historie industrielle: Belgique, Luxembourg, Pays Bas. Industrialisation et sociétés, 1873–1973. Sedes, Paris

Leiby J (1960) Carroll Wright and labor reform: the origin of labor statistics. Harvard University Press, Harvard

Lupton A (1893) Mining: an elementary treatise on the getting of minerals. Longmans, Green & Co, London and New York

MacRaid DM, Martin D (2000) Labour in British society, 1830–1914. McMilland, London

Marshall A (1915) Explosives: their manufacture, properties, tests and history. J. & A. Churchill, London

Martin M (2009) Allgegenwärtiger Tod. Arbeitsbedingungen und Mortalität im Ruhr-Bergbau bis zum Ersten Weltkrieg. Hist Soc Res 34:154–173

Matheis M (2020) Production, prices, and technology: a historical analysis of the United States coal industry. Essays Econ Bus Hist 38:70–104

Maurice W (1937) The evolution of the miners’ electric hand lamp. J Instit Elect Eng 81:367–380

McAteer D (2014) Monongah. The tragic story of the 1907 Monongah mine disaster: the worst industrial accident in US history. West Virginia University Press, Morgantown

McIvor A, Johnston R (2007) Miners’ lung: a history of dust disease in British coal mining. Ashgate, Aldershot

Melling J (1996) Safety, supervision and the politics of productivity in the British coalmining industry, 1900–1960. In: Melling J, McKinlay A (eds) Management, labour and industrial politics in Modern Europe: the quest for productivity growth during the twentieth century. Edward Elgar, Cheltenham and Brookfield, pp 145–173

Mills C (2010) Regulating health and safety in the British mining industries, 1800–1914. Ashgate, Farnham

Milward AS, Saul S (1973) The economic development of continental Europe, 1780–1870. Routledge, Abingdon

Minchinton W (1990) The rise and fall of the British coal industry: a review article. Vierteljahrschrift für Sozial- und Wirtschaftsgeschichte 77:212–226

Ministère de l'Intérieu (1904–1913) Annuaire statistique de la Belgique et du Congo Belge. Imprimerie A Lesigne, Brussels

Ministère des Travaux Publics (1904–1913) Statistique de l’industrie minérale et des appareils à vapeur en France et en Algérie. Imprimerie nationale, Paris

Mitchell BR (1984) Economic development of the British coal industry 1800–1914. Cambridge University Press, Cambridge

Mitchell BR (1992) International historical statistics: Europe, 1750–1988, 3rd edn. Stockton Press, New York

Mitchell B (1993) International historical statistics: the Americas, 1750–1988, 2nd edn. Stockton Press, New York

Mitchell BR (2003) International historical statistics: Africa, Asia & Oceania, 1750–2000, 4th edn. Palgrave McMillan, Basingstoke, Hampshire, and New York

Mokyr J (1990) The lever of riches: technological creativity and economic progress. Oxford University Press, New York and Oxford

Mokyr J (2009) The enlightened economy: an economic history of Britain, 1700–1850. Yale University Press, New Haven and London

Mokyr J (2010) The contribution of economic history to the study of innovation and technical change: 1750–1914. In: Hall BH, Rosenberg N (eds) Handbook of the economics of innovation, vol 1. North-Holland, Amsterdam, pp 11–50

Montant G (2020) Expansion, depression and collusion: the Belgian coal industry, 1901–1945. J Eur Econ Hist 49:55–108

Moss KN (1924) Ventilation of coal mines. In: The Mining Association of Great Britain (ed) Historical review of coal mining. Fleetway Press, London, pp 126–149

Murray JE, Silvestre J (2015) Small scale technologies and European coal mine safety, 1850–1900. Econ Hist Rev 68:887–910

Murray JE, Silvestre J (2020) Integration in European coal markets, 1833–1913. Econ Hist Rev 73:668–702

Murray JE, Silvestre J (2021) How do mines explode? Understanding risk in European mining doctrine, 1803–1906. Technol Cult 62:780–811

Neville RG (1978) The Courrières colliery disaster, 1906. J Contem Hist 13:33–52

Ó Gráda C (2016) Did science cause the industrial revolution? J Econ Lit 54:224–239

Otojanov R, Fouquet J, Granville B (2020) Factor prices and induced technical change in the industrial revolution (manuscript)

Parnell MF (1994) The German tradition of organized capitalism: self-government in the coal industry. Clarendon Press, Oxford

Paul JW, Ilsley LC, Gleim EJ (1924) Flame safety lamps. US Bureau of mines bulletin no 227. GPO, Washington, DC

Poole G (1924) The history and development of underground haulage. In: The Mining Association of Great Britain (ed) Historical review of coal mining. Fleetway Press, London, pp 89–104

Pouliakas K, Theodossiou I (2013) The economics of health and safety at work: an interdisciplinary review of the theory and policy. J Econ Surv 27:167–208

Pounds NJG, Parker WN (1957) Coal and steel in Western Europe. Indiana University Press, Bloomington

Ranestad K, Sharp PR (2021) Success through failure? Four centuries of searching for Danish coal. Bus Hist (forthcoming)

Reid D (1981) The role of mine safety in the development of working-class consciousness and organization: the case of the Aubin coal basin, 1867–1914. French Hist Stud 12:98–119

Rice GS (1914) Investigations of coal-dust explosions. T Amer Instit Mining Eng 50:552–585

Rice GS, Hartmann I (1939) Coal mining in Europe: a study of practices in different coal formations and under various economic and regulatory conditions compared with those in the United Sates. US Bureau of mines bulletin no 414. GPO, Washington, DC

Scott P (2006) Path dependence, fragmented property rights and the slow diffusion of high throughput technologies in inter-war British coal mining. Bus Hist 48:20–42

Singleton J (2016) Economic and natural disasters since 1900: a comparative history. Edward Elgar, Cheltenham

Singleton J (2020) Origins of disaster management: the British mine rescue system, c. 1900 to c.1930. Bus Hist (forthcoming)

Singleton J (2022) Breathing apparatus for mine rescue in the UK, 1890s–1920s. In: Gray P, Hall J, Herndon RW, Silvestre J (eds) Standard of living: essays in economics, history, and religion in honor of John E. Murray. Springer Nature, Cham

Smyth WW (1890) A rudimentary treatise on coal and coal mining. Crosby Lockwood and Son, London

Spencer EG (1984) Management and labor in Imperial Germany: Ruhr industrialists as employers, 1896–1914. Rutgers University Press, New Brunswick

Stewart JI (2003) Mining. In: Mokyr J (ed) The Oxford encyclopedia of economic history, vol 3. Oxford University Press, Oxford, pp 512–527

Trotter DA (1982) The lighting of underground mines. Trans Tech Publications, Montreal

US Bureau of Labor Statistics (1916) Coal-mine fatalities in the United States, 1915, and during the period 1870 to 1914. Monthly Rev US Bureau Labor Stat 3:61–72

Veneer L (2006) Provincial geology and the industrial revolution. Endeavour 30:76–80

Watteyne V, Meissner C, Desborough A (1908) The prevention of mine explosions: report and recommendations. US Geological Survey Bulletin no 369. GPO, Washington, DC

Wauthelet JM (1997) Accumulation and return on capital in the Belgian coal industry, 1850–1914. In: Van der Wee H, Blomme J (eds) The economic development of Belgium since 1870. Edward Elgar, Cheltenham, pp 205–219

Weisbrod B (1990) Entrepreneurial politics and industrial relations in mining in the Ruhr region: from managerial absolutism to co-determination. In: Feldman GD, Tenfelde K (eds) Workers, owners and politics in coal mining: an international comparison of industrial relations. Berg, New York, Oxford and Munich, pp 118–202

Wibail A (1914) L’évolution économique de l’industrie charbonniére Belge depuis 1831. Bulletin del’Institut des Sciences Eonomiques 6:3–30

Wright CD (1905) Coal mine labor in Europe. Twelfth special report of the Commissioner of Labor. GPO, Washington, DC

Wright G (2006) Natural resource industries. In: such R, Carter SB (eds) Historical statistics of the United Sates: earliest times to the present. Millennial edition, vol 4, part D: economic sectors. Cambridge University Press, Cambridge, MA, pp 4-275-394

Wright G (2015) The USA as a case study in resource-based development. In: Badia-Miró M, Pinilla V, Henry W (eds) Natural resources and economic growth: learning from history. Routledge, London and New York, pp 119–139

Wrigley EA (1961) Industrial growth and population change: a regional study of the coalfield areas of North-West Europe in the later nineteenth century. Cambridge University Press, Cambridge

Wrigley EA (2016) The path to sustained growth: England’s transition from an organic economy to an industrial revolution. Cambridge University Press, Cambridge

Acknowledgement

Although only my name is listed as author, this paper is a revision of a book project proposal John E. Murray (Rhodes College) and I wrote as part of a submission process, from which I decided to withdraw after John passed away in 2018. I hope my simplification and many alterations have not spoiled the main idea of John’s account. This essay would not have been possible without the contribution of Patrick Gray, who generously sent me John’s books, electronic documents, and computer programs on coal. I am grateful to Joel Mokyr, who helped us to refine early and incomplete drafts of the book proposal, Roger Fouquet, for sharing with me his unpublished co-authored manuscript, and Ruth Herndon and Timothy Guinnane for their support. I also benefited from comments by Jim Bessen, Ewout Frankema, Tamás Vonyó, and the rest of the participants in the Economic History Seminar at the Universidad de Zaragoza, the “Pre-industrial and modern trade” session at the XI European Social Science History Conference (Valencia), and the “The New Economic History of Patents and Innovation” session at the XVIII World Economic History Conference (Boston), where sections of earlier versions of this work were presented, as well as from bibliographical suggestions on the US by Mark Aldrich and William Boal. Arthur McIvor, Catherine Mills, and John Singleton kindly helped me to complete the British series on fatalities with information or inaccessible data during the pandemic Spring of 2020. The Government of Spain (research projects PGC2018-095529-B-I00 and PGC2018-096640-B-I00) and the Government of Aragon-European Fund for Economic and Regional Development (2020-2022) (research project S55-20R) have provided financial assistance.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Silvestre, J. (2022). Productivity, Mortality, and Technology in European and US Coal Mining, 1800–1913. In: Gray, P., Hall, J., Wallis Herndon, R., Silvestre, J. (eds) Standard of Living. Studies in Economic History. Springer, Cham. https://doi.org/10.1007/978-3-031-06477-7_16

Download citation

DOI: https://doi.org/10.1007/978-3-031-06477-7_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-06476-0

Online ISBN: 978-3-031-06477-7

eBook Packages: Economics and FinanceEconomics and Finance (R0)