Abstract

In this review chapter, we present the current state of the art of photovoltaic device technology. We begin with an overview of the fundamentals of solar cell device operation, and the nature of the solar energy spectrum and light absorption in devices. We then go into detail of the basics of solar cell operation, and the effects of various factors on the primary figures of merit, the open circuit voltage, short circuit current, and fill factor. In particular we focus on recombination, both in terms of the photocurrent and the dark current affecting the cell voltage. We then discuss heterojunction solar cells, and the general concept of carrier selective structures, which improve solar cell performance. We summarize the main single junction technologies and their efficiencies historically, starting with Si wafer-based technology and GaAs, then thin film technology, and organic solar cells, ending with recent developments of hybrid perovskite-based solar cells.

The limits of solar cell performance in terms of energy conversion efficiency are discussed, where we introduce the concept of detailed balance to derive the Shockley-Queisser limit for single junction cells. Methods of circumventing this single gap limit are discussed, which set the stage for discussing multijunction or tandem solar cells which currently hold the record for highest conversion efficiency in any solar technology. We then discuss nanotechnology in general, and how it is increasingly incorporated in modern solar cells. In this context, we discuss the use of nanostructures in improving light management in solar cells by enhancing light trapping beyond the classical limit. We discuss quantum dot/nanoparticle-based cells such as dye-sensitized solar cells and nanowire solar cells. Finally, we conclude by discussing advanced concept solar cell structures such as intermediate band, multiexciton generation, and hot carrier solar cells, and their theoretical capability of greatly exceeding the Shockley-Queisser limit.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Background and Basic Operation of Solar Cells

Solar cells are semiconductor-based devices primarily, which convert sunlight directly to electrical energy through the photovoltaic effect, which is the appearance of a voltage and current when light is incident on a material. The photovoltaic effect was first reported by Edmond Becquerel in 1839, who observed a voltage and current resulting from light incident on electrochemical cells. Later in the 1800s, the first solid-state solar cells were developed based on platinum-selenium junctions. The first semiconductor-based pn junction cell was developed in the late 1930s and patented in 1946 by Russell Ohl at Bell Laboratories. The first practical solar cell devices utilizing the solar spectrum were demonstrated in 1954 at Bell Laboratories. While too expensive at the time for terrestrial applications, the burgeoning space industry found the first commercial applications of solar cells, as lightweight and long lifetime power sources replacing traditional battery technology for spacecraft in the late 1950s. Photovoltaics has since developed into the fastest growing source of terrestrial renewable energy, with an installed global capacity of over 600 GW peak energy by the end of 2019. This growth in capacity has been driven by the exponential decrease in the manufacturing cost for photovoltaic panels, which has dropped from $75/watt in the late 1970s to under $0.30/watt today, as a result of continuous improvements in materials, device efficiency, and manufacturing scale-up. Coupled with this dramatic cost reduction, the lifetime of solar panels is in excess of 25 years, which has dramatically reduced the levelized cost of electricity (LCOE) from photovoltaics, with some recent utility-scale installations priced below $0.02/kWhr, cheaper than any other current source of electricity.

Figure 19.1 illustrates the photovoltaic conversion process in a pn homojunction (same material on each side). It shows the energy band diagram (representative of the potential energy of electrons) as a function of position across the junction, where Ec is the minimum energy of the conduction band, which is primarily in unfilled state, and Ev is the maximum energy of the valence band which is almost completely filled. They are separated by an energy gap, Eg (1.12 eV in the case of Si at room temperature, the dominant semiconductor material), where no states exist in the ideal material. The junction occurs between an n-type semiconductor material (intentionally doped with donor atoms that contribute electrons to the conduction band) and a p-type material doped with acceptors, which remove an electron from the valence band, leaving behind a positively charged hole, which behaves as a positive charge carrier. The degree of filling of either the conduction band by electrons or the valence bands by holes is represented by the Fermi energies on the n- and p-sides, denoted Efn and Efp in the figure. At equilibrium, the Fermi energies are the same across the junction. At the junction, because of the huge gradient of positive charge on one side and negative on the other, a space charge region (SCR) is established at the junction, which is devoid of free carriers, and has a high electric field which opposes the flow of free charge from the n-region to the p-region and vice versa. As shown in Fig. 19.1, this results in a potential barrier for electrons on the n-side (right side) to cross the junction, while it is likewise a potential barrier for holes from the p-side (left side) to move across (since the diagram is of electron potential energy, increasing hole potential and kinetic energy is downward).

In the quantum mechanical description of photovoltaics, photons (quanta of electromagnetic radiation) are absorbed if their energy, hν (ν is the frequency of the incident light), exceeds the bandgap, and, in so doing, excite an electron from a filled state in the valence band to an empty state in the conduction band, creating electron-hole pairs (EHPs) as shown. Photons below the bandgap are not absorbed, which is the first major loss mechanism in terms of conversion of optical to electrical energy. The photoexcited electron and hole each have an excess kinetic energy above or below the conduction and valence band edges, respectively, and on a very short time scale (picoseconds), they relax to the their respective band edges through thermal losses to the underlying semiconductor material (through phonon emission, where quantum mechanically, phonons are quanta of the wave-like vibrational motion of the crystal). Hence, all the excess energy of the photon above the bandgap is lost, which is the second major loss mechanism, limiting the conversion efficiency of a solar cell as discussed in Sect. 19.5.

Once an EHP is created by absorption of a photon, what is required is charge separation of the electron and hole to opposite contacts to establish a photocurrent. This process requires some sort of symmetry breaking in the material, which is provided by the SCR shown in Fig. 19.1, where, as shown, the photoexcited electron on the p-side, if it reaches the edge of the SCR through diffusive motion, is swept across by the high electric field contributing to the photocurrent. The corresponding hole of the initial EHP sees a barrier at the junction on the other hand and so preferentially finds its way to the contact in the p-type material where it is extracted. The opposite process occurs for photons absorbed on the n-side but with the result of a photocurrent in the same direction. If the electron or hole created on a given side of the SCR recombines, i.e., the conduction band electron annihilates a hole in the valence band either through being trapped in a defect state (Shockley-Read-Hall recombination) or directly via band to band recombination and light emission (radiative recombination), then that EHP is lost to the photocurrent generation process. Therefore, another contribution to the overall conversion efficiency is the competition between extraction of the carriers and recombination before carriers are separated by the junction.

In terms of the solar cell delivering power to an external load, Fig. 19.2 illustrates the equivalent circuit model for a solar cell and its load. It consists of an ideal current source corresponding to the photocurrent, Iph, in parallel with a diode, representing the pn junction. For a pn junction in the dark, when it is forward biased with a positive voltage applied to the p-side with respect to the opposite side, a large current can flow, due to the lowering of the potential barrier in Fig. 19.1, whereas in reverse bias, this barrier is increased by the bias, creating a large barrier to charge flow and hence small current. The general form of the diode current for junction devices is exponential

where VD is the voltage across the diode (the same as V, the voltage across the load in Fig. 19.2), q is the charge of an electron, n is the ideality factor which varies between 1 and 2 usually, and I0 is the reverse saturation current, which physically is a result of recombination of electrons and holes in and near the junction. As discussed in Sect. 19.3.1, recombination can be radiative, where a photon is emitted when an electron decays into a hole state; it can occur through intermediate trap states in the bandgap, or through Auger processes, and typically has an exponential dependence on the bandgap over the thermal voltage, i.e., −Eg/kT. Eq. 19.1 shows that for positive VD the current increases exponentially whereas in reverse bias, for negative VD, the current goes to a small value, I0. In terms of the equivalent circuit in Fig. 19.2, under short circuit current conditions (RL = 0), the short circuit current equals the photocurrent, Isc = Iph. As the resistance of the load increases from zero, there is an increasing voltage across the diode, VD = V = IRL, due to the photocurrent which forward biases the diode, increasing ID, and hence decreasing the net current to the load. The load current decreases until it goes to zero, corresponding to open circuit conditions when RL = ∞. Under open circuit conditions, ID = Iph = Isc. Equating the diode current with the short circuit current in Eq. (19.1) at open circuit voltage conditions, VD=Voc, leads to

The open circuit voltage depends most importantly on the reverse saturation current, I0, characteristic of the pn junction, and, as mentioned above, decreases exponentially with bandgap. Hence the open circuit voltage scales linearly with bandgap, increasing for increasing bandgap materials, and empirically is found to be about 0.4 V less than the bandgap for a given material in well-developed technologies, i.e., Voc ≈ EG(in volts) − 0.4 V.

Figure 19.2 also illustrates the current-voltage characteristic of the solar cell in the dark, and under illumination, where the convention has been used of defining the net solar cell current, I, as flowing into the device, corresponding to negative power in terms of the product of IV, or power generation. As can be seen, the I-V characteristic under illumination is shifted rigidly downward, which illustrates the assumption of superposition, that the dark current and photocurrent can be treated independently, which is not generally the case. The points A, B, and C along the curve denote the short circuit current, the maximum power point, and open circuit. The maximum power at point B is Pm = ImVm, which is less than the product IscVoc, due to the “roundness” of the I-V curve as seen in Fig. 19.2, characterized by the fill factor (FF), i.e., Pm = FFIscVoc. In terms of the total optical energy incident on the device area, Pin, the optical to electrical conversion efficiency, η, is given by

The optical to electrical conversion efficiency,η, Isc, Voc, and the fill factor, FF, are all figures of merit related to the performance of different photovoltaic technologies, discussed in more depth throughout the rest of this chapter. In what follows, we go into more depth into the materials and physics of present-day photovoltaics technology, starting with the properties of the solar spectrum, and then beginning with Si-based solar cells that are currently the dominant technology worldwide, and continuing through thin film and organic technologies. Due to space limitations, we only provide the basics of solar cell device physics, which are covered in more detail in [1]. We then look at what limits the efficiency of conventional solar cells, and look at more advanced approaches to high efficiency performance in terms of multiple junction solar cells, as well as advanced concept approaches, and implementations thereof using nanotechnology, and some perspectives on future developments in the field.

2 Solar Spectrum and Optical Properties

In the present section, we first introduce the properties of the solar spectrum in terms of its blackbody characteristic from the sun incident on Earth, and atmospheric absorption and scattering effects on the corresponding terrestrial solar spectrum which are relevant for solar energy conversion at different locations on Earth. We then discuss the physics of optical absorption in semiconductors, and some basic design considerations for solar cells in terms of maximizing absorption and the corresponding photocurrent.

2.1 Solar Irradiance

The solar spectrum in space is modeled to a high level of accuracy by Planck’s blackbody radiation law, where the intensity as a function of wavelength is given by

where Rsun is the radius of the sun, D is the distance from the sun, T is the temperature of the sun, λ is the wavelength, c is the speed of light in vacuum, h is Plank’s constant, and k is Boltzmann’s constant. In terms of the photon flux associated with this intensity, the number of photons per unit time per unit area is simply found by dividing by the photon energy.

where N is the photon flux in terms of number per unit time per unit area per unit wavelength.

Figure 19.3 shows the ideal blackbody intensity assuming a temperature of 5250 C in Eq. (19.4) (the solid curve), compared with the solar spectrum at the top of the Earth’s atmosphere, where the difference is quite small. The red curve shows the actual spectrum somewhere on the Earth’s surface, where absorption and reflection losses from atmospheric constituents (water, CO2, etc.) as well as Raleigh scattering (at shorter wavelengths) reduce the intensity of light, particularly at certain preferential absorption wavelengths.

Integration of Eq. (19.4) over all wavelengths (assuming the temperature of the sun is 5762 K) gives a value of 1366 W/m2, referred to as the solar constant, representing the maximum available solar power reaching the Earth. The intensity on Earth is reduced due to atmospheric absorption as evidenced in Fig. 19.3. While local fluctuations in intensity occur due to various local atmospheric effects such as clouds and humidity, in general, the solar intensity at the surface is reduced due to the increasing path length through the atmosphere, and consequent absorption and scattering, which increases with increasing latitude. The increase in path length is characterized by the air mass, which is defined as the ratio of path length through the atmosphere normalized by the shortest path length at the equator. Geometrically, the air mass is approximately given by

where θ is the angle between the sun at a given latitude and the normal to the atmosphere at the equator. Equation (19.6) comes from just the geometrical increase in path length in a rectangular geometry. If the curvature of the atmosphere itself is included, and empirical correction to Eq. (19.6) is given as

AM0 is top of atmosphere, therefore AM = 0. For the sun directly overhead, AM = 1. Given the air mass, AM, the solar intensity at any point is given by the approximate formula [1]

A widely used air mass is AM1.5, corresponding to a latitude of 48.2°, representing an average latitude of temperate zones in either the northern and southern hemispheres. The AM1.5 intensity is approximately 930 W/m2, significantly reduced from the solar constant. Because of atmospheric scattering (Raleigh) as well as dust particles, water vapor, etc., a fraction of the radiation incident on the solar panel is indirect, in the form of diffuse radiation, which comes in from all angles rather than directly from the disk of the sun itself. Both components, diffuse and direct, should be considered in modeling of photovoltaic system performance.

2.2 Optical Properties of Photovoltaic Materials

In the previous section, we discussed the intensity and spectral content of solar radiation. For describing solar cell design and operation, what is critically important is the absorption of the incident photons as a function of wavelength, described by the absorption coefficient of the semiconductor described in more detail below.

Optical absorption in semiconductors depends on band to band transitions from the valence band to the conduction band. Due to the quantum nature of light, the absorption of photons can only occur when hυ > EG (although in fact sub-bandgap photons can be absorbed through impurities and other states in the gap). The nature of such transitions and the strength of absorption depends on whether the semiconductor is a direct or indirect gap material. In the former case, transitions occur directly from valence to conduction band leading to strong absorption when the photon energy exceeds the bandgap. For indirect materials, the conduction and valence band minimum and maximum, respectively, occur at different crystal momentum, and therefore at the bandgap, a second-order phonon-assisted process is required, and hence absorption is reduced until a direct conduction band minimum is bridged by the photon energy.

The quantity characterizing absorption is the absorption coefficient, α, which is basically the inverse of the average depth a photon penetrates a material before being absorbed. Mathematically, this may be written

where Nph(x) is the photon flux at distance x relative to the surface and Ns is the photon flux incident on the surface. The change in the number of photons gives the generation rate, such that

The above equation for the generation rate shows that G varies not only with the wavelength of light but also with distance into the material. Figure 19.4 plots the absorption coefficient as a function of wavelength for several materials. As can be seen, the absorption coefficient for Si is weaker compared to GaAs and InP due to its indirect bandgap for the same relative photon energy to the gap itself (similarly for thin film materials like CdTe), with the consequence that the thickness of Si required for high quantum efficiency (i.e., the number of electrons collected per incident photon) is much higher than for direct gap materials like GaAs.

Absorption coefficient versus wavelength for several direct gap materials (GaAs, InP, CdTe, CdS) and two indirect gap materials (Ge, Si) as well as amorphous Si. (With permission from PVEducation.org)

As illustrated in Fig. 19.4, the absorption coefficient is weakest for a given material for long wavelength photons just above the bandgap in energy, while shorter wavelength photons are absorbed within a short distance from the surface. Thus, the design of a Si solar cell reflects the spectral nature of the absorbed photons. This is illustrated in Fig. 19.5 for a basic Si cell design, where longer wavelength red light has a relatively long absorption depth, whereas short wavelength blue light is absorbed near the surface.

The structure of a commercial Si solar cell device (left panel of Fig. 19.5) typically has a thick base region (here p-type), a narrow emitter layer that is highly doped to minimize lateral resistance, heavy doping near the back contact to reduce recombination of photogenerated electrons there (back surface field), and a grid top contact to the emitter which has narrow fingers to minimize optical reflection (right panel is a top view of the grid structure). The design of the top grid involves a trade-off between the shading due to the area of the grid, which reduces the optical absorption through reflection, and the lateral spreading resistance due to current flow in the emitter (n+) region toward the fingers. Another optical consideration is the reflection of light from the semiconductor surface due to the refractive index difference between the cell and the air (or glass). As shown in Fig. 19.5, the design of the basic cell structure includes an antireflection (AR) coating of a material with refractive index between that of the semiconductor and air (here, e.g., silicon nitride), with the thickness optimized for minimum reflection across the solar spectrum (Fig. 19.3). A number of different wide bandgap insulating materials are used for AR coatings such as SiO2, MgF2, and others. Additionally, transparent conducting oxides (TCOs) are often employed, especially in more advanced solar cell architectures, which are wide bandgap materials (EG > 3 eV) and typically heavily n-type self-doped materials due to defects and other sources. In addition to providing a role as an AR material, they provide a conducting surface layer which mitigates spreading resistance effects. As discussed in more detail in Sects. 19.3.2 and 19.7.3, other schemes under the general category of light management are employed to increase the path length of light within the semiconductor and thus increase absorption, including a back optical reflector and texturing the front surface to deflect normal incident light into random angles inside the absorbing layer.

3 Theory of Operation of Conventional Solar Cells

Homojunction solar cells are basically pn junction solar cells from conventional single crystal or multi-crystalline semiconductor wafer-based materials such as Si and GaAs that some authors [2] have referred to as first generation due to their early appearance in the historical development of photovoltaics discussed earlier. Here we provide a brief introduction to the theory of homojunction solar cells but refer the reader to more in-depth treatments of the subject in a number of textbooks [1, 3,4,5,6].

As discussed in Sect. 19.1, the overall current-voltage (I-V) relationship for a solar cell under illumination is assumed to be a linear superposition of the dark I-V of the underlying pn junction and the light-induced photocurrent which flows in the opposite direction. The dark current is ultimately dependent on minority carrier (i.e., holes in n-type material) recombination (including the contacts themselves), and as such, an understanding and control of this phenomena are critical to high performance. The photocurrent depends on both the optical generation process discussed in the previous section and on collection of the photogenerated carriers at the junction (shown in Fig. 19.1), which converts minority carriers into majority carriers. The collection process itself depends on minimizing recombination before the carriers reach the junction. The superposition approximation turns out to be well obeyed in state-of-the-art Si and III–V technologies, although less so in thin film and organic-based technologies, where the nonlinear dependence of recombination on intensity and other factors leads to a breakdown of this approximation. Nevertheless, we begin by considering recombination and its effect on dark current, followed by the photocurrent and control of series resistance effects, and then look at advances in performance through heterojunctions and carrier selective contacts, ending with a discussion of current performance limits of single crystal and multi-crystalline Si and GaAs technology.

3.1 Dark Current and Recombination

In the following, we discuss the various recombination mechanisms in semiconductors, and the role of recombination in the dark current of conventional junction solar cells.

3.1.1 Recombination and Minority Carrier Lifetime

Solar cells are highly dependent on the effective minority carrier lifetime, such that the minority carrier lifetime is one of the most important parameters in a solar cell. Solar cell technology can be described as maximizing the effective minority carrier lifetime, given practical constraints such as cost or scalability. The minority carrier lifetime affects both the short circuit current and open circuit voltage as mentioned above. Note that the effective minority carrier lifetime includes the effect of surfaces.

The minority carrier lifetime is dependent on multiple parameters, including the processing history of the material, the type and number of defects in the material, the solar cell operating point, and other device parameters. Here we seek to develop equations and values for the minority carrier lifetimes in terms of relevant material parameters.

The term minority carrier lifetime can refer to different physical recombination mechanisms. We define the general term to refer to the effective minority carrier lifetime, which is a combination of both bulk and surface recombination mechanisms. The effective minority carrier lifetime is related to the minority carrier lifetime from individual physical processes by the equation below

where the four lifetimes correspond to Auger recombination, radiative (direct) recombination, trap-based recombination (Shockley-Read-Hall), and surface recombination. The effective minority carrier lifetime is the parameter, which is usually measured and then de-convolved into its individual components by either additional measurements or by fitting calculations.

Radiative recombination is proportional to the density of electrons in the conduction band, and the density of holes in the valence band, expressed as

where Rrad is the radiative recombination rate of electron-hole pairs (EHPs), the proportionality constant, B, is the recombination coefficient, while n and p are the electron and hole concentrations, respectively. The net radiative recombination of excess minority carriers is the total radiative recombination minus the radiative recombination at equilibrium (where np = ni2, with ni the intrinsic concentration of the material)

The minority carrier lifetime for radiative recombination can be found by

Letting n = Δn + n0 and p = Δn + p0, where n0 and p0 are the equilibrium carrier concentrations, and using Δn = Δp (due to charge neutrality) gives

For low-level injection in n-type material (n0 ≫ Δn and n0 ≫ p0), where n0 ≅ ND, the donor concentration, the minority carrier recombination due to radiative recombination becomes τRad = 1/BND, while for the same case in p-type material, τRad = 1/BNA. Thus under low injection conditions, the value of the lifetime depends on the doping, but it does not depend on the number of carriers, which is determined by the injection level (the voltage of the solar cell).

For high-level injection on the other hand, Δn ≫ (n0 + p0), and τRad = 1/BΔn, which means the radiative lifetime decreases with increasing injection level, which is one way to differentiate this type of recombination in experiments such as time-resolved cathodoluminescence in which the injection level is controlled with the pump beam intensity.

Auger recombination is a three-particle interaction which occurs via two similar processes: (i) the recombination of an electron in the conduction band with a hole in the valence band, where the excess energy is given to an electron in the conduction band, and (ii) the recombination of an electron in the conduction band with a hole in the valence band, where the excess energy is given to a hole in the valence band.

In the first case, the particles involved in the recombination process are two electrons and a hole, and in the second, it is two holes and an electron. In each case, we subtract the recombination at equilibrium. The overall Auger recombination rate for these two processes is then

where Cn and Cp are the Auger recombination coefficients. Since Auger is often calculated in highly doped or highly excited material, we can usually neglect the ni2 term to get

Using the simpler form above and substituting \( {U}_{\mathrm{Auger}}\equiv \frac{\Delta n}{\tau_{{{\fontsize{6}{9}\selectfont\mathrm{Auger}}}}} \), and also writing n = Δn + n0 and p = Δn + p0 and using Δn = Δp (due to charge neutrality), gives

We sometimes only need the sum of these terms and this is called the ambipolar Auger coefficient Ca.

Similar to the radiative case above, under low-level injection conditions, the minority carrier recombination due to Auger in low-level injection becomes

for holes in n-type material and electrons in p-type material, respectively. Here the Auger lifetime decreases as the square of the doping concentration, which imposes a limitation in terms of high doping. Under high-level injection conditions, the lifetime depends inversely on the square of the injected carrier concentration (i.e., Δn large)

Finally, Shockley-Read-Hall (SRH)recombination is recombination mediated by traps. It is derived by considering the downward and upward transitions for an electron (hole) in a single trap level located at energy ET with density Nt. Electrons in the conduction band are assumed to be captured with a rate proportional to the capture cross section, σn, traveling with a thermal velocity \( {v}_{\mathrm{th}}=\sqrt{3 kT/{m}^{\ast }} \)

with a similar expression for holes in the valence band. Exponential activation of electrons out of the trap to the conduction band (and electrons from the valence band to the trap level) is assumed as well, leading to the SRH recombination rate

where

where Ei is the intrinsic Fermi energy (approximately midgap). For low-level injection, and assuming the trap is located at the intrinsic level, i.e., midgap, the electron and hole minority carrier lifetimes reduce to τn0 and τp0, respectively.

Surface recombination occurs due to traps at an interface or surface, with a two-dimensional density of trap states. Such states occur intrinsically due to the breaking of the translational symmetry of the crystal, and from dangling or differently bonded states on the surface. Since surface recombination occurs at a plane at a definite location, rather than distributed through the bulk of the solar cell, its effect in terms of the net recombination rate due to surface recombination depends on the distance from the surface. For that reason, the effect of surface recombination is often treated as a boundary condition on the flux due to recombination

where for minority carrier electrons (np), Dn is the diffusion coefficient and Sn is a parameter called the surface recombination velocity, which is a proportionality constant between the excess carrier concentration at the surface, ∆np (the rhs), and the flux toward the surface (lhs). Sn itself is proportional to the density of traps at the surface. An ohmic contact, in which equilibrium is established in the contact, can be thought of as surface recombination with an infinite recombination velocity (i.e., np = np0).

3.1.2 Dark Current

A pn diode is characterized by the presence of a space charge region (SCR) at the junction between the n- and p-regions due to the balance between the forces of carrier drift (due to electric fields) and diffusion (due to concentration gradients) between the different regions. The SCR is ideally assumed to be devoid of free carriers across its width W, with a fixed charged density due to ionized acceptors and donors for the p- and n-regions, respectively. This charge density is responsible for an electric field across the junction, which opposes the diffusion of carriers into the SCR (within the drift diffusion model of carrier transport), which in turn leads to a built-in potential between the two sides

and a corresponding width of the depletion region assuming an abrupt doping profile

where εs is the permittivity of the semiconductor, and we have included for generality the forward voltage, VD, applied to the p-side with respect to the n-side.

Under forward bias conditions in the dark, the conventional description of behavior of a pn junction device is that the equilibrium state of the semiconductor is broken, leading to a quasi-equilibrium in which excess minority carriers are injected across the junction from their corresponding majority carrier n- and p-regions, due to the lowering of the built-in potential across the junction, as given in the equations above. The dark current in a pn junction device then arises from recombination currents due to this excess carrier, both in the bulk of the n- and p-regions through diffusion outside the SCR, as well as recombination within the SCR.

The quasi-equilibrium approximation assumes that the effect of the forward bias is to increase the minority carrier concentrations on either side of the junctions at x = 0 and x′ = 0, as shown in Fig. 19.6, which illustrates an n (emitter) and p (base) structure. Under low-level injection conditions, the concentrations at these two points may be written

where \( {n}_{\mathrm{p}0}={n}_i^2/{N}_{\mathrm{A}} \) and \( {p}_{\mathrm{n}0}={n}_i^2/{N}_{\mathrm{D}} \) are the equilibrium concentrations of minority carrier electrons and holes on the p- and n-sides, respectively.

The regions outside the SCR defined by W in Fig. 19.6 are assumed to be charge neutral with no electric field. Hence, we can solve the semiconductor minority carrier diffusion equations in both regions

where Un,p and Gn,p are the recombination and generation rates for minority carriers, with Gn,p(x) given by Eq. (19.7), and the holes are solved in the x′ coordinate system on the left (positive x′ to the right). The solutions require two boundary conditions (BCs); Eq. (19.24) for the excess carrier concentration injected across the boundary serves as BCs at x, x′ = 0. At the other boundaries, we assumed the surface recombination conditions

For the case of the dark current, Gn,p(x) = 0, the general solutions are in the form of hyperbolic functions due to the combination of exponential solutions to the ordinary differential equations above.

The current densities on either side of the junction are expressed in terms of the diffusion current of charge carriers diffusing away from the junction in terms of the carrier gradients

The total current is the sum of these two in the general form of Eq. (19.1)

where the reverse saturation current density, J0, is given in general by.

where \( {L}_{\mathrm{n,p}}=\sqrt{D_{\mathrm{n,p}}{\tau}_{\mathrm{n,p}}} \) is the diffusion length for electrons (n) and holes (p), which is the average distance they diffuse before recombining, and the equilibrium minority carrier concentrations, np0 and pn0, have been written in terms of the doping concentrations on either side of the SCR, \( {n}_i^2/{N}_{\mathrm{A,D}} \), respectively. Here the form of the diode equation has an ideality factor n = 1. In the more general case including recombination in the space charge region and high-level injection at high bias, the ideality factor can vary between n = 1 and 2 depending on the bias.

The above expression simplifies in two cases, one in which the thicknesses of the emitter and base regions Wn and Wp are much larger than Lp and Ln, respectively (short base/emitter), and the other, which corresponds to the opposite, in which the regions are so short that no recombination occurs (short/base), further assuming ohmic contacts with infinite Sp and Sn (short base/emitter). This may be written generally as

where Xn, p = Wp, n for the short base/emitter case and Xn, p = Ln, p for the long base/emitter case.

The open circuit voltage given in Eq. (19.2) can be rewritten in terms of the current densities as

Clearly Voc depends on minimizing the dark current, characterized by J0, which arises due to recombination in the various regions and surfaces. Several general trends can be observed from the expression for J0. Increasing the doping on both sides increases the built-in potential and correspondingly Voc. However, the diffusion coefficients, Dn,p, are proportional to the carrier mobility, which degrade with increasing doping due to ionized impurity scattering. Further, for very high doping, there is increased recombination due to Auger processes which decreases the diffusion lengths, as well as bandgap narrowing effects, which increase ni due to its exponential dependence on the bandgap. Figure 19.7 shows the dependence of the open circuit voltage on doping in a conventional architecture, where the degradation of the diffusion length with doping correlates with a degradation of Voc.

Dependence of the open circuit voltage and carrier diffusion length on the base doping in a homojunction solar cell. (With permission from PVEducation.org)

The above analysis did not address specifically the role of surface recombination on the open circuit voltage, but looking at Eq. (19.30), with infinite recombination velocity, the dark current is clearly much larger than the case limited by the diffusion length. Thus, reducing Sn,p through passivation of the front and back surfaces is critical in good cell performance, particularly considering that in state-of-the-art Si solar cells, the diffusion length is typically much longer than the entire wafer thickness.

Figure 19.8 illustrates the solution of the minority carrier diffusion equation in the limit that the based width Wp is much less than the diffusion length, Ln, in Fig. 19.6, where the solution is just a straight line. In the case of a conventional ohmic contact, where Sn = ∞, the minority carrier concentration goes to zero at the boundary, and the current is given by the slope of the line times the diffusion coefficient for minority carrier electrons, Dn. As Sn decreases, so does the slope and the corresponding minority carrier current. Asymptotically, the solution goes back to the long base solution as Sn → 0.

Reducing the minority carrier current extracted through the front and back is therefore a major strategy in the design of solar cells for maximizing Voc. However, at the same time, we have to extract majority carriers through low resistance contacts, which is somewhat of a contradiction. Design of contacts which have high majority carrier extraction but low minority carrier extraction is the goal of carrier selective contact design, discussed in more detail in Sect. 19.3.4.

A traditional strategy for reducing minority carrier recombination in the contact region is the use of a back surface field (BSF), which usually involves having a higher doped region in the vicinity of the back contct. The isotope junction formed between a p+ and p-region results in a SCR with a field that opposes the flow of electrons toward the p contact, reducing the effective surface recombination velocity. This results in a Voc increase of several tens of mV.

The above analysis has considered the current density in a one-dimensional analysis, but another approach to reducing the effective recombination on the back is to minimize the contact area laterally through selective contacts to the base with local BSFs, where the rest of the back surface is highly passivated by a dielectric layer. Here the ratio of the passivated area is high compared to the actual contact area, with a commensurate reduction in dark current. This structure is the basic architecture of the PERC (passivated emitter and rear contact) solar cell, which is presently (in 2020) the dominant commercial Si technology, and has demonstrated cell efficiencies greater than 24% [7].

3.2 Photocurrent

The short circuit current density, Jsc, is directly related to the photocurrent density, resulting from light absorption in the solar cell, and is equal to this quantity when nonideal effects such as shunt and series resistance are minimized. Maximizing the short circuit current involves two main design factors: one is absorbing the maximum amount of light above the bandgap, and the other is maximizing the collection of light-generated carriers throughout the volume of the cell.

Maximizing the amount of light absorbed involves minimizing reflection both from the metallic front contact grid and from the surface of the cell where light is transmitted. As mentioned earlier, minimizing the front contact grid shading is a design optimization between the spacing and width of the fingers and the spreading resistance of the top layer which impacts the fill factor of the cell. Minimizing reflectance involves the design of an optimal AR coatings based on the spectral response characteristics of the cell as discussed in Sect. 19.2. In addition to the optical coating, texturing of the front (and back) surfaces is employed in commercial Si solar cells to increase the capture of light into the cell. Finally, either the thickness of the cell has to be sufficiently thick that light is not lost through the back side of the cell due to incomplete absorption, or light trapping techniques have to be employed so that photons make multiple passes through the absorber. The most straightforward approach is simply having an ideal reflecting back side, so that photons make at least two transits of the cell thickness. Texturing of the front surface leads to a high probability of being scattered again back into the cell rather than exiting the front surface. The maximum number of passes is expressed in the classical light trapping limit [8] for the maximum optical path length in the cell, \( \left\langle l\right\rangle =4{n}_{\mathrm{s}}^2W \), where ns is the index of refraction of the absorber and W is its thickness. Light trapping is discussed in more detail in Sect. 19.7.3. Reflection and absorption depend on characteristics of sunlight, solar cell optical properties, EG, and solar cell thickness, so that the optimum design is a nontrivial task.

The second important quantity associated with the short circuit current is the collection probability of the cell for the photoexcited carrier distribution, which is nonuniform and wavelength dependent due the wavelength dependence of the absorption coefficient. The collection probability is illustrated in Fig. 19.9. It represents the probability that an electron generated at some point relative to the SCR will be collected, where in the SCR it is commonly assumed that 100% of the carriers are collected due to the high electric field there.

Sketch of the collection probability versus distance in the device. The shaded region represents the SCR where the collection probability is unity. The panel (a) compares the collection probability with the generation rate, while the panel (b) shows the effect on the collection probability of surface passivation and diffusion length. (With permission from PVEducation.org)

In terms of the collection probability, the short circuit current can be written as an integral

where Eq. (19.7) has been substituted for the generation rate, and we have integrated over all wavelengths. The upper panel of Fig. 19.9 illustrates the overlap of the generation rate and the collection probability for one wavelength. As mentioned earlier, shorter wavelengths have a generation rate profile close to the top surface, whereas longer wavelength photons result in generation throughout the structure. The dependence of the collection probability with distance relative to the SCR depends on recombination, both bulk and surface recombination, through the solution of the minority carrier diffusion equations, as discussed below. Qualitatively, the effects of low and high bulk recombination, as well as low and high surface recombination (often referred to as the degree of surface passivation), are illustrated in Fig. 19.9, where the realization of high short circuit current requires both a high minority carrier lifetime in the bulk and well-passivated front and back surfaces.

A simple case in which analytical expressions can be derived is considering the solution of the minority carrier diffusion equations again on either side of the junction, with a constant G (both in terms of position and wavelength) throughout the device, which would be the case of a light source with a small absorption coefficient relative to the width of the cell. The minority carrier diffusion equations in Eq. (19.25) then have a simple inhomogeneous constant, which, in the limit of the diffusion lengths being much shorter than the widths of the emitter and base regions, gives the analytical form for the current density as the sum of the dark and light currents

where W is the width of the SCR, and it has been assumed that all the carriers generated in the SCR are collected. This analytical model gives the simple interpretation that all the carriers generated within a diffusion length of the edge of the SCR on either side of the junction are collected in addition to those generated within the SCR, and the short circuit current is the sum of these three contributions. Qualitatively, this situation corresponds to the collection probability profile illustrated in Fig. 19.9 for the low diffusion length case. As mentioned earlier, in state-of-the-art crystalline Si solar cells, the diffusion length is actually greater than the width of the base region, and passivation of the front and back surfaces plays a critical role in both the photocurrent and dark current.

An important characterization of the photocurrent response of a solar cell is in terms of its quantum efficiency(QE), which is defined as the ratio of electron-hole pairs collected to incident photons on the cell within a certain wavelength interval. Once the QE is known, the short circuit current density can be obtained from the integration of the QE with the spectrally resolved incident photon flux

The quantum efficiency provides useful information on the limiting mechanisms controlling the short circuit current. Fig. 19.10 shows a typical QE versus wavelength plot. The ideal quantum efficiency is zero below the bandgap and then jumps to unity above the bandgap and remains constant. In reality, there is reflection from the front surface, which depends on wavelength (in addition to the uniform loss due to the grid pattern, which reduces QE). At long wavelengths, the QE degrades due to the increased absorption depth of photons close to the bandgap energy, where they either are lost due to being absorbed further than a diffusion length from the junction or from not being absorbed due to the cell being too thin. For short wavelengths in the blue region, carriers are absorbed very close to the front surface, where surface recombination exists resulting in loss of collection in a traditional Si cell architecture. Thus, the quantum efficiency of a solar cell is an important characterization used in the optimization of the cell design.

Illustration of the quantum efficiency of a solar cell compared with the ideal quantum efficiency illustrating the various factors affecting its wavelength dependence. (With permission from PVEducation.org)

3.3 Series Resistance

The simple equivalent circuit model of a solar cell shown in Fig. 19.2 neglected two important parasitic effects that degrade mainly the fill factor defined in Eq. (19.3), that of shunt and series resistance. Figure 19.11 shows the modified equivalent circuit including these two effects modeled simply as linear lumped parameter elements. In general, these resistances are nonlinear, depending on the operating point of the device, but for analysis of the main effects, the linear model is sufficient.

Solar cell equivalent circuit including both shunt (Rsh) and series resistance (Rs). (With permission from PVEducation.org)

The effect of the shunt resistance is to effectively short the junction, leading to a parallel leakage current component which degrades the ideal diode behavior, with a corresponding degradation of the fill factor. Ideally, the shunt resistance is semi-infinite in a good device. Shunt leakage paths can originate due defects such as dislocations or grain boundaries that bridge SCR leading to a current transport separate from the ideal recombination currents discussed earlier. It can also originate from leakage around the edges of the cell due to poor isolation and potential metallization problems with the final cell design.

Series resistance can arise from the bulk resistance, contact resistance, the resistance of the metal top grid in the fingers, and importantly the spreading resistance in the emitter as the current spreads laterally to reach the fingers of the top contact metallization, illustrated in Fig. 19.12. Typically, the base resistance is small in comparison to the spreading resistance as the cross-sectional area is quite large. The metal contact resistance between the metal and the semiconductor, defined in terms of the specific contact resistance, is usually well behaved in commercial solar cells as well, and not the main source or resistance loss, while the resistance of the metal itself is not problematic if the finger width is sufficiently large. So the main component of series resistance of concern is usually the emitter spreading resistance, and the design of the finger spacing to minimize the power loss due to this resistance.

Illustration of the different components of series resistance in a solar cell. (With permission from PVEducation.org)

The emitter is typically quite thin, and current transport is primarily lateral in this layer. Therefore, it is more usual to talk about the sheet resistance of the emitter in terms of

where ρe is the bulk resistivity of the material, t is the thickness, while L and W are the length and width of the material that current is passing through. The quantity ρsh is the sheet resistance in ohms/square (Ω/□).

The problem requires solving the resistive power loss associated with the distributed current flow problem in which the current density is changing in the y direction relative to the grid finger as illustrated in the geometry shown in Fig. 19.13. The incremental power loss in a section dy is given by

The current flowing into the left finger is zero in the middle and increases linearly as y increases

The total power loss due to the current flowing into the left finger is therefore

At the maximum power point, the generated power is given by

where Jmp and Vmp are the current density and voltage at the maximum power operating point of the current-voltage characteristic of Fig. 19.2. Therefore, the fractional power loss is given by

As S increases as well as the sheet resistance, so does the fractional power loss. For ρsh=40 Ω/□, Jmp = 30 mA/cm2, Vmp = 450 mV, S < 4 mm is necessary for less than 4% total power loss. The optimal grid design minimizes this power loss while simultaneously minimizing shading loss.

Schematic of the finger geometry for calculating the spreading resistance in the emitter of a photovoltaic device. (With permission from the PVEducation.org)

3.4 Heterojunction Cells and Carrier Selective Contacts

Here we discuss heterojunction solar cells and the efficiency improvements due to the heterojunction, followed by a more general discussion of carrier selective contacts, of which heterojunctions can be considered a subset.

3.4.1 Heterojunctions

The highest efficiency solar cell technologies, either single junction or multijunction, employ heterojunctions between dissimilar semiconductor materials. Figure 19.14 illustrates the ideal band alignment between the two materials based on the electron affinity rule or Anderson model. This model assumes that the vacuum level can be treated as a reference level, which is assumed continuous in forming the heterojunction band diagram. The band offset in the conduction band is then the difference between the two electron affinities, χ1 − χ2. The conduction and valence band alignment can either be such to confine both electrons and holes (type I), either electrons or holes (type II), or staggered such that the VB of one material overlaps the CB of the other (e.g., InAs/GaSb). This model works well for some systems, e.g., InAs/GaSb and Si/Ge. However, deviations from Anderson model generally occur due to interface dipoles which allow the electrostatic potential to change discontinuously. Typically the band offsets are determined experimentally from capacitance voltage, photoemission, photoconductivity, and other techniques.

There are a variety of heterojunction structures in photovoltaics used in high performance devices in various technologies. In the context of conventional wafer-based technologies such as Si and GaAs, these include amorphous Si (a-Si)/c-Si (crystalline Si) heterostructures as a passivating as well as carrier selective contact (discussed in the next section), as well as TCO-based heterostructures, for example, ITO (indium tin oxide)/Si structures and a-Si/c-Si structures. GaAs typically employs AlxGa1-xAs ternary compounds as a heterojunction “window” layer to mitigate surface recombination and serve as a carrier selective contact.

From the standpoint of the ideal diode equation for the dark current as discussed in Sect. 19.3.1, the derivation can be slightly modified to account for the difference in bandgaps, which results in different intrinsic carrier concentrations, ni, on either side of the junction. The modified reverse saturation current is then given by

where the parameters have the same definition as Eq. (19.32) except that the intrinsic concentrations are different and significantly reduced in the wider bandgap material by a factor

Hence, one component of the minority carrier reverse saturation current is exponentially reduced by a factor involving the bandgap difference, leading to an increase in Voc. In general, however, reductions in J0 may be realized by selective controlling the minority carrier injection, which is the basis of the general topic of carrier selective contacts in the next section.

3.4.2 Thermodynamic and Detailed Balance Definition of Ideal Contacts

The ideal thermodynamic or detailed balance solar cell structure consists of an absorber material with a given quasi-Fermi-level separation, with the light-generated carriers extracted from the material at the quasi-Fermi-level energy asshown in Fig. 19.15 (see Sect. 19.5).

However, such a structure encounters several practical barriers relating to extracting the light-generated carriers. An ohmic contact (with the band diagram shown in Fig. 19.16) has high recombination for minority carriers, and therefore the carriers are extracted at the Fermi level rather than the quasi-Fermi level. This fact drives the need for a pn junction; we need to have two different Fermi levels in the semiconductor, and hence we need the pn junction used by the majority of solar cell structures.

Band structure of an ohmic contact. (a) The ideal band diagram of an ohmic contact. (b) Practical implementations of an ohmic contact. In all cases, there is a large density of allowed energy states in the contact (a metal), such that there the concentration of minority carrier is low and the quasi-Fermi level is identical to the Fermi level

The thermodynamically ideal contact for a detailed balance structure was termed a selective carrier contact by Würfel [5]. It consists of a contact which allows one type of carrier to be extracted, with the band diagrams shown in Fig. 19.17, consisting of a Fermi level in the contact material aligned with the quasi-Fermi level in the absorber material. The band structure has a large number of allowed energy states above the Fermi level in the contact material, and no allowed energy stated below the Fermi level of the contact material. The band structure diagram shows that a selective carrier structure is the “inverse” of the band structure of an ohmic contact.

Detailed balance and thermodynamic calculations also show that even a carrier selective contact incurs substantial losses in that extracting carriers from a carrier population with an energy given by a quasi-Fermi level loses substantial energy as the quasi-Fermi level is near the bottom of the energy distribution, and hence the higher energy of some carriers is lost. Solar cells which extract carrier at energies above the quasi-Fermi level are generally called hot carrier solar cells, and the contacts to such device are called energy selective contacts. They are discussed in Sect. 19.8.3. Their band structure is similar to a carrier selective contact structure, except that the allowed density of states is a narrow band. Overall, the type of contacts indicated by thermodynamic or detailed balance analyses is shown in Table 19.1.

A substantial optimization in solar cells has centered on minimizing the nonideal recombination associated with an ohmic contact. This involves addressing two features: (1) ensuring that the Fermi level is close to the quasi-Fermi level and (2) minimizing the recombination at the metal-semiconductor interface. Increasing doping, particularly using higher doping near the contacts, is an effective way to minimize both effects. However, high doping itself introduces non-idealities including bandgap narrowing and increased Auger recombination. The introduction of selective carrier contacts, initially through the HIT (heterojunction with thin intrinsic region) and later through a greater variation of structures such as TOPCon, has allowed solar cell efficiencies to more closely approach thermodynamic ideals. The next subsection describes the implementation of a selective carrier contact in the constraints of commercial silicon solar cell technologies, and examples of silicon selective contact solar cells.

3.4.3 Silicon-Based Selective Carrier Contact Solar Cells

The ideal implementation of a carrier selective contact consists of a material with a zero density of states below the Fermi level of the contact material, and a large density of states above it. There are several ways in which we can approximate such a band structure. The conceptually simplest way is to use a very wide bandgap semiconductor with quantum well used to adjust the Fermi level to the quasi-Fermi level in the absorber material. This is similar to a hot carrier contact in which the requirement of a narrow band for the density of states is relaxed to a wide band for the density of states above the lowest energy level, and hence quantum wells can be used instead of quantum dots.

In practice, however, particularly for large area silicon and thin film solar cells, a quantum well contact is not readily commercially feasible. A far simpler implementation is to use a very thin wide bandgap layer. The bandgap of the material needs to be wide enough such that there are theoretically no allowed states near the silicon band edge as shown in Fig. 19.18a. However, adjusting the Fermi level of this wideband material by doping is typically not useful, as the introduction of allowed energy levels from the dopants introduces energy states, which increase recombination. Further, because of the difficulty in doping wide bandgap materials or oxides, even with high doping, such materials are unlikely to have sufficient conductivity to avoid large resistive losses given the large currents from a solar cell. Instead of doping, we adjust the Fermi level in wide bandgap region adjacent to the solar cell by putting a doped wide bandgap semiconductor on top and using band offsets to achieve large band bending. The separation of an ideal selective carrier into two layers introduces the need to examine the transport, usually by tunneling and/or thermionic emission across the thin wide bandgap region.

There are several solar cell architectures which meet the above requirements. One group of solar cell structures uses silicon heterojunctions, initially developed using amorphous Si layers on a crystalline Si solar cell. These approaches are often called HIT solar cells (heterojunction with intrinsic thin layers) or SHJ (silicon heterojunctions). The HIT structure is shown in Fig. 19.20. It achieved an efficiency of 24.7% in 2014 [9], reaching the previously long-standing silicon efficiency record from the pn junction-based PERL solar cell. Since then numerous improvements have allowed solar cells based on silicon heterojunctions to reach 26.6% [10] in an interdigitated back contact structure (Fig. 19.20). Several companies have large-scale commercial production of HIT solar cells, including Panasonic and Tesla Solar. Key challenges for broader adoption of SHJ solar cell relate to the consistency in large-scale manufacturing and more expensive metallization for these solar cells. Metal screen printing for HIT solar cell uses different pastes and processing since SHJ require low temperature processes, and cannot use the high temperature sintering steps in conventional solar cells. A variety of other metallization processes are used to address these issues including using wires (SmartWire), copper plating, or metal stencils.

Overall, a selective carrier contact for a commercial solar cell generally consists of several features (Fig. 19.19): (1) a wide bandgap material often called a membrane with (a) sufficiently low interface defects where the defects have a minimal impact taking into account the band bending at the Si surface and (b) thin enough to support high tunneling/thermionic emission currents; (2) layers on the surface of the wide bandgap to adjust the Fermi level and to support lateral transport to the contacts; and (3) an approach in the silicon absorber to reduce the impact of interface defects.

Another selective contact technology is the TOPCon technology [11]. It is used as a rear contact approach for solar cells in which the emitter already closely approaches the ideal structure shown in Fig. 19.21. In the TOPCon structure, SiO2 is used as the membrane wide bandgap region. The Fermi level is adjusted by a polysilicon doped layer on the SiO2, and reducing the impact of interface states is accomplished by a thin doped layer in the silicon (which is diffused through the oxide). TOPCon solar cells have achieved 25.7% efficiency [12].

Schematic of a TOPCon solar cell. (With permission from [11])

4 Performance Comparison of Single Junction Technologies

In the following, we compare the performance of different single junction technologies, including Si, the III–V materials, II–VI and chalcogenide materials, and finally organic and perovskite-based cells. All are referenced to the conversion efficiency versus time of the various technologies, as discussed below.

4.1 Performance Limits of Si- and GaAs-Based Technologies

A primary performance metric for solar cells is the solar to electrical energy conversion efficiency, defined earlier by Eq. (19.3). The National Renewable Energy Laboratory (NREL) publishes annually a comparison of the efficiencies of all solar cell technologies versus time shown in Fig. 19.22. Silicon solar cell technology dominates 95% of the current world photovoltaic market, through both single crystal and multi-crystalline Si technologies [13], as shown by the various blue curves in Fig. 19.22. The current high efficiency record (as of 2020) reported for single junction Si device technology under 1 sun illumination to date is 26.7%, based on a heterojunction HIT structure (see Sect. 19.3.4) using a crystalline Si substrate with thin layers of amorphous Si (a-Si), which forms a heterojunction due to the larger bandgap of a-Si (∼1.7 eV) [10]. This cell record was demonstrated on a large area device, with an interdigitated back-side contact as shown in Fig. 19.20.

Measured solar cell efficiency records for various technologies versus time (NREL https://www.nrel.gov/pv/) (This plot is courtesy of the National Renewable Energy Laboratory, Golden, CO)

The highest efficiency for any single junction technology was reported by Alta Devices for a heterojunction AlGaAs/GaAs single crystal solar cells where they achieved 28.8%, as shown by the purple curves in Fig. 19.22 (see Ref. [14] for discussion). III–V semiconductor solar cells are normally too expensive for terrestrial flat plate solar applications due to the costs of the substrate materials. However, III–V-based cells, as well as their multijunction realizations (shown in purple below), are standard technologies for space applications, where radiation tolerance and efficiency versus weight are the main performance drivers.

4.2 Thin Film Technology

The Si and III–V technologies described in the previous section are mainly wafer based, which is a major contribution to their cost in terms of materials. Thin film solar cells, in contrast, are deposited using thin film technology onto a low-cost substrate material such as metal or glass. Since the quality (as characterized by its minority carrier lifetime and surface recombination velocity) of the deposited material is inferior to that of single crystal materials, thin film cells typically have lower efficiency but lower fabrication and material costs, thus achieving lower $/W cost, the other main metric of solar cell technology. Amorphous Si (a-Si) thin film solar was the dominant thin film technology several decades ago but has since been supplanted by II–VI CdTe heterostructure technology. A schematic cross section of a CdTe cell is illustrated in Fig. 19.23. Typically a heterostructure is used, with a wider bandgap “window” layer (here CdS with a bandgap of 2.5 eV), while CdTe has a bandgap of 1.32 eV. The structure is an inverted structure in which glass is used as the supporting substrate, followed by a thin transparent conducting oxide as the front contact through which light enters the cell. The wider bandgap CdS layer is deposited first followed by the polycrystalline CdTe layer (typically a few microns thick), and finally rear contacts. As shown in Fig. 19.22 by the green sets of data, CdTe cells have demonstrated over 21% performance by First Solar [15], and this is the basis for a number of large (>200 MW) utility-scale solar installations worldwide. Chalcogenide-based materials such as CIGS (CuInGaSe2) have demonstrated even higher efficiencies >23% [16] and are competing for market share.

4.3 Organic Solar Cells

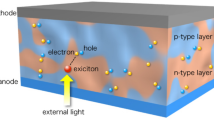

Organic solar cells are basically thin film solar cells based on organic semiconductor materials rather than inorganic semiconductors. In analogy to the energy band diagram of Fig. 19.1, organic materials are defined by their HOMO (highest occupied molecular orbital) and LUMO (lowest unoccupied molecular orbital) levels, which play the same role as the valence and conduction bands in inorganic semiconductors, respectively. A heterojunction is formed due to the lineup of the HOMO/LUMO levels of the two different materials (called donor and acceptor materials), rather than through doping in a pn junction. Excitonic effects play a strong role in organic materials; photoexcitation of an electron from a filled HOMO level to an empty LUMO level creates a strongly bound exciton, which diffuses as a bound (neutral) state to the heterointerface, where it dissociates at the barrier into separate free electrons and holes on either side of the heterojunction, which are then collected at the contacts giving rise to a photocurrent. Typically the lifetime of the exciton is quite short, leading to short diffusion lengths, and hence problems with charge collection. To circumvent this diffusion limitation, blended heterostructures with the donor and accepter materials interdiffused into a random network are employed, which provide better charge collection and short circuit current. A conventional organic solar cell includes P3HT (poly(3-hexylthiophene)), which acts as a donor material, and PCBM (6,6-phenyl-C61 butyric acid methyl ester), which acts as an acceptor material [17]. While efficiencies are generally lower than inorganic thin film approaches, the fabrication process for organic is much less expensive; organic layers can be sprayed or spun on, hence not requiring vacuum deposition or high temperature processing. Recent high performance organic cells have increasingly used more conventional thin film processing, however [18]. The improvement in efficiency with time of conventional organic cells is shown by the solid red circuits in Fig. 19.22 and tandem (discussed in Sect. 19.6) organic cells by the red triangles.

While research work on commercial ventures in niche markets continues on all organic photovoltaics, including incorporation of advanced concept and nanotechnology-inspired approaches discussed in more detail in Sect. 19.7, remarkable advances in performance have been achieved over the past decade on cells fabricated from hybrid organic-inorganic perovskite materials. These hybrid perovskite materials have the general perovskite crystal structure ABX3, most commonly methylammonium lead trihalide, CH3NH3PbX3, where A is the organic methylammonium, B is Pb, and X is a halogen (I, Br, or Cl) [19]. The bandgap ranges from 1.55 eV to 2.3 eV depending on the halide, where CH3NH3PbI3 corresponds to the lower value. This bandgap is well suited for terrestrial photovoltaics in terms of its maximum theoretical efficiency discussed in the next section. Perhaps more importantly, the transport properties of the hybrid perovskites are superior to those of the typical organic materials discussed in the preceding paragraph, with electron and hole mobilities comparable to inorganic semiconductors, and diffusion lengths on the order of microns. Excitonic effects are relatively weak as well. The early high performance results report for perovskite solar cells was based on the nanostructured dye-sensitized solar cell architecture [20], discussed in Sect. 19.7.2, in which the hybrid perovskite is infused into a mesoporous wide bandgap TiO2 structure which acts as an electron acceptor from the perovskite, while holes are extracted in an electrolytic liquid cell structure. This efficiency was greatly improved by replacing the liquid electrolyte with a solid organic hole transport layer (spiro-MeOTAD) [21], which is the basis of the current high efficiency cells shown in Fig. 19.22. In a further breakthrough leading to high efficiency cells, the Cambridge group further demonstrated that high performance devices may be fabricated in a planar structure in which CH3NH3PbI3 is essentially a polycrystalline semiconductor [22], resembling an organic thin film solar cell. As seen in Fig. 19.22, the performance of perovskite solar cells has one of the steepest slopes of any technology over a very short time period, reaching a record as of today of 25.2% at the Korea Research Institute of Chemical Technology (KRICT)/MIT, surpassing that of thin film inorganic technologies such as CdTe and CIGS. The advantage of perovskite technology is the low manufacturing cost, similar to those of organic and thin film processing, where solvent spin coating and vapor deposition are the two main synthesis methods. The main barrier to commercialization presently is issues related to the long-term stability, where degradation occurs due to the sensitivity of the perovskite to water vapor, which can occur over a matter of hours or days. Different approaches to encapsulation and improved materials processing ameliorate these problems, but long-term field testing and accelerated life testing are necessary to assure the longtime reliability of the technology (e.g., commercial Si solar modules are guaranteed for lifetimes in excess of 20 years).

5 Efficiency Limits for Photovoltaic Converter

The record solar to electrical conversion efficiencies shown in Fig. 19.22 are all monotonically increasing with time for different technologies, albeit at different rates, and to date, less than 50%. Thermodynamics provides a guide to what the maximum conversion efficiency of a solar converter can approach. For example, the classical Carnot efficiency, ηc = 1 − Ta/Ts, representing a reversible engine working between the temperature of the Earth, Ta, and that of the sun, Ts, would predict efficiencies close to 95%. However, the Carnot efficiency assumes infinitesimally small amounts of work performed with no entropy production (inherent in the reversible assumption), which does not model a practical converter. de Vos has surveyed various thermodynamic engines for solar energy conversion [23], which have been reviewed by Green (Chap. 3, [2]). Considering the entropy production associated with blackbody radiation and absorption, a more realistic value closer to 85.4% is obtained.

It is clear that there is a substantial gap between the present operating limits of solar cells and their thermodynamic potential, which has driven considerable research on overcoming fundamental barriers to efficiency. In the following, we review the limits of efficiency including the constraints on current technology through an idealized analysis based on the concept of detailed balance, and how to circumvent the assumptions inherent in the derivation of a single gap absorber to reach the potential limits of efficiency.

5.1 Shockley-Queisser Limit

Shockley and Queisser’s (SQ) analysis [24] of the limits of performance of photovoltaic devices, independent from their material parameters other than their energy gap, is the most well-cited work on this topic, although other such analyses appeared around the same time. The approach is based on the thermodynamic hypothesis of detailed balance and considers the only losses from the cell treated as an ideal blackbody absorber/emitter taking into account the chemical potential difference in the absorber due to absorption and external voltage. The idealized description assumes the following: (1) complete collection of all the photons incident on the absorber; (2) radiative recombination only; (3) one bandgap; (4) absorption across the bandgap in which one photon generates one electron-hole pair; (5) constant temperature in which the carrier temperature is equal to the lattice and ambient temperature; and (6) steady state, close to equilibrium.

The current density may be written as the sum of three terms, the first representing the incident photons absorbed above the bandgap of the semiconductor from direct blackbody radiation at the temperature of the sun given by Eq. (19.4), the second the diffuse blackbody radiation collected outside the incident cone of the direct radiation, and finally the third term the blackbody radiation from the solar cell (Eq. (19.4) modified by the quasi-Fermi energy splitting of the absorber equated to the external voltage)

with

Here C is the concentration factor, Eg is the material bandgap, and V is the voltage across the cell. If a solar spectrum other than the ideal blackbody spectrum is used, then the first term is simply replaced by the integral of the photon flux above the bandgap.

In Eq. (19.46), the “dark” current discussed in the previous section is only due to blackbody radiation from the semiconductor absorber, which in effect is due to radiative recombination within the semiconductor generating photons above the bandgap. The power density delivered by the cell is the product of J(V)V, which has a maximum power point corresponding to the maximum conversion efficiency. The calculated results are shown in Fig. 19.24, where the black curve is the calculated efficiency versus bandgap for an AM1.5 terrestrial solar spectrum (hence the multiple maxima due to spectral features). The maximum efficiency without concentration is around 33.7% corresponding to maxima at 1.1 and 1.4 eV (conveniently close to Si and GaAs, respectively), while the effect of concentration is to increase the efficiency. The rest of Fig. 19.24 illustrates the principal losses compared to 100% efficiency. The main losses include loss of photons with energy below the bandgap (transparency) and loss of the excess energy of the photon above the bandgap (thermalization) in terms of energy relaxation of photoexcited carriers back to the band edges, with thermalization being the main loss for small bandgap materials and optical transparency the main loss for high bandgaps. Additionally there are other losses including unavoidable heat loss to the surroundings and irreversible entropy generation [25].

5.2 Overcoming the Shockley-Queisser Limit

The detailed balance efficiency versus bandgap shown in Fig. 19.24 has a number of assumptions built-in that may be circumvented in order to exceed the single gap SQ limit. Here we discuss some of those assumptions and strategies for avoiding them to overcome the single gap limitations.

Broadband Solar Spectrum:

As discussed in Sect. 19.2.1, the solar spectrum is a broadband in nature as described by Planck’s law, which leads to particular shape of the maximum efficiency curve versus bandgap, representing a trade-off in losses between transparency and thermalization. If the input spectrum were monochromatic, for example, then the optimum bandgap would match the photon energy of such a source, and the efficiency would theoretically approach the thermodynamic limit since both transparency and thermalization would be eliminated. Transforming the solar spectrum to a narrower spectrum would therefore circumvent one of the assumptions in Eq. (19.46), and attempts at up/down conversion of portions of the solar spectrum through phosphors or two-photon absorption/emission have been pursued.

OneElectron-hole PairCreated Per Photon Absorbed:

The assumption in Eq. (19.46) is that one EHP is excited per photon. However, if the excess energy of the electron or hole above their respective band edges is more than twice the bandgap, a second EHP may be created through the process of impact ionization, where the excess kinetic energy is transferred to creation of the second EHP. This process reduces the thermalization loss by converting excess photon energy into increased photocurrent. Kolodinski et al. considered carrier multiplication in the SQ limit of conventional Si solar cells [26]; however the effect was negligible due to restrictions on the threshold energy for impact ionization to occur due to momentum conservation in bulk crystals. In more recent years, strong multiplication effects have been measured in nanostructured systems such as quantum dots and nanowires in which momentum conservation is relaxed [27], discussed in more detail in Sect. 19.8.2. There the effect is referred to as multiexciton generation (MEG), as optical absorption occurs primarily through excitonic states in strongly confined systems like quantum dots and nanocrystals.

The Extracted Carrier Energies Correspond to the Band Edges: