Abstract

Electronic textile (or e-Textile) is the material integrating digital information transmission ability and traditional fabric characteristics, which leads to great tactile interaction. However, the current research of the interaction of e-Textile are still influenced by the interaction mode adopted from electronic devices, such as the capacitive touch of the interactive elements. In this paper, we want to focus on how to interact with e-Textile in more textile characteristic ways, and pay more attention to the tactile semantics of materials in the process of interaction design. In order to apply the unique interactive way and interactive ability of e-Textile, this paper designs a group of interactive lighting devices. The lights combined with e-Textile can be used as output information to give feedback to the interactive behavior. The research for different interaction of e-Textile will expand the extension of fabric interaction mode, and tap the great potential of textile material properties in human-computer interaction.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Background

Fabric is the object that has been in contact with people for the longest time in the world. It is the second layer of human skin and the next possible information presentation carrier. As an indispensable material in people’s life, the significance of textiles is self-evident.

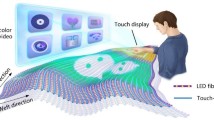

As a research field, e-Textile emerged with the development of conductive yarn. And its background is the prominent research fields such as wearable computing and entity interaction design [1]. E-Textile is the fabric that can embed digital components such as LED lights, minicomputers and sensors. As people are more and more interested in man-machine interface, the information input ability of e-Textiles can bring the possibility of digitalization to traditional fabrics, such as project Jacquard of Google [2]. and large-area display fabrics of Fudan University [3]. The texture of textile materials also provides a unique tactile experience for the interaction of e-Textile. But at present, the interaction of e-Textile is still using the traditional way adopted from electronic products.

In this paper, the electronic components are embedded and integrated into the traditional fabric, and we also design a tactile interaction device combining with the e-Textile interaction mode as the application.

1.2 Contribution

Although there are many researches on e-Textile today [4,5,6], the main point we focused on is the interactive way which is of great fabric characteristics.

We present two main contributions of this paper. On the one hand, combined with the existing research on tactile interactive material semantics, as well as the ability of information input and behavior monitoring of e-Textile, it provides the possibility of digital development for traditional fabrics.

On the other hand, instead of using the existing point-to-point interaction based on capacitive sensing to input information, this paper focuses on the physical properties and material properties of the fabric itself, and studies the functional significance of the structure and state of the fabric in electronic applications. It provides a research direction for the interaction of e-Textile to highlight the characteristics of material specialization and emotion.

2 Research on e-Textile

2.1 Development Status

In 1997, Rehmi Post and Maggie Orth introduced the interface with wire embroidery into the field of wearable computing [7]. However, e-Textile and wearable computing are two different concepts, because the key technology of e-Textile lies in the seamless integration of textiles and electronic components, such as microcontrollers, sensors and actuators.

Pailes Friedman [8] believes that the revolutionary significance of e-Textiles lies in that this integration method greatly expands the capability boundary of traditional fabrics, making them have the functions of energy exchange, storage and compilation for the first time.

E-Textile can provide multi-layer functions in a variety of new materials, including sensing, tactile, lighting and so on. As Dakova [9] pointed out, textiles reveal new ways of interaction and may support future innovative applications in the field of pervasive computing. At present, the interaction modes of e-Textile are click, slide, press, stretch and so on, and the capacitive touch is mainly used. The design of interactive elements refers to the buttons, sliders and so on in the entity interaction interface. In the e-Textile interface, it is the main form to imitate interactive elements through textile, embroidery and other ways.

In recent years, the research of e-Textile is more focused on embroidering conductive yarn on the fabric. Through user experiments, the recognition ability of individuals for interactive elements is studied, and the design principles in GUI field (such as Gestalt theory) are still applicable in the interface of e-Textile. Holleis [10] studied the structure of fabric interface. The author introduced the results of user research and summarized it as a guide for designing wearable accessories and clothing.

The Disadvantage of e-Textile Interaction.

E-Textile interaction belongs to the category of entity interaction, but its interaction mode and feedback ability are different from entity interaction. Comparing capacitive touch input with entity interaction, due to the limitation of interface and the fact that the interactive elements of e-Textile have no entity button, there is no button feedback when clicking or touching. B. P. Challis & A. D. n. Edwards of the University of York in the UK [11] found that double-click is an inappropriate form of interaction in static display. If there is no tactile feedback, double-click will become very inefficient.

This violates the timeliness and effectiveness of the operation feedback design principle. E-Textiles should be developed to pay more attention to the properties of the fabric itself, and more in line with the nature of the fabric interaction, rather than limited by the interaction form of electronic products.

The Advantages of e-Textile Interaction.

On the one hand, its deformation ability and softness enable the fabric to adapt to different shapes. The foldable and retractable features also make it portable and adaptable. On the other hand, the embedded integration of electronic components makes the form of information collection no longer limited to hard sensors.

Swatchbook [12] is an experimental project to study the interaction mode of e-Textile. Ramyah Gowrishankar and others mentioned that most e-Textiles still follow the interactive habit of electronic products [13]. In short, the advantage of e-Textile is the advantage of fabric itself. In order to give full play to the advantages of e-Textile interaction, we should explore and develop the material properties of the fabric itself.

2.2 Study on the Properties of Fabric Materials

In people’s life, based on each individual’s life experience, habits, and individual memories, people will build a cognitive knowledge base related to fabrics, in which different materials, products, shapes, touch, environment, vision, etc. related to fabrics have complex mapping and correlation with each other, and the cognition related to fabrics is complex and diverse. This chapter attempts to construct the cognitive knowledge base related to fabric by exhausting the physical state of fabric and the interaction ways related to fabric, and expand the extension of fabric interaction ways from the perspective of materials, so as to fully tap the great potential of textile material attributes in digital interaction.

Physical Properties of Fabric.

The study of fabric cognition can start from exploring the physical properties of fabric itself. This paper attempts to focus on the overall fabric material categories, summarize the characteristics of fabric materials, and pay attention to the fabric materials and corresponding forms in daily life. Based on the summary of the physical properties mentioned by Ramyah Gowrishankar, this paper further summarizes the physical state of the fabric, so as to facilitate the follow-up research on the interaction mode related to the fabric, and make better use of the affordance of the fabric in the design practice, as shown in Fig. 1.

Among these attributes, the degree of association with fabric attributes is also different. The degree of association here refers to whether a certain physical property can only be possessed by fabric and cannot be replaced by other materials. For example, folding, tearing, turning over, storage and other physical states can be replaced by paper or other thinner flexible plastic materials. The physical functions such as draping, tying, weaving and stretching are relatively difficult to be replaced by other kinds of materials, that is, these physical functions are more closely related to the fabric.

In the design practice of this paper, we will try to choose the form from the summarized physical state of textiles, combined with the relevant interaction methods, to show the new form of fabric interaction with the material advantages.

Interaction Mode of Fabric.

Due to the material characteristics of the fabric itself, the interaction of the fabric is relatively more unique. This paper summarizes the unique interaction modes of different forms and materials of fabrics. For fabrics in different states, people can interact with them in a variety of different ways (see Fig. 2).

Based on it, different kinds of interaction methods have requirements for the fabric’s own state or material. This paper sorts out the fabric state requirements corresponding to the relevant interaction modes, as well as the fabric properties required in the corresponding state and the corresponding textile products and intentions, as shown in Table 1.

Combined with the research on the emotional attributes and physical form of fabric, it is very able to show the interaction of fabric characteristics, such as “poke”, “hold”, “touch” and other interaction ways, which can be mapped with the emotional attributes such as “warmth” and “plush”. It is also consistent with the emotional interaction design direction that this paper wants to try.

The above arrangement of fabric related interaction provides basic research support for the research on the interaction mode of e-Textile with material characteristics.

3 Interactive Device Design

3.1 Design Target

By studying the physical properties and material affordance of traditional fabrics, combined with the information input ability of e-Textiles, we finally completed a series of device designs that interact in the unique way of fabrics.

Because some fabrics give people warm, natural, close feeling and encourage people to touch. In physical characteristics, it is warm, soft, plush, thick and translucent. After consideration, we decided to present in the form of lamps combined with fabric. From the perspective of metaphor, there are some overlapping parts between the semantics of light and fabric, which involve warmth, trust and closeness. The light through the fabric can present a unique visual texture, giving people a soft feeling. From the perspective of signal transmission, the device integrates and processes the user’’s behavior data, and finally converts it into the control of lighting parameters, such as switch, brightness, color temperature, flicker frequency, etc. The device is called ClothLight.

In the design process, this paper will consider the device form, fabric material affordance, device interaction mode, device light feedback form and device space display form.

3.2 Device Form Design

In the process of device design and scheme selection, this paper considers the following design elements as the principle to select the design scheme.

-

The form of the fabric is integrated with the light.

-

The state and form of the fabric seem to be interactive and could encourage interaction.

-

The form of fabric is diversified.

-

The matching of different fabric thickness and light transmittance with the brightness range of light source is considered.

To sum up, in the scheme design and selection, in order to promote the organic combination of light and fabrics, consider the interactivity of fabric form and highlight the sensing ability of fabric, this paper is more inclined to choose the fabric state with less rigid support structure in the scheme selection, as shown in Fig. 3, that is, the fabric is in a more natural state (such as hanging, hanging, hanging, etc.), in the form of unfolding.

Referring to the implication of fabric demonstration and its form on interaction mode, we finally decided to combine five different fabric forms with light, and carry out device interaction in different interaction modes (see Fig. 4).

In order to better guide the users natural interaction, we also consider the encouraging effect of fabric texture on interaction behavior. For example, soft fabrics wrapped in cotton can cause people to want to hug, press or poke. We comprehensively consider the visual expression and tactile feeling, on the basis of comprehensively showing the uniqueness of traditional fabrics and the interactive ability of e-Textiles, we try to show the fabric performance and material characteristics (see Fig. 5).

4 Device Implementation

From the perspective of information input and output, the implementation method of the device can be summarized as follows: the e-Textile detects the users interactive behavior and converts it into digital signal input control system, which converts the digital signal into light control signal and outputs it in the form of light change. After the formal design scheme is determined, we mainly need to make conductive fabrics and lamps.

4.1 Blending Experiment

The color and material of the ready-made conductive fabric are relatively single, and can’t reflect the material and tactile characteristics of the fabric itself, while the conductive adhesive tape and conductive ink are attached to the fabric, both the function and interaction form are relatively limited.

Considering from the design goal, the combination of traditional fabric and conductive yarn can not only retain the texture of the fabric, but also give full play to the tactile characteristics and emotional cognitive attributes of the fabric. Combined with the experimental results of some conductive materials and the fabric requirements of the device design, after comparison and sample test, we finally decided to use two kinds of yarn blended weaving method for the production of e-Textile.

Conductive Yarn Selection.

A series of experiments were carried out to screen con-ductive yarns. The selection goal is to retain the original traditional fabric properties as much as possible. On the basis of considering the processing difficulty, the two kinds of yarns should be organically integrated as far as possible. In this paper, we choose manual loom, electric loom, circular simple loom and simple shuttle loom to carry out small sample experiment. The experimental process is shown in Figs.6, 7, 8, 9, 10 and 11. The con-clusion is that silver fiber conductive yarn is more suitable for blending than stainless steel yarn.

Experiment C: mixed knitting experiment of wool and stainless-steel yarn. When knitting on a simple circular loom, the thread is often jammed and the machine often needs to be adjusted. In the textile process, it is very easy to twine and be off-line, which greatly increases the difficulty of mixed textile.

Experiment E: mixed knitting experiment of wool and silver fiber conductive yarn. Silver fiber yarn is light and soft. The blended fabric of silver fiber yarn and non-conductive yarn basically retains the fabric characteristics of the original non-conductive yarn. This kind of conductive yarn has little interference to the traditional fabric and has good conductivity.

Non-conductive Yarn Selection.

Combined with the form design and texture require-ments of the five devices, we choose different yarn and stitch methods, which are: rib stitch method which can produce fabric with good tensile property combined with silk thread with strong draping feeling, mohair with soft plush combined with knitting method, coarse cotton thread combined with knitting method, etc.

4.2 Conductivity Test

In this paper, the conductivity of conductive fabric, resistance change test and capacitance sensing test are carried out (Fig. 12).

The resistance change experiment shows that: due to the mixed textile of knitting structure and conductive yarn, a number of small coils will be formed in the fabric, and these coils will produce self-induction effect [14]. When the diameter of the coil changes in the process of stretching, the resistance of the whole fabric will change, so the stretching degree of knitted fabric can be detected by the change of fabric resistance. This device uses the mpr121 capacitance sensor, which has 12 interfaces, can judge the capacitance change of each interface and the conductive object connected with it, and can effectively and quickly accurately input the capacitance time point and duration. The results show that the change of fabric resistance caused by stretching is obvious.

The capacitive sensing experiment shows that the conductive yarn is embedded all over the whole fabric, and the signal input will be generated when touching the fabric in the capacitive sensing test.

4.3 Effect of Device

After the device design and practice, this paper finally completed a total of five groups of eight pieces of fabric lighting device (Figs. 13 and 14).

In the device interaction design, the interaction actions related to fabric materials are stretching, touching, repeatedly touching and stamping. The sensing methods are resistance change sensing and capacitance sensing. The feedback form is the increase of light intensity and the change of color temperature.

4.4 User Test

In order to verify the device interaction could reflect the fabric material affordance, and the accuracy of the device interaction can be implied by the material physical state and material characteristics, we use the observation method and interview method to carry out the user feedback experiment.

The sample size of the tested users is 54, including 48 teachers and students from various departments of Tsinghua University, 2 exhibition hall staff, and 4 visitors from outside the University. The experiment takes the form of camera shooting in the early stage and interview in the later stage. Without the interference of the researchers, the behavior of visitors is observed through the camera.

93% of the visitors interact with the device spontaneously without interactive guidance. This proves that the material properties of e-Textile can encourage people to interact with it. Among the five kinds of fabrics, the fabric with the highest probability of being touched is the fabric of plush material placed on the lamp ball, whose interaction probability is 98%. The fabric filled with cotton ranked second with 90% interaction rate. For each form of fabric, the interaction behavior of visitors is different. For example, for the hanging fabric, 24 visitors touch the fabric, 11 visitors push it to shake it, only 7 visitors hold it up, and 2 visitors stretch it down.

After the observation, we interviewed the selected observers about their subjective evaluation. 94% of the respondents said that they could feel the warmth and softness brought by the fabric and light. It can also feel the behavior detection ability of the fabric through the lighting after touching. And 86% of the people said that the five groups of devices are very typical of the physical state of the fabric, and their form can well indicate the interaction mode of the device. Most people expressed full curiosity and expectation for future work.

5 Conclusion

This paper summarizes the physical properties, emotional cognitive properties and material semantics of fabric, discusses how to apply the traditional fabric affordance demonstration in the field of e-Textile interaction, and embeds the conductive yarn into the fabric. Combined with the material properties of traditional fabrics and the information collection and sensing ability of e-Textiles, the interaction mode with fabric characteristics is explored and tried.

However, in this paper, the research on the sensing ability of e-Textiles is only limited to capacitance sensing and resistance stretching sensing. The latter has some technical limitations in the application process. For example, for conductive fabrics with poor resilience, the sensing method of resistance change for the e-Textile is life limited. Therefore, from the perspective of technical limitations, other kinds of sensing methods will be tried in the future, or on this basis, the stability of the technology will be enhanced.

In addition, the research on the interaction mode of e-Textile is still in the exploratory stage. In the follow-up research, we will explore the practical application significance of e-Textile from a more valuable perspective.

1. References

Post, E R., Orth, M., Russo, P R.: E-broidery: Design and fabrication of textile-based computing. IBM Systems journal 39(3.4), 840–860(2000).

Poupyrev, I., Gong, N W., Fukuhara, S.: Project Jacquard: interactive digital textiles at scale. In: Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems, pp. 4216–4227. (2016)

Large-area display textiles integrated with functional systems: Shi X, F., Zuo Y, S., Zhai P, T. Nature 591, 240–245 (2021)

Loss, C., Gonçalves, R., Lopes, C.: Smart coat with a fully-embedded textile antenna for IoT applications. Sensors 16(6), 938 (2016)

Klamka, K., Dachselt, R., Steimle, J.: Rapid Iron-On User Interfaces: Hands-on Fabrication of Interactive Textile Prototypes. In: Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, pp. 1–14. (2020).

Mečņika, V., Hoerr, M., Krieviņš, I.: Smart textiles for healthcare: applications and technologies. Rural Environment. Education. Personality 7, 150–161 (2014)

Gilliland, S., Komor, N., Starner, T.: The Textile Interface Swatchbook: Creating graphical user interface-like widgets with conductive embroidery. In: International Symposium on Wearable Computers (ISWC), pp. 1–8. (2010).

Gaddis, R.: What is the future of fabric? these smart textiles will blow your mind. what-is-the-future-of-fabric-these-smart-textiles-will-blow-your-mind, (2014).

Mlakar, S., Haller, M.: Design Investigation of Embroidered Interactive Elements on Non-Wearable Textile Interfaces. In: CHI ‘20: CHI Conference on Human Factors in Computing Systems, pp. 1–10. (2020).

Holleis, P., Schmidt, A., Paasovaara, S.: Evaluating capacitive touch input on clothes. In: Proceedings of the 10th international conference on Human computer interaction with mobile devices and services, pp. 81–90. (2008).

Challis, B.P., Edwards, A.D.N.: Design principles for tactile interaction. In: Brewster, S., Murray-Smith, R. (eds.) Haptic HCI 2000. LNCS, vol. 2058, pp. 17–24. Springer, Heidelberg (2001). https://doi.org/10.1007/3-540-44589-7_2

Swatchbook Exchanges. The E-Textile Summercamps Electronic Textile Swatch Exchange, http://etextile-summercamp.org/swatch-exchange/videos/.

Gowrishankar, R., Bredies, K., Ylirisku, S.: A Strategy for Material-Specific e-Textile Interaction Design. In: Schneegass, S., Amft, O. (eds.) Smart Textiles. HIS, pp. 233–257. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-50124-6_11

Fobelets, K.: Knitted Coil for Inductive Plethysmography. In: Multidisciplinary Digital Publishing Institute Proceedings, vol. 32, p. 2 (2019)

Acknowledgement

. This research was supported by 2019 National Social Science Foundation Art Project “Interaction Design Method Research based on AI”, the number is 19BG127.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Meng, X., Wu, Q. (2021). Design of an Interactive Device Based on e-Textile Material. In: Stephanidis, C., et al. HCI International 2021 - Late Breaking Papers: Multimodality, eXtended Reality, and Artificial Intelligence. HCII 2021. Lecture Notes in Computer Science(), vol 13095. Springer, Cham. https://doi.org/10.1007/978-3-030-90963-5_6

Download citation

DOI: https://doi.org/10.1007/978-3-030-90963-5_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-90962-8

Online ISBN: 978-3-030-90963-5

eBook Packages: Computer ScienceComputer Science (R0)