Abstract

Some cutting edge technologies for power generation make use of Supercritical \(CO_2\) cycles to improve efficiency and reduce emissions. While all of these technologies are characterized by non-premixed combustion conditions, premixed flames at very high pressure are an almost unexplored field, being concerns on their stability a strong limiting factor. In this study, premixed methane flames in a carbon dioxide atmosphere have been characterized numerically with a one dimensional detailed chemistry solver. Their distinctive characteristics such as flame speed and thickness have been determined at pressures from 100 to 300 bar and at varying \(CO_2\) concentration levels, as a first, fundamental step towards the characterization of their stability limits.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Combustion in devices such as liquid rocket engines and diesel engines is often designed to happen at very high pressure to allow the most efficient operation. Temperature and pressure of the fluids involved can have values which are across or higher than their critical ones. In this conditions, fluids are in the so called transcritical or supercritical state, where real gas effects on both mixing and combustion processes are of significant importance. Real gas effects consist in abrupt changes of thermodynamic and transport properties such as mixture density, enthalpy, heat capacity, viscosity and a vanishing surface tension, which eliminates the liquid-gas sharp interface [35]. Although this might seem to be a simplification since it removes the need for a two-phase flow treatment, a founding pillar of the standard numerical treatment of fluid flows is taken down: the equations of state (EOS) for the subcritical state lose their validity at this conditions and need to be modified with the inclusion of real gas effects. Also, real gas thermodynamic functions such as enthalpy, heat capacity and acoustic speed, need to be derived from the new equation of state and transport properties, which are usually modelled with simple but effective laws (e.g. Sutherland), need a more accurate modelling that takes into account the effects of inter-molecular forces [19]. The importance of real gas effects has been underlined in numerous works [4, 5, 19, 26, 32]. For many applications, supercritical combustion happens in the non-premixed regime. There is a wide range of studies of counterflow diffusion flames configurations that investigate the laminar non-premixed flame structure at supercritical conditions. In [19] hydrogen–oxygen diffusion flames are analysed to determine the effect of parameters such as pressure, strain rate and inlet temperature on the flame. Extinction limits of the same kind of supercritical diffusion flames as well as the influence of pressure on the heat release have been studied in [18]. Hydrocarbons mixtures have been investigated in [36] as well as the effect of fuel composition in [20]. To improve computational efficiency, the flamelet method [29, 30] is preferred to the direct solution of a conservation law for each chemical species involved in the combustion process when a time and length scale separation of turbulence and chemistry can be assumed. With regards to supercritical combustion, the method has been proven to be valid in [40] and employed in successive works [19, 22]. In [9] the flamelet method is employed in the development of a model for the simulation of reacting mixtures of real gases. In [39] a tabulated method based on the flamelet assumption is developed for LES applications. Alongside the applications mentioned above and the big trend in the combustion of hydrogen, interest is growing in the development of supercritical carbon dioxide (\(sCO_2\)) combustors, motivated by the increased heat-to-electricity conversion efficiencies and higher power density [24] if compared with steam-based power cycles. Dilution of fuel-air mixture by recirculation of burned gases is also more commonly employed to reduce NOx emissions, thanks to lower peak combustion temperatures, and to improve flame stability [21]. A deeper understanding of the dynamics and structure of \(CO_2\)-diluted premixed flames at supercritical conditions is therefore of significant importance for the further development of such technologies. Numerical investigations have been performed on combustors [6] and on jets [8] of methane in a supercritical \(CO_2\) environment. In the context of premixed flames at supercritical conditions, an important aspect to be investigated are the stability mechanisms in relation to geometrical and boundary conditions, starting from the considerations of premixed flames at low pressures done in [10] and [38]. Adebiyi et al. [2] investigated the propagation characteristics of premixed laminar flames in Oxy-Fuel combustion at supercritical conditions in a \(CO_2\)-atmosphere, however they used a single-step Arrhenius-type chemistry. A further application where \(CO_2\)-diluted flames can be found is the combustion of biogas obtained from anaerobic digestion of organic matter. In this context, there have been many works [3, 7, 11, 14,15,16,17, 27], both experimental and numerical, investigating the laminar flame properties such as flame speed and thickness in \(CO_2\)-diluted flames with varying fuel dilution grade, equivalence ratios, unburnt mixture temperature and pressure conditions. In a recent review of these works [37], the fundamental findings for laminar flames of methane/air/carbon dioxide and propane/air/carbon dioxide mixtures are summarized. The pressure conditions examined to date, however, do not exceed the 10 bar and it might be interesting to investigate the effects of very high pressure on this kind of flames.

2 Scope of Research

Within this work, numerical calculations of premixed methane flames with various amounts of \(CO_2\) in the premixed mixture, at very high pressures, have been performed. Starting point will be the calculation of biogas-like mixtures, for which flame speed, thickness and temperatures will be examined and the trend by varying \(CO_2\)-dilution grade will be compared with results obtained at atmospheric condition. Next, premixed flames of mixtures typical of oxy-fuel combustion with varying \(CO_2\) concentration will be analysed. With regards to the numerical methods, the influence of the equation of state and of the reaction mechanism will be investigated. These results should lay the foundations for a subsequent application to turbulent flows as done in [9, 22], where, however, essentially diffusion flames have been taken into account. An FGM approach [34] will be developed, for which one-dimensional calculations in the physical space at various levels of equivalence ratio and/or different temperature of the unburnt mixture are performed and parametrized as a function of some progress variable and mixture fraction to generate a lookup table to be used in combination with CFD solvers.

3 Methodology

The work is carried out with the one dimensional solver CHEM1D [1] where the underlying ideal gas model has been replaced by a real-gas ansatz allowing a description of the combustion manifolds consistent with the thermodynamic model adopted for flow solution. The solver has been extended with the Peng-Robinson [28] equation of state and the calculations of enthalpy and isobaric heat capacity have been modified consistently with the new equation of state. The calculation of transport coefficients (viscosity and thermal conductivity) has been adapted to high pressure conditions with the introduction of Chung’s rules for mixtures at high pressure which are, despite the scarceness of experimental data for the calculation of the correlation coefficients, one of the best analytical approximations available [31]. The importance of the real gas models (equation of state, thermodynamics and transport), has been systematically analysed in [13] for hydrodynamic flames where supercritical water is present. The conclusions drawn in this work state that the most important modification to the model is the equation of state, which has a major influence on the flame propagation speed. A key aspect when dealing with detailed chemistry computations is the choice of the reaction mechanism. Within this work, the widely used GRI 3.0 reaction mechanism [33] will be compared with the Aramco 2.0 [25] mechanism as well as with a reduced version of the latter. The first mechanism, comprising 53 species and 255 reactions, has been extensively validated for the combustion of hydrocarbons for pressures up to 10 atm but its performance in the high pressure range is questionable. The Aramco2.0 mechanism comprises 493 species and 2716 reactions and has been validated for methane combustion up to 260 atm. In [23], the two mechanisms are compared for the prediction of Ignition Delay Time in \(CH_4\)/\(O_2\)/\(CO_2\) mixtures at pressures up to 300 atm and Aramco2.0 mechanism seems to yield superior results. In the present context, however, a major drawback of the Aramco2.0 mechanism is the huge number of species which are taken into account. In fact, the calculation of mixture averaged critical properties, needed for both the iterative calculation of density with PR-EOS as well as for the calculation of transport coefficients, involves repeated double loops on the species so that the computational time is proportional to the square of the number of species and the time needed for the calculation of a single flamelet increases by order of magnitudes when combining the real gas model with this mechanism. To overcome this limitation, a reduced mechanism targeted to the present application has been calculated with a computational tool [12] using the method of Global Pathway Selection to select the most relevant species and reactions. The resulting mechanism contains 37 species and 223 reactions, and will be also compared to GRI3.0 and Aramco2.0 mechanisms.

4 Results and Discussion

4.1 Validation at Atmospheric Conditions

\(CO_2\)-diluted flames have been first analysed at atmospheric conditions in order to perform comparisons with available experimental data. The composition of the mixtures is listed in Table 1. The analysis has been restricted to stoichiometric mixtures. Pressure is set to 1 bar and the temperature of the unburnt mixture is \(T_u = 300\) K.

Figure 1a shows the temperature profile along the one dimensional flame, which is almost identical at this conditions for the three reaction mechanisms. In Fig. 1b, the laminar flame speed has been compared with experimental data: a good agreement is achieved and the values calculated in the present work lie in the range of experimental results. Figures 1c and 1d show respectively the variation with \(CO_2\) dilution of flame thickness and thermal expansion ratio, defined as the ratio between unburnt mixture and burnt mixture densities. Lines do not coincide because of the slightly different pressure in the results from [37], although the trend is clearly the same. The findings reported in the literature are here all reproduced, in particular the lower temperature of the flame, lower speed and higher thickness with the increase in dilution of fuel with \(CO_2\) .

4.2 High Pressure

The analysis has been repeated for the mixtures defined in Table 1 at the pressures of 100 and 200 bar, with the different reaction mechanisms and with both the standard ideal gas model and the real gas formulation.

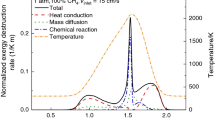

Flamelets at 200 bar, mixture of Table 1

Figure 2a and 2b show the comparison of the temperature profiles in the physical space at 200 bar respectively for different reaction mechanisms (Fig. 2a) and different EOS and transport modelling (Fig. 2b). In Fig. 2a, although the temperatures of reaction products are the same, differences in temperature profiles can be noticed between the GRI and Aramco mechanisms, as a results of the higher pressure. For what has been said in the introduction about these mechanisms, it could be argued that results obtained with the Aramco mechanisms should be closer to reality. For as much as regards its reduced version, the solutions can hardly be distinguished. Comparisons of flame thickness and speed between the two mechanisms, which are not shown for brevity, gave the same result. This confirms that the reduction carried over doesn’t imply a significant deviation from the full model, at least for the purposes of this study. For this reason, as discussed in the introduction, the reduced mechanism will be used in place of the full one and all plots that will be shown in the following sections are obtained with the reduced Aramco2.0 mechanism. The comparison of the gas models (Fig. 2b), obtained using the reduced Aramco2.0 mechanism, confirms the expected deviations from the ideal behaviour, especially in the development of the temperature field.

Flamelets at 100 and 200 bar, mixture of Table 1

In Fig. 3, a comparison of flame speed and thickness between the two gas models is shown. For both models, the same trends of the atmospheric results are reproduced. As seen in Fig. 2b, the real gas modelling results in a higher thickness and lower flame speed and differences at this pressure level are not negligible.

4.3 Supercritical

Oxy-Fuel flames with various level of \(CO_2\) at different pressures have been analysed. The compositions of the mixtures are listed in Table 2. The temperature of the unburnt mixture is set to \(T_u = 300\) K and flamelets at a pressure level of 100, 200 and 300 bar have been calculated. With this mixture composition and at this conditions, some states of the flame exceed critical values for both pressure and temperature.

Flamelets solution in \(T_r\)-\(p_r\) diagram, mixtures of Table 2

In Fig. 4, the states of the mixture resulting from the calculation of the flamelet solutions as a function of reduced pressure and reduced temperature are shown. The grey lines are isolines of compressibility factor Z, where values of Z different from one are an indicator of the degree of departure from ideality of the mixture. We see that the points corresponding to lower temperature values (unburnt mixture) have compressibility factor values much smaller than one with pressure and temperature higher than their critical ones. Figure 5 shows the relevant change in calculated density and thermal conductivity with the Peng-Robinson EOS and Chung’s rules for transport properties for the mixture with the highest content of \(CO_2\) (\(X_{CO2}=0.8\)) at the different values of pressure. Values of density are up to two times larger than the corresponding ideal value, while differences in the values of thermal conductivity are even higher and we observe slopes changes in the transition from the supercritical to the ideal behaviour.

Comparison of ideal and non ideal formulations for mixtures of Table 2

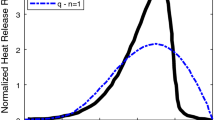

Flamelets at 100, 200 and 300 bar, mixtures of Table 2

Figure 6 shows the variation of flame speed and thickness for the oxy-fuel case at varying \(CO_2\) concentration levels. While the trend with the increase of carbon dioxide concentration is once again confirmed, it is interesting to look closer at the pressure dependency of these results. Points at 200 and 300 bar are closer to each other than the corresponding points at 100 and 200 bar. The pressure dependency of flame thickness is better seen in Fig. 7, where the flame thickness is shown normalized by the value at 100 bar and as a function of pressure. We observe that the trend is between 1/p and \(1/\sqrt{p}\) and changes with \(CO_2\) concentration. Moreover, the curve for \(X_{CO2}=0.8\) seems to be closer to 1/p, which is anomalous if compared with the other curves.

5 Conclusions and Future Works

The calculations performed in this work are a first numerical characterization with detailed chemistry of premixed flames for the combustion of supercritical mixtures with high levels of \(CO_2\) dilution. The lack of experimental data for comparison at higher pressures doesn’t allow to draw conclusions on the accuracy of calculations, although the high efforts in the accurate modelling suggest that a certain degree of closeness to reality could be reached. The comparison between the ideal and the real gas approaches have been shown to underline the importance of taking into account real gas effects. Reaction mechanisms also proved to play a very important role. The calculations will be extended to draw continuous lines at varying pressures and carbon dioxide dilution levels, so that tendencies which are not clear with a limited number of points can be better recognized. The one dimensional calculations here performed, also, will be the base for the construction of manifolds to be used in two and three dimensional calculations in combination with a CFD solver.

References

CHEM1D: A one-dimensional laminar flame code, Eindhoven University of Technology

Adebiyu, A.A., Kemenov, K., Akkerman, V.: Numerical simulation of oxy-fuel premixed combustion in a supercritical \(CO_2\)-diluted environment. Proc. West Virginia Acad. Sci. 90(1) (2018)

Bai, Z., Wang, Z., Yu, G., Yang, Y., Metghalchi, H.: Experimental study of laminar burning speed for premixed biomass/air flame. J. Energy Resour. Technol. 141(2), 022206 (2019)

Banholzer, M., Pfitzner, M., Sakellarakis, D., Wright, Y.M., Vera-Tudela, W., Boulouchos, K.: Numerical investigation of nozzle-geometry variations and back-pressure changes on high pressure gas injections under application-relevant conditions. Technical report, SAE Technical Paper (2018)

Banuti, D.T., Hannemann, V., Hannemann, K., Weigand, B.: An efficient multi-fluid-mixing model for real gas reacting flows in liquid propellant rocket engines. Combust. Flame 168, 98–112 (2016)

Banuti, D.T., Shunn, L., Bose, S., Kim, D.: Large Eddy Simulations of Oxy-Fuel combustors for direct-fired supercritical \(CO_2\) power cycles. In: The 6th International Symposium on Supercritical \(CO_2\) Power Cycles (2018)

Bosschaart, K.J., De Goey, L.: The laminar burning velocity of flames propagating in mixtures of hydrocarbons and air measured with the heat flux method. Combust. Flame 136(3), 261–269 (2004)

Chong, S.T., Tang, Y., Hassanaly, M., Raman, V.: Turbulent mixing and combustion of supercritical jets. In: 55th AIAA Aerospace Sciences Meeting, p. 0141 (2017)

Cutrone, L., De Palma, P., Pascazio, G., Napolitano, M.: A flamelet/progress-variable approach for the simulation of turbulent combustion of real gas mixtures. In: 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, p. 4567 (2008)

De Goey, L., Van Oijen, J., Kornilov, V., ten Thije Boonkkamp, J.: Propagation, dynamics and control of laminar premixed flames. Proc. Combust. Inst. 33(1), 863–886 (2011)

Elia, M., Ulinski, M., Metghalchi, M.: Laminar burning velocity of methane-air-diluent mixtures. J. Eng. Gas Turbines Power 123(1), 190–196 (2001)

Gao, X., Yang, S., Sun, W.: A global pathway selection algorithm for the reduction of detailed chemical kinetic mechanisms. Combust. Flame 167, 238–247 (2016)

Gao, Z., Wang, H., Song, C., Luo, K., Fan, J.: Real-fluid effects on laminar diffusion and premixed hydrothermal flames. J. Supercrit. Fluids 153, 104566 (2019)

Goswami, M., Derks, S.C., Coumans, K., Slikker, W.J., de Andrade Oliveira, M.H., Bastiaans, R.J., Luijten, C.C., de Goey, L.P.H., Konnov, A.A.: The effect of elevated pressures on the laminar burning velocity of methane + air mixtures. Combust. Flame 160(9), 1627–1635 (2013)

Gu, X.J., Haq, M.Z., Lawes, M., Woolley, R.: Laminar burning velocity and Markstein lengths of methane-air mixtures. Combust. Flame 121(1–2), 41–58 (2000)

Halter, F., Chauveau, C., Djebaïli-Chaumeix, N., Gökalp, I.: Characterization of the effects of pressure and hydrogen concentration on laminar burning velocities of methane-hydrogen-air mixtures. Proc. Combust. Inst. 30(1), 201–208 (2005)

Hinton, N., Stone, R.: Laminar burning velocity measurements of methane and carbon dioxide mixtures (biogas) over wide ranging temperatures and pressures. Fuel 116, 743–750 (2014)

Huo, H., Wang, X., Yang, V.: A general study of counterflow diffusion flames at subcritical and supercritical conditions: oxygen/hydrogen mixtures. Combust. Flame 161(12), 3040–3050 (2014)

Lacaze, G., Oefelein, J.C.: A non-premixed combustion model based on flame structure analysis at supercritical pressures. Combust. Flame 159(6), 2087–2103 (2012)

Lapenna, P.E., Ciottoli, P.P., Creta, F.: The effect of fuel composition on the non-premixed flame structure of LNG/LOx mixtures at supercritical pressure. In: 54th AIAA Aerospace Sciences Meeting, p. 0690 (2016)

Lefebvre, A.H.: Gas Turbine Combustion. CRC Press, Boca Raton (1998)

Ma, P.C., Banuti, D., Hickey, J.-P., Ihme, M.: Numerical framework for transcritical real-fluid reacting flow simulations using the flamelet progress variable approach. In: 55th AIAA Aerospace Sciences Meeting, p. 0143 (2017)

Manikantachari, K., Vesely, L., Martin, S., Bobren-Diaz, J.O., Vasu, S.: Reduced chemical kinetic mechanisms for oxy/methane supercritical \(CO_2\) combustor simulations. J. Energy Resour. Technol. 140(9), 092202 (2018)

McClung, A., Brun, K., Chordia, L.: Technical and economic evaluation of supercritical oxy-combustion for power generation. In: The 4th International Symposium-Supercritical CO2 Power Cycles (2014)

Metcalfe, W.K., Burke, S.M., Ahmed, S.S., Curran, H.J.: A hierarchical and comparative kinetic modeling study of c1–c2 hydrocarbon and oxygenated fuels. Int. J. Chem. Kinet. 45(10), 638–675 (2013)

Müller, H., Niedermeier, C.A., Matheis, J., Pfitzner, M., Hickel, S.: Large-eddy simulation of nitrogen injection at trans-and supercritical conditions. Phys. Fluids 28(1), 015102 (2016)

Nonaka, H., Pereira, F.: Experimental and numerical study of \(CO_2\) content effects on the laminar burning velocity of biogas. Fuel 182, 382–390 (2016)

Peng, D.-Y., Robinson, D.B.: A new two-constant equation of state. Ind. Eng. Chem. Fundam. 15(1), 59–64 (1976)

Peters, N.: Turbulent Combustion. IOP Publishing, Bristol (2001)

Pitsch, H.: Large-eddy simulation of turbulent combustion. Annu. Rev. Fluid Mech. 38, 453–482 (2006)

Reid, R.C., Prausnitz, J.M., Poling, B.E.: The Properties of Gases and Liquids (1987)

Sakellarakis, V.D., Banholzer, M., Llugaliu, D., Wright, Y., Pfitzner, M., Boulouchos, K.: Assessment of real-gas effects in high-pressure gas injection at engine-relevant conditions. In: 12th International ERCOFTAC Symposium on Engineering Turbulence Modelling and Measurements (2018)

Smith, G.P.: Gri-mech 3.0 (1999). http://www.me.berkley.edu/gri_mech/

Van Oijen, J., De Goey, L.: Modelling of premixed laminar flames using flamelet-generated manifolds. Combust. Sci. Technol. 161(1), 113–137 (2000)

Wang, X., Huo, H., Yang, V.: Supercritical combustion of general fluids in laminar counterflows. In: 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, p. 1165 (2013)

Wang, X., Huo, H., Yang, V.: Counterflow diffusion flames of oxygen and n-alkane hydrocarbons (ch4-c16h34) at subcritical and supercritical conditions. Combust. Sci. Technol. 187(1–2), 60–82 (2015)

Wang, Z., Yelishala, S.C., Yu, G., Metghalchi, H., Levendis, Y.A.: Effects of carbon dioxide on laminar burning speed and flame instability of methane/air and propane/air mixtures: a literature review. Energy Fuels 33(10), 9403–9418 (2019)

Yu, J., Yu, R., Bai, X., Bastiaans, R., Van Oijen, J., De Goey, L.: Heat transfer and flame stabilization of laminar premixed flames anchored to a heat-flux burner. Int. J. Hydrogen Energy 41(3), 2037–2051 (2016)

Zips, J., Müller, H., Pfitzner, M.: Efficient thermo-chemistry tabulation for non-premixed combustion at high-pressure conditions. Flow Turbul. Combust. 101(3), 821–850 (2018)

Zong, N., Ribert, G., Yang, V.: A flamelet approach for modeling of liquid oxygen (LOX)/methane at supercritical pressures. In: Forty-Sixth AIAA Aerospace Sciences Meeting and Exhibit, vol. 946, pp. 1–16. AIAA (2008)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Lo Presti, F., Post, P., di Mare, F., van Oijen, J. (2021). Numerical Characterization of Premixed Methane Flames in Vitiated Atmosphere at Supercritical Conditions. In: Pini, M., De Servi, C., Spinelli, A., di Mare, F., Guardone, A. (eds) Proceedings of the 3rd International Seminar on Non-Ideal Compressible Fluid Dynamics for Propulsion and Power. NICFD 2020. ERCOFTAC Series, vol 28. Springer, Cham. https://doi.org/10.1007/978-3-030-69306-0_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-69306-0_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69305-3

Online ISBN: 978-3-030-69306-0

eBook Packages: EngineeringEngineering (R0)