Abstract

The future mobility presents new safety requirements. In addition to the passenger compartment, batteries and hydrogen tanks need also to be intensively protected. High-strength, hot-formed steels, die-cast components and new material pairings pose new challenges for selecting and parametrization the used joining technology. For this reason, the Coupled Process Analysis (CPA) method, for supporting the design and monitoring of joining processes, is presented. From as early as 12 data sets from simulation or experiment (micrograph), it is possible to map interdependencies between the quality criteria of the join and the acting process parameters. The resulting possibilities are illustrated by means of the numerical design of a clinch and a riveted joint as well as the experimental, image-based sampling of a weld seam. Finally a supplemented by a presentation of the potentials in quality monitoring in series operation of the automotive process chain will be done. The combination of high flexibility with respect to the in- and output variables (visual images, FE-meshes, process curves, discrete values), low modeling effort and the image based representation of the interdependencies makes the approach suitable even for employees with lower qualification.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The reduction of development cycles is an essential criterion for achieving competitive advantages in automotive engineering. At the same time, the growing use of mixed construction concepts in body manufacturing (e.g. steel/aluminum sheet) is increasing complexity in production, which significantly raises the requirements for meeting quality targets.

Digitization in production is growing steadily. The development process generates data from experimental tests and numerical simulations. This data is used to determine suitable process parameters for manufacturing methods such as joining technology. More and more process, measurement and simulation data is available to manufacturers, but there are still methods missing to gain useful insights. Especially when the test sample size is small, the process data is incomplete and the type of recorded data differs, there is no satisfactory solution approach available. The best example of this is a glance at vehicle production where up to 500 stamped sheet metal parts are joined in up to 120 fixtures to get a complete body, and each process step has an varying level of impact on the dimensional stability of the car body (Hu et al. 2001).

2 Statistical Modelling in Joining

2.1 Mechanical Joining

Machine learning methods have already been used in research work on mechanical joining technology. Oudjene presents a combination of response surface method and moving least square approximation to optimize the tool contour during clinching (Oudjene and Ben-Ayed 2008; Oudjene et al. 2009). In a sensitivity analysis performed by Lambiase, the main effects of tool parameters on undercut and neck thickness are determined by an artificial neural network (ANN) (Lambiase and Di Ilio 2013). Also, based on a genetic algorithm (GA), the tool geometry is optimized with respect to the joint strength. Roux optimizes the tool geometry with respect to strength parameters of the joining partners using a kriging-based model (Roux and Bouchard 2013). For the targeted design of clinching processes, Drossel investigate the application of an FE-based approach for sensitivity analysis (Drossel et al. 2014). The objective of the study was to optimize the strength-related quality parameters for different sheet thickness and material combinations. Wang uses Bezier curves parameterized in their control points to describe the die geometry. By varying the control points, die geometry can be optimized to avoid crack formation when clinching thin sheets (Wang et al 2017). Schwarz propose an optimization approach based on principal component analysis to improve the quality of the joined joint (Schwarz et al. 2020). In Thoms and Kalich (2002), neural networks were used to predict process parameters as well as joint strengths in solid stamp riveting. In the studies, Hahn and Tan (2003), Hahn et al. (2005) and Tan et al. (2006), neural networks and later k-nearest neighbor regressions were first used to predict the load carrying capacity of clinch joints. In Breckweg (2006) neural networks to classify defects in process monitoring for radial clinching are used. For self-pierce-riveting, the influence of fluctuating component properties, such as sheet thickness and strength variations, on the joining point formation was investigated and concepts for adaptive process adjustment were demonstrated (Jäckel et al. 2016).

2.2 Welding

Three main methods are used for statistical modeling of experimental welding data: Response Surface Method, Taguchi Method and Artificial Neural Networks (Dhas and Dhas 2012).

A popular method for the mathematical description of cause-effect relationships in welding is the response surface method (RSM). Here, a multi-dimensional response surface is used to establish a relationship between the input parameters and one or more quality-relevant target variables. To plan the experiments, a full factorial experimental design is often used in RSM with the Central Composite Design (CCD). The first experimental studies based on RSM are shown by Gunaraj and Murugan (1999) to identify the optimum weld geometry in submerged arc welding. The welding parameters considered within the models are clamping voltage, wire feed rate, welding speed and welding nozzle distance to the sheet.

Xu use RSM for weld optimization of thick-walled pipes joined by gas shielded arc welding. The objective is to establish a relationship between six welding parameters and three weld parameters determined in the micrograph (Xu et al. 2014). In Liao et al. (2018), RSM is used to predict the ideal weld geometry in TIG welding of pipelines. The geometry of the weld is analyzed using three parameters (weld depth, weld width, weld protrusion) in the micrograph. Welding power, welding speed and welding position are identified as important input variables for the model. In contrast, the optimization of the laser beam welding process is based on the RSM of Padmanaban and Balasubramanian (2010). The focus is on the model-based prediction of the tensile strength of a laser beam welded magnesium alloy with variation of laser power, welding speed and focus position. Further experimental investigations based on the RSM can be found, for example, in Acherjee et al. (2009) and Srivastava and Garg (2017).

Another statistical method that is frequently used in welding parameter studies is the Taguchi Method (TM). The TM is an experimental design that aims at minimizing the experimental scatter as well as the robust design of the process (Dhas and Dhas 2012). Rao use the TM in combination with a multiple regression model for arc welding. Input variables for the model are wire feed rate, workpiece thickness, pulse current intensity, and welding speed. Experimental results show that the model can predict the quality relevant parameters of the weld geometry with a high accuracy (Rao et al. 2009). In Anawa and Olabi (2008) the focus is on the optimization of laser beam welded components. The influence of the laser power, the laser speed and the focus position on the weld geometry is investigated. The functional relationship between welding parameter and weld is realized via nonlinear regression models. In contrast, using laser welded aluminum alloys as an example, Pan show that TM can be used to increase the tensile strength of the welded joint (Pan et al. 2005). Furthermore, Eşme (2009) describes the applicability of TM to optimize the tensile shear strength for spot welded geometries. Datta attempt to combine TM with PCA to convert the multivariate optimization problem into a univariate one for submerged arc welding (Datta et al. 2009). On the other hand, a comparison between the RSM and the TM is shown in Sivaraos Milkey et al. (2014).

In addition to RSM and TM, numerous studies deal with the optimization of welding parameters using ANN. Mirapeix shows in Mirapeix et al. (2007) a diagnostic method of welding defects based on a KNN. The quality of the weld is evaluated using the plasma spectrum. Lightfoot develop a KNN architecture that can be used to reduce the weld-induced distortion of marine steel plates (Lightfoot et al. 2004). In Ismail et al. (2013) a KNN-based model is presented which is able to predict the weld geometry characterized by two specific parameters for laser beam microwelding of thin sheet structures. Acherjee determine the correlation between process parameters and quality related target variables based on a nonlinear KNN model for laser transmission welding of thermoplastic (Acherjee et al. 2011). Laser power, laser speed, working distance and clamping pressure are selected as welding parameters for the model. Model target variables considered are tensile shear strength and weld width. A very comprehensive review on statistical analysis of welding processes can be found in Benyounis and Olabi (2008) and Dhas and Dhas (2012).

Due to the possibility of numerical calculation of welding processes, optimization of welding process parameters can also be performed based on computer simulations. In this context, the potential of welding simulation lies in a reduction of time-consuming and cost-intensive welding experiments (Yang et al. 2018). Against this background, Yang et al. (2018) and Jiang et al. (2016) propose an FEA-based method for model-based prediction of weld geometry for laser beam welding. Kriging models form the basis of the statistical investigations, with laser power, laser speed, and focus position selected as input parameters in both cases. On the other hand, an approach to combine FEA and RSM to optimize the temperature field and weld geometry for laser beam welding is shown in Acherjee et al. (2012).

2.3 Data-Based Forecasting Models in Automotive Car Body Production

In the context of digitalization, the possibilities of data-based analysis and prognosis in car body production are increasing. In previous development projects on the digitization of car body production, for example, the influence of fluctuating sheet metal properties on component quality and geometry was investigated in deep drawing (Purr et al. 2015; Kriechenbauer et al. 2020). It was shown that an adaptive reaction to process fluctuations in deep drawing can be realized with actuators integrated in the tools (Bäume et al. 2016). Schwarz describe that it is possible to predict the interactions of process parameters on the component geometry for deep drawing using data-based statistical models (Schwarz et al. 2018, 2021).

3 Coupled Process Analysis

Traditionally, quality assurance is the instance in which most of the data for the final product is determined. The classic implementation is mostly carried out on a random sample basis and under laboratory conditions. In the course of Industry 4.0, more and more data is now being collected along the production line. This data includes product data (dimension, strength, etc.) from the real process (Behrens et al. 2018), as well as simulation data, which is collected in an early planning phase (Wahl et al. 2011). The aim of the data acquisition is to determine the effect of process parameter variations on quality-relevant target variables (e.g. dimensional accuracy, strength values).

However, the statistical analysis of these data is very challenging in terms of data diversity and data volume. In most cases, the results are in the form of multidimensional data sets (e.g. finite element (FE) meshes from simulations). If the simulation result (e.g. deviation, temperature, stress) is determined at each mesh node of the FE mesh, the connection of the process parameters with this target variable has to be considered as a multivariate statistical problem due to the large number of nodes in a FE mesh.

To solve this problem, a machine learning method already exists in the form of Coupled Process Analysis (CPA), which deals with the evaluation of multidimensional data sets along production process chains. The aim of the CPA modeling algorithm is to combine the dependent and independent data sets along any multi-stage process chain so that the causal relationships can be determined using surrogate models.

The solution consists in projecting the multivariate data basis (e.g. sheet thickness distribution, deviation field) into a low-dimensional subspace by means of Fourier- and variance-based reduction methods as shown in Schwarz et al. (2018, 2020, 2021) (see Fig. 1). In this subspace, computation of surrogate models and sensitivities is much less complex due to the low dimension. The statistical quantities calculated in the subspace can then be visualized as a shape-based area plot via a back-projection process onto the reference mesh. This allows the functional relationship between the process parameters and the defined target variable to be visualized in a spatially resolved manner for each node of the finite element mesh.

The strength and focus of CPA lie in the creation of surrogate models by applying efficient data reduction methods. In summary, the application of the CPA results in the following advantages:

-

Data diversity: Processing of multivariate input data (discrete values, mesh surface data, images).

-

Data size: The CPA requires only a very small sample size for a large number of input variables.

-

Range of applications: The CPA can be used both in the planning stage and in series production.

-

Shape-based visualization: User-friendly representation of complex inter-relationships.

The possibility to process and evaluate multivariate data sets results in a higher gain of knowledge, whereby the set quality targets can be reached faster.

4 Application of CPA Algorithm in Joining

4.1 Laser Beam Welding

The objective of the first case study is the development of a process-specific software demonstrator for the virtual prediction of both welding parameters to be set (given welding results) and multivariate welding results (given parameters) based on surrogate models for the example of laser beam welding. This goal is to be achieved by developing an approach based on CPA with which the complete two-dimensional weld geometry can be processed as a multivariate data set and statistically evaluated.

In contrast to the state of the art, the welding parameters are to be linked to multivariate welding result variables with the aid of selected model functions, which can consist of over one million dependent result values (see Fig. 2). To verify the functionality of the CPA, three welding process parameters (laser power, focus position, laser speed) were varied in the experiment and only 12 real image-based micrographs were generated as data basis.

It has been demonstrated that it is possible to process entire image micrographs or even weld cross-section contours by statistical models and thus to predict complex welding results, such as the geometry of the heat-affected zone or/and the fusion area, and to visualize them in a 2D result plot.

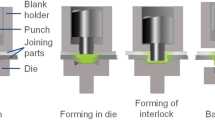

4.2 Clinching

FEM-based parameter studies have great relevance in the design of clinch tools. Often, only a small number of target parameters such as geometry parameters, strength values or forces are taken into account to analyze the quality of the joined joint. On the basis of CPA, a description of the entire clinch geometry becomes possible via a mathematical model. The aim of the optimization is to maximize the interlock and neck thickness for the entire clinch contour.

For the process design of the clinching process, a 2D simulation model was created using the FE solver Deform. The FE model is parameterized in such a way that the input parameters can be systematically varied within defined parameter limits during each simulation run. As input parameters, ten tool and process parameters (e.g. diameter of the die, diameter of the punch, blank thickness), were varied. To achieve the most uniform distribution of samples in the experimental space, a sample set with 100 design variants was generated using Latin Hypercube Sampling (LHS).

As shown in Fig. 3, the CPA algorithm is able to create a surrogate model that mathematically generates the 2D cross-sectional geometry of the mechanical joint in real time as the tool parameters change freely in parameter space. The interactions between tool parameters and clinch contour can be reproduced with a very high forecasting quality.

Furthermore, it could be shown that the additional application of an evolutionary algorithm offers the possibility to optimize the entire clinch contour with regard to relevant joint parameters such as undercut and neck thickness.

4.3 Self Pierce Riveting

The aim of the research project was to develop a FE-solver-independent joining assistance system for self-pierce riveting that visualizes the functional relationship between process parameters and user-defined result variables such as joining point geometry, crack formation or tool load as a 2D cross-sectional model in real time on the basis of joining process simulation data.

To build the database, a rotationally symmetric 2D simulation model was constructed using the software Simufact Forming and 150 simulation variants were calculated. A total of 14 process parameters (e.g. blank thickness, diameter die, riveting height) were modified in the simulation. For a user-friendly use of the CPA models, a software demonstrator was built (ref. Fig. 4). In this demonstrator, the 14 input parameters are set using sliders and, based on this input data set, the predicted joining point contour is immediately visualized. Based on this geometry, the characteristic parameters and the maximum joining force of the predicted joint are automatically calculated. In addition, the user can have the predictions of all integrated output variables displayed. These are visualized node/element-wise via color gradients, as one is used to from commercial simulation software. In addition, it is possible to directly display the value of the currently selected output size for nodes in the software by clicking on the corresponding accounts. If another output size is selected, then not only the coloring/scale will change, but also the value of the selected node will be updated.

4.4 Car Body Manufacturing

In this case study CPA algorithm is used to identify causal relationships in industrial process chains such as car body manufacturing. The database comprises in-line measurement data and fixture adjustments for a series system in which approx. 600 cars (Porsche Panamera) were built. The objective was to determine the causal effects of the measured values and the fixture adjustments of the steps “front section”, “rear section”, “floor center” and the assembly “underbody” on the “body assembly” (Fig. 5). The “side panels” are measured separately and included in the process input.

It is shown that by applying the CPA method to a car body process chain, it was possible to combine dependent data sets (e.g. geometry) and independent input data sets (e.g. fixture adjustments) to form a surrogate model. The cause of variations in the assembly stage could be identified and used to derive compensation measures. The accuracy of the final car body assembly and the process chain efficiency are significantly improved.

5 Conclusion

Digitization is steadily growing in joining processes. More and more data on the process, measurement and simulation is available to manufacturers. The aim of the data acquisition is to determine the effect of process parameter variations on quality-relevant target variables (e.g. dimensional accuracy, strength values).

Within the paper, Coupled Process Analysis (CPA) was presented for the statistical analysis of joining processes. The CPA is a machine learning method that is designed to recognize quality-relevant process parameters in a few simulation or production runs and to make corresponding compensation suggestions. The strength and focus of CPA lie in the creation of surrogate models by applying efficient data reduction methods. This allows multivariate data structures (images, in-line measurement data, FE-meshes) to be processed and complex relationships to be visualized with maximum information content for the user.

Moreover, a verification shall be conducted regarding the ability of CPA to determine correlations in other joining processes. Furthermore, the transferability of the CPA method to other industrial processes can be examined, e.g. in medicine, the chemical.

References

Acherjee, B., Misra, D., Bose, D., Venkadeshwaran, K.: Prediction of weld strength and seam width for laser transmission welding of thermoplastic using response surface methodology. Opt. Laser Technol. 41(8), 956–967 (2009). https://doi.org/10.1016/j.optlastec.2009.04.007

Acherjee, B., Mondal, S., Tudu, B., Misra, D.: Application of artificial neural network for predicting weld quality in laser transmission welding of thermoplastics. Appl. Soft Comput. 11(2), 2548–2555 (2011). https://doi.org/10.1016/j.asoc.2010.10.005

Acherjee, B., Kuar, A.S., Mitra, S., Misra, D.: Modeling and analysis of simultaneous laser transmission welding of polycarbonates using an FEM and RSM combined approach. Opt. Laser Technol. 44(4), 995–1006 (2012). https://doi.org/10.1016/j.optlastec.2011.10.018

Anawa, E.M., Olabi, A.G.: Using Taguchi method to optimize welding pool of dissimilar laser-welded components. Opt. Laser Technol. 40(2), 379–388 (2008). https://doi.org/10.1016/j.optlastec.2007.07.001

Bäume, T., Zorn, W., Drossel, W.-G., Rupp, G.: Iterative process control and sensor evaluation for deep drawing tools with integrated piezoelectric actuators. Manuf. Rev. 3(H3) (2016). https://doi.org/10.1051/mfreview/2016002

Behrens, B.-A., Groche, P., Krüger, J., Wulfsberg, J.P.: WGP-Standpunkt Industriearbeitsplatz 2025. Technical Report, WGP Wissenschaftliche Gesellschaft für Produktionstechnik e.V., Hannover (2018)

Benyounis, K.Y., Olabi, A.G.: Optimization of different welding processes using statistical and numerical approaches—a reference guide. Adv. Eng. Softw. 39(6), 483–496 (2008). https://doi.org/10.1016/j.advengsoft.2007.03.012

Breckweg, A.: Automatisiertes und prozessüberwachtes Radialclinchen höherfester Blechwerkstoffe. Doctoral thesis, University of Stuttgart (2006)

Datta, S., Nandi, G., Bandyopadhyay, A., Kumar Pal, P.: Application of PCA-based hybrid Taguchi method for correlated multicriteria optimization of sub-merged arc weld. A case study. Int. J. Adv. Manuf. Technol. 45(3–4), 276–286 (2009). https://doi.org/10.1007/s00170-009-1976-0

Dhas, J.E.R., Dhas, S.J.H.: A review on optimization of welding process. Procedia Eng. 38, 544–554 (2012). https://doi.org/10.1016/j.proeng.2012.06.068

Drossel, W.-G., Falk, T., Israel, M., Jesche, F.: Unerring planning of clinching processes through the use of mathematical methods. KEM 611–612, 1437–1444 (2014). https://doi.org/10.4028/www.scientific.net/KEM.611-612.1437

Eşme, U.: Application of Taguchi method for the optimization of resistance spot welding process. Arabian J. Sci. Eng. 34(2B) (2009)

Gunaraj, V., Murugan, N.: Application of response surface methodology for predicting weld bead quality in submerged arc welding of pipes. J. Mater. Process. Technol. 88(1–3), 266–275 (1999). https://doi.org/10.1016/S0924-0136(98)00405-1

Hahn, O., Tan, Y.: Vorhersage des Tragverhaltens von Clinchverbindungen unter quasi-statischer Scherzugbelastung mittels eines neuronalen Netzes. Schweißen Und Schneiden 4, 138–143 (2003)

Hahn, O., Tan, Y., Voight, H.-M.: Maschinelles Lernen zur Vorhersage der Tragfähigkeit von Clinchverbindungen. UTF Sci. 1 (2005)

Hu, M., Lin, Z., Lai, X., Ni, J.: Simulation and analysis of assembly processes considering compliant, non-ideal parts and tooling variations. Int. J. Mach. Tools Manuf. 41(15), 2233–2243 (2001). https://doi.org/10.1016/S0890-6955(01)00044-X

Ismail, M.I.S., Okamoto, Y., Okada, A.: Neural network modeling for prediction of weld bead geometry in laser microwelding. Adv. Opt. Technol. 5, 1–7 (2013). https://doi.org/10.1155/2013/415837

Jäckel, M., Falk, T., Landgrebe, D.: Concept for further development of self-pierce riveting by using cyber physical systems. Procedia CIRP 44, 293–297 (2016). https://doi.org/10.1016/j.procir.2016.02.073

Jiang, P., Cao, L., Zhou, Q., Gao, Z., Rong, Y., Shao, X.: Optimization of welding process parameters by combining Kriging surrogate with particle swarm optimization algorithm. Int. J. Adv. Manuf. Technol. 86(9–12), 2473–2483 (2016). https://doi.org/10.1007/s00170-016-8382-1

Kriechenbauer, S., Müller, P., Mauermann, R., Drossel, W.-G.: Extension of process limits with bidirectional deep drawing: In: Behrens, B.A., Brosius, A., Hintze, W., Ihlenfeldt, S., Wulfsberg, J.P. (eds.) Production at the Leading Edge of Technology. WGP 2020. Lecture Notes in Production Engineering. Springer, Berlin, Heidelberg (2020). https://doi.org/10.1007/978-3-662-62138-7_10

Lambiase, F., Di Ilio, A.: Optimization of the clinching tools by means of integrated FE modeling and artificial intelligence techniques. Procedia CIRP 12, 163–168 (2013). https://doi.org/10.1016/j.procir.2013.09.029

Liao, B., Shi, Y., Cui, Y., Cui, S., Jiang, Z., Yi, Y.: Mathematical model for prediction and optimization of weld bead geometry in all-position automatic welding of Pipes. Metals 8(10), 756 (2018). https://doi.org/10.3390/met8100756

Lightfoot, M.P., Bruce, G.J., McPherson, N.A., Woods, K.: The application of artificial neural networks to weld-induced deformation in ship plate. Welding J. 23–30 (2004)

Mirapeix, J., García-Allende, P.B., Cobo, A., Conde, O.M., López-Higuera, J.M.: Real-time arc-welding defect detection and classification with principal component analysis and artificial neural networks. NDT & E Int. 40(4), 315–323 (2007). https://doi.org/10.1016/j.ndteint.2006.12.001

Oudjene, M., Ben-Ayed, L.: On the parametrical study of clinch joining of metallic sheets using the Taguchi method. Eng. Struct. 30(6), 1782–1788 (2008). https://doi.org/10.1016/j.engstruct.2007.10.017

Oudjene, M., Ben-Ayed, L., Delamézière, A., Batoz, J.: Shape optimization of clinching tools using the response surface methodology with moving least-square approximation. J. Mater. Process. Technol. 209(1), 289–296 (2009). https://doi.org/10.1016/j.jmatprotec.2008.02.030

Padmanaban, G., Balasubramanian, V.: Optimization of laser beam welding process parameters to attain maximum tensile strength in AZ31B magnesium alloy. Opt. Laser Technol. 42(8), 1253–1260 (2010). https://doi.org/10.1016/j.optlastec.2010.03.019

Pan, L.K., Wang, C.C., Hsiao, Y.C., Ho, K.C.: Optimization of Nd. YAG laser welding onto magnesium alloy via Taguchi analysis. Opt. Laser Technol. 37(1), 33–42 (2005). https://doi.org/10.1016/j.optlastec.2004.02.007

Purr, S., Meinhardt, J., Moelzl, K., Ostermair, M., Hagenah, H., Merklein, M.: Stamping plant 4.0—data mining for investigation and prediction of quality issues in manufacturing car body parts. In: Landgrebe, D., Drossel, W.-G., Putz, M. (eds.) 5th International Conference on Accuracy in Forming Technology and 22nd Saxon Conference on Forming Technology SFU 2015, pp. 623–642. Verlag Wissenschaftliche Scripten, Tagungsband; Auerbach (2015). https://doi.org/10.5120/12106-8375

Rao, P.S., Gupta, O.P., Murty, S.S.N., Rao, A.B.K.: Effect of process para-meters and mathematical model for the prediction of bead geometry in pulsed GMA welding. Int. J. Adv. Manuf. Technol. 45(5–6), 496–505 (2009). https://doi.org/10.1007/s00170-009-1991-1

Roux, E., Bouchard, P.: Kriging metamodel global optimization of clinching joining processes accounting for ductile damage. J. Mater. Process. Technol. 213(7), 1038–1047 (2013). https://doi.org/10.1016/j.jmatprotec.2013.01.018

Schwarz, C., Ackert, P., Mauermann, R.: Principal component analysis and singular value decomposition used for a numerical sensitivity analysis of a complex drawn part. Int. J. Adv. Manuf. Technol. 894, 2255–2265 (2018). https://doi.org/10.1007/s00170-017-0980-z

Schwarz, C., Kropp, T., Kraus, C., Drossel, W.-G.: Optimization of thick sheet clinching tools using principal component analysis. Int. J. Adv. Manuf. Technol. 106, 471–479 (2020). https://doi.org/10.1007/s00170-019-04512-5

Schwarz, C., Link, P., Ihlenfeldt, S., Drossel, W.-G.: Application of Fourier-related data reduction methods in sheet metal forming. Procedia CIRP 99, 206–265 (2021). https://doi.org/10.1016/j.procir.2021.03.038

Sivaraos Milkey, K.R., Samsudin, A.R., Dubey, A.K., Kidd, P.: Comparison between Taguchi method and response surface methodology (RSM) in modelling CO2 laser machining. Jordan J. Mech. Indust. Eng. 8(1), 35–42 (2014)

Srivastava, S., Garg, R.K.: Process parameter optimization of gas metal arc welding on IS:2062 mild steel using response surface methodology. J. Manuf. Process. 25, 296–305 (2017). https://doi.org/10.1016/j.jmapro.2016.12.016

Tan, Y., Hahn, O., Du, F., Voigt, H.: Non-destructive determination of the loading capacities of clinched DC 04 joints by kNN-regression. Mater. Test. 48(5), 211 (2006)

Thoms, V., Kalich, J.: Prozessvorhersage beim Stanznieten mit neuronalen Netzen, EFB-Forschungsbericht Nr. 179. EFB 2002, Hannover (2002)

Wahl, M., Schulz, F., Altermann, T., Eckert, A.: Die Prozesskettensimulation - Ein Beitrag zum virtuellen Karosseriebau. In: Neugebauer, Reimund, (eds) Karosserien fertigen - nachhaltig und effizient, pp. 259–269. Verlag Wissenschaftliche Scripten, Tagungsband; Zwickau (2011)

Wang, M., Xiao, G., Li, Z., Wang, J.: Shape optimization methodology of clinching tools based on Bezier curve. Int. J. Adv. Manuf. Technol. 24(1) (2017). https://doi.org/10.1007/s00170-017-0987-5

Xu, W.H., Lin, S.B., Fan, C.L., Zhuo, X.Q., Yang, C.L.: Statistical modelling of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int. J. Adv. Manuf. Technol. 72(9–12), 1705–1716 (2014). https://doi.org/10.1007/s00170-014-5799-2

Yang, Y., Gao, Z., Cao, L.: Identifying optimal process parameters in deep penetration laser welding by adopting Hierarchical-Kriging model. Infrared Phys. Technol. 92, 443–453 (2018). https://doi.org/10.1016/j.infrared.2018.07.006

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Schwarz, C., Ackert, P., Falk, T., Puschmann, M., Mauermann, R., Drossel, WG. (2022). Model-Based Joining Process Design for the Body Shop Process Chain. In: da Silva, L.F.M., Martins, P.A.F., Reisgen, U. (eds) 2nd International Conference on Advanced Joining Processes (AJP 2021). Proceedings in Engineering Mechanics. Springer, Cham. https://doi.org/10.1007/978-3-030-95463-5_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-95463-5_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-95462-8

Online ISBN: 978-3-030-95463-5

eBook Packages: EngineeringEngineering (R0)