Abstract

The use of superplasticizers (SPs) in concrete makes it possible to obtain high-strength concretes at the design age. However, their application can reduce the early concrete strength. The use of the latest SPs based on polycarboxylate esters (PCE) allows you to adjust the heat-moisture treatment (HMT) regime. A comparative analysis of the cement stone structure formation was carried out depending on the modification of PCE and sulfonated naphthalene formaldehyde (SNF) under HMT conditions at 60 °C. For the first 2 h of HMT, the amount of C3A and C4AF is greater in the stone with PCE by 12 and 8.5% than in the compositions without additives and 6 and 2% higher than in the compositions with SNF. The introduction of SNF in cement paste leads to an increased content of AFt by 32% compared to a stone with PCE. The content of CaSO4 ⋅ 2H2O in the compositions with PCE was found to be twice as high as in the samples with SNF and without additives for 2 h of HMT. The number of clinker minerals after HMT according to the mode (0 + 6 + 2) h in the stone with PCE is higher than in the compositions without additives and with SNF, but the differences are lower. In general, the results indicate the relaxation of temperature stresses in the cement stone body when PCE is added. Thus, the study indicates the possibility of regulating the HMT modes during the hardening of plasticized cement systems.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Cement

- Heat-moisture treatment

- Superplasticizer

- Polycarboxylate ester

- Sulfonated naphthalene formaldehyde

- Phase content

- Gypsum

- Ettringite

1 Introduction

In modern construction practice, concrete is increasingly used with various additives. According to the Russian State Standard (GOST) 24211–2008, additives are divided into the regulatory properties of concrete and mortar mixtures (f. ex., superplasticizers), regulating properties of concretes and mortars (f. ex., accelerators and retarders, curing), giving concrete and solutions with special properties (f. ex., frost and water-repellent) and mineral supplements (f. ex., slag, metakaolin) [1,2,3].

The most common additives in concrete technology are plasticizers and superplasticizers. In such additives based on naphthalenes (SNF) and melamine sulfonates (SMF), and modified lignosulfonates (LS), the polymer molecule, due to its negative electric charge, is adsorbed on the surface of the entire cement grain. At the same time, sulfonates are rapidly and almost completely absorbed. As a result of this phenomenon, water loses access to the cement components, and the setting rate of the cement is significantly reduced up to the rupture of the plasticizer film [1, 4, 5].

In the last decade, the market for concrete modifiers has been increasingly replenished with superplasticizers based on PCE. Their adsorption properties can be purposefully controlled by changing the number of carboxylate groups and the charge density. For example, shorter side chains with a constant carboxylate-to-ether ratio (C/E) and an increase in the C/E ratio with a constant side chain length lead to an increase in the retarding effect. This effect is explained by the fact that in both cases the density of the carboxylate groups increases, which leads to more efficient adsorption and, probably, to a longer delay in the cement hydration [6, 7]. Due to the steric repulsion in PCE plasticizers’ presence, the cement grains are dispersed and kept at a distance. This principle of operation is called “spatial dispersion” [2, 8].

Depending on the specific tasks caused by the concrete manufacturing technology, it becomes possible to regulate the properties of concrete mixtures by optimizing the PCE molecules’ chemical structure. Polymers with long side chains make it possible to obtain concretes with high early strength. This is explained by the following mechanism of action of the additives: the molecules of such PCEs quickly adsorbed on cement particles, are oriented by their side chains perpendicular to the surface. Creating a spatial repulsion effect, they do not cover the cement particle's entire surface but provide access to water molecules for hydration. At the same time, there is an intensive increase in the strength of the cement stone [9,10,11].

Heat-moisture treatment (HMT) is the most common method for producing concretes with high tempering strength. However, the concrete subjected to HMT has lower physical and mechanical properties (strength, frost resistance, crack resistance) than a similar concrete stone of natural hardening. That is due to a temperature gradient in the solidifying concrete body, the formation of directed capillary porosity. Elevated temperatures (up to 90–95 °C), prolonged steaming (12–16 h) significantly increase energy costs, and as a result, harmful CO2 emissions into the atmosphere. Besides, the cost of reinforced concrete products increases, the formwork’s turnover and the production rate of finished products and structures significantly decrease [12, 13].

Consumers and manufacturers are always interested in obtaining high-quality concrete in the shortest possible time with the lowest energy costs [14, 15]. Since the most important component of the concrete matrix, which determines all its properties, is cement stone, the study of its structure formation, under the combined action of plasticizing additives and temperature, is of undoubted interest and will allow you to regulate the concrete properties directly.

It is known that PCE adsorption at the initial stage mainly occurs on the surface of C3A and C4AF, also monosulfates and ettringite. In contrast, adsorption of LS, SNF, and SMF is less selective for the cement phases [11, 16,17,18]. It is important to understand what changes occur in cement stone composition in the early stages at elevated temperatures. Particularly, the hydration rate of cement increases with the rise of temperature, leading to higher early strength.

Morphology and microstructure of hydration products are directly linked to the curing temperature. As the temperature increases, there is an increase in the C–S–H density and a more heterogeneous hydration product structure [19, 20]. With the addition of PCE, there is a certain slowdown in hydration, which depends on the molecular structure and dosage of the polymer [9, 21].

It is also noted that when modifying cement pastes at an early stage, dispersed short bars of ettringite are formed. The main PCE effect on ettringite precipitation is related to a strong increase of ettringite specific surface area. After 5 min of hydration, the surface area increase related to ettringite precipitation can be six times higher in the presence of PCE. At the same time, when adding PCE, the total amount of ettringite by weight decreases [22].

The microstructure of SNF plasticized cement pastes hydrated for 28 days, composed closely packed structure consisting of ill crystalline and nearly amorphous calcium silicate hydrates representing the main hydration product, also hexagonal crystals of calcium aluminate hydrates and calcium hydroxide. This is a highly dense structure [4].

At the same time, the microstructure of cement stone with PCE is represented by fine needle-like ettringite minerals and thin Ca(OH)2 layers with a large specific surface area. Consequently, the formed neoplasms that crystallize in the presence of a complex additive in a finely dispersed form fill the pores and capillaries of the cement stone, strengthening and compacting its structure [23].

The authors conducted a study of cement stone phase composition with PCE, depending on the duration of presteaming to the temperature rise under conditions with a 6-h HMT at 60 °C and 2-h cooling. It is proved that there is a tendency to reduce the amount of ettringite and portlandite minerals in cement stone in the PCE presence. The proportion of unreacted clinker minerals C3A and C4AF is higher in compositions with PCE after HMT. No significant differences were recorded in the mineralogical composition of cement stone samples that harden during HMT with presteaming for 2 h and without it [24, 25].

However, the change in the phase composition of cement stone at the early stages of hydration, particularly during the first hours of HMT, has not been sufficiently studied. To further develop production concrete technology and establishing the factors that aimed to regulate the structure of the formed cement stone is necessary to determine which growths arise in the cement when it is modifying with superplasticizers of different action types in different temperature conditions. In this regard, we have conducted studies of the phase composition of cement stone with PCE and SNF additives in the early stages of HMT.

2 Methods

The main objective of this investigation is to study the phase composition of neoplasms of plasticized cement systems at the early stages of hardening.

Portland cement CEM I 42.5N produced by “Gornozavodskcement” company was used as a binder. The physical and mechanical properties of cement and the mineralogical composition of cement clinker are shown in Table 1.

The reduction of the water-cement ratio was achieved due to the polycarboxylate superplasticizer Sika ViscoCrete 24 HE of the Swiss concern “Sika”. For comparison, cement stone structure formation with the introduction of a superplasticizer based on SNF compounds S-3 from “Polyplast” is considered. The dosage was taken following the technical data sheets of additives (0.4% by cement mass). The amount of mixing water was selected based on the condition of equal mobility of cement pastes. The mobility was controlled by lowering the Vic device’s pestle according to the Russian standard (GOST) 310.3-76 until the normal density was reached. The compositions of the test samples are presented in Table 2.

The samples were tested for 2 h of hardening at 20 °C and 8 h after HMT according to the mode without presteaming, 6-h steaming at 60 °C, and 2-h cooling. After reaching the required time (2 and 8 h), the cement stone samples were crushed in a press and ground to powder. The resulting material was sifted through a sieve with a cell size of 0.27 mm and placed in a 50 ml container, and filled with a 99.99% solution of isopropyl alcohol to stop hydration.

X-Ray Diffraction (XRD) analysis is chosen to determine the mineralogical composition, changes, and identification of neoplasm products during cement stone hardening. CuKa radiation is used, monochromatized (λ(Cu–K) = 1.54060 Å) by a germanium curved Johanson monochromator; the operating mode of the X-ray tube is 30–40 kV, 20–30 mA, the scanning step is 0.05°. The experiments were performed at a temperature of 20 °C in the Bragg-Brentano geometry with a flat sample.

3 Results and Discussion

The water-cement (w/c) ratio of equal-moving cement pastes decreased due to the water-reducing action of PCE (Sika ViscoCrete 24 HE) by 13.3%, while the introduction of an additive based on SNF (S-3) reduced it by only 2.3%.

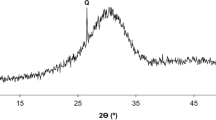

Figure 1 shows the XRD pattern of a cement stone sample without additives after 2 h of HMT (sample No. 1).

Figures 2 and 3 show X-ray images of a cement stone sample with 0.4% PCE Sika ViscoCrete 24HE and 0.4% additive S-3 (SNF) after 2 h of HMT (samples No. 2 and No. 3, respectively).

Based on the conducted studies (Figs. 1, 2 and 3), it was found that the modification of cement pastes with PCE leads to the blocking of the positive-potential minerals of trialcium aluminate with d = [2.68 Å] and brownmillerite with d = [7.29; 2.65; 2.05 Å], as evidenced by an increase in the intensity of the corresponding diffraction maxima in comparison with samples No. 1 (without additives) and No. 3 (with the addition of SP based on SNF). Besides, in sample No. 2, the amount of ettringite with d = [9.73; 5.61; 4.70; 2.20 Å] decreased, resulting from PCE adsorption on this mineral and the lack of water tolerance to the mineral C3A.

The amount of clinker minerals alite and belite in the sample with polycarboxylate SP is higher compared to the non-additive sample No. 1 and with the SP based on SNF No. 3, as evidenced by an increase in the diffraction maxima with interplane distances d = [5.93; 5.48; 3.03; 2.96; 2.77; 2.74; 2.60; 2.32; 1.98; 1.77 Å] and d = [2.88; 2.77; 2.60; 2.29 Å], respectively.

Modification of cement pastes by SP based on SNF leads to a decrease in portlandite content with d = [4.91; 3.11; 2.63; 1.93; 1.80 Å] compared to samples No. 1 and No. 2. At the same time, the amount of ettringite formed (d = [9.73; 5.61; 4.70; 2.20 Å]) is significantly higher than in sample No. 1 (without additives) and No. 2 (with PCE), which indicates the formation of a loose aluminate structure for the first 2 h of hardening in the sample with S-3. This phenomenon is explained by the different actions of PCE (mainly steric repulsion effect) and the products of SNF polycondensation (electrostatic effect).

Distinct peaks with d = [7.62; 4.26 Å] corresponding to the mineral CaSO4⋅2H2O added to the cement to regulate the setting time were recorded in the samples with polycarboxylate SP at 2 h of HMT. In samples No. 1 and No. 3, the relative intensity of the peaks is lower by 29 and 41%, respectively, compared to the gypsum peak of sample No. 2, which allows us to conclude that tricalcium aluminate is blocked, as a result of which unbound CaSO4⋅2H2O minerals are detected.

The above-described conclusions about the structure formation of the phase composition for the first 2 h of the HMT indicate the relaxation of the resulting stresses from thermal action in the cement stone body modified with PCE.

Figures 4, 5, and 6 show X-ray images of cement stone samples without additives and with various SPs after HMT in the mode (0–6–2) h (samples No. 4, 5, and 6, respectively).

Similarly, as in the first 2 h of HMT at 60 °C in sample No. 5 with a PCE after the HMT mode according to the scheme (0–6–2) h, the amount of unreacted clinker minerals of alite d = [5.93; 3.03; 2.96; 2.77; 2.74; 2.60; 2.32; 1.98; 1.77 A], C3A with d = [2.68 Å], and brownmillerite with d = [7.29; 2.65; 2.05 Å] are lower than in the samples without additives and with SP based on SNF, which indicates a slight slowdown in hydration.

X-ray phase analysis of cement stone samples was performed. The semi-quantitative calculation is performed, taking into account 19–29% of the amorphous phase. The mineral content in the cement stone samples is shown in Table 3.

According to the study results, it was found that the use of PCE and SNF leads to a slowdown in the hydration processes of Portland cement for the first 2 h of HMT.

However, the slowing of hydration is more pronounced in the composition with polycarboxylate SP, which is reflected in a significant amount of unreacted minerals of tricalcium aluminate and brownmillerite, as well as alite and belite. This phenomena is explained by the selective adsorption of PCE-based SP on clinker minerals C3A and C4AF, and on ettringite. As a result, the CaSO4⋅2H2O content was twice as high in compositions with PCE.

A noticeable decrease in the concentration of portlandite in a sample with SNF after 2 h of HMT and a significant increase in ettringite content at the early stage of Portland cement hardening was found, which explains the low strength of the composition.

With an increase in HMT time to 8 h (at the mode of (0–6–2) h), the amount of clinker minerals in the composition with PCE is also higher than in the sample without additives and with SP based on SNF. Still, the differences are significantly lower than after 2 h of HMT.

4 Conclusions

-

1.

It was found that the amount of unreacted clinker minerals C3A and C4AF in compositions with PCE is 12 and 8.5% higher than in compositions without additives after 2 h of HMT, which is explained by the selective adsorption of PCE on cement grains in contrast to SNF.

-

2.

The amount of ettringite formed in the first 2 h of HMT is higher in cement stone with SNF by 4% and 32% in comparison with compositions without additives and with PCE, respectively. The concentration of portlandite in the sample with SNF is noticeably lower, which leads to the formation of a loose cement stone structure at this stage of cement hardening.

-

3.

In cement stone with PCE by the end of the first 2 h of HMT, the gypsum content is two times higher than samples without additives and SNF, which allows us to conclude that tricalcium aluminate is blocked, as a result of which unbound minerals CaSO4⋅2H2O are found.

-

4.

The conducted studies have shown that the amount of clinker minerals in the composition with PCE is also higher than in the sample without additives and with SNF after TVE according to the regime (0–6–2) h, but these changes are significantly less than after 2 h of HMT.

-

5.

5. There is a reduced content of ettringite and portlandite minerals in the cement stone with PCE at the 8-h HMT mode by 3% and 8% compared to the sample with SNF and without additives, respectively.

-

6.

The above-described conclusions on the structure formation of the phase composition for the first 2 h of HMT indicate the relaxation of the resulting stresses from thermal exposure when modifying compositions with SP based on PCE. It becomes possible to regulate the HMT modes in terms of accelerating construction’s pace without significantly reducing the physical and mechanical properties.

References

Gelardi G, Mantellato S, Marchon D, Palacios M, Eberhardt AB, Flatt RJ (2016) Science and technology concrete admixtures. Elsevier Inc., pp 149–218

Dobshits LM, Kononova OV, Anisimov SN, Leshkanov AY (2014) Fundam Res 5:945

Khudhair MHR, El Hilal B, Elharfi A (2018) J Mater Environ Sci 9:1722

El-Gamal SMA, Al-Nowaiser FM, Al-Baity AO (2012) J Adv Res 3:119

Robeyst N, De Schutter G, Grosse C, De Belie N (2011) Mag Concr Res 63:707

Winnefeld F, Becker S, Pakusch J (2007) Cem Concr Compos 29:251

Yamada K, Ogawa S, Hanehara S (2000) Spec Publ 351

Flatt RJ, Houst YF (2001) Cem Concr Res 31:1169

Schmidt W, Brouwers HJH, Kühne HC, Meng B (2014) Cem Concr Compos 49:111

Falikman VR (2009) Pop Concr Sci 2:88

Plank J, Hirsch C (2007) Cem Concr Res 37:537

Mironov SA (1966) Symposium on structure of portland cement paste and concrete. Washington, pp 465–474

Neville AM (2012) Properties of concrete

Smirnova OM (2016) Mag Civ Eng 6:12

Leshkanov AY, Anisimov SN, Kononova OV, Minakov YA, Smirnov AO (2015) Mod Probl Sci Educ 2:6

Schmidt W (2014) Design concepts for the robustness improvement of self-compacting concrete: effects of admixtures and mixture components on the rheology and early hydration at varying temperatures. Ph.D. Thesis, Eindhoven University of Technology, The Netherlands

Yoshioka K, Tazawa EI, Kawai K, Enohata T (2002) Cem Concr Res 32:1507

Regnaud L, Nonat A, Pourche S, Pellerin B (2006) Proceeding of the 8th CANMET/ACI international conference on superplasticizers and other chemical admixtures in concrete. Sorrento, pp 389–408

Gallucci E, Zhang X, Scrivener KL (2013) Cem Concr Res 53:185

Lothenbach B, Matschei T, Möschner G, Glasser FP (2008) Cem Concr Res 38:1

Zingg A, Winnefeld F, Holzer L, Pakusch J, Becker S, Figi R, Gauckler L (2009) Cem Concr Compos 31:153

Dalas F, Pourchet S, Rinaldi D, Nonat A, Sabio S, Mosquet M (2015) Cem Concr Res 69:105

Bogdanov RR, Ibragimov RA (2017) Mag Civ Eng 5:14

Leshkanov AY, Dobshits LM, Anisimov SN (2020) Conf IOP. Ser Mater Sci Eng 869:032038. https://doi.org/10.1088/1757-899X/869/3/032038

Leshkanov AY, Dobshits LM, Anisimov SN (2020) Conf IOP. Ser Mater Sci Eng 896:012094. https://doi.org/10.1088/1757-899X/896/1/012094

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Leshkanov, A., Dobshits, L., Anisimov, S. (2022). Phase Content of Plasticized Cement Systems in the Early Stages of Heat-Moisture Treatment. In: Akimov, P., Vatin, N. (eds) Proceedings of FORM 2021. Lecture Notes in Civil Engineering, vol 170. Springer, Cham. https://doi.org/10.1007/978-3-030-79983-0_6

Download citation

DOI: https://doi.org/10.1007/978-3-030-79983-0_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-79982-3

Online ISBN: 978-3-030-79983-0

eBook Packages: EngineeringEngineering (R0)