Abstract

In vibration-based structural parameter identification, wavelet transformation has been widely used for extraction of damage pertinent data for onward identification of structural parameters or the occurrence of anomalies. Among wavelet-based techniques, the use of wavelet packet node energy (WPNE) as damage-sensitive features has attracted much research interest in more recent years. WPNE features contain detailed information which can be highly sensitive to local damages. However, most of the existing studies in the literature on using wavelet energy-based features have been numerical and involved idealised assumptions such as perfect and identical excitations among different tests. This paper presents an investigation into the tolerance of a wavelet packet energy with neural network approach to uncertainties in the input excitations and measurement noises. WPNEs are extracted from vibration signals from impact tests as feature proxies and a back-propagation neural network is used for classification. The method is firstly applied on a beam model using finite element simulations, in which variation in the excitations and measurement noises are incorporated to investigate the susceptibility of the approach to such uncertainties. Subsequently, the method is applied to the experimental data from the laboratory test of a steel beam. The results from both the numerical simulations and the experimental verification demonstrate that the wavelet energy with neural network approach to detecting structural changes is workable, and given a reasonably controlled impact test, it is possible to identify the initiation of damage with good accuracy.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Early damage detection

- Wavelet packet transform (WPT)

- WPT node energy features

- Digital twin

- Machine learning

5.1 Introduction

Wavelet energy-based features are thought to provide comprehensive information that may be extremely sensitive to local damages in vibration-based structural damage detection. Wavelet packet transform (WPT) energy was developed [1] as an alternate method of extracting time-frequency information from vibration signals. In the study by Yen and Lin [1], WPT energy features were used with neural networks for classification. Numerical simulations of a helicopter gearbox were used to test the viability of the classification technique. The findings showed that WPT features outperformed FFT features, and with eight sensors, good classification was achieved. WPT features have since been extensively researched in the identification of damage in civil engineering structures. Wavelet transform-based features have been shown to be effective in detecting, localising, and quantifying damages in many numerical and experimental investigations. Han et al. [2] presented the wavelet energy rate index as a damage measure based on WPT energy derived from 29 acceleration signals and demonstrated the technique on a numerically simulated simply supported beam and an actual steel beam. The index was shown to be sensitive to structural local damage in both simulated and experimental studies. In their research, two assumptions are used: (a) reliable undamaged and damaged structural models are available, and (b) all excitations are identical and repeatable. Mikami et al. [3] utilised the power spectrum density of WPT components as a damage detection index and used computational and experimental data collected from a steel beam to validate the identification technique. The suggested index was shown to be sensitive to damages.

Damage detection using just the feature proxy often necessitates a large number of sensors providing spatial information. Some research studies have looked at better mapping of the connections between feature proxy and structural state with a small number of signal sources with the use of machine learning techniques in classification and identification. Sun and Chang [4] used numerical simulations of a three-span continuous bridge under impact excitation to explore the application of WPT and the neural network model for damage assessment. The findings revealed that WPT energies derived from a single signal source could identify damage location and levels of severity.

However, the majority of previous research on wavelet energy-based features has been numerical and based on idealised assumptions such as perfect and identical excitations. This paper presents an investigation into the tolerance of a wavelet packet energy with neural network approach to uncertainties in the input excitations and measurement noises. WPNEs are extracted from vibration signals from impact tests as feature proxies, and a back-propagation neural network is used for classification. The method is firstly applied on a beam model using finite element simulations, in which variation in the excitations and measurement noises are incorporated to investigate the susceptibility of the approach to such uncertainties. Subsequently, the method is applied on the experimental data from the laboratory test of a steel beam.

5.2 Background Theories and Methodology

5.2.1 WPT Energy-Based Damage-Sensitive Feature

The wavelet transform (WT) is a signal processing method that has been widely used in a variety of fields. It goes beyond the Fourier transform in that it reveals signal characteristics in both the time and frequency domains. Wavelet transform defines a signal with coefficients that reflect the direct proportions between a basis function called mother wavelet and the original signal by shifting and dilating the mother wavelet [5]. WPT has a tree structure where the original signal is transformed into approximations and details at each level. As a result, a greater frequency domain resolution is obtained. Figure 5.1 shows an example wavelet packet transform tree structure.

The signal is decomposed by the following standard expressions:

where \( {u}_0^{(0)}(t)=\varphi (t) \) is the scaling function, \( {u}_1^{(0)}(t)=\varphi (t) \) is the wavelet function, j is the decomposition level, k is the translation parameter, and n is the modulation parameter. The terms h(k) and g(k) are quadrature mirror filters, and the corresponding function sets H = {h(k)}k = z and G = {g(k)}k = z denote the low-pass filter and the high-pass filter, respectively. After being decomposed for j times, 2j signal components are obtained. The sum of the component signals can represent the original signal f(t) as:

where \( {f}_j^i(t) \) denotes the ith component signal at the jth decomposition level \( , {C}_j^i(t) \) denotes the wavelet packet coefficients, and \( {\psi}_{j,k}^i(t) \) denotes wavelet packet functions. Then, wavelet packet node energies (WPNEs) can be calculated as:

The WPNE denotes the energy content in a specific frequency band without taking into account the time-variant characteristic. Normalised wavelet packet node energy (NWPNE) E i in i-frequency band is expressed as:

where E f denotes the sum of all terminal WPNEs and it represents the total signal energy. The effects of gross variation, particularly in the magnitudes of the excitations, can be largely eliminated by normalisation. As a result, the NWPNE is selected as the damage-sensitive feature and neural networks are used as inputs. The appropriate level of WPT to be employed is assessed in this research using an entropy-based selection technique [6].

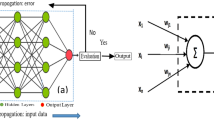

5.2.2 Back-Propagation (BP) Neural Network

Because of strong nonlinearity, the relationship between NWPNE and a structure’s dynamic properties is difficult to establish directly. Previous research has shown that back-propagation (BP) neural networks can generally be applied to implement pattern recognition in structural damage identification. In this study, feedforward BP neural networks with an input layer for receiving input data, a hidden layer for processing data, and an output layer for decision-making and outputting results are employed. The NPWNEs are used as inputs. The BP neural network training process includes forward and back propagation. The inputs are sent through levels in forward propagation resulting in an error. The error feedback is used to iteratively change the weights and biases in back propagation. When the loss assessed by validation data stops improving, the training procedure will be completed. Cross entropy loss is used in this case which is defined as:

where p(u) denotes one-hot encoding vector of the true label and q(u) denotes the corresponding output. A scaled conjugate gradient approach is used to train a BP neural network for classification, where each structural state is considered a class. The structural conditions include intact and damaged at various locations. Therefore, the output layer will include representation of the presence and location of the structural damage. In this work, the hidden layers and output layer adopt logistic sigmoid functions and softmax functions, respectively. As a loss function, the cross entropy function is applied to the softmax output. A one-hot encoded vector is employed as a label. For example, a vector of [0,1,0,0,0,0,0,0,0,0] represents the class of damage at segment 2. The number of hidden neurons is estimated by the empirical formula as follows:

where L is the number of hidden layer nodes, m is the number of input nodes, n is the number of output nodes, and k is a constant, k ∈ [1, 10].

5.2.3 WPT Energy and Neural Network Integrated (WPNE-NN) Approach

The key procedures of WPNE-NN approach are explained as follows. Firstly, vibration signals from the structure under investigation are acquired. The signals are taken in the form of acceleration time histories. Secondly, WPNE features are created from wavelet packet transform of the acquired vibration measurements. Daubechies mother wavelets have been shown to be the optimum choice for analysing acceleration signals [7]. In the present wavelet packet analysis, ‘Daubechies 4’ is chosen as the mother wavelet. The vibration signals are translated into feature vectors created by WPNEs throughout the feature extraction. Thirdly, supervised neural network training is carried out. With the trained NN, WPNE feature from a new measurement can be used to determine the structural state.

A two-stage strategy for identifying damage is proposed in this study. The challenge of damage detection and localisation is first treated as a classification problem. Once the location is known, the second step treats the damage extent quantification at the particular location as a fitting problem. Therefore, two distinct neural networks are trained in each stage. The first stage involves training a BP neural network (NN-I) using a scaled conjugate gradient technique to perform classification on each structural state. The structural states include intact and damage at various locations. As a result, the NN-I’s output indicates the occurrence and location of a damage. In the second stage of damage quantification, assuming that the location of the damage has been determined in the first stage, the training dataset is reduced to samples taken at the damaged location. Bayesian regularisation is a training function that updates the weight and bias according to Levenberg-Marquardt optimisation and maximises the log probability density towards a correct answer. The output of NN-II will indicate the degree of damage, in the present case the reduced local bending stiffness (or rigidity).

The samples are randomly divided into training, validation, and test sets by a specified proportion. The training set is used to train the neural networks, and the validation set is used to provide an unbiased evaluation of a model fit on the training set. The training, validation, and test data size ratios are set at 70%, 15%, and 15%, respectively. For simplicity in the demonstration of the procedure, it is assumed that damage only occurs in a single segment of the structure, which is consistent with the stated goal of the current approach in detecting incipient damage.

5.3 Numerical Investigation

In this section an investigation into the tolerance of the wavelet-neural network integrated approach to variation in the input excitations and measurement noises is carried out using a finite element beam model. Damages are simulated as stiffness reduction in segments of the structure.

5.3.1 Model Setup

Timoshenko beam elements are used to model an isotropic homogeneous beam in Abaqus. The beam measures 3.2 m in length, 0.15 m in width, and 0.12 m in depth. The material parameters of the beam are as follows: mass density = 2450 kg/m3; elastic modulus = 38.8 GPa; Poisson’s ratio = 0.2; and structural damping in all modes = 0.5%.

The beam is supported at 0.05 m from each end, resulting in a net span of 3.1 m. The beam is meshed into 200 elements throughout its length in the computation to ensure the accuracy of the dynamic analysis. The beam is marked with ten equal-length segments over the net span for the purpose of representing damage to the beam and measurement locations. As illustrated in Fig. 5.2, the ten segments are labelled segment 1–10, and the dividing points between segments are labelled P1 to P9 (excluding the support nodes).

Excitations are modelled as vertical impact point loads at P3. The vertical acceleration response is also recorded for 1 s at P3 (i.e. driving point response) with a sample rate of 2500 Hz. The acceleration signals are imported into MATLAB successively, and the NWPNEs are calculated. As an example, Fig. 5.3 shows a recorded acceleration signal from the beam in its intact state and the corresponding NWPNEs at the seventh WPT level from the signal.

5.3.2 Damage Identification Procedure

In the numerical model, ten single damage cases are simulated by a stiffness reduction to segment 1–10, respectively. For each location, 16 levels of stiffness reduction from 0% to 30% at a 2% interval are simulated. The total samples thus amount to 165. Samples are grouped into 11 classes. Ten of these classes represent structural states that damage occurs in one of the ten segments, and the last class represents intact state. The impact excitation is simulated by applying a pulse force downward at point P3 in all cases. The standard pulse force has an isosceles triangle shape in time series with a magnitude of 100 N and a duration of 0.002 s. The acceleration signals collected at P3 are decomposed by WPT with a mother wavelet db4 to seventh levels generating a total of 128 NWPNEs for each signal. The level of WPT is determined through entropy analysis mentioned in Sect. 5.2. Hence, 128-dimensional feature vectors are extracted and employed as input in the neural networks for training and damage identification. The number of hidden neurons is set at 15, as explained in Sect. 5.2. The sizes of training, validation, and test sets are 115, 25, and 25, respectively. The training process of NN-I automatically stops after 42 iterations when generalisation stops improving, as indicated by an increase in the cross-entropy error of the validation samples resulting in a cross-entropy error of 2.17 e−7. Figure 5.4a shows the identification result where the output class of 25 test samples are marked as red dots. It can be seen that only 1 of them fall out of the target classes which are indicated as blue squares. This means 24 out of 25 tests are correct in the structural state identification and the accuracy is 96%.

In damage extent quantification, assuming the damage location is already determined, the training and testing are conducted on that specific class. In order to examine the performance of NN-II on damage quantification at all locations, the same process is repeated on all ten classes. In each class, 11 samples are used for training, 2 for validation, and 2 for testing where samples are randomly selected in each dataset. Therefore, there are 20 tests in total. The result is shown in Fig. 5.4b. The maximum error in estimation of stiffness reduction is within 2.2%. The above results demonstrate that under an ideal condition with identical excitations, the WPNE-NN approach is capable of identifying damage with high accuracy using even just one signal source.

5.3.3 Effect of Measurement Noise

Some explorations in the robustness of the approach to Gaussian white noise have been made in previous numerical studies [8,9,10]. Under idealised identical excitations, the approach has demonstrated good resistance to noise up to a level of signal to noise ratio (SNR) of 10. However in a real environment, there are more complicated noises contaminating the measured signals due to various interferences, such as ambient vibrations, imperfectness of structures, electrical noises on sensors, etc. Noises from various sources are usually mixed together in the measured signals. They usually come in three common forms, namely, continuous, periodic, and impulsive. Gaussian white noise is an idealised form of continuous noise where the energy in all frequencies are uniform. However, real continuous noises may contain non-uniform frequency contents. Therefore, the effect of noises that could realistically occur in impact vibration tests in a real measurement environment is investigated. Five types of noises are discussed and compared. Figure 5.5 shows time series and power spectrum densities of the normalised noises for example. The noise in Fig. 5.5a is Gaussian white noise whose spectrum is nearly flat across the frequency range. Figure 5.5b shows a continuous noise whose energy gradually deceases as frequency increases in spectrum. It is also known as a coloured noise. Figure 5.5c shows an impulsive noise which occurs only in a short period of time. Its spectrum is generally flat, and the energy gradually decreases when reaching high-frequency range. Figure 5.5d shows a periodic noise. Due to the complexity of frequency contents, its spectrum appears irregular. In Fig. 5.5e, the abovementioned four noises are combined into a mixture whose spectrum contains all the features of these noises.

The noisy signals are obtained by adding the noise to the 165 samples mentioned above. The noise level is quantified by SNR which is defined in decibel as:

where A s and A n denote the root mean squares of the acceleration response and the noise, respectively. Three levels of noises are generated in MATLAB with SNR of 10, 20, and 30. For each type of noise at each SNR level, random noise samples are generated and added into the 165 samples resulting in 15 noise-contaminated datasets. Figure 5.6 shows NWPNE features extracted from clean and various noise-contaminated signals at SNR20. By appearance, Gaussian white noise and impulsive noise barely alter the NWPNE feature, while coloured noise has a significant effect. By comparing to their corresponding spectrum, noises with relatively uniform energy distributions tend to have less impact on the features.

With the same setting of the neural networks and identification procedures, damage localisation and quantification are conducted on the datasets independently. The results are shown in Table. 5.1.

The results show that Gaussian white noises and impulsive noises hardly affect the performance of this approach in damage localisation. However, the accuracy in localisation decreases markedly when coloured noises and periodic noises are introduced; nevertheless the overall performance of the approach may still be considered acceptable. On the other hand, errors in damage quantification increase as noise level increases. Particularly, coloured and periodic noises result in more significant increases in the errors of the damage quantification. The performance under the mixture of the noises is close to the case with coloured noise, which is the major contributor to the errors herein. The approach is more resistant to Gaussian white noise and impulsive noises and less so against noises with non-uniform energy distributions. Therefore, in real application, the latter type of noises should be avoided as much as possible. If such noise components are identified from the measurements, targeted denoising may be required. Up to a noise level with SNR = 20, the performance of the approach in damage identification is still satisfactory, even with small (incipient) damages.

5.3.4 Variation in Excitations

In an actual measurement environment, the variation in the impact force may be characterised in three basic aspects, namely, magnitude, duration, and the pulse shape. The variation in the impact duration not only affects the input energy but also the energy distribution in the frequency spectrum, which may result in a more complicated interference to the damage-sensitive features. In the time history of a real excitation signal, it is common to observe more than one peak at the start of the impact due to the imperfectness of the contacting surfaces, and this introduces further complexity in terms of the input energy and frequency contents of the excitation. Therefore, all the three types of variations could potentially have a significant influence on the WPNEs; hence, by incorporating these variations in the impact excitation, it will provide critical insight into the achievable performance of the WPNE-based approach in a real measurement environment. The numerical investigation is carried out to examine the effectiveness of the approach in the following aspects: (1) with variation in the magnitudes of excitations, (2) with variation in the impulse shapes of the excitations, (3) with variation in the duration of the excitation impulse. All the numerical tests are conducted under a Gaussian white noise (SNR 20)-contaminated condition. The state of identical excitations under Gaussian white noise is compared against as benchmark which echoes the conditions commonly adopted in most existing studies.

Variations in magnitudes, shapes, and durations of excitations are introduced step by step. In order to simulate variation in magnitudes of excitations, impulse loads with identical durations of 0.002 s and varying peak values between 100 N and 500 N are employed. All excitations are in isosceles triangle shapes in time history. An example of excitation variations in magnitude is shown in Fig. 5.7a. The 165 samples are simulated again. In each damage case, a unique excitation of 0.002 s duration and a randomly sampled peak force within the above specified range were created.

It should be pointed out that, despite the variation in magnitude, the power spectra of the impulses are still perfectly flat within the frequency range of interest and it does not disturb frequency distribution remarkably. To further broaden the variability of the excitation, excitation pulse forces varying not only in peak magnitude but also in the pulse shape in the time series are introduced. Figure 5.7b shows the pulse excitation with variable magnitude and pulse shape, while the duration of the excitation is kept at 0.004 s. Different excitations are generated by adjusting the peak value randomly between 100 N and 500 N.

White noises of SNR = 30 are added into the acceleration responses and damage identification is conducted. Next, variation in the excitation duration is introduced which effectively alters the frequency contents (and hence the input energy distribution in the frequency domain). Excitations with identical peak value of 100 N and randomly varying duration between 0.002 s and 0.004 s are created. They are applied respectively in the simulation of the abovementioned 165 samples.

The damage identification results are shown in Fig. 5.8. It can be seen that the variation in the excitation magnitude does not affect markedly the classification (NN-I, detection, and localisation) performance. The variation in the excitation pulse shape causes a decrease in the classification accuracy (NN-I) to 84%. The variation in the duration appears to cause the most significant effect, and the classification accuracy decreases to 76%. In the damage quantification (NN-II), the maximum error increases notably to more than 16% when variations in shape and duration are involved. Therefore in real testing, compared to excitation magnitudes, better control in duration and pulse shape of excitations should be focused on to minimise the uncertainties at the contact point.

5.4 Experimental Investigation

In order to further examine the performance of the approach in a real measurement condition, an experiment was conducted on a flat steel beam with fixed-end boundaries. Steel clamping plates and bolts were used to fix the two ends of the beam on strong steel supports. The stiffness of the supports is deemed considerably larger than the testing specimen, so that it can be regarded as a fixed support. The beam measured 1020 mm in length and had a cross-sectional area of 50 mm by 6 mm. Figure 5.9 depicts both a sketch and a photograph of the setup.

A measurement array was constructed by dividing the beam into ten segments along its length, resulting in nine joints between the two supports labelled P1 to P9. To avoid a nodal point in any of the first few mode configurations, the excitation was imposed vertically between P4 and P5, and an accelerometer was placed at P6. The duration of the record was set to 6 seconds, and the sampling rate was set at 1650 Hz. All hammer impact locations were controlled within a 2 cm by 2 cm square at midpoint between P4 and P5. All excitation forces were of a peak between 10 N and 20 N. A mass of 12 g was employed as the additional mass, which is equal to 0.5% of the beam weight. By attaching the mass at P1 to P9, respectively, nine structural states were generated. There were a total of ten states including the instance of no mass attached. The beam was excited for 20 times in each state, for a total of 200 samples. For the second stage of the approach for damage quantification, four levels of the magnitude of damage were created by adding masses of 6 g, 12 g, 24 g, and 36 g, respectively, at P3. In each state, the beam was excitated for 5 times, and totally 20 samples were recorded. The 15 samples from cases of 6 g, 24 g, and 36 g are used for training and validation with a dividing ratio of 13:2. The five samples from the case of 12 g are used for testing.

From the measured signals, the 128-dimensional feature vectors consisting of NWPNEs at seventh level of WPT are extracted and used as the inputs of the neural network. The number of neurons in hidden layer is set as 20. The outputs are 10-dimensional one-hot encoded vectors. Thus, the structure of the neural network in terms of neuron numbers in each layer is 128-20-10. The sizes of training, validation, and test datasets in this case are 140, 30, and 30, respectively, based on the same division ratio mentioned above. The training of the neural network completes with 36 iterations, and a cross entropy error is 8.34 × 10−5.

The test (prediction) result is illustrated in Fig. 5.10 showing a satisfactory accuracy of 93.3% in damage localisation and acceptable maximum error in damage quantification in the real measurement environment.

5.5 Conclusions

Through numerical investigations, this paper demonstrates that the wavelet energy with neural network (WPNE-NN) approach to damage identification is generally impervious to the measurement noises up to a level with SNR = 20. As the noise level further increases, interference from the types of noises with non-uniform energy distributions in the frequency domain becomes more apparent, whereas Gaussian white noise or impulsive noise continue to have a negligible effect. Additionally, variation in the excitation magnitude does not affect markedly the damage identification performance, while the variation in pulse shape and durations of excitations causes more noticeable interference.

The experimental investigation demonstrated that in a real measurement environment with hand controlled excitations, the WPNE-NN approach delivered good accuracy in damage detection and localisation and an acceptable margin of error in damage quantification.

Therefore, it may be concluded that the WPNE-NN approach to detecting structural changes is workable, and with a reasonably controlled impact test, it is possible to identify initiation of damage with good accuracy.

References

Yen, G.G., Lin, K.C.: Wavelet packet feature extraction for vibration monitoring. IEEE Trans. Ind. Electron. 47(3), 650–667 (2000)

Han, J.G., Ren, W.X., Sun, Z.S.: Wavelet packet based damage identification of beam structures. Int. J. Solids Struct. 42(26), 6610–6627 (2005)

Mikami, S., Beskhyroun, S., Oshima, T.: Wavelet packet based damage detection in beam-like structures without baseline modal parameters. Struct. Infrastruct. Eng. 7(3), 211–227 (2011)

Sun, Z., Chang, C.C.: Structural damage assessment based on wavelet packet transform. J. Struct. Eng. ASCE. 128(10), 1354–1361 (2002)

Graps, A.: An introduction to wavelets. IEEE Comput. Sci. Eng. 2(2), 50–61 (1995)

Coifman, R.R., Wickerhauser, M.V.: Entropy-based algorithms for best basis selection. IEEE Trans. Inf. Theory. 38(2), 713–718 (1992)

Mallat, S., Peyre, G.: A wavelet tour of signal processing the sparse way preface to the sparse edition. In: Wavelet tour of signal processing: the Sparse Way, 3rd edn. Elsevier (2009)

Liu, Y.-Y., Ju, Y.-F., Duan, C.-D., Zhao, X.-F.: Structure damage diagnosis using neural network and feature fusion. Eng. Appl. Artif. Intell. 24, 87–92 (2011)., 2010.08.011

Ghiasi, R., Torkzadeh, P., Noori, M.: A machine-learning approach for structural damage detection using least square support vector machine based on a new combinational kernel function. Struct. Health Monit. 15(3), 302–316 (2016)

Cao, M., Ding, Y., Ren, W., Wang, Q., Ragulskis, M., Ding, Z.: Hierarchical wavelet-aided neural intelligent identification of structural damage in Noisy conditions. Appl. Sci. 7(4), 391 (2017). 1–20

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Society for Experimental Mechanics, Inc.

About this paper

Cite this paper

Zhang, X., Lu, Y. (2023). Wavelet Energy Features for Damage Identification: Sensitivity to Measurement Uncertainties. In: Mao, Z. (eds) Model Validation and Uncertainty Quantification, Volume 3. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham. https://doi.org/10.1007/978-3-031-04090-0_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-04090-0_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-04089-4

Online ISBN: 978-3-031-04090-0

eBook Packages: EngineeringEngineering (R0)