Abstract

This study describes an experimental investigation into the fundamental mechanical properties of masonry incorporating fired-clay bricks and hydraulic lime mortars under ambient-dry and wet conditions, used in many historic structures. The investigation includes tests on cylindrical cores in compression, square panels in diagonal compression and triplets in shear. Apart from conventional measurements, the use of digital image correlation techniques enables a detailed assessment of the influence of moisture on the constitutive properties and on the response kinematics of the member, including behaviour characteristics of the brick-mortar interfaces, crack propagation in tension and confinement effects in compression. The tests results show that on average the uniaxial compressive strength of wet brick–mortar cylinders is about 15% lower than their dry counterparts, whilst the shear strength of wet triplets is about 20% lower than of those in dry conditions. The diagonal tension strength of wet panels depends largely on the mortar properties and is about 30% lower on average than that of the dry panels. Based on the test results, the material shear-compression strength envelopes for wet and dry masonry are evaluated and compared with existing assessment models.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Clay bricks and stone blocks have been widely used as the main construction materials in historic structures. These are rarely provided with protection systems against moisture or rising damp, nor against significant temperature variations. Amongst the main causes of degradation of heritage masonry is the presence of high moisture content resulting from capillary absorption of groundwater. It is recognised that moisture can affect both the mechanical characteristics of masonry, as well as the plaster and rendering, and its effects need to be identified in combination with other structural problems (Cotic et al. 2013). A fundamental understanding and quantification of moisture effects on the mechanical properties of porous building materials such as masonry is hence required.

The behaviour of masonry components under combined normal and shear actions can be largely characterised by three independent mechanisms: shear sliding, diagonal cracking, and compressive crushing. These mechanisms are typically assessed through material tests to define the limit strength domain of masonry in the form of shear-precompression diagrams (Malyszko 2004). The interface brick-mortar bed joint response is characterised by a proportionality between shear and precompression in a Mohr-Coulomb type representation and is often obtained from small-scale triplet tests (Pelà et al. 2017). It has been shown that the mortar-brick interface shear response is dependent on the moisture content, porosity, mortar strength, and conditioning type (Franzoni et al. 2014). A recent comparative study on wet and dry triplets also indicated that the shear strength of wet triplets is, on average, about 20% lower than in dry conditions for practical ranges of precompression (Bompa and Elghazouli 2020a).

The diagonal cracking mechanism, on the other hand, is characterised by splitting or stepped sliding along the mortar joints, with the ultimate condition depending on the properties and geometry of the brick and mortar as well as their interaction (Malyszko 2004). Although various representative diagonal panel tests are reported in the literature, particularly for comparing strengthened and non-strengthened cases (Koutas et al. 2014), such tests on wet conditions seem to be lacking. The third mechanism defining the shear-compression stress space is masonry crushing. Whilst there is general agreement that moisture reduces the compressive strength and elastic modulus of masonry, this varies with the mortar properties and brick unit porosity (Sathiparan and Rumeshkumar 2018; Bompa and Elghazouli 2020b).

In this paper, the performance of fired-clay brick-lime mortar components in ambient-dry and wet conditions, corresponding to 48 h submersion in water, are investigated through a series of compressive tests on square diagonal panels, cylindrical cores and shear tests on triplets. The bricks and mortars were selected to resemble the properties of masonry components investigated in a wider research programme on the management and conservation of heritage masonry structures in Historic Cairo (Elgahzouli et al. 2018). This paper focuses on the assessment and quantification of the influence of moisture on the constitutive response and mechanical properties of masonry components and enable the assessment of the material shear-compression strength envelopes for the masonry investigated in this paper.

2 Constituent Materials

Commercial fired clay facing solid bricks with measured sizes of 229 × 110 × 66 mm were used for the construction of all specimens. The measured average compressive strength of brick units parallel to the testing bed, obtained from a minimum of three tests, was about 15.5 MPa in both dry and wet conditions, with the latter corresponding to full submersion in water for 48 h. From readily available materials, this type of fired-clay bricks has the closest physical and mechanical properties to those from the Mausoleum of Fatima Khatun (Umm al-Salih) built in the 13th century in Cairo, which is assessed in the project.

The characteristics of the selected fired-clay bricks are hence within the range of those from the site survey, typically found in such heritage masonry, and can be used for comparative assessments and structural repair studies. The moisture content of both conditioning cases for bricks was assessed. The ambient-dry samples and those submersed in tap water for a minimum of 48 h, were dried in an oven for 6 h at 60 ℃ and another for 18 h at 105 ℃ until the sample mass was relatively constant. The moisture content of ambient-dry bricks was 0.07% by weight (wt.%), and 10.46 wt.% for those submersed in water.

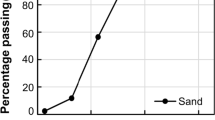

Mortars incorporating natural hydraulic lime (NHL5) with a binder-to-aggregate ratio of 1:3 were selected for the study as these are typically used for conservation works. These are singular binders which combine hydraulic with air setting, obtained by carbonation with atmospheric CO2. The free lime Ca(OH)2 is above 15%, whilst the sulphates content is below 2%. Mortars with a consistency of 180–200 mm were prepared in 15 L buckets and mixed until becoming homogenous using a hand-held electric paddle mixer. Samples of fresh mortar were taken selectively, covered with a plastic sheet and removed from moulds after five days.

Compressive strengths were determined from compression tests on a total of 95 ambient-dry and wet cubes (50 × 50 × 50 mm). The resulting strengths of the mortars in ambient-dry conditions were in the range of flm = 2.08–5.11 MPa, reducing to flm = 0.70−2.37 MPa under wet conditions. An average reduction in elastic modulus in the range of 50% was typically observed due to moisture. Additionally, the moisture content of both conditioning cases for NHL mortar samples was assessed following the same procedure as for the bricks. The moisture content of the lime mortars was 2.54% by weight (wt.%) for ambient-dry samples and 10.80 (wt.%) for those in water.

3 Experimental Assessment

3.1 Shear Triplet Tests

A total of 30 specimens of b × h × t = 227 × 229 × 111 mm (±2.8 × 2.0 × 2.9 mm), were subjected to varying levels of pre-compression (σc = 0–2.5 MPa). The specimen reference adopts the format Txyyz, where x indicates the specimen conditioning (D for dry, and W for wet); yy represents the pre-compression stress (e.g. 00 for 0 MPa, and 15 for 1.5 MPa), and z represents the specimen sequence (a, b, c, etc.). From the total number of specimens, 15 were kept in laboratory conditions (T = 24–30 ℃, RH = 30–50%), whilst the remaining 15 specimens were wet.

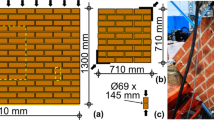

A stiff four-post hydraulic servo-controlled machine with a capacity of 750 kN was used for testing the triplets in shear. The two lateral bricks of each triplet were positioned on 65 mm wide and 115 mm deep steel blocks, which were connected to the machine bed through a series of hinges (Fig. 1). A 65 mm wide steel block and a hinge were used to transfer the load from the actuator to the central brick. Prior to applying the monotonic displacement procedure to the central brick, a preload equivalent to axial stresses of up to 2.5 MPa was applied through four threaded ties and recorded by a load cell (denoted as ‘5’ in Fig. 1a). Besides the transducers used to record overall deformations, a digital image correlation (DIC) system was used to obtain strain fields from all triplet tests (Fig. 1b).

Figure 2 illustrate the average shear stress versus displacement (τ – δs) curves for various values of pre-compression (σc) for the dry (TD) and wet (TW) specimens. As observed, the shape of the τ – δs curves depends on the level of pre-compression σc, with the shear strength τm increasing proportionally with σc. Additionally, the test results indicate a reduction in τm for wet (TW) specimens in comparison with the dry (TD) counterparts for the same level of σc. By comparing the τ – δs curves in Fig. 2, it can be observed that depending on σc, 7–32% reductions in τm occur between dry and wet cases. A larger reduction of τm around 48% is obtained for cases with σc = 0 MPa.

For both dry and wet tests, when σc = 0 MPa, the failure initiated at one of the four brick-mortar interfaces propagating abruptly throughout the depth of the specimen. After the peak shear stress τm was reached, as shown in Fig. 2b, the specimen separated into two distinct bodies and τ dropped instantaneously to zero. For triplets with 0.25 ≥ σc ≥ 1.5 MPa, failure occurred on the faces of both sides of the mortar layer with multiple cracks forming inside each layer. Test observations showed that the mortar from dry specimens had less cohesion, breaking in multiple lumps, whilst the mortar from wet specimens had less fracture surfaces due to paste-like consistency.

3.2 Diagonal Compression Tests

The diagonal tests on single leaf square panels had b × h × t = 710 × 710 × 110 mm (Fig. 1b, d). The specimen reference adopts the format D-Yz, where D stands for diagonal panel), Y represents the conditioning (D for air-dry or W for wet) and z represents the specimen sequence (1, 2, 3, etc.). Prior to testing, the wet specimens were submersed 3/5 of depth in water and were sprinkled with a hose from the top. The tests on diagonal panels were carried out in a rig which included a main loading transfer frame with a 1000 kN Instron actuator and a connected load cell and a hinge. As shown in Fig. 3a, b, the specimens were positioned and loaded through V-shaped supports. The load was applied from the actuator to the top support. To ensure uniform contact between the loading/support plates and the specimen, a thin timber panel was used.

Figure 4a depicts the average stress-strain behaviour of the tested panels. In these tests, the ultimate condition occurs when the principal tensile stresses perpendicular to the compressed strut reaches the maximum tensile strength of the masonry. The shear stress was determined using Eq. (1), in which P is the applied load, α is the angle between the panel diagonal and horizontal axis, parallel to the bed joint.

The parameters b, h and t are the panel width, height and thickness, respectively, whilst n is a factor which depends on the perforations (n = 1 for solid bricks). The shear strain γ, is the sum of the absolute vertical and horizontal strains, εv and εh, respectively (Eq. 2). The shear stiffness G of the wet specimens was reduced by about 39% and 33%, compared to the corresponding dry panels, respectively. As for the triplet tests, a DIC system was used to assess strain fields (Fig. 4b).

The typical crack patterns illustrated in Fig. 4b, obtained from full-field DIC measurements, indicate a typical brittle panel response with failure surfaces following the principal tensile stresses within the specimen. The response of Specimen D-D1 was characterised by loss of bond at a horizontal bed joint at the centre of the panel at around 90% of the peak capacity τu. For the wet Specimen D-W3, the failure patterns illustrated in Fig. 4b resembled those of their corresponding dry counterparts. However, the first strain concentrations associated with loss of bond at the brick-to-mortar interface occurred between 73–75% of their ultimate strength. In addition to stiffness and strength reduction due to moisture, the above results indicate that the bond properties are also influenced by the moisture content. concentration at a horizontal bed joint was observed around 85% of peak load.

3.3 Compression Tests

The cylinders were divided equally into two groups: wet and dry. Half of the specimens were kept in laboratory conditions (T = 24–30 ℃, RH = 30–50%), whilst the remaining specimens were in wet conditions by full submersion in water for 48h. To assess the compressive strength of the masonry, cylinders made of two vertical brick cores, with a mortar joint of about 10 mm in between, were extracted from undamaged masonry walls (Elghazouli et al. 2021). The cylinders had a diameter d = 69 mm and height of around h = 145 mm, representing an aspect ratio h/d ≈ 2.10. Such geometries (h/d ≥ 2.0) are required to ensure a uniaxial stress state at mid-height of the specimen and to obtain the material strength rather than the response of the specimen (Oliveira et al. 2006). As illustrated in Fig. 5a, the specimens were tested in a four-post Instron 3500 kN machine and the testing arrangement included top and bottom high strength steel transfer plates, with the actuator at the top. A DIC system was used to assess surface deformations and strain fields (Fig. 5b).

As shown in Fig. 6a, b, the response of cylinders in compression exhibits a typical brittle response with significant softening immediately after the peak. Based on the stress-strain (σ-ε) curves from Fig. 6a, b, it can be observed that both the elastic modulus and the compression strength are notably influenced by the moisture. The dry specimens had, on average, about 18% and 16% higher stiffness and strength, respectively, compared to their wet counterparts. Additionally, the volumetric strain (εvol) is illustrated against the stress-to-strength ratio (σ/fm) in Fig. 6c as an average of the test curves for each configuration (Bompa and Elghazouli 2020c). As shown in the figure, with the increase in σ/fm, the mortar developed dilation earlier than the brick components, and this effect is stronger for the wet specimen in comparison to the ambient-dry counterpart.

Close inspection of other results from the literature, on masonry elements made of solid clay bricks and lime mortar (Sathiparan and Rumeshkumar 2018), indicate that the compressive strength is relatively constant for values of moisture between 0% and 2–3%, which correspond tao oven-dry and air-dry conditions, respectively. Beyond this value, a gradual reduction in compression strength in the range of 15% occurs with the increase in moisture up to values around 10–13%. It is worth noting that the moisture content is dependent on the porosity of the material, a parameter which governs the total water absorption. Hence, the above comments are specific to the masonry components investigated in this paper.

4 Shear-Compression Envelopes

The tests described herein can be used to evaluate the shear-compression (τ-σ) failure envelopes. This enables a detailed insight into the moisture effects on the mechanical properties of masonry. The shear sliding properties of masonry joints can be determined from triplet tests and the diagonal tension strength can be assessed from diagonal panel tests. The failure envelope is then capped by compression crushing (Li et al. 2005).

The shear sliding is generally represented by a Mohr-Coulomb criterion (Eq. 3) with model coefficients c and μ. As given in Eq. 4, the cohesion c is referred to in codified provisions as the initial shear strength fv0 and is representative of cases without normal load (σ = 0) (BS EN 1996-1-1 2005). The slope of the Mohr-Coulomb criterion μ = tanϕ is typically considered in codes as a value of 0.4. However, as shown by the tests from Sect. 3.1, this is about 50% higher than that suggested by codified guidance, with μdry = 0.62 and μwet = 0.58.

The linear representation of τ-σ for shear sliding, using Eq. 5, is marked with ‘(1)’ and represented by an inclined dashed line in Fig. 7. To represent ranges of the sliding failure mode, the dashed line is offset to intersect the average of the two triplet test results. It is worth noting that Eq. 5 applies for singular brick-mortar interfaces.

To obtain these parameters for masonry elements of larger sizes, the interface parameters c and μ would need to be replaced with \({\text{c}}^\prime\) and \({{\upmu}}^\prime\) using Eq. 6, in which hb and lb are the height and length of the brick unit, respectively (Mann and Muller 1982). By considering the size effect, the shear stress limit condition moves to lower stress levels. In other terms, the inclined dashed line, marked with ‘(1)’ is shifted downwards in Fig. 7a to ‘(1*)’. The same approach was applied to obtain the τ-σ for shear sliding for wet conditions, as shown in Fig. 7b.

The response of the diagonal panel tests is characterised by principal stresses acting in the two main specimen directions: a compression field for the direction of load, and a perpendicular tension field. This failure criterion is referred to as ‘tensile stress’, and requires the diagonal tensile strength as an input parameter ft. This parameter corresponds to the unit strength obtained from diagonal tests τu (Eq. 1). The average test results from Fig. 4 are used as input in Eq. (7) (Li et al. 2005) to plot the second curve ‘(2)’ of the shear-compression τ-σ envelope shown in Fig. 7a, b. The grey areas represent the test ranges.

The third failure mode, denoted ‘(3)’ in Fig. 7a, b, and estimated using Eq. 8, is used to cap the τ-σ failure envelope. This third mode is related to the principal compressive stress criterion for the case of biaxial compression (Malyszko 2004), in which fm is the compressive strength of masonry obtained from cylindrical cores with the bed joint perpendicular to the loading direction. The parameter nc accounts for the compressive strengths parallel and normal to the bed joints (nc = 1.0 herein). As for the diagonal tension case, the grey areas adjacent to the average τ-σ for ‘(3)’ correspond to the test strength domain obtained from cylinder testing. The dashed grey and black vertical lines from Fig. 7a, b, marked with ‘(3*)’, represent the uniaxial compression strength ranges. The intersection between the three failure criteria determine the τ-σ failure envelope for a given type of masonry. When a pair of stresses (τ, σ) falls on or outside the envelope, this would represent failure.

5 Concluding Remarks

This paper described an experimental investigation into the fundamental mechanical properties of masonry elements incorporating fired-clay bricks and hydraulic lime mortars under ambient-dry and wet conditions, corresponding to 48h of submersion in water. Tests on shear triplets, square panels under diagonal compression, and cylindrical cores in compression, were included. After describing the constituent materials, specimen details and instrumentation, the main test results and key observations resulting from detailed test measurements were reported.

Shear triplet tests showed that for specimens without pre-compression the failure was characterised by specimen separation into two distinct bodies, with the shear stress dropping instantaneously. On the other hand, for tests with pre-compression, failure occurred at the brick-mortar interface and propagated through the mortar layer. Moreover, the mortar from dry specimens had less cohesion, breaking in multiple lumps, whilst the mortar from wet specimens had fewer fracture surfaces due to paste-like consistency. The results show that the shear strength of wet triplets was about 20% lower on average than of those in dry conditions.

A direct comparison between the average load displacement curves of dry and wet specimens tested under diagonal compression showed that moisture reduced both the elastic stiffness and the strength on average by about 35% and 29% of the dry specimens, respectively. Full-field DIC measurements also showed that the cracking load was reduced by moisture with the brick-to-mortar interface bond loss occurring at around 75% and 85% of ultimate for the wet and dry specimens, respectively. Compression tests on cylindrical cores indicated that all uniaxial compression properties were lower when moisture was present. For the configurations tested in this study, the reduction in the elastic modulus and compressive strength was on average in the range of 13% and 15%, respectively, between the dry and wet cases.

The tests were used to assess the shear-compression failure envelope, which enables an in-depth understanding of moisture effects on the mechanical properties of masonry. The clay-brick/lime-mortar masonry envelope, which comprises three regimes, namely shear sliding, diagonal tension, and compression crushing, showed that the envelope for wet masonry lies consistently within the limit condition for dry masonry, indicating reductions in strength across all shear-precompression ranges as a function of the governing response.

References

Bompa, D.V., Elghazouli, A.Y.: Experimental and numerical assessment of the shear behaviour of lime mortar clay brick masonry triplets. Constr. Build. Mater. 262, 120571 (2020a). https://doi.org/10.1016/j.conbuildmat.2020.120571

Bompa, D.V., Elghazouli, A.Y.: Compressive behaviour of fired-clay brick and lime mortar masonry components in dry and wet conditions. Mater. Struct. 53, 60 (2020b). https://doi.org/10.1617/s11527-020-01493-w

Bompa, D.V., Elghazouli, A.Y.: Stress–strain response and practical design expressions for FRP-confined recycled tyre rubber concrete. Constr. Build. Mater. 237, 117633 (2020c). https://doi.org/10.1016/j.conbuildmat.2019.117633

BS EN 1996-1-1: Eurocode 6: Design of masonry structures—General rules for reinforced and unreinforced masonry structures. British Standards Institution, UK (2005)

Cotic, P., et al.: Effect of moisture on the reliability of void detection in brickwork masonry using radar, ultrasonic and complex resistivity tomography. Mater. Struct. 46(10), 1723–1735 (2013). https://doi.org/10.1617/s11527-012-0011-3

Elghazouli, A., Butler, A., Mourad, S., Cheeseman, C., Elyamani, A.: Interdisciplinary approach for the management and conservation of UNESCO World Heritage Site of Historic Cairo. Application to Al-Ashraf Street. UK Research and Innovation, 7 July 2019 (2018)

Elghazouli, A.Y., Bompa, D.V., Mourad, S.A., Elyamani, A.: In-plane lateral cyclic behaviour of lime-mortar and clay-brick masonry walls in dry and wet conditions. Bull. Earthq. Eng. 19, 5525–5563 (2021). https://doi.org/10.1007/s10518-021-01170-5

Franzoni, E., Gentilini, C., Graziani, G., Bandini, S.: Towards the assessment of the shear behaviour of masonry in on-site conditions: a study on dry and salt/water conditioned brick masonry triplets. Constr. Build. Mater. 65, 405–416 (2014). https://doi.org/10.1016/j.conbuildmat.2014.05.002

Koutas, L., Bousias, S.N., Triantafillou, T.C.: Seismic strengthening of masonry-infilled RC frames with TRM: experimental study. J. Compos. Constr. 19(2), 04014048 (2014). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000507

Li, T., Galati, N., Tumialan, J.G., Nanni, A.: Analysis of unreinforced masonry concrete walls strengthened with glass fiber-reinforced polymer bars. ACI Struct. J. 102(4), 569 (2005)

Malyszko, L.: In-plane shear and tensile strength tests of small brickwork specimens. In: Structural Analysis of Historical Constructions-2 Proceedings of the IVth Int. Seminar on Structural Analysis of Historical Constructions, 10–13 November 2004, Padova, Italy (2004)

Mann, W., Muller, H.: Failure of shear-stressed masonry. An enlarged theory, tests and application to shear walls. Proc. Br. Ceram. Soc. 30, 223–235 (1982)

Oliveira, D.V., Lourenço, P.B., Roca, P.: Cyclic behaviour of stone and brick masonry under uniaxial compressive loading. Mater. Struct. 39(2), 247–257 (2006). https://doi.org/10.1617/s11527-005-9050-3

Pelà, L., Kasioumi, K., Roca, P.: Experimental evaluation of the shear strength of aerial lime mortar brickwork by standard tests on triplets and non-standard tests on core samples. Eng. Struct. 136, 441–453 (2017). https://doi.org/10.1016/j.engstruct.2017.01.028

Sathiparan, N., Rumeshkumar, U.: Effect of moisture condition on mechanical behavior of low strength brick masonry. J. Build. Eng. 17, 23–31 (2018). https://doi.org/10.1016/j.jobe.2018.01.015

Acknowledgements

The study was supported by the Arts and Humanities Research Council of the UK Research and Innovation agency, within the project “Interdisciplinary approach for the management and conservation of UNESCO World Heritage Site of Historic Cairo - Application to Al-Ashraf Street”, Grant No. AH/R00787X/1. The authors would like to acknowledge the support provided by the technical staff of the Structures Laboratories at Imperial College London.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bompa, D.V., Elghazouli, A.Y. (2022). Shear-Compression Failure Envelopes for Clay Brick Lime Mortar Masonry Under Wet and Dry Conditions. In: Vayas, I., Mazzolani, F.M. (eds) Protection of Historical Constructions. PROHITECH 2021. Lecture Notes in Civil Engineering, vol 209. Springer, Cham. https://doi.org/10.1007/978-3-030-90788-4_17

Download citation

DOI: https://doi.org/10.1007/978-3-030-90788-4_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-90787-7

Online ISBN: 978-3-030-90788-4

eBook Packages: EngineeringEngineering (R0)