Abstract

This study is aimed at testing a new method to improve fishpond water quality in the acid sulfate soil areas by using biogas slurry (BS). Two experiments were implemented on-site at the fishpond to test for quantity of biogas slurry applied and fish growing status. In the first experiment, treatment of 75% BS had water pH increased from 3.3 to 6.5 after 1.5 months; DO values and Chlorophyll-a concentrations were reasonably high (5.2 ppm and 143.05 μg/L). In the second experiment, the daily weight gain of Snakeskin gourami (0.002 g/day) in treatment 1 was significantly lower than that in treatment 2 (0.051 g/day) and treatment 3 (0.049 g/day); however, the survival rate and the fish yield of fingerling nursing in treatment 2 (22.19% and 270 kg/1000 m2) were similar to those in treatment 3 (22.44% and 264 kg/1000 m2). For Climbing perch, the daily weight gain of the fingerlings in treatment I (0.004 g/day) was significantly lower than those in treatment II (0.045 g/day) and in treatment III (0.048 g/day). In conclusion, treatment 75% BS (153 m3/1000 m2) is considered the best rate to improve water pH and produce good yield of fish for farmer’s income.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Within the field of agriculture, many of national and international scientists have continually researched and implemented the aspects of design, construction and soil improvement in reality, especially on the acid sulfate soil areas. The research results are of different levels and time depending on the variety of soil compositions. Accordingly, there have been previous studies in Vietnam such as the use and management of acid sulfate soil in aquaculture (Singh, 1985), the construction of fishery–forestry–agriculture model on the acid sulfate soil due to the ecological function of cajuput forest (Duong, Ton, & Edward, 2001), etc. Such findings have made a great contribution to the enlargement of culture areas, the productivity and profit increase for manufacturers on the Mekong delta acid sulfate soil.

It is obvious that to decrease the amount of acid sulfate farmers have always used the conventional methods like powdered lime or the mixture of lime and organic fertilizer resulting in a considerable increase of water pH. The use of 15 kg/100 m2 lime increased water pH from 4.1 to 7.3 (Edwards, Kaewpaitoon, McCoy, & Chantachaeng, 1986). Besides, the organic fertilizer, especially animal manure is also one of effective materials for pond treatment. The organic fertilizer, a nutritious source, consumed by plankton becomes the natural food source available in water. This food source helps fish grow up quickly to create high productivity. Moreover, the decrease of disease transmission has also contributed to the development of fish yield. However, due to the growth of intensive agriculture, the environment gets more and more polluted because of untreated waste in an appropriate manner. There are varied methods of treating and reusing the waste like composting so as to directly and indirectly feed aquatic species. In particular, the use of biogas slurry is the most efficient treatment in the aquaculture development.

Biogas slurry is a product of the decomposition of organic matter. It is also considered an alternative energy source used in each household for cooking, lighting and heating as well. Biogas slurry includes solid and liquid waste involving a high degree of organic substances and inorganic nutritious salinity such as nitrogen and phosphorus. Biogas slurry was used in aquaculture and algae ponds and rice paddy. The organic substance usage can treat many kinds of waste, reuse nutrients, create valuable products and reduce pollution (Le & Nguyen, 2015). Nevertheless, there is little research on the use of nutritious source included in biogas slurry for pond treatment on the acid sulfate soil areas. Therefore, the study aims to find out effective methods of improving water quality in the acid sulfate soil areas by using biogas slurry. In addition, the experimental study on nursing some appropriate species is expected to enhance the effectiveness of soil treatment for production and the development of aquaculture models in each household, increasing the income for local communities.

2 Methodology

2.1 Design of the Experiment

The experiments on pond treatment and fish nursing were conducted on Hoa An Center, Can Tho University, located at the most acid sulfate soil area of the Mekong delta. The research was carried out in dry season. Each pond covers an area of 4 m2 (2.0 m × 2.0 m) and 1.2 m depth.

Experiment 1. The treatment of water pH infected ponds by biogas slurry.

The experiment consists of six treatments with three repeated and randomly arranged.

-

Treatment 1 (NT I): 100% organic fertilizer (pig manure) use (30 kg/100 m2).

-

Treatment 2 (NT II): biogas slurry use with 75% TN in organic fertilizer.

-

Treatment 3 (NT III): biogas slurry use with 100% TN in organic fertilizer.

-

Treatment 4 (NT IV): biogas slurry use with 125% TN in organic fertilizer.

-

Treatment 5 (NT V): biogas slurry use 150% TN in organic fertilizer.

-

Treatment 6 (NT VI): pond treatment without using biogas slurry.

All the above treatments were applied using CaO powdered lime (150 g/m2). The time for all treatments showed the stability of water pH and Chlorophyll-a concentrations in the ponds.

Experiment 2. Nursing the fingerlings of fish in treated ponds.

After experiment 1, the treated fish pond was applied in nursing the fingerlings of Snakeskin gourami (Trichopodus pectoralis) and Climbing perch (Anabas testudineus). Experiment on each species includes three treatments with three repeated in 60 days.

-

Experiment on nursing the fingerlings of Snakeskin gourami.

-

Treatment 1: using biogas slurry without food supply.

-

Treatment 2: using biogas slurry and 50% of food supply.

-

Treatment 3: using biogas slurry and 100% of food supply.

-

-

Experiment on nursing the fingerlings of Climbing perch.

-

Treatment I: using biogas slurry without food supply.

-

Treatment II: using biogas slurry and 50% of food supply.

-

Treatment III: using biogas slurry and 100% of food supply.

-

Three day-old fingerlings of Snakeskin gourami and Climbing perch were nursed in the practical field of the College of Aquaculture and Fisheries. The nursing density is 400 fish/m2. The food supply followed the procedure of fingerlings nursing of Department of Freshwater Aquaculture, College of Aquaculture and Fisheries, Can Tho University, Vietnam. All experiments were carried out in accordance with national guidelines on the protection of animals and experimental animal welfare in Vietnam (Vietnam National Assembly, 2015).

2.2 Sample Collection and Analysis

The cycle of collecting sample: water temperature, pH, dissolved oxygen (DO), total nitrogen (TN), total phosphorus (TP) and Chlorophyll-a in experiments 1 and 2 were collected and analyzed every 4 days. During the process of nursing, the fingerlings were examined every 15 days on their growth. The survival rate and productivity were also collected.

Collecting and analyzing organic fertilizer (pig manure): the pig manure of 30 days was put into PVC bags and kept at 4 °C for analysis. The analysis criteria include TN and TP concentrations.

-

TN was determined by Kjeldahl method.

-

TP was determined by Kjeldahl and by ascorbic acid photometric method.

Collecting and analyzing the water sample of biogas slurry: the water temperature, pH and DO were on-site measured by HANNA meter. TN and TP were analyzed at the laboratory of College of Aquaculture and Fisheries. The sample was kept at 4 °C.

-

TN was determined by Kjeldahl method.

-

TP was determined by Kjeldahl and by ascorbic acid photometric method.

-

Chlorophyll-a concentrations were determined by acetone extraction method.

Collecting and analyzing the fingerlings sample: the sample was collected by rackets and analyzed every 15 days. The average of 30 fish/pond were kept in plastic buckets. The sample was weighted by the electronic scale (± 0.001) and then put into the ponds.

The applied formulas are as follows:

2.3 Data Analysis

All the data was collected and statistically analyzed by SPSS 13.0 software.

3 Results

3.1 Water Quality of Biogas Slurry and Organic Fertilizer (Pig Manure)

The experiment results are the basis for the evaluation and measurement of nutritious content. As can be seen from the tables, the amount of TN and TP in biogas slurry is so high and unstable. Samples from three analyzing turns at different times of a day showed that TN content in biogas slurry fluctuates between 69.12 and 87.32 mg/L, whereas the fluctuation in TP is between 146.60 and 194.73 mg/L. Concerning organic fertilizer, TN through the analysis accounts for 6.500–7.000 mg/g and at 6.787 mg/g on average while TP fluctuates between 0.602 to 1.306 mg/g, on average 0.958 mg/g. Therefore, this is considered valuable material resulting in lower production cost as well as higher income for farmers in the region of the Mekong delta (Tables 44.1 and 44.2).

3.2 Pond Treatment with Biogas Slurry

3.2.1 Water Temperature

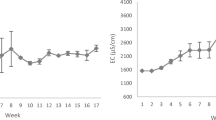

Fig. 44.1 illustrates no wild fluctuation of water temperature among the treatments using biogas slurry in the acid sulfate-infected ponds (p > 0.05). The water temperature fluctuates from 27.3 to 31.2 °C, on average 29.3 °C. The figures demonstrate stable temperature of treated ponds. In comparison with previous research in the Mekong delta, there were no disadvantages for the living and developmental process of aquatic system (Pekar, Be, Dung, & Cong, 1998).

3.2.2 Water pH

The research on water in acid sulfate soil in Long Xuyen, An Giang province (Duong, Son, Oanh, Lien, & Ngoc, 1999) points out that water pH fluctuates from 4.57 to 6.35 in natural environment. After 2 years of pond treatment by using poultry manure through the integrated chicken-fish farming system, farmers have gradually applied the treated ponds in developing forms of aquaculture. According to Boyd (1998), the fluctuation of 7.5–8.5 is the value of water pH suitable for the growth of plankton and fish (Fig. 44.2).

The research on biogas slurry usage in acid sulfate-infected ponds shows that water pH in experiment ponds in different treatments causes a high fluctuation. Before treatment, water pH is around 2.64–3.25. However, data from the experiments indicate a steady increase in water pH from 3.04 to 7.61 (p < 0.05). Therefore, it takes 45 days from the beginning of using biogas slurry in treated ponds until water pH reaches the stable value. The water pH in all treatments has been dramatically improved: treatment I of 6.35, treatment II of 6.50, treatment III of 6.29, treatment IV of 6.48, treatment V of 6.53, and control treatment VI of 4.5 significantly lower (p > 0.05). It can be explained that rain helps clear out acid sulfate in the infected ponds. Besides, the high level of waste from biogas slurry including decomposed organic matter causes an upward trend in TN, TP, and Chlorophyll-a concentrations in ponds. This condition creates a buffer system increasing the absorption of ion H+ but limiting the acid sulfate formation at the water body of aquatic areas.

To sum up, water pH recorded from the treatments in fluctuation of 6.05–7.61 supports the previous studies of Boyd (1990) and Pekar et al. (1998) on the development of aquaculture in naturally aquatic environment as well as in acid sulfate-infected areas at the Mekong delta.

3.2.3 Dissolved Oxygen

The analysis of dissolved oxygen in water during the treatment of acid sulfate-infected ponds is described in Fig. 44.3. The survey on the oxygen dissolved in nursing ponds shows that there is a dramatical fluctuation (p < 0.05) of oxygen content between untreated and treated ponds. Before the experiments, oxygen content in the treatments fluctuates between 1.47 and 2.6 ppm. At the starting time of all treatment, dissolved oxygen fluctuates between 3.07 and 6.63 ppm, the lowest value is demonstrated in treatment VI (3.07 ppm). Until the end of treatment and nursing process (the fingerlings of Snakeskin gourami and Climbing perch), dissolved oxygen in treated ponds reaches a stable value fluctuating between 4.03 and 5.20 ppm. This value totally meets the demand of DO for respiratory process and metabolism of aquatic system. However, as running the system of nursing ponds, there is a considerable fluctuation (p < 0.05) of DO among the treatments in the experiment. DO content varies from 1.83 to 5.57, and sharply declines (p < 0.05) at treatments IV (1.83–4.8 ppm) and V (1.83–4.9 ppm).

Compared with DO demand of aquatic species, the quality of water in the experiments is not very good. According to Wedemeyer (1996) and Post (1987), the demand of DO suitable for warm water fish in intensive culture is at 4 ppm. Meanwhile, Boyd (1998), Egna and Boyd (1997), Blakely and Christopher (1989), and Barnabe (1994) hold the view that suitable DO content fluctuates between 3.5 and 6.5 ppm. The sharp increase of TN in treatments IV and V (16.18 ppm and 15.69 ppm) is the main reason of the drop in DO in treatments IV of 125% and V of 150%. Therefore, water changing (30–50%) is an important solution to adjusting TN and maintaining the good quality of DO content in water. This method greatly improves the respiratory process and metabolism of fish nursing.

3.2.4 TN

Figure 44.4 indicates a dramatical fluctuation of TN in the treatments, especially treatments I (0.28–1.02 ppm) and VI (0.19–1.05 ppm) compared with treatments II (0.26–8.82 ppm), III (0.31–10.85 ppm), IV (0.10–16.18 ppm) and V (0.20–15.69 ppm) (p < 0.05). The experiment results point out that besides the advantages of inorganic and organic nutrition supply, the increase in TN causes a sharp drop in DO in treated ponds. This condition badly affects the respiratory process, metabolism as well as consumption of nursing fish. Duong and Lam (2004) found out that suitable TN content in ponds’ nursing freshwater prawn is below 2 ppm. In reality, therefore, manufacturers have to adjust the waste from biogas slurry based on the water quality of nursing ponds so as to maintain the stability of water quality and improve the yield of nursing species.

3.2.5 TP

Figure 44.5 shows the fluctuation of TP in six treatments using biogas slurry in acid sulfate-infected ponds for nursing. Appropriate TP concentrations are nutritious for the development of plankton building a buffer system for the stable growth of nursing species. However, the rise of TP content leads to the pollution of water (Boyd, 1990). The experiments indicate TP content in all the treatments accounts for a steadily high value of 0.01–0.98 ppm. Especially, after the treatment ended, the average content of TP varies from 0.20 to 0.95 ppm whereas it reaches a peak at 0.95 ppm (p < 0.05) in treatment I. In practice, 36–45 days after pond treatment, manufacturers can start nursing without using biogas slurry in the ponds unless they intend to feed some kinds of fish consuming compost.

3.2.6 Chlorophyll-a Concentration

There is a great change of Chlorophyll-a concentration (p < 0.05) among six treatments (Fig. 44.6). Chlorophyll-a concentration fluctuates between 1.37 μg/L and 6.90 μg/L before experiment. However, owing to the influence of organic fertilizer together with biogas slurry, Chlorophyll-a makes a difference after conduct the treatments. After 45 days, Chlorophyll-a concentration approaches a low level of 2.48–4.85 μg/L in treatments I and VI. Conversely, in treatments II, III, IV and V, Chlorophyll-a is higher from 11.07 to 11.90 μg/L. At the end of the experiment, there is a considerably high concentration of Chlorophyll-a in treatments II (143.05 μg/L) and IV (144.80 μg/L) compared with a low Chlorophyll-a concentration in treatments VI (3.50 μg/L) and I (26.01 μg/L) (p < 0.05).

These figures indicate that biogas slurry plays a key role in providing organically and inorganically nutritious salinity, an essential part of increasing natural food supply in aquatic areas. Besides, the positive influence of biogas slurry on water quality increase in acid sulfate-infected ponds results in the improvement of water pH (2.65–6.67), oxygen (1.77–5.53 ppm), TN (0.55–8.82 ppm) and Chlorophyll-a (3.20–143.05 μg/L). This condition is caused by the organic materials covering the pond bed to limit acid sulfate release into water. The result of treatment II (75% biogas slurry use) improves water quality in the infected ponds. Therefore, the result of experiment 1 is continually applied in experiment 2.

3.3 Experiments on Fingerlings Nursing in Treated Ponds

3.3.1 The Growth of Snakeskin Gourami and Climbing Perch Fingerlings in the Nursing Process

The values from Tables 44.3 and 44.4 indicate the fluctuation of water pH (6.33–7.21) and DO (3.43–5.53 ppm) in the nursing ponds. This is such a beneficial environment that the fingerlings of Snakeskin gourami and Climbing perch can develop in treated ponds. For Snakeskin gourami (60 nursing days), the weight and weight gain in treatment 2 (3.05 g/fish and 0.051 g/day) and treatment 3 (2.94 g/fish and 0.049 g/day) are higher than those in treatment 1 (0.14 g/fish and 0.002 g/day) (p < 0.05). Compared with the weight gain of the fingerlings in uninfected ponds, this value is relatively lower, yet still acceptable. Moreover, the appropriate concentration of DO (2.47–5.20 ppm) along with Chlorophyll-a, a natural food supply for the fingerlings of Snakeskin gourami are the reason for the difference in their weight and growth in the two treatments (Pillay, 1990). For Climbing perch, the results showed the weight and weight gain in treatment II (2.69 g/fish and 0.045 g/day) and treatment III (2.88 g/fish and 0.048 g/day) are higher than those in treatment I (0.24 g/fish and 0.004 g/day) (p < 0.05). Accordingly, 100% industrial food supply with a high protein content influences more on the growth of fingerlings nursing in treatment III (0.048 g/day) than that in treatment II (0.045 g/day).

3.3.2 The Survival Rate and Yield of Snakeskin Gourami and Climbing Perch Fingerlings

As can be seen from Table 44.5 and Fig. 44.7, there is a significant difference (p < 0.05) in the survival rate and the yield of Snakeskin gourami in treated ponds. In the experiment on nursing Snakeskin gourami, the survival rate (15.83%) and yield (8.9 kg/1000 m2) in treatment 1 (biogas without food supply) are at lowest position (p < 0.05) compared with those in treatment 2 (22.19%, 270 kg/1000 m2) and treatment 3 (22.44%, 264 kg/1000 m2). However, there is no significant difference (p > 0.05) between treatment 2 (biogas and 50% food supply) and treatment 3 (biogas and 100% food supply) in terms of the survival rate and yield.

For Climbing perch, from Table 44.5 and Fig. 44.7, there is also a significant difference (p < 0.05) in treatments I, II, and III in terms of fish survival rate and fish yield. The highest point appears in treatment III (14.06%, 161 kg/1000 m2), followed by the values in treatment II (12.58%, 135 kg/1000 m2), and the lowest values is in treatment I (10.81%, 10.4 kg/1000 m2). The difference in eating style (Climbing perch is one of omnivores) and the percentage of industrial food with high nutritious content (32–35% protein) are the main reasons for the different survival rate and fish yield as well (Pillay, 1990).

In short, after the treatment of acid sulfate-infected ponds by biogas slurry usage, manufacturers can entirely use the treated ponds for fingerlings nursing. The weight gain of fingerlings initially in treated ponds is not as high as that in uninfected ponds (pH = 7.5–8.0). However, the survival rate recorded from treatment 2 for Snakeskin gourami and treatment III for Climbing perch is quite high without much difference in comparison with the fingerlings nursing in uninfected ponds. Consequently, the treatment of 75% biogas slurry use (153 m3/1000 m2) will make a great condition to the fingerling nursing activities in the acid sulfate soil areas in the Mekong delta.

3.4 Analysis and Comparison of the Treatment Effectiveness of Acid Sulfate-Infected Ponds

As figured out in Table 44.6, using 75% biogas slurry is the most effective method of improving the water quality, followed by the use of organic fertilizer (pig manure). For treatment using lime, more time of water treatment is expected to maintain the stability of technical and environmental parameters that leads to the success in running the nursing ponds in the field of aquaculture.

4 Conclusions and Recommendations

4.1 Conclusions

Using biogas slurry with nutrients content of TN (69.12–87.32 mg/L) and TP (146.60–194.73 mg/L) considerably improves the water quality in acid sulfate-infected ponds for fish nursing.

Among the six tested treatments, treatment II (biogas slurry with 75% TN in organic fertilizer) after 45 days leads to good results of water pH (6.5), dissolved oxygen (5.2 ppm) and Chlorophyll-a (143,05 μg/L).

The fingerlings of Snakeskin gourami and Climbing perch grow well in treated ponds after 45 days by using biogas slurry with water pH (6.33–7.21) and DO (3.43–5.53 ppm). For Snakeskin gourami of 60 nursing days, the weight and weight gain in treatment 1 (0.14 g/fish, 0.002 g/day) are lower than those in treatment 2 (3.05 g/fish, 0.051 g/day) and treatment 3 (2.94 g/fish, 0.049 g/day). In treatment 2, the survival rate and yield (22.19%, 270 kg/1000 m2) are equivalent to those in treatment 3 (22.44%, 264 kg/1000 m2). For Climbing perch, there is a difference (p < 0.05) in the weight as well as weight gain in treatment I (0.24 g/fish, 0.004 g/day) compared with those in treatments II (2.69 g/fish, 0.045 g/day) and III (2.88 g/fish, 0.048 g/day). The highest values of the survival rate and fish yield appear in treatment III (14.06%, 161 kg/1000 m2).

The treatment of using 75% biogas slurry (153 m3/1000 m2) has brought great benefits to the maintenance of good water quality and nursing techniques, increasing the income to local communities as well.

4.2 Recommendations

Owing to the continual change of nutritious concentrations in biogas slurry, the treatment on acid sulfate-infected ponds needs repeated experiments in order to lay out the foundations of the treatment process with biogas slurry use.

References

Barnabe, G. (1994). Aquaculture biology and ecology of cultured species (403 p). Ellis Horwood.

Blakely, D. R., & Christopher, T. H. (1989). Inland aquaculture development handbook (183 p). St Edmundsbury Press Ltd.

Boyd, C. E. (1990). Water quality in ponds for aquaculture (482 p). Birmingham Publishing.

Boyd, C. E. (1998). Water quality for pond aquaculture (37 p). International Center for Aquaculture and Aquatic Environments Alabama Agriculture. Experiment Station Auburn University.

Duong, N. L., & Lam, M. L. (2004). The integrated aquaculture system (p. 87). Can Tho University. (in Vietnamese).

Duong, N. L., Son, V. N., Oanh, D. T. H., Lien, N. T. K., & Ngoc, L. B. (1999). Assessment of the development of aquatic fauna and flora in problem soil areas in relation with aquaculture aspects. Scientific report (p. 28). Can Tho University.

Duong, V.N., Ton, P.T., and Edward M. (2001). Integrating Melaleuca cajuputi with rice in an agro-forestry trial on acid sulphate soil in the Mekong Delta, Vietnam. Retrieved July 21, 2018, from https://www.researchgate.net/publication/308118285.

Edwards, P., Kaewpaitoon, K., McCoy, E. W., & Chantachaeng, C. (1986). Pilot small-scale crop/ livestock/ fish integrated farm. Asian Institute Technology Research Report No., 184, 131 p.

Egna, H. S., & Boyd, C. E. (1997). Dynamics of pond aquaculture (411 p). Lewis Publishers in an imprint of CRC Press.

Le, H. V., & Nguyen, V. C. N. (2015). Organic waste management and re-use. Can Tho University Publishing House. (in Vietnamese).

Pekar, F., Be, N. V., Dung, D. T., & Cong, N. V. (1998). The eco-technological analysis of fish farming households in the Mekong delta, Vietnam. WES scientific report (p. 16). Can Tho University.

Pillay, T. V. R. (1990). Aquaculture: Principles and practices (575 p). Fishing News Books, A Division of Blackwell Publishing Ltd, Oxford.

Post, G. B. (1987). Textbook of fish diseases (288 p). TFH Publications.

Singh, V. P. (1985). Management and utilization of acid sulfate soils for aquaculture (105 p). University of the Philippines in the Visayas.

Vietnam National Assembly (2015). Law on Animal Health No. 79/2015/QH13.

Wedemeyer, G. A. (1996). Physiology of fish in intensive culture systems (225 p). ITP International Thompson Publishing.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Duong, N.L., Nguyen, H.T., Nguyen, V.C.N. (2022). An Experimental Study on Using Biogas Slurry to Improve the Water Quality of Aquaculture Systems in Acid Sulfate Soil Areas. In: Nguyen, A.T., Hens, L. (eds) Global Changes and Sustainable Development in Asian Emerging Market Economies Vol. 2. Springer, Cham. https://doi.org/10.1007/978-3-030-81443-4_44

Download citation

DOI: https://doi.org/10.1007/978-3-030-81443-4_44

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-81442-7

Online ISBN: 978-3-030-81443-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)