Abstract

The post-yield hardening (PYH) behaviour is an important character of FRP confined concrete which has been studied by researchers worldwide for decades. In the phenomenon-based level, the authors propose a 3D geometrical method to interpret the mechanisms of analysis-oriented models. This method unifies most existing analysis- and design-oriented models. For the mechanism-based study, the physical behaviour of the FRP confined concrete is revealed by X-ray computed tomography (CT), and the initiation and propagation of the internal cracks are captured by the scanned images. Further, path dependency of FRP confined high-strength concrete (HSC) and nonlinear biaxial behaviour of FRP tube are modelled using the 3D geometrical method. Finally, this paper provides an introduction to the recent development of composite structural elements from the authors’ research group, which can maximize the confining efficiency and can improve the structural performance significantly.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The studies of FRP confined concrete have been conducted by researchers over the past decades. With the passive confinement provided by the FRP, the stress-strain behaviour of the concrete can have a bi-linear response with a second ascending portion, which is completely different from that confined by conventional materials such as steel. This behaviour is attractive to researchers and engineers because it can change the structural responses from elastoplastic to bilinear with post-yield hardening (PYH). Hence, various composite structural members have been developed and investigated to date. This paper presents the recent research outcomes of the authors’ research group on the FRP confined concrete. First, a new 3D geometrical approach for interpreting analysis-oriented models of FRP confined concrete is introduced. This approach can intuitively present the mechanisms of most existing analysis- and design- oriented models. Second, the physical phenomenon and mechanisms of FRP confined concrete are presented via X-ray computed tomography (CT) technology. The CT scanning images show that during the second portion of the bilinear stress-strain curve, the confined concrete separates into discrete parts and the internal friction dominates the second ascending branch. Third, this paper discusses several specific issues of FRP confined concrete such as path dependency of high-strength concrete (HSC) and the effect of nonlinear biaxial behaviour of the filament-wound FRP tube. Finally, the authors provide an introduction to series of recently developed novel composite elements which can effectively make use of the PYH behaviour of FRP confined concrete in the structural member level.

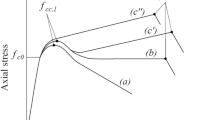

2 Analysis-Oriented Models for FRP Confined Concrete: 3D Interpretations

The state of the uniformly confined concrete can be expressed by four variables: axial strain (\({\varepsilon }_{c}\)), lateral strain (\({\varepsilon }_{l}\)), axial stress (\({\sigma }_{c}\)), and lateral confining stress (\({\sigma }_{l}\)). The relationships for the four variables are interpreted graphically (Yang and Feng 2020). As shown in Fig. 1a, the concrete state is a pair of points in the two coordinate systems, and the test results are the trace of the state points during the loading process. The \({\varepsilon }_{c}\)-\({\sigma }_{l}\)-\({\sigma }_{c}\) relationship is governed by the active confined concrete model (herein denoted as the 1st equation), as shown by the red mesh in the axial stress coordinate system. Similarly, the equation governing the relationship of \({\varepsilon }_{l}\)-\({\sigma }_{l}\)-\({\varepsilon }_{c}\) is denoted as the 2nd equation, which is shown by the blue mesh in the lateral strain coordinate system. The relationship between \({\varepsilon }_{l}\) and \({\sigma }_{l}\) is denoted as the 3rd equation. If the concrete is actively confined, \({\sigma }_{l}\) will be a constant value and does not change with \({\varepsilon }_{l}\), whereas if the concrete is passively confined, the 3rd equation depends on the properties of the confining material. If the path-independent assumption is valid, the pair of points must lie on the surfaces in corresponding coordinate systems, and as the loading process continues, the state points will change and leave two traces in the two coordinate systems. In fact, all types of test curves are projections of the state traces on different planes, and the shapes of the result curves are controlled by the above mentioned three equations. The concrete state traces of actively and passively confined concrete are plotted in Fig. 1b-d, respectively. For actively confined concrete, as shown in Fig. 1b, the projections of the state traces on the \({\varepsilon }_{l}\)-\({\sigma }_{l}\) plane are straight lines parallel to the \(\overrightarrow{{\varepsilon }_{l}}\) axis, which means that the confining stress does not change with lateral expansion. If concrete is confined by linear elastic FRP (Fig. 1c), the 3rd equations are straight lines passing through the origin. The slopes of the lines of the 3rd equations denote the confining stiffness. Figure 1d shows the case of concrete confined by steel, such as steel tube confined concrete columns without considering steel buckling. The \({\varepsilon }_{l}\)-\({\sigma }_{l}\) curve starts from the origin with a linear ascending portion before the steel yields, after which the confining stress remains constant and does not change with lateral expansion. Therefore, the behaviour of steel confined concrete is similar to that of concrete confined by linear FRP before the steel yielding point. When the confining steel yields, the axial stress-strain behaviour follows the scenario of active confinement. In summary, the 1st and 2nd equations are constitutive relationships of concrete, and the 3rd equation is the external constraint of the state path denoting the mechanical properties of the confining material.

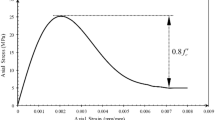

3 Physical Phenomenon and Mechanisms of FRP Confined Concrete

Analysis-oriented models can capture the stress-strain behaviour of FRP confined concrete with sufficient accuracy. However, they belong to phenomenon-based models which are mainly calibrated by test data and lack of physical explanations especially for the second portion. To have a better understanding of the physical behaviour of the confined concrete, X-ray computed tomography technology was adopted herein as a non-destructive measure to observe the internal state of confined concrete loaded to different stages. There are three specimens tested and scanned. The concrete cylinders had a diameter of 150 mm and height of 300 mm. The unconfined concrete cylinder strength f’co = 56.2 MPa. The specimens denoted as G1, C2 and C12 were wrapped with 1 layer of GFRP, 2 layers of CFRP and 12 layers of CFRP, representing weakly confined, moderately confined and heavily confined, respectively. Figure 2 shows the four stages at which the specimens were scanned, and the visible cracks are highlighted. The four stages for scanning are predetermined by monotonic loading test on the specimens from the control group. Stage A is for unloaded specimens; Stage B is that the specimens were loaded up to f’co; Stage C is at the transition point of the specimen’s stress-strain curve; and stage D is that the test were stopped just before the ultimate state of the specimen. As can be seen from the figure, there are no visible cracks before the transition points for all specimens. For weakly and moderately confined specimens, the cracks initiated at the corner of the specimens at the transition point. When the specimens reached their ultimate condition, cracks propagated about 30° to the axial load. It is interesting that for the heavily confined specimen, there is no crack observed at the transition point, however, the cracks at the ultimate state are perpendicular to the axial load. Generally, for weakly and moderately confined specimens, internal cracks forms at the transition point and propagate with the loading process. The specimens will finally fail as concrete cone. The post transition stage of the FRP confined concrete is the process that the concrete changes from continuum solid to discrete elements. During this process, the dominating internal action changes from cohesion to friction between particles. For the heavily confined specimen, due to the strong confining stress, the internal cracks propagate horizontally, indicating that the failure mechanism is different from the weakly and moderately confined cases. This phenomenon needs further investigating.

4 Applications of the 3D Geometrical Approach

The analysis-oriented models imply the path independent assumption, so that the concrete state points lie on the same surface regardless of the confining mode being active or passive. It is proven to be valid for normal strength concrete (NSC). However, it is found that for high-strength concrete (HSC), the axial stress of passive confinement is lower than that of actively confinement with all other state variables being the same, which indicates that the path independent assumption is not applicable. Most existing analysis-oriented models employ different 1st equations for actively or passively confined cases. The confining mode should be determined before applying this kind of models. The authors of this paper propose a new model framework based on the 3D geometrical interpretation method, which can automatically identify the confining mode from the concrete state path without artificial intervention (Yang and Feng 2021). The mechanism of this model is shown in Fig. 3. There are three key issues for this model: (1) active 1st equation; (2) damage criteria; and (3) reduction rules for the post damaged 1st equation. It is assumed that the path dependency of HSC is the formation of internal cracks. When the state path reaches the damage criteria, corresponding subsequent 1st equation is reduced following certain rules. With this approach, difference between active and passive axial stress can be modelled with a unified model without predetermination of the confining mode.

In the previously introduced 3D geometrical method, the relationship between lateral stress and lateral strain is solely depend on the uniaxial behaviour of the confining material. However, when using filament-wound FRP tubes as external confinement, the biaxial behaviour of the tube is not negligible, which means the axial compression strain and lateral expansion strain of the tube are coupled. Therefore, the 3rd equation is refined from a plane into a 3D surface, as shown in Fig. 4. The refinement of the 3rd equation employs the classical laminated plate theory and considering the nonlinear shear behaviour of FRP (Tang et al. 2015, Li et al. 2021). The nonlinear biaxial behaviour of FRP tube brings relaxation of the lateral confining stress, hence the conventional models overestimate the strength of FRP tube confined concrete.

5 Application Strategies of FRP Confined Concrete

The post-yield hardening (PYH) behaviour of FRP confined concrete has drawn much attention from researchers and engineers who are aiming at developing composite structures that can maximize the performance of confined concrete and hence achieve PYH in the structural level. With PYH behaviours, the seismic performance of structures can be improved significantly, and it may even bring revolutions in the design philosophy (Qiang et al. 2019). However, the PYH behaviour only occurs when the concrete is uniformly confined, e.g., circular columns under axial compression load. According to the investigations conducted by Wang (2018), even with limited eccentricity, the FRP confined circular concrete column will lose the PYH behaviour. This is caused by non-uniformly distributed confining stress. In practice, the cases of columns under concentrated axial load are rare, and most of the vertical structural elements are designed to withstand combined compression and bending actions. Therefore, maximizing the confining efficiency is one of the key problems to bring the advanced FRP materials into practise.

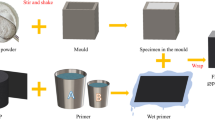

In order to solve this problem, the authors’ team have proposed three generations of structural elements for the composite members during the past years, namely, FRP confined concrete core (FCCC-O), FRP-confined concrete core-encased rebar (FCCC-R) and FRP-confined concrete core-encased prestressed rebar (FCCC-PR). The basic idea is to apply passive confinement to the regions with high compression stress in the member’s cross section, which is shown in Fig. 5. When the composite member is subjected to combined compression and bending actions, the locally confined concrete can have PYH behaviour. Moreover, in the latest generation (FCCC-PR), the locally confined concrete is prestressed through high strength steel bar, which can not only activate the confining effect in the early stage, but also postpone the concrete cracking when subjected to tension. The novel structural elements can be implemented into columns and shear walls, and it is proven to be effective by experimental investigations (Wang et al. 2019, Hu et al. 2021).

6 Summary

This paper presents the recent works on FRP confined concrete conducted by the authors’ research group. The 3D geometrical method which provides an intuitive interpretation of the mechanism of phenomenon-based models for FRP confined concrete. The X-ray CT scanning reveals the physical behaviour of the FRP confined concrete during the post transition stage. The results show that for the weakly and moderately confined concrete, internal cracks initiate at the transition point and propagate inclined to the axial direction at about 30°. For the heavily confined concrete, the cracks lie perpendicular to the axial direction. Further, path dependency of HSC and nonlinear biaxial behaviour of FRP tube are modelled using the 3D geometrical approach. In the end, the authors introduced a series of structural elements which can maximize the confining effect and are suitable for composite sections.

The behaviour of confined concrete has been studied for nearly a century. Various of theories and models have been developed. However, to fill the gap between laboratory investigation and field applications, there are still some problems need to be solved in the future: (1) FRP confined concrete under eccentric load; (2) non-uniform confinement; (3) explanation and understanding of phenomenon-based model and the corresponding physical mechanisms; and (4) further improve the effectiveness of FRP confined concrete in composite structures.

References

Hu L, Feng P, Lin H, Yang JQ, Qiang H (2021) Seismic performance of composite shear walls with embedded FCCCs in boundary elements. Compos Struct 257:113126

Li S, Xu M, Yan S, Sitnikova E (2021) On the objectivity of the nonlinear along-fibre shear stress–strain relationship for unidirectionally fibre-reinforced composites. J Eng Math 127(1):1–13. https://doi.org/10.1007/s10665-021-10098-3

Qiang H, Feng P, Qu Z (2019) Seismic responses of postyield hardening single-degree-of-freedom systems incorporating high-strength elastic material. Earthq Eng Struct Dynam 48:611–633

Tang Z, Wang C, Yu Y (2015) Failure response of fibre-epoxy unidirectional laminate under transverse tensile/compressive loading using finite-volume micromechanics. Compos B 79:331–341

Wang J (2018) Structural behaviours of PPR-CFFT column and joint for ocean construction. Ph.D. Thesis, Tsinghua University

Wang Z, Feng P, Zhao Y, Yu T (2019) FRP-confined concrete core-encased rebar for RC columns: Concept and axial compressive behaviour. Compos Struct 222:110915

Yang JQ, Feng P (2020) Analysis-oriented models for FRP-confined concrete: 3D interpretation and general methodology. Eng Struct 216:110749

Yang JQ, Feng P (2021) Analysis-oriented model for FRP confined high-strength concrete: 3D interpretation of path dependency. Compos Struct 278:114695

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Feng, P., Yang, JQ., Li, Z. (2022). FRP Confined Concrete: What, Why, and How?. In: Ilki, A., Ispir, M., Inci, P. (eds) 10th International Conference on FRP Composites in Civil Engineering. CICE 2021. Lecture Notes in Civil Engineering, vol 198. Springer, Cham. https://doi.org/10.1007/978-3-030-88166-5_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-88166-5_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-88165-8

Online ISBN: 978-3-030-88166-5

eBook Packages: EngineeringEngineering (R0)