Abstract

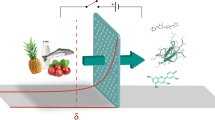

Separation processes are an important part of today’s food industries, especially in the case of specific bioactive components due to their health benefits. In general, processing of bioactive food ingredients assumes the introduction of integrated system directed to their separation, fractionation, and recovery. Recently, membrane distillation (MD) has been considered as an alternative membrane-based separation and concentration process in food technology. MD separates volatile components from aqueous feed solution into the permeate through microporous hydrophobic membranes, by means of the vapor pressure difference on both membrane sides. This chapter contains the analysis of the ongoing literature related to recovery and purification of food bioactive compounds using membrane distillation. Insights into the use of different MD configurations have been discussed and typical advantages and drawbacks over conventional technologies and other membrane processes have been highlighted.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Separation processes are nowadays an integral part of agricultural and food industries. The reason is that bioactive substances in nature are hard to be find in the pure form. In general, some type of separation is applied before these substances are consumed or further processed, especially in the case of functional food and the nutraceuticals. The main objective in food bioactive processing is the development of fully integrated process to minimize the loss and diminution of bioactivity. Typical bioactive components that can be found in food products are anthocyanins, phenolic acids, catechins, flavonones, flavonols, non-flavonoid polyphenols and other phenolic compounds (Castro-Muñoz et al. 2016a, 2018a, b). The problem scientists need to face in the processing of bioactive components is the separation of specific components from complex matrix and their purification. The type of selected separation is usually based on physical properties of molecules such as their size, structure and physico-chemical characteristics (Díaz-Montes et al. 2020a). Each separation and purification technique should be capable of effective separation at a low cost, without any activity loss of compounds. Concentration of aqueous solutions of bioactive components is one of the most important unit operation while processing the food (Castro et al. 2020; Castro-Muñoz and Yañez-Fernandez 2015). It concerns the processing of beverages, fruit juices, vegetable and herbal extracts, milk, whey, etc. The volume reduction of concentrates through dewatering reduces their transport, storage and packaging costs and simultaneously makes them more resistant to chemical and microbial degradation. Conventional methods used for liquid concentration in food industry such as multistage vacuum evaporation (Jiao et al. 2004) are highly energy consuming and can change organoleptic and nutritional characteristics of the product due to the high operating temperatures (Varming et al. 2004; Toribio and Lozano 1986; Ibarz et al. 2011). Over the years, many industries have accepted the applications of membrane technology in some conventional processes and separation of food bioactive ingredients. In general, the advantages of membrane-based processes in bioactive components processing include the replacement of the highly energy consuming evaporation process, reutilization of wastewater, reduction of waste treatment volume and relatively low capital requirements (Cassano et al. 2010; Castro-Muñoz 2018). The disadvantages include the problems with the maintenance and durability of the membranes such as the length of operating life, replacement costs, chemical inertness, pH sensitivities and fouling problems. Various membrane processes such as microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), forward osmosis (FO), reverse osmosis (RO) and pervaporation have already gained huge interest in food processing field of research (Castro et al. 2020; Alvarez et al. 1997; Sant’Anna et al. 2012; Castro-Muñoz et al. 2020a, Castro-Muñoz 2020a). Among them, membrane distillation (MD) is an emerging thermally driven membrane process with several advantages over others. First of all, it operates with lower temperatures and pressures comparing to conventional distillation and pressure driven membranes processes (Gontarek et al. 2021). In addition, it is less susceptible to fouling than MF, UF, RO (Lawson et al. 1996; Onsekizoglu 2012).

This chapter covers the theoretical aspects of the MD process together with mathematical principles related to heat and mass transfer. Different configurations and variants of MD are presented. Secondly, the most commonly used commercial membranes will be introduced and the membrane requirements will be given with a brief overview on the optimal membrane parameters based on the recent literature data. Finally, the application of MD process in food bioactive components processing is evaluated, along with advantages and disadvantages and comparison to other membrane processes.

2 Principles of Membrane Distillation

Membrane distillation was first described by Bodell (1963) in 1963, who patented the apparatus and methods for converting non-potable aqueous fluids to potable water, where vapor and not liquid was permeating through a silicone rubber membrane. In 1967, Weyl (1967) issued another US patent that referred to the use of a porous hydrophobic membrane for improving the efficiency of desalination. In the late 1960s, Findley was the first to publish the results of the work on vaporization through porous membrane using a variety of membrane materials and basic theoretical study on direct contact membrane distillation (DCMD) (Findley 1967; Findley et al. 1969). The author noticed the potential of MD as an economical alternative of evaporation, however, he stated that first of all, low cost and long-life membranes with desirable characteristics need to be developed. At that time, the interest in MD process has temporarily decreased, subsequently, the advent of new membrane manufacturing techniques in the early 1980s, renewed the interest on this process, as the membranes with high porosity value and low thicknesses became available.

2.1 Process Fundamentals and Theory

The driving force of MD process is a vapour pressure gradient between feed and permeate solutions that is induced by the temperature difference across the membrane. The solutions are separated by microporous membrane that due to its hydrophobic character prevents the permeation of aqueous phase (Wang et al. 2016). At the entrance of each pore, liquid/gas interface is formed. Subsequently, the vapour phase is transported through the membrane to the permeate side where it condensates.

Along with the mass, the heat transfer also occurs. There are two important heat transfer mechanisms. The conductive heat transfer along the membranes pores that occurs together with the vapor diffusion causes temperature change at the both membrane boundary layers. This leads to a temperature gradient in the feed and permeate (between the bulk and boundary layer) and results in the convective heat transfer. Schematic illustration of heat flux in direct contact MD is shown in Fig. 4.1.

Convective heat transfer at the feed boundary layer Qf can be described by Eq. 4.1:

while convective heat transfer at the permeate boundary layer Qp:

Conductive heat transfer across the membranes can be given by Eq. 4.3:

where hf, hp and hm are the heat transfer coefficients of the feed, permeate and membrane, respectively, while Tf, Tf,m, Tp and Tp,m represent the temperature of the feed, temperature of the feed in the boundary layer, temperature of the permeate and temperature of the permeate in the boundary layer, respectively (Srisurichan et al. 2006). The temperature differences between the boundary layers and the bulk phases at both feed and permeate side reduce the driving force for mass transfer what is called temperature polarization. Increasing the feed temperature make temperature polarization phenomena more significant. Temperature polarization (ψ) is defined as follows:

Such equation describes the effect of heat transfer at boundary layer and the total heat transfer resistance for a given system. When the temperature polarization value reaches 1, the feed and permeate temperature is constant and stable regardless of the distance from the membrane and the resistances of thermal boundary layer are reduced. This situation could only happen if the membrane does not conduct heat at all. When the value reaches 0, the system is controlled by large thermal boundary layer resistance. Typically, for DCMD temperature polarization value lies between 0.4 and 0.7 (Curcio and Drioli 2005). Few approaches have been proposed in the literature to reduce the temperature polarization effects such as thorough mixing, increasing flow rates or inducing turbulent flow using mesh spacers in the flow channels (Cath et al. 2004; Martínez-Díez et al. 1998; Chernyshov et al. 2005).

In the case of mass transfer in MD process it occurs due to the vapor transport that is induced by vapor pressure gradient between both membrane sides. In general MD mass transfer can be described by molecular diffusion or Knudsen diffusion model, depending on the membrane pore size (Khayet et al. 2004). The first model is applied for relatively large membrane pore size and states the predominance of collisions between molecules, as denoted by Eq. (4.6). The Knudsen model describes the systems where the mass transfer is determined by the collisions between molecule and pore walls as denoted by Eq. 4.5.

-

1.

Knudsen diffusion model:

where ε, r, τ, Mi and δ are porosity, pore radius, tortuosity, molecular weight of vapor and membrane thickness, respectively.

-

2.

Molecular diffusion model:

where D, P and pa are the Fick’s diffusion coefficient, total pressure in the pore and air pressure in the pore, respectively.

During MD operation the concentration of solutes in feed solution becomes higher at the liquid/gas interface than in the bulk feed. This phenomenon is called concentration polarization. Concentration polarization coefficient (CPC) is given by Eq. 4.7:

where cf, m is a concentration of the solute at the membrane surface and cf is a concentration of the solute in the bulk feed.

2.2 Membrane Requirements

For an efficient operation of a MD process, the perm-selective barrier should present a highly hydrophobic surface, which is preferred since it may concurrently repel the water molecules in liquid state and favor the vapor transport. For this reason, superhydrophobic membranes gained special attention in MD process. The phenomena of surface wetting by a liquid and its physiochemical principle have been already well studied. A droplet resting on a solid surface can take a form of equilibrated shape and remain on the surface as a droplet or spread into a thin layer on the material surface. The behavior of the droplet depends on three thermodynamically balanced interfacial tensions that relate to the existence of an interface between liquid and vapor, solid and liquid and solid and vapor (Shirtcliffe et al. 2010). The wettability of the solid surface is dominated mainly by its chemistry and structure. It gives the possibility to easily control the surface wettability by varying one of these parameters.

Proper membrane selection is a key aspect in MD separation performance. There are various types of hydrophobic and porous membranes that meet the MD criteria. To date, the most popular materials used for MD membranes production are polypropylene (PP) (Tang et al. 2010), polytetrafluoroethylene (PTFE) (Zhu et al. 2013), and poly (vinylidene fluoride) (PVDF) (Zhang et al. 2013). Among them, PP membranes show the highest solvent resistance and crystallinity, while PVDF membranes easily dissolve in solvents such as dimethylformamide (DMF) and triethylphosphate (TEP). Despite this, PVDF exhibit good thermal and chemical resistance. PTFE membranes are considered as the most hydrophobic, however this polymer is difficult for processing.

In general, these polymeric membranes are obtained through stretching, sintering or phase inversion (Curcio and Drioli 2005). Membrane properties such as pore size, hydrophobicity, porosity, thickness, thermal conductivity and tortuosity have a direct effect on membrane separation performance (Castro-Muñoz et al. 2021; Gontarek et al. 2019). Therefore, recent works in MD area are focused on development of membranes with higher fluxes, excellent anti-wetting properties, enhanced stability and low cost (Perrotta et al. 2017; Tijing et al. 2016; Zhang et al. 2018).

Wetting Resistance

During MD process, membrane is in constant contact with liquid feed solution. Usually, for this process aqueous feed solutions are used, therefore membranes should possess a strong hydrophobicity to prevent the wetting and simultaneously maintain retention of non-volatile solutes. In practice, the enhancement of the observed surface hydrophobicity is based on increasing the surface roughness and lowering solid/liquid interface energy. Membrane susceptibility to wetting can be evaluated using the liquid entry pressure (LEP) parameter, which is defined as the pressure required for the liquid to pass through the membrane. To achieve high LEP value and simultaneously good wetting prevention, membrane material should have small pore size, high surface tension and low interface energy between membrane and liquid. Selected properties affecting the wetting resistance of membranes are summarized in Table 4.1.

Membrane Thickness

Thickness of the membrane affects the flow in the MD process in an inversely proportional way. Thinner membrane reduces the mass transfer resistance, thereby increasing the vapour flux. On the other hand, the thickness of the membrane affects the phenomenon of conductive heat loss during the MD process. Therefore, membrane should be as thick as possible to reduce heat loss. However, this aspect conflicts with the requirement of high vapour fluxes. Hence, there is a need to optimize this parameter. According to the literature, the optimal membrane thickness for a MD process should be in the range of 30–60 μm (Laganà et al. 2000).

Membrane Porosity

Porosity is defined as the ratio between volume of the pores and the total volume of the membrane. Membrane porosity is directly proportional to the evaporation surface area, hence, higher porosity of the membrane leads to higher vapour fluxes (Susanto 2011). Additionally, increase in porosity level of the membrane reduces the conductive heat loss, since the conductive heat transfer coefficient of the gases entrapped in the membrane pores is generally an order of magnitude smaller than the conductive heat transfer coefficient of the hydrophobic membrane material (Lawson et al. 1996). It has been estimated that membrane porosity value for an efficient MD should be in the range between 30–85% (El-Bourawi et al. 2006), however usually, this value is greater than 60%.

Membrane Pore Size

As mentioned previously, microporous membranes are used for MD, however, the exact pore size of the membranes for the MD process must be optimized to prevent wetting of the membrane and at the same time ensure the greatest possible flux. In general, an optimum pore size value depends on MD application and the type of the feed solution. Schneider et al. (1988) estimated that for wetting prevention, a maximum pore diameter should range from 0.5 to 0.6 μm. In general, uniform pore size is preferable to maintain stability of vapour flux mechanism (Susanto 2011).

Pore Tortuosity

The shape of membrane pores also affects the MD process, e.g. the deviation of the pore shape from the cylindrical structure called membrane tortuosity. It is defined as the ratio between average length of the pores and membrane thickness. When the pores in the membrane create tortuous paths, the flux of the diffusing molecules is reduced, thus for a higher vapour flux, lower tortuosity is desired. In general, the most frequently assumed tortuosity value is 2 (Phattaranawik et al. 2003).

Thermal Conductivity

To minimize the heat loss during MD operation, it is important to use the membrane material with low heat conductivity. The heat loss reduction leads to higher energy efficiency, lower susceptibility to temperature polarization phenomena and higher vapour flux. Therefore, the most promising approach is the selection of highly porous membrane. As mentioned before, the thermal conductivity of polymer membrane is significantly higher than thermal conductivity of gases filling the membrane pores. Thermal conductivities of membranes materials, such as PP, PTFE, PVDF lies in the range between 0.11 for PP up to 0.27 Wm−1 K−1 for PTFE at 23 °C (Alkhudhiri et al. 2012).

Table 4.2 shows some examples of the commercial membranes commonly used in MD by several researchers, together with their main characteristics. These membrane modules were actually designed for other membrane operations such as microfiltration. Since commercially available membranes does not meet all the MD requirements, there is a need to design novel membranes. Nevertheless, there is a certain limitation in hydrophobicity improvement of smooth surfaces. For example, in the case of smooth PVDF, a surface that is saturated by fluorinated methyl groups, it is possible to reach a maximum 120° contact angle (Liao et al. 2013). Therefore, the enhancement of the surface hydrophobicity is based on increasing the surface roughness (Tijing et al. 2016). Thus, to achieve a strong water repellent rough membrane, a proper modification must be adopted focusing on the creation of micro- and nanostructured surface. Recent studies have evaluated the potential of nanofillers incorporation into polymer membrane to modify the structure and physicochemical properties of membranes, such as hydrophobicity, porosity, surface charge density, chemical, thermal and mechanical stability (; Castro-Muñoz et al. 2019a, 2020b; Ahmad et al. 2020). The new generation of membranes modified with inorganic materials, such as carbon nanotubes (Tijing et al. 2016; Castro-Muñoz et al. 2020c), graphene (Gontarek et al. 2019; Castro-Muñoz et al. 2019b), clay (Prince et al. 2012), silica (Zhang and Wang 2013) and titanium dioxide (Meng et al. 2014), has become a promising approach for superhydrophobic MD membranes preparation.

2.3 MD Configurations

Various configurations for MD operation can be used such as direct contact membrane distillation (DCMD), air gap membrane distillation (AGMD), sweeping gas membrane distillation (SGMD) and vacuum membrane distillation (VMD). In general, the difference among MD configurations lies in the method of vapour condensation on the permeate side (Fig. 4.2).

In DCMD, both feed and permeate liquids are in direct contact with the hydrophobic microporous membrane. As the permeate has lower temperature than feed it is used as a condensing fluid. Due to its set up simplicity, this configuration is most often used in laboratories. On the other hand, the direct contact of liquids with the membrane leads to heat loss across the membrane. Therefore, DCMD is characterized with the lowest thermal efficiency among the MD configurations. In AGMD the vapour passing through the membrane is condensed on the cold surface. The membrane and cold surface are separated by the air gap. This configuration reduces the heat loss throughout the membrane. In SGMD configuration, vapour passing through the membrane is sweeping and carrying by a cold inert gas outside the membrane module where condensates. Despite the obvious advantages of this configuration such as low heat loss and reduced mass transfer, it is relatively rarely used because of the higher operational cost than other configurations. In VMD, the vacuum is applied on the permeate side inducing the process driving force. Due to the low pressure, condensation takes place outside of the membrane module.

2.4 Osmotic Distillation

The osmotic distillation (OD) is a method for water evaporation and solution concentration. It is considered as a non-thermal variant of membrane distillation. Similarly, as conventional MD, the driving force is the vapour pressure gradient across the membrane, between two solutions: feed and striping solution—usually brine, however it is induced by the concentration difference. Hypertonic salt solutions of brine are usually used (Wang and Min 2011). In some cases, the feed is additionally heated to a little higher value than that of the brine, which further increases the driving force (Zambra et al. 2014). It allows to obtain higher process yields. Such a process is called osmotic membrane distillation (OMD) (Gryta 2018). As the OD process can be carried out at room temperature and atmospheric pressure, it is a great candidate for food stuffs processing without a degradation of heat-sensitive components and volatiles loss.

2.5 Membrane Modules

A membrane module for MD must meet several requirements. It should exhibit a high packing density (defined as the ratio of membrane area to the packing volume) and must provide both high feed and permeate flow rates that are usually introduced tangentially to the membrane or in cross-flow mode. Membrane module should assure the possibility of flow rate with high turbulence to provide heat and mass transfer between the bulk solution and the solution at boundary layer, thus, to mitigate the temperature polarization and concentration polarization effects. To prevent flooding of membrane pores that can be caused by a high transmembrane hydrostatic pressure, MD module should provide low pressure drop along the membrane module length. Moreover, the MD module should ensure the maintenance uniform temperature of the liquid solutions along the module length without a heat loss to the environment. The membrane module material should be properly selected so that the used feed solutions do not cause its destruction (e.g. due to corrosion) There are several membrane modules that are commonly used by MD researchers, such as plate and frame, spiral wound, tubular, capillary or hollow fiber (Alkhudhiri et al. 2012; Castro-Muñoz and Fíla 2018a).

In the case of plate and frame module the membrane and the spacers are layered together between two plates. For this module, the membrane is usually prepared as discs or flat sheets. It is widely used on laboratory scale, as it is easy to clean and replace, moreover flat sheet membranes are easy to prepare and handle. The packing density is relatively low. Usually, the use of the membrane support is required to enhance mechanical strength. To prevent excessive concentration and temperature polarization, mass and heat transfer rates between the bulk solution and boundary layer must be sufficient. Some authors proposed the use of spacer-filled channels for the plate and frame membrane modules in both the feed and permeate side of the membrane. The use of spacers led to the flow characteristics change and promoted regions of turbulence (Martínez-Díez et al. 1998; Phattaranawik et al. 2001).

In spiral wound membranes, the flat sheet membrane, porous membrane support, feed and permeate spacers are enveloped and rolled around a perforated central collection tube. The feed solution passes across the membrane surface in an axial direction. The permeate flows to the perforated central collection tube. The spiral wound membrane is characterized by greater packing density than that of the plate and frame module, moderate susceptibility to fouling and acceptable energy consumption. Flat membrane module having a membrane area of 0.01 m2 was used for pineapple juice concentration and clarification (Babu et al. 2008). The module consists of porous hydrophobic polypropylene membrane supported with polyester mesh between viton gasket and two stainless steel frames.

The hollow fiber module is made of connected hollow fibers that are sealed inside a shell tube. In this type of module, there are two approaches for the feed and permeate flow. One of them is inside-outside approach when the feed solution flows along the inner part of hollow fiber, while the permeate is collected outside of the membrane fiber. Another one, outside-inside approach, when the feed solution flows along the outer parts of hollow fibers and the permeate is collected in the inner part. No support is needed for this type of module, furthermore, it is characterized by high packing density and low energy consumption (El-Bourawi et al. 2006). However, it has high tendency to fouling, and the membranes are usually an integral part of the module (Pichardo-Romero et al. 2020), thus it is difficult to clean and replace them. For this reason, clarification is a crucial pretreatment step during fruit juice concentration by MD using a hollow fiber module, to mitigate the fouling and enhance MD fluxes (Cassano and Drioli 2007; Conidi et al. 2020).

In tubular membrane modules, the tube-shaped membrane is inserted between hot and cold fluid cylindrical chambers. These modules offer low tendency to fouling and provide much higher membrane surface area to module volume ratio compared to plate and frame modules (Khayet 2011). It can be used for high viscous liquids since it is characterized by higher cross-flow velocities and large pressure drop. On the other hand, it has a high operating cost.

3 Application in Food Industry

3.1 Juices Concentration and Clarification

As mentioned previously, MD as a process that operates with mild temperatures and atmospheric pressures, can be applied for evaporation, and thus juice concentration without the risk of valuable component degradation. This hypothesis was first confirmed on the basis of preliminary studies on effective concentration of orange juice using microporous PVDF membrane in MD process, that was performed by Calabro et al. (1994). They observed very good retention of soluble solids, sugars, and organic acids. Thereafter, many papers have been published proving that MD is an effective method for concentration of fruit juices such as orange (Deshmukh et al. 2011), apple (Gunko et al. 2006), black currant (Bagger-Jørgensen et al. 2004), kiwi fruit (Cassano and Drioli 2007), pineapple (Hongvaleerat et al. 2008) and grape (Rektor et al. 2006) juices. Table 4.3 summarizes the studies on the concentration of fruit juices along with the most relevant results.

3.1.1 Effect of Process Parameters on Juice Processing

According to Cassano and Drioli (2010), the fluxes in MD are dependent on various process parameters such as: applied temperatures and temperature difference between feed and permeate, feed concentration and flow rates of feed and permeate solutions.

In general, high feed temperatures during MD process are proposed to enhance evaporation efficiency (EE). This parameter is defined as the ratio between the part of the heat which contributes to evaporation to the total heat input in the module (Smolders and Franken 1989). However, in the case of fruit juice processing, high operation temperatures are unfavorable due to the quality reduction and formation of compounds such as hydroxymethyl furfural and furan (Crews and Castle 2007; Vranová and Ciesarová 2009). In addition, increasing the feed temperature causes a higher susceptibility to the temperature polarization effect (Castro-Muñoz et al. 2020c; Hwang et al. 2011). For this reason, the optimization of operating temperature is one of the most important steps.

Jorgensen et al. (2011) examined the potential of two MD configurations for recovery of aroma compounds from black currant. They evaluated the influence of various parameter such as feed temperature and feed flow on the permeate flux and concentrate quality. Twelve aroma compounds were selected for examination of concentration factor. At the highest tested feed temperature, the highest concentration factors have been observed. For the most hydrophobic and volatile aroma compounds the concentration factors ranged from 12.1 to 9.3 at 45 °C. The highest tested temperature of the feed and the feed flow rate equal 400 L/h resulted in an aroma recovery up to 84 vol.%. The authors compared the efficiency of the aroma recovery using SGMD and VMD. As it turns out, the SGMD process was less influenced by the flow rate, and more by the temperature. Concentration by VMD process reduced the operation time, as higher fluxes have been achieved. Due to the longer time required for SGMD for the concentration, a higher loss of aroma compounds such as anthocyanins and polyphenols was observed, comparing to the VMD.

Onsekizoglu et al. (2010) evaluated the potential of MD for the concentration of apple juice. According to their studies, the effect of the feed flow rate on transmembrane flux is inconsiderable compared to the effect of temperature difference across the membrane. During MD, the clarified apple juice with initial total soluble solids (TSS) contents of 12 oBrix was concentrated up to 65oBrix. Moreover, the nutritional and sensorial quality of the permeate was very similar to the original juice. MD, as opposed to traditional thermal evaporation, allowed to maintain the bright natural color and pleasant aroma of concentrated juice.

During MD operation, it is important to maintain the constant trans-membrane vapor pressure to avoid a reduction in permeate flux (Laganà et al. 2000). Quist-Jensen et al. (2016) examined the concentration of clarified orange juice using DCMD. They observed the evaporation flux decay in the preconcentration step, and they explained it with the reduction of temperature difference between the feed and permeate side. However, experimental results indicated that in the final concentration step, the trans-membrane flux decay can be affected by the increase in juice viscosity. Using two-step DCMD process, the TSS content in clarified orange juice increased from 9.5 oBrix up to 65 oBrix. Gunko et al. (2006) observed an important temperature gradient dependence on the capacity of DCMD process. Their results showed that the decreasing the cooling water temperature from 30 °C to 10 °C, increases the flux almost two times (180%), when the feed temperature was 50 °C. However, similar decrease of the cooling water temperature for the feed temperature equal 70 °C causes only 10% flux increase. The highest permeate flux of around 28 L/m2 h was obtained for the initial concentration process. When TSS content reached 50 °Brix, the permeate flux decreased to 9 L/m2 h. Further reduction of flux was observed together with the juice concentration up to 60–65 °Brix.

Lagana et al. (2000) used polypropylene hollow-fiber DCMD modules to obtain highly concentrated apple juices up to 64 °Brix. They concluded that flux rates were mainly dependent on temperature polarization coefficient, rather than concentration polarization coefficient which is insignificant.

3.1.2 Integrated Membrane Processes

One of the main problem in fruit juices processing is the presence of colloidal particles and suspensions that may lead to clogging or blocking of membrane pores (Castro-Muñoz et al. 2016b; Castro-Muñoz and Fíla 2018b; Valencia-Arredondo et al. 2020). According to Mirsaeedghazi et al. (2009), the cake layer formation on the membrane surface causing the membrane fouling, is created within 5 min of raw pomegranate juice processing. Such a layer deposited on the membrane increases its susceptibility to wetting and can result in a liquid permeation through the membrane. Typical foulants in fruit juices are pectins, cellulose, lignin and hemicelluloses (Meng et al. 2014; Díaz-Montes and Castro-Muñoz 2019). According to He et al. (2007), the pre-clarification of the apple juice causes significantly higher fluxes during further UF operation. For pectin removal, enzymatic pretreatment can be applied as a first step of juice clarification (Galiano et al. 2019). The enzymes can hydrolyze pectins and partially hydrolyze other macromolecules and polysaccharides. An additional enzymatic pretreatment and flocculation have been proven to improve the efficiency of membrane process during apple juice clarification (Onsekizoglu et al. 2010). Lukanin et al. (2003) have evaluated the effect of an enzymatic pretreatment on the tendency of protein deposition. The protein level deposition on the hydrophobic membrane during subsequent OD process decreased significantly after the enzymatic pretreatment.

Sort of benefits can be achieved while combining MD with pressure driven membrane separation processes, such as microfiltration (MF) and ultrafiltration (UF). Prefiltration is usually used to remove suspended solids from the fruit juices what leads to their viscosity reduction and higher fluxes during MD concentration step. Reduction of juice viscosity improve hydrodynamic conditions in the membrane channel, thereby decreasing susceptibility to concentration and temperature polarization (Lukanin et al. 2003).

Rektor et al. (2006) used MD after the MF and reverse osmosis (RO) concentration for further water removal from grape juice. The authors obtained the final juice concentration over 60 °Brix. Hongvaleerat et al. (2008) used OD to concentrate single strength and clarified pineapple juices. Preconcentration by thermal evaporation under vacuum resulted in flux enhancement during OD concentration from 6.1 kg h−1 m−2 for the single strength juice up to 8.5 kg h−1 m−2 for the preconcentrated juice. Cassano and Drioli (2007) examined the permeate quality after OD process of clarified kiwi fruit juice concentration. The raw kiwi fruit juice was first clarified using an UF laboratory pilot unit, after submitted to an OD concentration step. The clarified kiwi fruit juice was concentrated from 9.4 oBrix up to final values of 66.6 oBrix. The analytical measurements proved that concentration by OD has no influence on the acid ascorbic content and total antioxidant activity (TAA), while concentration by thermal evaporation caused a reduction of 87% of Vitamin C and 50% of TAA.

Onsekizoglu (2013) proposed the use of an integrated MD process capable of concentrating pomegranate juice under mild conditions, and evaluated the impact of coupled operation on product quality and process performance. The pomegranate juice was clarified by UF and concentrated by MD. Clarification through UF resulted in an improved clarity of the juice, simultaneously allowed to maintain organic acid content during clarification. UF step resulted in reduction of macromolecular particles in the juice, which tend to deposit on the membrane surface. Such a deposition may cause a membrane wetting and can result in a non-allowable in MD convective flow of liquid through the membrane. The use of integrated process allowed to obtain concentrated pomegranate juice (up to 57 °Brix) and to preserve its original characteristic, such as TAA, total phenolic content (TPC), total titratable acidity (TTA), total monomeric anthocyanins (TMA), pH and color.

The use of RO or FO processes, as a preconcentration step before OD or MD, has also been shown to be an effective method for high quality fruit juice concentrates production by Pagani et al. (2011) for concentration of Acerola juice, by Galaverna et al. (2008) for concentration of blood orange juice, and by Cassano et al. (2003) for concentration of citrus and carrot juices. Kozak et al. (2009) applied MF prefiltration and RO preconcentration before main black currant juice concentration by DCMD. During pretreatment it was possible to increase the concentration from 15 to 22 oBrix, while further concentration by DCMD leads to 58 oBrix using a temperature difference of only 19 °C.

Sotoft et al. (2012) proposed a conceptual process design using integrated membrane processes for the concentration of blackcurrant juice and aroma recovery. The combination of membrane processes included VMD, for aroma recovery (Castro-Muñoz 2019a), and RO, NF and DCMD for water removal was proposed as an alternative for traditional multiple step evaporators. The plant scale was based on handling 20 t/h of raw juice and the production was calculated for 17,283 ton of concentrated juice per year. Based on the mass balances, membrane areas and module numbers, the economical potential of the process was evaluated. The estimated production cost for concentration of juice from 12 °Brix to 66°Brix was 0.40 €/kg. It was 43% lower than the cost of a conventional thermal evaporation while considering the membrane lifetime of one year. To make the process even more economical, the authors proposed to increase the membrane life time up to 2 or 3 years.

3.2 Dairy Products Processing

Kezia et al. (2015) investigated the ability of DCMD to concentrate the waste effluent from the cheese making industry. They used flat sheet PTFE membrane with PP non-woven support layer, and salty whey effluent as a feed solution. The feed was composed of minerals, proteins and sugars. Even though, the feed solution was prefiltrated through MF membrane prior to DCMD concentration step, a decline in feed flux was observed due to the presence of trace protein. Adding to the prefiltration step UF membrane led to a stable flux over 10 h of operating time. Starting from 10 wt% of solids in the feed, a final total solids concentration of 30 wt% and the water recovery up to 83% was achieved. Kujawa et al. (2019) tested polymeric porous hydrophobic membranes (PP and PTFE) in AGMD process, for dairy products concentration. They found it to be an effective approach for whey and lactose solutions concentration and simultaneous production of high-quality water with retention higher than 99%. Authors compared MD results with the performance of MF, for which a rejection ranging from 80 to 90% was observed.

Moejes et al. (2020) optimized and modelled RO and AGMD network for the concentration of milk. RO was found to be favorable until its maximum achievable concentration, while AGMD was energy intensive for this type of application. This was due to the energy necessary to maintain a sufficient cross flow, which must be heated and cooled. This energy requirement is growing when the fouling phenomena occurs. To improve the performance of AGMD for milk concentration authors proposed different approaches, e.g. increasing the temperature of feed and permeate side to their maximum acceptable values and the use of available waste heat.

Numerous studies stated the occurence of fouling phenomena while processing dairy components by MD (Kujawa et al. 2019; Hausmann et al. 2013a, 2013b; Tomaszewska and Białończyk 2013). Fouling layers cause heat and mass transfer resistances leading to significant flux decline in MD process (Tijing et al. 2015). Hausmann et al. (2011) tested the possibility of MD application for dairy processing. In general, the MD requires the use of hydrophobic membranes which may lead to interactions with any hydrophobic components, such as proteins and fats, thus result in membrane wetting. Therefore, authors evaluated the influence of the main dairy components on the membrane and overall process performance. Whole milk, skim milk, whey and lactose powder solution were tested separately in DCMD. Results showed the flux decline over time, caused by the membrane fouling. In the case of whey solution, fouling was related to time, while during skim milk solution test fouling was more related to dry-matter concentration. The fouling mechanism of dairy stream during membrane distillation has been described in detail in another paper by Hausmann et al. (2013c). In the case of skim milk and whey solutions the fouling starts with the deposition of salts and proteins. However, in the case of skim milk processing fouling occurred within a few minutes through a formation of homogeneous layer, which increases in thickness over time. Whey solution caused the formation of fouling patches that grew across the membrane area and remained reversible for much longer time periods. This type of fouling layer was less dense, thus caused smaller flux decline with time than skim milk fouling layer.

One of the possible approach to reduce membrane fouling is to make the membranes more hydrophilic (Pichardo-Romero et al. 2020; Khayet et al. 2006; Castro-Muñoz 2020b). Chanachai et al. (2010) coated hydrophobic hollow fiber PVDF membrane with highly hydrophilic chitosan. The effect of this modification was tested in oil feed solution containing limonene via OD unit. Results showed that the coating resulted in higher vapour fluxes while inhibiting the flavor loss. Moreover, uncoated membrane showed a significant flux decline after 100 min of operation. After 5 h of uncoated membrane testing 18.86 mg/l of CaCl2 was found in retentate solution indicating membrane wetting. On the contrary, chitosan coated membrane showed stable flux with time and no wetting susceptibility.

3.3 Ethanol Removal

During the ethanol production and sugar fermentation several by-products are formed (Castro-Munoz et al. 2018, 2019c), which inhibit further yeast productivity leading to low ethanol concentration in fermentation broth (5–12%). An increase in the ethanol concentration may represent a lower cost of its removal through distillation, however, it is difficult to obtain due to inhibition phenomena. The MD is an economical alternative process to traditional energy intensive distillation that can be successfully applied for continuous removal of ethanol and other fermented products from the broth (Tomaszewska and Białończyk 2011; Gryta et al. 2000; Zhang et al. 2017; Fan et al. 2019). In addition, the removal of other volatile substances from fermentation broth may decrease the inhibition effect of these compounds on yeast productivity. These volatile compounds are aliphatic acids such as formic, acetic, propionic, butyric, valeric and hexanoic, alcohols (2,3-butanediol), aromatic compounds and furfural (Couallier et al. 2006). Gryta (2001) performed ethanol production in tubular bioreactor integrated with MD. The author carried out the fermentation process with the yeast concentration of 20 g/dm3 that resulted in the productivity level of 5.5 g/dm3h of ethanol. The process efficiency almost reached the theoretical value of the fermentation. The fermentation under similar conditions, but without MD leads to the productivity decrease to 2.6 g/dm3h. The fermentation efficiency decreased significantly after 10 h of process duration resulting in the final efficiency below 50%. Gryta and Barancewicz (2011) evaluated the possibility of removing not only ethanol but also other volatile compounds from fermentation broth using MD. They observed that apart from ethanol, mainly acetic acid and propionic acid were evaporated from the feed to distillate. Recent studies by Kumar et al. (2017) showed that membrane-integrated system (MF, NF and DCMD) for bioethanol production can operate for many hours without any significant concentration polarization effect and flux decline. Such a system can be driven by solar energy, representing an energy efficient and eco-friendly approach for ethanol removal and purification.

Banat and Al-Shannag (2000) evaluated the potential use of MD to recover dilute acetone-butanol-ethanol solvents from aqueous solution. The authors used multicomponent Stefan-Maxwell-based mathematical model to predict the AGMD performance. The results confirmed the effectiveness of MD in alleviating the inhibitory effect of acetone-butanol-ethanol on the microbial culture. The increase of the feed temperature led to the butanol selectivity increase, which was considered as the most toxic solvent among those mentioned. The authors found that optimum feed temperature for butanol separation was 55 °C, and interestingly, it was the most preferentially removed solvent (in spite of its high boiling point, compared to acetone and ethanol).

Several studies evaluated the potential of MD to dealcoholize alcoholic beverages (Castro-Muñoz 2019b). Varavuth et al. (2009) used microporous PVDF hollow fiber membrane for ethanol removal from ethanol diluted solution and wine using OD. They found this process to be capable of alcohol permeation, however, the study showed the significant reduction of ethyl acetate and iso-amyl alcohol (70% and 44%, respectively after 6 h of operation). Ethanol removal using OD resulted in 34% reduction of ethanol in tested wine. Similar studies by Hogan et al. (1998) showed the capability of OD to reduce alcohol content in wine up to 6% with minimum loss of its flavor and fragrance components. Purwasasmita et al. (2015) proved the possibility of VMD for beer dealcoholization process. The effect of feed and vacuum pressure on flux and selectivity was investigated. Non-porous thin-film composite polyamide was used as a membrane module. The results indicated that beer dealcoholization using VMD can reduce the alcohol content from 5%-vol. to 2.45%-vol. within 6 h, without losing any nutrients and flavoring components. A slight loss of maltose was related to the adsorption phenomena on the membrane surface, therefore, for the recovery of the flavor compound, membrane flushing was proposed.

3.4 Anthocyanins Concentration

Anthocyanins concentration using membrane technology, e.g. through ultrafiltration and nanofiltration membranes has been already studied by several researchers (Avram et al. 2017; Cassano et al. 2014; Ceron-Montes et al. 2015). However, the application of gas-filled membrane in the form of OD and MD to concentrate anthocyanins is not common. Nevertheless, there are some investigations that have considered the use of OD and MD integrated processes. Jampani and Raghavarao (2015) compared thermal evaporation with integrated aqueous two-phase extraction with membrane processes such as OMD and forward osmosis (FO) for concentration of red cabbage anthocyanins. The results showed that degradation constant of anthocyanins was lower in the case of both integrated processes when compared to anthocyanins concentration obtained by thermal evaporation. However, an integrated process involving FO was found to be the most suitable for the purification and concentration of anthocyanins. Their concentration increased from 508.05 mg/L to 3123.45 mg/L for FO integrated process, while only to 945.32 mg/L for OMD integrated process. Similar results were obtained by Nayak and Rastogi (2010). In the case of FO, the anthocyanin extract was concentrated from 49.63 mg/l up to 2.69 g/l, while in the case of OMD process, the concentration of anthocyanin achieved only 72 mg/l at the same operation time. However, migration of sodium chloride was observed during FO operation, while during OMD there was no transfer of osmotic agent. Patil and Raghavarao (2007) reported the recovery of anthocyanins from radish by performing UF, RO, and OMD processes with different combinations to evaluate the efficiency of each system. UF step was used to remove tannin, pectin, and other suspended solids, and resulted in a clear extract. RO step was used for preconcentration of anthocyanins from 1 to 4 °B. The separation by OMD resulted in concentration of extract up to 17.5 °B after 20 h using CaCl2 as an osmotic agent. It took 30 h to achieve the same extract concentration using another osmotic agent (K2HPO4). The authors compared the OMD results with the performance of conventional evaporation process (vacuum evaporator). The concentration of anthocyanin increased up to 9 °B after three passes. The integration of UF, RO, and OMD gave a concentration increase of 25-fold higher than that of the initial feed (from 1 to 26 °B). As a result, it has been proven that the concentration of anthocyanin by integrated membrane system was more favorable than conventional or individual processes. Kozak et al. (2009) have examined the effectiveness of anthocyanin concentration using DCMD. The analytical measurements results showed that the anthocyanin content increased proportionally to the increase of the TSS from 1.868 g/L before MD, up to 3.805 g/L after MD step. Anari et al. (2019) concentrated bioactive anthocyanins from aqueous extracts of muscadine grape pomace using OD and DCMD. Due to the sensitive nature of anthocyanins (Castro-Muñoz et al. 2018a), the maximum feed temperature was limited to 40 °C and the permeate temperature was 10 °C. Concentration factor of total anthocyanins after processing using OD reached 1.07, while for DCMD it was equal 1.6. A combination of OD and DCMD gave the highest concentration factor of 2.78 and the highest observed fluxes. The authors also highlighted other advantages of combined OD-DCMD process, such as minimal required pretreatment, reduction of equipment costs and faster processing compared to the individual OD operation. The results quoted above suggested that MD process deserves more interest in the anthocyanin concentration application as it may become an alternative to conventional method and a cost-effective unit operation. However, prior to actual manufacturing process, selection of an appropriate membrane and regeneration of the membrane must be considered and optimized.

4 Fouling and Its Control

One of the main issues of membrane-based processes including MD is membrane fouling (Pichardo-Romero et al. 2020; Cassano et al. 2015). Fouling reduces membrane performance due to the deposition of suspended or dissolved substances on the membrane surface and within the membrane pores. It deteriorates heat and mass transport across the membranes, therefore membranes have to be cleaned more frequently. For food processing, fouling becomes more complicated phenomenon due to the complexity of the processed products composition. The fouling in MD can take several forms depending on the chemical composition of the feed bulk solution, such as inorganic fouling (scaling), colloidal fouling, organic fouling and biological fouling (biofouling) (Tijing et al. 2015). Scaling is caused by the deposition of inorganic precipitates, such as calcium sulfates, calcium carbonates and magnesium carbonates. Basically, these inorganic precipitates are deposited on the membrane when their concentration in the feed solution exceeds their saturation concentrations. Colloidal fouling on the membrane surface refers to the accumulation of biologically inert particles and colloids. Organic fouling is mainly associated with the deposition or adsorption of organic matters, such as humic acid, fulvic acid, protein, polysaccharides, and polyacrylic polymers (Díaz-Montes et al. 2020b). Biofouling refers to the formation of biofilms by various microorganisms, such as bacteria and fungi, on the membrane surface. The morphology of the fouling layer determine its resistance mechanisms, e.g. non-porous layer results in both thermal and hydraulic resistances, while a porous one contributes only to thermal resistance (Gryta 2008).

Ding et al. (2008) investigated the fouling resistance during the concentration of traditional Chinese medicine via DCMD. The observed trans-membrane water flux decline due to the membrane fouling that introduced an additional thermal resistance in the boundary layer. They found prefiltration to be a more effective way than centrifugation for mitigating membrane fouling, while for effective cleaning of fouled hollow fiber membrane they proposed gas back-washing within membrane module. An intermittent back-washing could kept trans-membrane flux at relatively high level during concentration process, however, full recovery of the initial flux value was not possible as a gas of only 10 kPa gauge pressure was used for back-washing. Higher gauge pressure could cause the membrane demage. In another work Ding et al. (2011) applied bubbling as an effective startegy to control polarization and fouling formed in concentrating traditional Chinese medicine extract through DCMD. Gas bubbling induces the flow and improves shear stress at the membrane surface. An introduction of intermittent gas bubbling to the feed side of membrane module gave possibility for effective fouling control, through deposited foulants removal from membrane surface by created two phase flow. It was also noted that the simultaneous increase of gas flow rate, gas bubbling duration, and the decrease of MD duration can improve the cleaning efficiency of gas bubbling strategy. Durham and Nguyen (1994) evaluated the effectiveness of several cleaning agents for hydrophobic membranes fouled by tomato paste in OD process. The cleaning regime was determined by the membrane surface tension. 1% NaOH was found to be the most effective cleaner for membranes with a surface tension greater than 23 mN/m, however, repeated fouling/cleaning trials lead to hydrophobic integrity demage. On the other hand, for membranes with a surface tension less than 23 mN/m, P3 Ultrasil 56 was the most effective cleaner, additionally, fouling/cleaning trials did not affect membrane performance; stable water vapour flux and no salt leakage were still observed.

5 Concluding Remarks and Future Prospects

MD gained huge interest in processing of food and food bioactive components due to its lower energy requirement and milder process conditions in comparison with conventional distillation and pressure driven membrane processes. It results in minimal thermal damage and high quality of products. Due to the possibility of effective operation at low temperatures, MD can be driven by alternative energy sources for example waste energy or solar energy, thus MD may represent an energy efficient approach for food processing. This feature makes the process more attractive for industrial implementation. Although in recent years a few pilot plants studies have been proposed for desalination, most of MD studies regarding concentration and food components processing are still at laboratory scale.

Flux decline with time due to the membrane fouling is one of the main challenges for food processing using MD technology, since membranes require regular periodic cleaning to remove foulants and keep the permeability within a given range. The risk of fouling and wetting of membrane pores affect the membrane durability and limit their applications in this field. The studies in long term MD performance needs to be done to make the MD process more promising in food industry. Effective fouling control techniques for MD must be developed. The current techniques for the control of fouling are limited to feed pretreatment and membrane cleaning.

Theoretical 100% rejection of nonvolatile solutes is one of the major advantages of MD, however, evaporation fluxes are much smaller when compared with RO and thermal evaporation. Further efforts need to be established in this field, especially on flux enhancement possibilities.

References

Ahmad MZ, Castro-Munõz R, Budd PM (2020) Boosting gas separation performance and suppressing the physical aging of polymers of intrinsic microporosity (PIM-1) by nanomaterial blending. Nanoscale 12:23333–23370

Alkhudhiri A, Darwish N, Hilal N (2012) Membrane distillation: a comprehensive review. Desalination 287:2–18

Alvarez V, Alvarez S, Riera FA, Alvarez R (1997) Permeate flux prediction in apple juice concentration by reverse osmosis. J Membr Sci 127:25–34

Anari Z, Mai C, Sengupta A, Howard L, Brownmiller C, Wickramasinghe SR (2019) Combined osmotic and membrane distillation for concentration of anthocyanin from muscadine pomace. J Food Sci 84:2199–2208

Avram AM, Morin P, Brownmiller C, Howard LR, Sengupta A, Wickramasinghe SR (2017) Concentrations of polyphenols from blueberry pomace extract using nanofiltration. Food Bioprod Process 106:91–101

Babu BR, Rastogi NK, Raghavarao KSMS (2008) Concentration and temperature polarization effects during osmotic membrane distillation. J Membr Sci 322:146–153

Bagger-Jørgensen R, Meyer AS, Varming C, Jonsson G (2004) Recovery of volatile aroma compounds from black currant juice by vacuum membrane distillation. J Food Eng 64:23–31

Bagger-Jørgensen R, Meyer AS, Pinelo M, Varming C, Jonsson G (2011) Recovery of volatile fruit juice aroma compounds by membrane technology: sweeping gas versus vacuum membrane distillation. Innov Food Sci Emerg Technol 12:388–397

Banat FA, Al-Shannag M (2000) Recovery of dilute acetone-butanol-ethanol (ABE) solvents from aqueous solutions via membrane distillation. Bioprocess Eng 23:643–649

Bodell BR (1963) Silicone rubber vapor diffusion in saline water distillation. United States Pat Ser 285:32

Calabrò V, Jiao BL, Drioli E (1994) Theoretical and experimental study on membrane distillation in the concentration of orange juice. Ind Eng Chem Res 33:1803–1808

Cassano A, Drioli E (2007) Concentration of clarified kiwifruit juice by osmotic distillation. J Food Eng 79:1397–1404

Cassano A, Drioli E (2010) Membrane contactors in integrated processes for fruit-juice processing, vol 3. ISBN 9783527314829

Cassano A, Drioli E, Galaverna G, Marchelli R, Di Silvestro G, Cagnasso P (2003) Clarification and concentration of citrus and carrot juices by integrated membrane processes. J Food Eng 57:153–163

Cassano A, Conidi C, Drioli E (2010) Physico-chemical parameters of cactus pear (Opuntia ficus-indica) juice clarified by microfiltration and ultrafiltration processes. Desalination 250:1101–1104

Cassano A, Conidi C, Ruby-Figueroa R (2014) Recovery of flavonoids from orange press liquor by an integrated membrane process. Membranes (Basel) 4:509–524

Cassano A, Conidi C, Ruby-Figueroa R, Castro-Muñoz R (2015) A two-step nanofiltration process for the production of phenolic-rich fractions from artichoke aqueous extracts. Int J Mol Sci 16:8968–8987

Castro-Muñoz R, Boczkaj G, Gontarek E, Cassano A, Fíla V (2020) Membrane technologies assisting plant-based and agro-food by-products processing: a comprehensive review. Trends Food Sci Technol 95:219–232

Castro-Muñoz R (2018) Separation, fractionation and concentration of high-added-value compounds from agro-food by-products through membrane-based technologies. In: Smithers G (ed) Reference module in food science. Elsevier, ISBN ISBN: 978-0-08-100596-5

Castro-Muñoz R (2019a) Pervaporation: the emerging technique for extracting aroma compounds from food systems. J Food Eng 253

Castro-Muñoz R (2019b) Pervaporation-based membrane processes for the production of non-alcoholic beverages. J Food Sci Technol 56:2333–2344

Castro-Muñoz R (2020a) Breakthroughs on tailoring pervaporation membranes for water desalination: a review. Water Res 187:116428

Castro-Muñoz R (2020b) The role of new inorganic materials in composite membranes for water disinfection. Membranes (Basel) 10

Castro-Muñoz R, Fíla V (2018a) Progress on incorporating zeolites in matrimid® 5218 mixed matrix membranes towards gas separation. Membrane 8. https://doi.org/10.3390/membranes8020030

Castro-Muñoz R, Fíla V (2018b) MEMBRANE-BASED technologies as an emerging tool for separating high-added-value compounds from natural products. Trends Food Sci Technol

Castro-Muñoz R, Yañez-Fernandez J (2015) Valorization of Nixtamalization wastewaters (Nejayote) by integrated membrane process. Food Bioprod Process 95

Castro-Muñoz R, Yáñez-Fernández J, Fíla V (2016a) Phenolic compounds recovered from agro-food by-products using membrane technologies: an overview. Food Chem 213:753–762

Castro-Muñoz R, Barragán-Huerta BE, Yáñez-Fernández J (2016b) The use of nixtamalization waste waters clarified by ultrafiltration for production of a fraction rich in phenolic compounds. Waste and biomass valorization, vol 7

Castro-Munoz R, La Iglesia ÓD, Fíla V, Téllez C, Coronas J (2018) Pervaporation-assisted esterification reactions by means of mixed matrix membranes. Ind Eng Chem Res 57:15998–16011

Castro-Muñoz R, Conidi C, Cassano A (2018a) Membrane-based technologies for meeting the recovery of biologically active compounds from foods and their by-products. Crit Rev Food Sci Nutr 0:1–22

Castro-Muñoz R, Fíla V, Barragán-Huerta BE, Yáñez-Fernández J, Piña-Rosas JA, Arboleda-Mejía J (2018b) Processing of Xoconostle fruit (Opuntia joconostle) juice for improving its commercialization using membrane filtration. J Food Process Preserv 42:1–9

Castro-Muñoz R, Galiano F, de la Iglesia Ó, Fíla V, Téllez C, Coronas J, Figoli A (2019a) Graphene oxide – filled polyimide membranes in pervaporative separation of azeotropic methanol–MTBE mixtures. Sep Purif Technol 224:265–272

Castro-Muñoz R, Buera-Gonzalez J, de la Iglesia O, Galiano F, Fíla V, Malankowska M, Rubio C, Figoli A, Tellez C, Coronas J (2019b) Towards the dehydration of ethanol using pervaporation cross-linked poly(vinyl alcohol)/graphene oxide membranes. J Membr Sci 582:423–434

Castro-Muñoz R, Galiano F, Figoli A (2019c) Chemical and bio-chemical reactions assisted by pervaporation technology. Crit Rev Biotechnol 39:884–903

Castro-Muñoz R, Díaz-Montes E, Cassano A, Gontarek E (2020a) Membrane separation processes for the extraction and purification of steviol glycosides: an overview. Crit Rev Food Sci Nutr 4:1–23

Castro-Muñoz R, Agrawal KV, Coronas J (2020b) Ultrathin permselective membranes: the latent way for efficient gas separation. RSC Adv 10:12653–12670

Castro-Muñoz R, Gonzalez-Valdez J, Ahmad Z (2020c) High-performance pervaporation chitosan-based membranes: new insights and perspectives. Rev Chem Eng 1–16

Castro-Muñoz R, González-Melgoza LL, García-Depraect O (2021) Ongoing progress on novel nanocomposite membranes for the separation of heavy metals from contaminated water. Chemosphere 270

Cath TY, Adams VD, Childress AE (2004) Experimental study of desalination using direct contact membrane distillation: a new approach to flux enhancement. J Membr Sci 228:5–16

Ceron-Montes GI, San Martin-Martinez E, Yañez-Fernandez J, Quezada-Cruz M, Castro-Muñoz R (2015) Preliminary purification of anthocyanins from blue corn by adsorption and electrophoresis. Rev Mex Ing Quim 14

Chanachai A, Meksup K, Jiraratananon R (2010) Coating of hydrophobic hollow fiber PVDF membrane with chitosan for protection against wetting and flavor loss in osmotic distillation process. Sep Purif Technol 72:217–224

Chernyshov MN, Meindersma GW, de Haan AB (2005) Comparison of spacers for temperature polarization reduction in air gap membrane distillation. Desalination 183:363–374

Conidi C, Castro-Muñoz R, Cassano A (2020) Membrane-based operations in the fruit juice processing industry: a review. Beverages 6:1–39

Couallier EM, Payot T, Bertin AP, Lameloise ML (2006) Recycling of distillery effluents in alcoholic fermentation: role in inhibition of 10 organic molecules. Appl Biochem Biotechnol 133:217–237

Crews C, Castle L (2007) A review of the occurrence, formation and analysis of furan in heat-processed foods. Trends Food Sci Technol 18:365–372

Curcio E, Drioli E (2005) Membrane distillation and related operations – a review. Sep Purif Rev 34:35–86

Deshmukh SK, Sapkal VS, Sapkal RS (2011) Evaluation of direct contact membrane distillation for concentration of orange juice. Int J Chem Res 01:39–48

Díaz-Montes E, Castro-Muñoz R (2019) Metabolites recovery from fermentation broths via pressure-driven membrane processes. Asia Pac J Chem Eng 14:e2332–e2322

Díaz-Montes E, Gutiérrez-Macías P, Orozco-Álvarez C, Castro-Muñoz R (2020a) Fractionation of Stevia rebaudiana aqueous extracts via two-step ultrafiltration process: towards rebaudioside a extraction. Food Bioprod Process 123:111–122

Díaz-Montes E, Yáñez-Fernández J, Castro-Muñoz R (2020b) Microfiltration-mediated extraction of dextran produced by Leuconostoc mesenteroides SF3. Food Bioprod Process 119:317–328

Ding Z, Liu L, Yu J, Ma R, Yang Z (2008) Concentrating the extract of traditional Chinese medicine by direct contact membrane distillation. J Membr Sci 310:539–549

Ding Z, Liu L, Liu Z, Ma R (2011) The use of intermittent gas bubbling to control membrane fouling in concentrating TCM extract by membrane distillation. J Membr Sci 372:172–181

Durham RJ, Nguyen MH (1994) Hydrophobic membrane evaluation and cleaning for osmotic distillation of tomato puree. J Membr Sci 87:181–189

El-Bourawi MS, Ding Z, Ma R, Khayet M (2006) A framework for better understanding membrane distillation separation process. J Membr Sci 285:4–29

Fan S, Li J, Liu Y, Xiao Z (2019) Bioethanol production in membrane distillation bioreactor with permeate fractional condensation and mechanical vapor compression. Energy Procedia 158:21–25

Findley ME (1967) Vaporization through porous membranes. Ind Eng Chem Process Des Dev 6:226–230

Findley ME, Tanna VV, Rao YB, Yeh CL (1969) Mass and heat transfer relations in evaporation through porous membranes. AICHE J 15:483–489

Galaverna G, Di Silvestro G, Cassano A, Sforza S, Dossena A, Drioli E, Marchelli R (2008) A new integrated membrane process for the production of concentrated blood orange juice: effect on bioactive compounds and antioxidant activity. Food Chem 106:1021–1030

Galiano F, Mecchia A, Castro-Muñoz R, Tagarelli A, Lavecchia R, Figoli A (2019) Enzyme-mediated extraction of limonene, linalool and linalyl acetate from bergamot peel oil by pervaporation graphical abstract keywords. J Membr Sci Res 5:187–193

Gontarek E, Macedonio F, Militano F, Giorno L, Lieder M, Politano A, Drioli E, Gugliuzza A (2019) Adsorption-assisted transport of water vapour in super-hydrophobic membranes filled with multilayer graphene platelets. Nanoscale 11:11521–11529

Gontarek E, Castro-Muñoz R, Lieder M (2021) New insights of nanomaterials usage towards superhydrophobic membranes for water desalination via membrane distillation: a review. Crit Rev Environ Sci Technol

Gryta M (2001) The fermentation process integrated with membrane distillation. Sep Purif Technol 24:283–296

Gryta M (2008) Fouling in direct contact membrane distillation process. J Membr Sci 325:383–394

Gryta M (2018) The long-term studies of osmotic membrane distillation. Chem Pap 72:99–107

Gryta M, Barancewicz M (2011) Separation of volatile compounds from fermentation broth by membrane distillation. Polish J Chem Technol 13:56–60

Gryta M, Morawski AW, Tomaszewska M (2000) Ethanol production in membrane distillation bioreactor. Catal Today 56:159–165

Gunko S, Verbych S, Bryk M, Hilal N (2006) Concentration of apple juice using direct contact membrane distillation. Desalination 190:117–124

Hausmann A, Sanciolo P, Vasiljevic T, Ponnampalam E, Quispe-Chavez N, Weeks M, Duke M (2011) Direct contact membrane distillation of dairy process streams. Membranes (Basel) 1:48–58

Hausmann A, Sanciolo P, Vasiljevic T, Weeks M, Schroën K, Gray S, Duke M (2013a) Fouling of dairy components on hydrophobic polytetrafluoroethylene (PTFE) membranes for membrane distillation. J Membr Sci 442:149–159

Hausmann A, Sanciolo P, Vasiljevic T, Kulozik U, Duke M (2013b) Performance assessment of membrane distillation for skim milk and whey processing. J Dairy Sci 97:56–71

Hausmann A, Sanciolo P, Vasiljevic T, Weeks M, Schroën K, Gray S, Duke M (2013c) Fouling mechanisms of dairy streams during membrane distillation. J. Memb. Sci. 441:102–111

He Y, Ji Z, Li S (2007) Effective clarification of apple juice using membrane filtration without enzyme and pasteurization pretreatment. Sep Purif Technol 57:366–373

He K, Hwang HJ, Woo MW, Moon IS (2011) Production of drinking water from saline water by direct contact membrane distillation (DCMD). J Ind Eng Chem 17:41–48

Hogan P, Canning R, Peterson P, Johnson R, Michaels A (1998) A new option: osmotic distillation. Chem Eng Prog 94:49–61

Hongvaleerat C, Cabral LMC, Dornier M, Reynes M, Ningsanond S (2008) Concentration of pineapple juice by osmotic evaporation. J Food Eng 88:548–552

Hwang HJ, He K, Gray S, Zhang J, Moon IS (2011) Direct contact membrane distillation (DCMD): experimental study on the commercial PTFE membrane and modeling. J Membr Sci 371:90–98

Ibarz A, Garza S, Garvín A, Pagán J (2011) Degradation of mandarin juice concentrates treated at high temperatures. J Food Process Eng 34:682–696

Jampani C, Raghavarao KSMS (2015) Process integration for purification and concentration of red cabbage (Brassica oleracea L.) anthocyanins. Sep Purif Technol 141:10–16

Jiao B, Cassano A, Drioli E (2004) Recent advances on membrane processes for the concentration of fruit juices: a review. J Food Eng 63:303–324

Kezia K, Lee J, Weeks M, Kentish S (2015) Direct contact membrane distillation for the concentration of saline dairy effluent. Water Res 81:167–177

Khayet M (2011) Membranes and theoretical modeling of membrane distillation: a review. Adv Colloid Interf Sci 164:56–88

Khayet M, Velázquez A, Mengual JI (2004) Modelling mass transport through a porous partition: effect of pore size distribution. J Non-Equilibrium Thermodyn 29:279–299

Khayet M, Matsuura T, Mengual JI, Qtaishat M (2006) Design of novel direct contact membrane distillation membranes. Desalination 192:105–111

Kozák Á, Békássy-Molnár E, Vatai G (2009) Production of black-currant juice concentrate by using membrane distillation. Desalination 241:309–314

Kujawa J, Chrzanowska E, Kujawski W (2019) Transport properties and fouling issues of membranes utilized for the concentration of dairy products by air-gap membrane distillation and microfiltration. Chem Pap 73:565–582

Kumar R, Ghosh AK, Pal P (2017) Fermentative energy conversion: renewable carbon source to biofuels (ethanol) using Saccharomyces cerevisiae and downstream purification through solar driven membrane distillation and nanofiltration. Energy Convers Manag 150:545–557

Laganà F, Barbieri G, Drioli E (2000) Direct contact membrane distillation: modelling and concentration experiments. J Membr Sci 166:1–11

Lalia BS, Guillen-Burrieza E, Arafat HA, Hashaikeh R (2013) Fabrication and characterization of polyvinylidenefluoride-co-hexafluoropropylene (PVDF-HFP) electrospun membranes for direct contact membrane distillation. J Membr Sci 428:104–115

Lawson KW, Lloyd DRM, distillation. II. (1996) Direct contact MD. J. Memb. Sci. 120:123–133

Liao Y, Wang R, Fane AG (2013) Engineering superhydrophobic surface on poly(vinylidene fluoride) nanofiber membranes for direct contact membrane distillation. J Membr Sci 440:77–87

Lukanin OS, Gunko SM, Bryk MT, Nigmatullin RR (2003) The effect of content of apple juice biopolymers on the concentration by membrane distillation. J Food Eng 60:275–280

Martínez-Díez L, Vázquez-González MI, Florido-Díaz FJ (1998) Study of membrane distillation using channel spacers. J Membr Sci 144:45–56

Meng S, Ye Y, Mansouri J, Chen V (2014) Fouling and crystallisation behaviour of superhydrophobic nano-composite PVDF membranes in direct contact membrane distillation. J Membr Sci 463:102–112

Mirsaeedghazi H, Emam-Djomeh Z, Mousavi SM, Aroujalian A, Navidbakhsh M (2009) Changes in blocking mechanisms during membrane processing of pomegranate juice. Int J Food Sci Technol 44:2135–2141

Moejes SN, van Wonderen GJ, Bitter JH, van Boxtel AJB (2020) Assessment of air gap membrane distillation for milk concentration. J Membr Sci 594:117403

Nayak CA, Rastogi NK (2010) Comparison of osmotic membrane distillation and forward osmosis membrane processes for concentration of anthocyanin. Desalin Water Treat 16:134–145

Onsekizoglu P (2012) Membrane distillation: principle, advances, limitations and future prospects in food industry. In: Distillation-advances from modeling to applications, pp 233–266

Onsekizoglu P (2013) Production of high quality clarified pomegranate juice concentrate by membrane processes. J Membr Sci 442:264–271

Onsekizoglu P, Bahceci KS, Acar MJ (2010) Clarification and the concentration of apple juice using membrane processes: a comparative quality assessment. J Membr Sci 352:160–165

Pagani MM, Rocha-Leão MH, Barbosa Couto AB, Pinto JP, Ribeiro AO, dos Santos Gomes F, Cabral LMC (2011) Concentration of acerola (malpighia emarginata dc.) juice by integrated membrane separation process. Desalin Water Treat 27:130–134

Patil G, Raghavarao KSMS (2007) Integrated membrane process for the concentration of anthocyanin. J Food Eng 78:1233–1239

Perrotta ML, Saielli G, Casella G, Macedonio F, Giorno L, Drioli E, Gugliuzza A (2017) An ultrathin suspended hydrophobic porous membrane for high-efficiency water desalination. Appl Mater Today 9:1–9

Phattaranawik J, Jiraratananon R, Fane AG, Halim C (2001) Mass flux enhancement using spacer filled channels in direct contact membrane distillation. J Membr Sci 187:193–201

Phattaranawik J, Jiraratananon R, Fane AG (2003) Effect of pore size distribution and air flux on mass transport in direct contact membrane distillation. J Membr Sci 215:75–85

Pichardo-Romero D, Garcia-Arce ZP, Zavala-Ramirez A, Castro-Muñoz R (2020) Current advances in biofouling mitigation in membranes for water treatment: an overview. PRO 8:182

Prince JA, Singh G, Rana D, Matsuura T, Anbharasi V, Shanmugasundaram TS (2012) Preparation and characterization of highly hydrophobic poly(vinylidene fluoride) – clay nanocomposite nanofiber membranes (PVDF-clay NNMs) for desalination using direct contact membrane distillation. J Membr Sci 397–398:80–86

Purwasasmita M, Kurnia D, Mandias FC, Khoiruddin; Wenten, I.G. (2015) Beer dealcoholization using non-porous membrane distillation. Food Bioprod Process 94:180–186

Quist-Jensen CA, Macedonio F, Conidi C, Cassano A, Aljlil S, Alharbi OA, Drioli E (2016) Direct contact membrane distillation for the concentration of clarified orange juice. J Food Eng 187:37–43

Rektor A, Vatai G, Békássy-Molnár E (2006) Multi-step membrane processes for the concentration of grape juice. Desalination 191:446–453

Sant’Anna V, Marczak LDF, Tessaro IC (2012) Membrane concentration of liquid foods by forward osmosis: process and quality view. J Food Eng 111:483–489

Schneider K, Hölz W, Wollbeck R, Ripperger S (1988) Membranes and modules for transmembrane distillation. J Membr Sci 39:25–42

Shirtcliffe NJ, McHale G, Atherton S, Newton MI (2010) An introduction to superhydrophobicity. Adv Colloid Interf Sci 161:124–138

Smolders K, Franken ACM (1989) Terminology for membrane distillation. Desalination 72:249–262

Sotoft LF, Christensen KV, Andrésen R, Norddahl B (2012) Full scale plant with membrane based concentration of blackcurrant juice on the basis of laboratory and pilot scale tests. Chem Eng Process Process Intensif 54:12–21

Srisurichan S, Jiraratananon R, Fane AG (2006) Mass transfer mechanisms and transport resistances in direct contact membrane distillation process. J Membr Sci 277:186–194

Susanto H (2011) Towards practical implementations of membrane distillation. Chem Eng Process Process Intensif 50:139–150

Tang N, Jia Q, Zhang H, Li J, Cao S (2010) Preparation and morphological characterization of narrow pore size distributed polypropylene hydrophobic membranes for vacuum membrane distillation via thermally induced phase separation. Desalination 256:27–36

Terki L, Kujawski W, Kujawa J, Kurzawa M, Filipiak-Szok A, Chrzanowska E, Khaled S, Madani K (2018) Implementation of osmotic membrane distillation with various hydrophobic porous membranes for concentration of sugars solutions and preservation of the quality of cactus pear juice. J Food Eng 230:28–38

Tijing LD, Woo YC, Choi JS, Lee S, Kim SH, Shon HK (2015) Fouling and its control in membrane distillation-a review. J Membr Sci 475:215–244

Tijing LD, Woo YC, Shim WG, He T, Choi JS, Kim SH, Shon HK (2016) Superhydrophobic nanofiber membrane containing carbon nanotubes for high-performance direct contact membrane distillation. J Membr Sci 502:158–170

Tomaszewska M, Białończyk L (2011) The investigation of ethanol separation by the membrane distillation process. Polish J Chem Technol 13:66–69

Tomaszewska M, Białończyk L (2013) Influence of proteins content in the feed on the course of membrane distillation. Desalin Water Treat 51:2362–2367

Toribio JL, Lozano JE (1986) Heat induced browning of clarified apple juice at high temperatures. J Food Sci 51:172–175

Valencia-Arredondo JA, Hernández-Bolio GI, Cerón-Montes GI, Castro-Muñoz R, Yáñez-Fernández J (2020) Enhanced process integration for the extraction, concentration and purification of di-acylated cyanidin from red cabbage. Sep Purif Technol 238:116492

Varavuth S, Jiraratananon R, Atchariyawut S (2009) Experimental study on dealcoholization of wine by osmotic distillation process. Sep Purif Technol 66:313–321

Varming C, Andersen ML, Poll L (2004) Influence of thermal treatment on black currant (Ribes nigrum L.) juice aroma. J Agric Food Chem 52:7628–7636

Vranová J, Ciesarová Z (2009) Furan in food – a review. Czech J Food Sci 27:1–10

Wang L, Min J (2011) Modeling and analyses of membrane osmotic distillation using non-equilibrium thermodynamics. J Membr Sci 378:462–470

Wang Q, Li N, Bolto B, Hoang M, Xie Z (2016) Desalination by pervaporation: a review. Desalination 387:46–60

Weyl P K (1967) Recovery demineralised water from saline water

Zambra C, Romero J, Pino L, Saavedra A, Sanchez J (2014) Concentration of cranberry juice by osmotic distillation process. J Food Eng 144:58–65

Zhang Y, Wang R (2013) Fabrication of novel polyetherimide-fluorinated silica organic-inorganic composite hollow fiber membranes intended for membrane contactor application. J Membr Sci 443:170–180

Zhang J, Dow N, Duke M, Ostarcevic E, Li J, De; Gray, S. (2010) Identification of material and physical features of membrane distillation membranes for high performance desalination. J Membr Sci 349:295–303

Zhang J, Song Z, Li B, Wang Q, Wang S (2013) Fabrication and characterization of superhydrophobic poly (vinylidene fluoride) membrane for direct contact membrane distillation. Desalination 324:1–9

Zhang Q, Nurhayati, Cheng CL, Lo YC, Nagarajan D, Hu J, Chang JS, Lee DJ (2017) Ethanol production by modified polyvinyl alcohol-immobilized Zymomonas mobilis and in situ membrane distillation under very high gravity condition. Appl Energy 202:1–5

Zhang H, Li B, Sun D, Miao X, Gu Y (2018) SiO 2 -PDMS-PVDF hollow fiber membrane with high flux for vacuum membrane distillation. Desalination 429:33–43

Zhu H, Wang H, Wang F, Guo Y, Zhang H, Chen J (2013) Preparation and properties of PTFE hollow fiber membranes for desalination through vacuum membrane distillation. J Membr Sci 446:145–153

Zuo J, Bonyadi S, Chung TS (2016) Exploring the potential of commercial polyethylene membranes for desalination by membrane distillation. J Membr Sci 497:239–247

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information