Abstract

The technologies based on paper and flexible material allow developing devices for diagnostic tests of the type Point-of-Care - PoC. These technologies enable the development of sensor devices and actuators for tests and diagnostics in humans and animals, since the materials used are thin, light, flexible and inexpensive, when compared with traditional Silicon technologies. These sensor platforms or devices are simple to manufacture, batch production, easy to use and are environmentally friendly. The pencil on paper allows the produced of many types of sensors, in special, sensors that using the piezoresistive effect for individual monitoring of human breathing.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Paper as a substrate is a new field of interest for electronics and a new opportunity for the development of new devices due to its low cost, lightness, flexibility and biocompatible and recyclable nature.

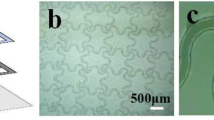

The literature [1,2,3] indicates that it is possible to deposit different materials on paper substrates. In this work, pencil graphite obtained by mechanical exfoliation is used, without the use of chemical solvents. This technique is known as GoP – Graphite on Paper or PoP – Pencil on Paper, as shown in Fig. 1 [1,2,3,4,5,6,7,8].

In this article, we intend to introduce the procedure for manufacturing and developing humidity sensors for applications in masks for human breathing.

Humidity sensors, in particular, are being applied in industrial processing and environmental control, domestic applications, the automotive industry, the medical field, precision agriculture, industry in general and a wide variety of other applications [7]. The literature [1] shows that flexible electronic devices have the potential for different applications, including human movement detection and wearable thermal therapy.

Otherwise, rapid diagnosis can have wide applications in different areas, such as medical clinic, food safety, environmental monitoring and veterinary medicine, among others. PoC – type diagnostic tests are easy to use, fast and inexpensive, especially in countries with limited resources, hence the importance of new methodologies for the manufacture of sensor devices. PoC diagnostics facilitate disease detection and control, treatment monitoring and make it possible to address global health problems. Technologies based on platforms that use paper, flexible material and graphite films enable new devices in the area of PoC diagnostics [4].

Piezoresistive mechanical stress sensors on flexible substrates that can convert mechanical deformations through variations in electrical resistance provide a simple and practical detection tool in the area of health monitoring, human movement detection, personal health, man-machine interface and so-called electronic skin.

Flexible electronic devices on paper substrate are a great innovation as it is biocompatible, recyclable and biodegradable. Among the devices that can be manufactured are mechanical strain gauges, force and pressure sensors that use thin films of graphite pencil. Graphite sensors on flexible polymeric substrates can be applied in the manufacture of different devices, such as wearable devices, sensors for internet of things, bioengineering and applications in several other areas of science and technology [5, 6].

1.1 Fundamental Concepts

The fundamental component of the sensors for mass, pressure, acceleration, inertia, among others is the strain gauge because its function is to convert mechanical loads into an electrical signal, that is, it is from this device that the environment variables are measured can be controlled.

In order to explore an organic material for making a sensor device chose to use the graphite making up 2B pencil trace on paper substrate according to Eq. (1).

Where, \(\rho\), is the resistivity of the material, \(L\), is length, \(w\), is width and, \(t\), the thickness of the deposited film.

The piezoresistive effect in thin films of graphite on paper substrate is defined by Eq. (2).

Where, \(\pi_{{{{\uppi {\rm ijkl}}}}}\), is the piezoresistive coefficient tensor, an intrinsic property of the material chosen as sensor elements, and which can be adjusted by specific doping techniques. The mechanical stress in the structure of the material is given by, \( T_{kl}\), where, \(\frac{{\Delta {{\uprho {\rm ij}}}}}{{\uprho }}\), is the ratio of the electric resistivity when the material is subjected to external tensile forces or mechanical deformations [5].

In general, the structures of the films deposited on the substrates have a thickness much smaller than the thickness of the substrate itself \(t_{s} \gg t_{f} \) therefore; the mechanical stresses are transmitted integrally from the substrate to the film according to the theory of small deflections as shown in [9].

The sensitivity factor, \(GF \), is dependent on the crystallographic orientation of the material, this case, graphite and is related to the piezoresistive coefficient through the Young’s modulus, \(E\), given by Eq. (3).

Equation (3) shows the sensitivity of the graphite sensor element.

1.2 Characteristics of the Paper Substrate

Paper is a biodegradable and abundant material, it has been used for centuries for printing, packaging, and liquid absorption. The paper is porous, consisting of a hydrophilic network of interwoven cellulose fibers. This network defines the mechanical and fluid properties of the material. In recent years, paper has become increasingly interesting as a material in new applications.

Figure 2 illustrates the structure of the cellulose fibers in a schematic way and a SEM – scanning electron microscopy of the paper with 430× magnification. The small white dots next to the paper fibers indicate residues due to the production processes of the sheets.

Schematic representation of the cellulose fiber structure adapted [10] and view of a sheet of white sulfite paper seen in the SEM

Cellulose fibers in paper are wooden cells (or pieces of wood) which can even have 2 mm to 5 mm long and 20 μm to 40 μm wide, depending on their natural origin. The cellulose-based cell wall consists of small fibrils, which in turn are made of microfibers with a diameter of about 3 nm to 20 nm. While the amorphous parts between fibrils consist mainly of hemicelluloses and lignin, microfibrils consist of chains of cellulose that partially form crystalline regions of cellulose and are held together by hydrogen bonding [10].

The level or degree of crystallinity of the cellulose fibers as well as the number of free hydroxyl groups are of fundamental importance for the absorption of water by the paper. As a result, it is hygro-expandable and the tension of the deposited graphite film.

The ratio between the dimensional variation, resulting from a change in the moisture content and its initial dimension, defines the hygroexpansibility of the paper according to Eq. (4) [11].

where, \(\varepsilon_{h}\), hygroexpansibility of the paper in %, \(\Delta_{l}\), variation in length and, \(l_{0}\), initial length of the sample.

Cellulosic fibers are hygroscopic and absorb water quickly. However, under equilibrium conditions, the humidity of the paper depends on the relative humidity as well as the ambient temperature.

The fibers absorb water internally and, on the surface, so that they expand when they absorb and contract when they lose water. This expansion and contraction effect is transmitted to the deposited graphite film, changing its electrical resistance due to the piezoresistive effect shown in Eq. (2) [9].

The humidity of the paper decreases with increasing temperature and increases with relative humidity, in balance with the environment. Therefore, a graphite piezoresistor deposited on this substrate presents a mechanical deformation that can be measured, indicating the relative humidity absorbed by the paper, in this case, by the humidity sensor.

The resistivity variations of the piezoresistor are amplified and delivered to the analog input of a microcontroller system which performs adjustments, filters, and performs mathematically and computationally the electrical voltage signals corresponding to relative humidity. This principle is used to detect the breathing of humans. Figure 3 illustrates the possible arrangement for the sensor if placed in a breathing mask.

The sensitivity of the sensing element is defined as the ratio of the relative difference in electrical resistance over the difference in relative humidity, given by the equation,

where, \({\raise0.7ex\hbox{${\Delta R}$} \!\mathord{\left/ {\vphantom {{\Delta R} {R_{0 } }}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{${R_{0 } }$}}\), is the variation of electrical resistance and \(\Delta RH\) the variation of relative humidity.

1.3 Characteristics of the Graphite Film

Graphite is constituted of infinite layers of carbon formed by sp2 hybridization. In each layer, the sheet of graphene, a carbon atom bonds to three other atoms, forming a flat arrangement of fused hexagons. Sp2 hybridization occurs with carbon atoms making a double bond [5]. Figure 4 illustrates the structure of the graphite and shows the homogeneity of the film after thermal annealing on the paper substrate. This figure was obtained by SEM with 180x magnification.

Due to the relocation of π electrons graphite can conduct electricity and therefore has electrical resistivity. In diamond, for example, this movement of the electrons is very small making it slightly conductive of electrical current.

The extreme anisotropy makes graphite a mineral with peculiar properties, being responsible for an electrical resistivity of 5 × 103 Ω⋅m in the direction perpendicular to the plane and 5 × 10–6 Ω⋅m in the direction parallel to the plane.

Unlike other materials, graphite undergoes a process called “relaxation resistivity”, that is, resistivity depends on the intrinsic characteristics of the material itself [12].

2 Results and Discussions

Flexible and extensible detection electronics for wearable devices and health monitoring are complex integrated systems, composed of flexible substrates, special conductive films, detection materials and, occasionally, encapsulation materials. As such, special attention is needed to the individual functions of each constituent component, their interactions and how these interactions affect the performance of the system and its biocompatibility to prevent infections or contamination.

Wearable devices require durable and compatible substrates for various scenarios of both invasive and, in this work, non-invasive application in human health care.

In this work, two characterizations of electrical sensitivity of graphite piezoresistors were obtained, due to the paper's hygroexpandability with the variation of relative humidity, \(RH\), as shown in Fig. 5 and Fig. 6.

In Fig. 5, the 13.1% decrease in relative humidity caused an increase in the variation of electrical resistance when comparing day 1 with day 2. Otherwise, in Fig. 6 it is verified that the difference of approximately 10% relative humidity and variation of 1 °C caused an increase in the electrical resistance of the sensor element.

The variation in electrical resistance is measured and the signal is conditioned via a microcontroller showing the sensitivity (mV/%RH) according to the electrical supply voltage.

Table 1 shows a comparison between some results presented in the literature. However, processes and materials have their own characteristics, and it is important to use different methods for functional evaluation.

3 Conclusions

The results of this work are promising and contribute to the care of human health it allows the development of disposable respirators with possible monitoring of the absorbed oxygen rate, based on the hypo-expandability of the paper with humidity and the piezoresistive effect of the film graphite.

The sensor element studied must subsequently undergo a test stage following the protocols of the health area.

Flexible detection electronics will change conventional medical diagnostic methods and revolutionize medical instruments by making them portable, wearable, remote and possibly low cost.

References

Dinh, T., Phan, H., Qamar, A., Nguyen, N., Dao, D.: Flexible and multifunctional electronics fabricated by a solvent-free and user-friendly method. RSC Adv. (2016). https://doi.org/10.1039/C6RA14646E

Mahadeva, S.K., Walus, K., Stoeber, B.: Paper as a platform for sensing applications and other devices: a review. ACS Appl. Mater. Interfaces (2015). https://doi.org/10.1021/acsami.5b00373

Gabbi, R., Rasia, L.A., Valdiero A.C., Gabbi, M.T.T.: An aproach for computational simulation of the elements piezoresistives of graphite. Int. J. Develop. Res. 19150–19155 (2018)

Shafiee, H., et al.: Paper and flexible substrates as materials for biosensing platforms to detect multiple biotargets. Sci. Rep. 5, 8719 (2015). https://doi.org/10.1038/srep08719

Rasia, L.A., Leal, G., Koberstein, L.L., Furlan, H., Massi, M., Fraga, M.A.: Design and Analytical Studies of a DLC Thin-Film Piezoresistive Pressure Microsensor. In: Figueroa-García, J.C., López-Santana, E.R., Villa-Ramírez, J.L., Ferro-Escobar, R. (eds.) WEA 2017. CCIS, vol. 742, pp. 433–443. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-66963-2_39

Rasia, L.A., Pedrali, P.C., Furlan, H., Fraga, M.A.: Design and Characterization of Graphite Piezoresistors in Paper for Applications in Sensor Devices. In: Figueroa-García, J.C., Duarte-González, M., Jaramillo-Isaza, S., Orjuela-Cañon, A.D., Díaz-Gutierrez, Y. (eds.) WEA 2019. CCIS, vol. 1052, pp. 577–583. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-31019-6_48

Chen, Z., Lu, C.: Humidity sensors: a review of materials and mechanisms. Sens. Lett. 3, 274–295 (2005). https://doi.org/10.1166/sl.2005.045

Lin, C.-W., Zhao, Z., Kim, J., Huang, J.: Pencil drawn strain gauges and chemiresistors on paper. Sci. Rep. 4(3812), 2–6 (2014). https://doi.org/10.1038/srep03812

Rasia, L.A., Pedrali, P.C., Valdiero, A.C.: Characterization of piezoresistive sensors of graphite on paper substrate. In: 16th LACCEI International Multi-Conference for Engineering, Education, and Technology: “Innovation in Education and Inclusion”, 19–21 July 2018, Lima, Peru. https://doi.org/10.18687/LACCEI2018.1.1.327

Tobjörk, D., Österbacka, R.: Paper electronics. Adv. Mater. 23, 1935–1961 (2011). https://doi.org/10.1002/adma.201004692

Mohammadzadeh, A., Barletta, M., Gisario, A.: Manufacturing of cellulose-based paper: dynamic water absorption before and after fiber modifications with hydrophobic agents. Appl. Phys. A 126(5), 1–11 (2020). https://doi.org/10.1007/s00339-020-03577-4

Lu, W., et al.: Voltage‐induced resistivity relaxation in a highdensity polyethylene/graphite nanosheet composite, [S.l.], pp. 860–863 (2007). https://doi.org/10.1002/polb.21111

Popov, V.I., Nikolaev, D.V., Timofeev, V.B., Smagulova, S.A., Antonova, I.V.: Graphene based humidity sensors: the origin of resistance change. Nanotechnology 28(35) (2017). https://doi.org/10.1088/1361-6528/aa7b6e

Han, J.-W., Kim, B., Li, J., Meyyappan, M.: Carbon nanotube based humidity sensor on cellulose paper. J. Phys. Chem. C. 116, 22094−22097 (2012). https://doi.org/10.1021/jp3080223

Ling, T.Y., et al.: Sensing performance of nanocrystalline graphite based humidity sensors. IEEE Sens. J. 25539 (2019). https://doi.org/10.1109/JSEN.2019.2905719

Zhang, J., et al.: Pencil-trace on printed silver interdigitated electrodes for paper-based NO2 gas sensors. Appl. Phys. Lett. 106, 143101 (2015)

Acknowledgments

The authors thank the Regional University of the Northwest of the State of Rio Grande do Sul and the Foundation for Research Support – FAPERGS and CNPq for financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Rasia, L.A., Andrades, C.E., Heck, T.G., Rasia, J. (2021). Approach Pencil-on-Paper to Flexible Piezoresistive Respiration Sensor. In: Figueroa-García, J.C., Díaz-Gutierrez, Y., Gaona-García, E.E., Orjuela-Cañón, A.D. (eds) Applied Computer Sciences in Engineering. WEA 2021. Communications in Computer and Information Science, vol 1431. Springer, Cham. https://doi.org/10.1007/978-3-030-86702-7_25

Download citation

DOI: https://doi.org/10.1007/978-3-030-86702-7_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-86701-0

Online ISBN: 978-3-030-86702-7

eBook Packages: Computer ScienceComputer Science (R0)