Abstract

Viscous characteristics of a Newtonian fluid is described by the dynamic (absolute) and the kinematic viscosity coefficients. The dynamic viscosity coefficient expresses the required applied force per unit area of the one laminar plane of the fluid in order to move it with respect to the adjacent, at an unit velocity. The Kinematic viscosity coefficient is the ratio of dynamic viscosity coefficient and the density of the fluid. This paper presents two simple software procedures for determination of the kinematic viscosity coefficient of real fluids. In addition, the laboratory experimental measurements of some oils’ viscosities were done to confirm the proposed procedures, and are presented in the paper as well. The authors intended for the procedures to be used for educational purposes at the college level entry.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

All fluids are real fluids, as an ideal fluid is an imaginary non-viscous substance which does not display surface tension. In the nature, no such fluid exists, however there are fluids with higher or lower viscosity coefficients.

Viscosity is the measure of the diffusion of momentum due to the microscopic molecular nature of the real fluids [1]. The effect of the momentum is production of resistance to the shearing motions within the fluid. Therefore, this resistance is a frictional force with the origins in interactions among molecules building the fluid. The net frictional force dissipates organized, macroscopic forms of energy, which is kinetic energy in the flow field, and converts it into disorganized, microscopic form of energy, which is heat.

It was shown by Stokes that the frictional force on a sphere moving with constant velocity in a fluid, depends on the sphere’s diameter, velocity, and the shear viscosity. The dependence is obtained by solving the equations of motion for the translational flow of fluid around a rigid sphere assuming stick boundary conditions. If slip boundary conditions are assumed, the frictional force is smaller [2]. This is known as the Stokes law, and the frictional force is often called the drag force, to distinguish it from the mechanical friction.

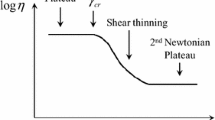

This contribution is limited to the Newtonian fluids, which are fluids that do not change their viscous characteristics when a force is applied [3]. All oils are Newtonian fluids. However, viscous characteristics depend on time and temperature. Since the aim of this study is to present procedures for real fluid model or simulation in order to determine viscosity coefficients of engine oils and oils of similar consistencies, the viscous characteristics of analyzed oils weakly depend on both, the time and temperature parameters.

Furthermore, the analyzed fluids are assumed to flow in a laminar motion, which means that the particles of the fluid are grouped and move in regular parallel paths [4]. These paths are not interrupted by any constant flows in the perpendicular direction. That said, the instantaneous deformations of the laminar planes caused by the passing of the object between the planes are small turbulences which do not change the overall direction of the flow of the fluid.

Viscous characteristics of a Newtonian fluid is described by the dynamic (absolute) and the kinematic viscosity coefficients. The dynamic viscosity coefficient expresses the required applied force per unit area of the one laminar plane of the fluid in order to move it with respect to the adjacent, at an unit velocity. The Kinematic viscosity coefficient is the ratio of dynamic viscosity coefficient and the density of the fluid. The usual notation of the engine oil viscosity is of the form: XW-NN, where X indicates the flow rate at zero degrees, whereas NN indicates the kinematic viscosity coefficient at 100 °C.

This paper presents two simple software procedures for determination of the kinematic viscosity coefficient of real fluids, oils. First procedure is a model done in the MATLAB software, and the second procedure is a simulation done in the FlowVision software. Both software procedures were developed in accordance with the principles of the Ostwald viscosimeter [5]. The Ostwald viscosimeter is a manual apparatus for determination of viscosities of solutions of known densities. It is a glass U-tube with two bulbs connected by a capillary. One measures the time of the flow of a solution of unknown viscosity between two markings, and does so again for a standard sample. Solving the equations of motions for the unknown solution and the standard sample gives the ratio of the viscosities equal to the ratio of the densities times the ratio of flow times [6]. That said, manual measurements could result with an error due to individual readings, so recently the Ostwald viscosimeter was modified into digital electro-viscosimeter [2]. Furthermore, [8] proposed the Ansys software solution of the manual Ostwald viscosimeter. However, in this contribution a mathematically simpler approach is proposed. This approach relies on the same base principle of the Ostwald viscosimeter, but does not require the sample solution for comparison. By modelling a closed ball-beaker system, in which the ball is moving thru a liquid, the ball’s movement allows for determination of the viscosity of a fluid, due to the principle of relative motion. In addition, the laboratory experimental measurements of oils’ viscosities were done to confirm the results of the procedures, and are presented in the paper as well. To eliminate manually measuring the flow times, which could result with an error, an Arduino probe was programmed to measure the time parameter in the laboratory setup. The authors intended for the procedures to be used for educational purposes at the college level entry, but can be used as an initial step of the maintenance of a vehicle as well, as proposed in [9].

2 The Model

To determine the kinematic viscosity coefficient, a simple setup was imagined: A small homogeneous rounded rigid body, the ball, falling in a glass tube filled with fluid. The width of the tube relative to the radii of the ball is such that the effects of the tube walls are neglectable. In a slip model, the motion of the ball is just translatory from the top of the tube to the bottom of the tube. In a stick model, the ball rotates in between lamellar planes of the fluid, changing the direction of the spin, while moving translatory from the top to the bottom of the tube.

In the following analysis of the real fluid, the forces acting on the ball are considered immediately after the ball is set in motion.

2.1 Assuming Slip Boundary Conditions

The forces acting on the ball of the mass \(m\) and radii \({r}_{b}\) moving in the fluid are: The gravitational force \(\vec{F}_{G}\) directed downwards, the buoyant force \(\vec{F}_{B}\) directed upwards, and the drag force \(\vec{F}_{D}\) directed upwards. The equation of motion considering the magnitudes of the acting forces is then:

By definition, the gravitational force equals \(mg\), where \(g\) is gravitational constant. The buoyant force depends on the density of the fluid \({\rho }_{f}\) and the volume of the ball \({V}_{b}\) as \({\rho }_{f}{V}_{b}g\). The Stokes law for the real fluid, assuming slip boundary conditions, gives the drag force on the ball as \(6\pi \eta {r}_{b}v\), where \(\eta \) is the kinematic viscosity coefficient and \(v\) the ball’s velocity. Therefore, Eq. (1) becomes:

To simplify the Eq. (2), all constants are written as \(\alpha ={F}_{G}-F\) and \(\beta =6\pi \eta {r}_{b}\). Now, the Eq. (3) is of the form:

To obtain the velocity of the ball in dependence of time, the further is applied:

Solutions of the Eq. (4) were obtained in MATLAB software using the procedure shown in Fig. 1.

The duration of the procedure was set on \(t = 2\,{\text{s}}\). When the magnitude of the gravitational force equals the sum of the magnitudes of the buoyant and the drag force acting on the ball, the ball stops accelerating and further has constant velocity called terminal velocity \({v}_{T}\). While the ball is moving at \({v}_{T}\), it is possible to determine the kinematic viscosity coefficient \(\eta \). For paraffin oil, common oil and glycerol, the results of the procedure are presented in Table 1, where \({t}_{T}\) is the time required to achieve the terminal velocity \({v}_{T}.\)

2.2 Assuming Stick Boundary Conditions

In a real fluid the ball rotates while overall moving translatory. The rotation of the ball is caused by interaction of the ball with the lamellar planes of the fluid (as if the ball is falling in between window curtains). These interactions cause the changing spin of the ball’s rotation as well. As a reaction, the lamellar planes also deform slightly and shortly, which is commonly known as turbulence. Therefore, the Stokes law for the real fluid assuming stick boundary conditions, gives the drag force to be:

where \(C\) is a drag coefficient and for a small homogeneous rigid rounded object \(C=0.5,\) and \(S\) is the surface area of the ball.

Inserting Eq. (5) in the Eq. (1), gives:

Let the \(\gamma =\frac{1}{2}C{\rho }_{b}S\) as all parameters are constants and it simplifies the writing. Following the same steps done for the slip model, one obtains:

Solutions of the Eq. (7) were obtained in MATLAB software using the procedure shown in Fig. 2.

The duration of the procedure was set on \(t = 2\,{\text{s}}\). The results of the procedure are presented in Table 2.

3 The Simulation of the Real Fluid

To simulate the real fluid two softwares were used, the FlowVision and the Solidworks. The SolidWorks software was used to create a domain where the ball is moving. This domain was created using real life parameters of a glass beaker which was later used in a laboratory setup (presented in the Sect. 4). On the other hand, the FlowVision software allows simulation of the real fluid movement where parameters are adjusted for the movement of the observed ball, and separately for fluid behavior. Note that the simulation assumes stick boundary conditions.

First step was to set a physical model by adding a hydrostatic layer and specifying the following parameters: gravity vector, g-point, and stratum (thickness and density). The second step was to create a substance, which is the real fluid, by setting parameters: aggregative state, molar mass, density, viscosity, and specific heat capacity. All the parameters that were set correspond to the real fluids used in the later experiment. The next step was to determine fluid behavior. FlowVision enables description of physical model of motion with the Navier–Stokes theorem which is embedded in the software. The turbulence can be realized by setting in the “Physical processes” window: “Motion” to “Navier–Stokes model” and “Turbulence” to the desired model. The following step refers to the moving ball and adjusting parameters of radii, subdivisions, mass, and translation. In the FlowVision software, the ball can move in any direction of the 3D space, so the remaining settings were set in order to control the direction of the ball’s motion. In the end, the ball was positioned in the Cartesian coordinate system at the very top of the previously inserted graduated beaker, as shown in Fig. 3.

Upon setting all mentioned parameters, simulation was started. Results of the simulation for the three real fluids, paraffin, common oil and glycerol, are presented in Table 3. Additionally, the kinematics of the ball was inspected. The time dependencies of the ball’s velocities in the three analyzed fluids are shown in Fig. 4, Fig. 5 and Fig. 6. As seen in the figures, the ball is accelerating for the time \(\mathrm{d}s\) until it reaches definite terminal velocity \({v}_{T}\), which is constant for the rest of the simulation. This indicates that the simulation reflects the physical situation well.

4 The Laboratory Setup

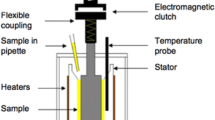

To test if the simulated real fluid was real, experimental measurements of the kinetic viscosity coefficients were done. The laboratory setup, shown in Fig. 7, followed the simulated situation: a glass beaker of radii \(R=0.024\) m and height \(H\) was filled with the real fluid. The time parameter \(\mathrm{d}t\) was measured with the Arduino programmed probe. The probe gave the time required for the ball to pass the fraction of the path \(\mathrm{d}s=0.025\) m of the overall distance \(H\). In addition, when the \(\mathrm{d}t\) became constant, it indicated that the ball was moving with constant velocity. The terminal velocity \({v}_{T}\) was equal to distance over a sum of times. Characteristics of the ball were known and were:

-

Density \({\rho }_{b}=1380\) kg/m3,

-

Mass \(m = 6.244 \cdot 10^{ - 4} \,{\text{kg}}\),

-

Radii \(r_{b} = 4.762 \cdot 10^{ - 3} \;{\text{m}}\),

-

Surface area \(S = 7.126 \cdot 10^{ - 5} \;{\text{m}^2}\).

Once the terminal velocity was obtained, all parameters were plugged into Eq. (7), which was solved for the only unknown parameter \(\eta \). The results of the measurements are presented in Table 4.

5 Comparison of Results Obtained by the Model, the Simulation and Experimentally

Kinetic viscosity coefficients of three real fluids were determined by three means, by modelling, by simulation, and experimentally. As the same setup was used in all three methods, it is justified to make a comparison of the results obtained. Absolute differences among the results are presented in Table 5, whereas relative differences among the results are presented in Table 6, where \({\Delta }_{M-S}\) indicates the difference between the model and the simulation, \({\Delta }_{M-E}\) indicates the difference between the model and the experiment, and the \({\Delta }_{S-E}\) indicates the difference between the simulation and the experiment. For better visualization of the results obtained by the three methods, they are shown in Fig. 8.

As was expected, the model done in the MATLAB Software and the simulation done in the FlowVision gave almost identical results, the exception being kinetic viscosity coefficients of the glycerol, with the absolute difference of, that is relative difference of only 0.1%. Kinetic viscosity coefficients of all tested fluids in laboratory setup are slightly higher than the coefficients obtained by the model and the simulation. This is due to the additional turbulence caused by placing the ball in the fluid. However, their relative differences are all less than 5%, as seen in the Table 6, which is to say that the modeled and the simulated fluid was done real.

6 Conclusions

Kinetic viscosity coefficients of three real fluids were determined by three means. In all three methods, the same setup was used: a ball falling in the tube filled with viscous fluid. Firstly, the model of the real fluid was done in the MATLAB software. Secondly, the real fluid was simulated in the FlowVision, upon building the domain in the Solidworks. Finally, the coefficients were determined experimentally.

Relative differences among the results revealed the following: The kinetic viscosity coefficients obtained by the model and by the simulation statistically do not differ, which indicates that both approaches give solid results. Furthermore, the relative difference between the results obtained experimentally and the results obtained by the model, as well as the relative difference between the results obtained experimentally and the results obtained by the simulation, is less than statistically significant (<0.05). Nevertheless, this small difference exists due to the fact that additional turbulence was caused while dropping the ball in the glass beaker while performing the experiment in the laboratory setup, which was not included in the model/simulation.

However, it can be concluded that the simple model or simulation presented in this contribution is well to be used to determine the viscosity coefficients of the real fluids which viscose characteristics do not strongly depend on time.

References

Doering, C.R., Gibbon, J.D.: Applied Analysis of the Navier-Stokes Equations. Cambridge University Press, London (1995)

Walser, R., Mark, A.E., van Gunsteren, W.F.: On the validity of Stokes’ law at the molecular level. Chem. Phys. Lett. 303(5–6), 583–586 (1999)

Papanastasiou, T., Georgiou, G., Alexandrou, A.N.: Viscous Fluid Flow. CRC Press, New York (2021)

Fjørtoft, R.: Application of integral theorems in deriving criteria of stability for laminar flows and for the baroclinic circular vortex. Grøndahl and søns boktr, I kommisjon hos Cammermeyers boghandel, Oslo (1950)

Janakiraman, D.: Wilhelm Ostwald, the father of physical chemistry. Resonance 17(5), 454–466 (2012)

Langton, N.H., Vaughan, P.: The effects on flow time of tilting an Ostwald viscometer. J. Sci. Instr. 42(5), 317 (1965)

Saxena, I., Kumar, V.: Automatic version of Ostwald viscometer for conductive liquids. Instr. Exp. Tech. 64(2), 327–330 (2021)

Azziz, H.N., Hussein, E.Q., Abdulhameed, M.A.: Analysis of fluid flow states in viscometers in ansys software. In: IOP Conference Series: Materials, Science and Engineering, vol. 1067, no. 1, pp. 012091-012116 (2021)

Glavaš, H., Karakašić, M., Kljain, M., Desnica, E.: Essential preventive automobile maintanance during a pandemic. Tehnički vjesnik 6(28), 2190–2199 (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Dukić, J., Jukić, D. (2022). Real Fluid Simulation for Determination of Engine Oil Viscosity. In: Glavaš, H., Hadzima-Nyarko, M., Karakašić, M., Ademović, N., Avdaković, S. (eds) 30th International Conference on Organization and Technology of Maintenance (OTO 2021). OTO 2021. Lecture Notes in Networks and Systems, vol 369. Springer, Cham. https://doi.org/10.1007/978-3-030-92851-3_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-92851-3_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92850-6

Online ISBN: 978-3-030-92851-3

eBook Packages: EngineeringEngineering (R0)