Abstract

There has been tremendous attention and effort directed toward improving the safety and quality of healthcare in prior decades. There have been real gains, but also challenges, to the success and sustainment of improvement efforts. We know that our organizations, and those of our peers, are safer and deliver higher quality care than they ever have. To this end, this chapter demonstrates the need for a case-based approach toward patient safety and quality improvement. For our hospitals to overcome improvement plateaus and get to zero harm, we need to approach our work differently. Theoretical underpinnings have served us well; however, we need to present cases and real problems that have been amenable to the theoretical approaches. There is a myriad of issues we continue to struggle with, such as spreading learned best practices and sustaining improvement. This chapter uses catheter-associated urinary tract infections (CAUTIs) as an exemplar of how one organization employed their respective quality tools to reduce their CAUTI rate. The focus of this chapter will be on the Donabedian quality triad, the preventable harm index, and alignment of these concepts with an organization’s mission, vision, and values. This chapter is not intended to be a primer on how to reduce CAUTIs, but rather a framework for this textbook on how to embark and sustain a quality improvement initiative using a case-based approach.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Baldrige framework for performance excellence culture

- Donabedian model

- Hawthorne effect

- Lean

- Institute for Healthcare Improvement (IHI)

- IHI Model for Improvement

- Plan-Do-Study-Act (PDSA)

- Preventable harm index

- Quality

- Safety

- System of profound knowledge

- Six Sigma

- Framework for execution

- Toyota Production System (TPS)

-

To demonstrate the burning platform of patient safety and quality improvement in the current healthcare era as it relates to the achievement of zero harm

-

To explain how varying improvement methodologies can co-exist to drive improvement in an organization with the use of an adapted simple, common language that fosters improvement across all layers of the enterprise

-

To connect the work of patient safety and quality improvement to the mission, vision, and values of an organization

-

To understand the value of learning best practices and methods from non-healthcare industries

A tertiary care free-standing hospital has a problem with catheter-associated urinary tract infections (CAUTIs). This problem is not new. The organization tackled CAUTIs 4 years prior with the creation of an overarching structure which resulted in new processes and better outcomes. As the compliance with these refined processes improved, the absolute number of CAUTIs went down. However, in the past 18 months, the number of CAUTIs has slowly crept back up. This issue is further compounded by the fact that the rate has significantly worsened even as the organization has reduced their Foley catheter days dramatically. The clinicians only place catheters when they are most needed; hence the numerator has increased, while the denominator has decreased in the CAUTI rate equation. The executive leadership and Hospital Board demand an improvement from the quality and safety team. This can be the self-defeating prophecy for many teams trying to reduce the CAUTI rate – the absolute number of events is decreasing but the rate (which is used for benchmarking) continues to increase.

Opening Question/Problem

This chapter is not about CAUTIs or specific tactics to reduce these infections – that will be discussed elsewhere in this text. Rather, this chapter discusses the improvement framework and approach toward patient safety and quality improvement that transcends individual hospital acquired conditions and can be broadly applied to quality improvement initiatives in the organization.

Introduction/Overview

There have been significant strides made to advance patient safety and quality improvement in the past two decades. Hospitals, and other organizations, reacted to the clarion call from the Institute of Medicine’s seminal work, To Err is Human [1]. Since this publication, hospitals and healthcare systems have made tremendous investments in people, processes, and technology – all with an aim to improve the quality and safety of care delivery. We have seen improvement; however, there are issues that still persist and have not improved at the same rate as other measures. Many organizations are struggling with their progress toward zero harm; they have seen a plateau in their improvement and are looking for novel approaches and strategies.

Early in the journey, there was an educational component which was missing in this work. As such, initial efforts were appropriately targeted toward increasing capability (the ability, from a skills perspective, of healthcare workers to embark upon quality improvement initiatives) (Key Point Box 1.1).

Key Point Box 1.1 Capability Vs. Capacity

Capability – the intellectual understanding, knowledge and practical application of improvement science

Capacity – the ability to take on quality improvement projects

Much of the efforts immediately after To Err is Human focused on extrapolating the theoretical underpinnings from systems science, reliability, and quality improvement from other industries to educate those of us in healthcare. This was initially quite successful, as there was a whole new lexicon introduced into healthcare. Previously fertile ground was now inundated with theoretical quality improvement applications. As expected, improvement followed as the proverbial low-hanging fruit (Fig. 1.1) was harvested. Some of the success in the early 2000s was a result of the Hawthorne effect (which states that improvement will occur when those performing the work know they are being observed); however, not surprisingly, in many instances, these results were not sustained (Key Point Box 1.2).

Key Point Box 1.2 Sustain

A common problem in quality improvement is the ability to sustain projects for prolonged periods of time. Smart aim statements usually include verbiage to indicate the degree of improvement over a prescribed period of time (6, 9 months, etc.). It is the leader’s role to ensure that the project “sticks” and that true improvement is achieved.

Nevertheless, healthcare was quick to embrace this renewed interest in the safety of their patients and the quality of care delivery; furthermore, the public, government, and payers were expecting such improved care to be delivered quickly.

During the past decade, it has become clearer that the low-hanging opportunities have been addressed. A clear understanding of the journey of healthcare improvement, via the continuous quality improvement framework, resulted in organizations realizing several disadvantages. They were in for the long-haul and real improvement would take years, not months. Improvement would be elusive, rather than straightforward. It would yield further disappointments, not all success.

To increase, or at least continue, their trajectory of improvement, health systems need to change their level of sophistication. Figure 1.1 demonstrates a rubric, and guiding principle, used and presented by one of the editors (RKS) in explaining the complexity necessary to continually improve outcomes for our patients. To understand where healthcare is at present in the quality improvement journey, one can overlay the improvements in healthcare, since 2000 to present, with the level of sophistication necessary to achieve sustained outcomes (Fig. 1.1).

Vignette 1.2

Four years prior, the organization made the reduction of hospital acquired conditions, especially infections, a priority. A new structure was put in place. A physician and nurse co-led the CAUTI team which also included stakeholders from the inpatient floors, the operating room, and the emergency department. The team chartered this work and put in place processes to address the key drivers from their CAUTI road map, using the IHI Model for Improvement. The initial results were impressive – an 80% reduction in CAUTIs in just a few years. However, over the past 18 months, outcomes have slipped, and there has been an increase in CAUTIs. Much has changed in the past 5 years in hospitals with regard to quality improvement. The CAUTI team believes that they need to refresh their quality improvement approach. They are struggling with how to do this with competing organizational priorities. This is further complicated by the ever-changing national perspective, and potentially competing improvement methodologies, which may be frustrating staff.

In the early 2000s, much of the improvements were a result of targeting low-hanging fruit and using basic resources to drive improvements. We would train teams on whatever improvement methodology aligned with our organizational quality improvement teams (Institute for Healthcare Improvement (IHI) Model for Improvement [2], Lean, Six Sigma, etc.). Usually, that basic theoretical education sufficed to collect the “easy to reach” improvement opportunities. This was essentially the era of demanding improvement.

As we evolved our understanding and techniques, the issues became more complex and mandated differing strategies. Organizations started collectively focusing on improvement. Improvement science transcended the quality improvement department, such that it was considered to be the job of hundreds of individuals in an organization. When leadership held teams (and themselves) accountable for outcomes and demanding improvement, said improvements were made to a higher degree of reliability. The next evolution in outcomes will require structures and processes that have specific and unique internal improvements and address systems design.

Healthcare is emerging from its, at times, insular history and is now turning to other industries such as our airline counterparts, Toyota, the US Navy, Alcoa, and others, for models of operational excellence that support a culture of safety and continuous process improvement. Dr. W. Edwards Deming [3] spoke of the importance of systems thinking as a key ingredient for improvement. His System of Profound Knowledge consists of four key points: appreciation of system, theory of knowledge, psychology of change, and understanding variation. It has had significant impact on some of the aforementioned models of excellence [4]. The Theory of Knowledge incorporated the Plan-Do-Study-Act (PDSA) cycle which is the most commonly discussed unit of improvement science-directed change.

Dr. Donabedian emphasized the importance of systems awareness and design [5]. His widely used theoretical framework (commonly referred to as the Donabedian triad) is composed of three crucial points: structure, process, and outcome. In our organizations, we employ the Donabedian quality triad when embarking on projects or when delving deeper to understand why a system is not performing as expected (Key Point Box 1.3). By having the improvement team take a step backward and move “upstream” from the outcome, the role of structure and process becomes clear. The improvement team needs to look beyond outcomes and ask the provocative questions of what structures are in place and if we are holding teams accountable for the processes that we deem necessary to drive improvement.

Key Point Box 1.3 Donabedian Quality Triad

Structure, Process, Outcome

Vignette 1.3

The initial work in CAUTIs for the organization started approximately 4 years prior. The organization was admittedly and knowingly behind other organizations as they had lost focus and sustainment. To address this, a structure was put in place. Not only was thought given to the constituency of the team (size, representation, need for contrarians, etc.) but also to its reporting structure. The improvement team was explicit in its desire to recruit an executive sponsor to champion the work and provide organizational alignment – ultimately between executive management and the Board. The committee was chartered and reported to progressively more influential hospital level quality committees. The absolute number of CAUTIs were tabulated monthly and presented in a collated format, along with the other hospital acquired conditions, to management, leadership, and the Board in a consistent fashion. Once the improvement team’s membership and reporting structure had been clearly delineated, attention was turned to processes. For the CAUTI work, best practices were gleaned from literature, national collaboratives [6], hospital associations, and infectious disease experts. In turn, a decision was made to adopt a bundle from a national collaborative. The bundle, consisting of five items, was adopted and adherence to it was measured.

With a trend in CAUTIs that was contrary to our global aim, and continuing to affect patients, this organization took a pause. They evaluated not only the structure and processes but took a higher level approach to ask if they were using the correct methodologies. The initial key driver diagram from 4 years ago was reviewed and refreshed. Many members of the prior team had moved on from the organization or were not actively involved in the present work. A revised key driver diagram was created and shared throughout the organization.

There exist several quality improvement methodologies and myriad permutations of the foundational methods. Many healthcare organizations are steeped in the understanding of the IHI Model for Improvement and Lean [2, 4]. The IHI Model for Improvement uses a conceptual framework to understand variation, clarify processes, plan tests of change, and measure and accelerate improvement and includes aims, key drivers, and measurement. Lean is an improvement methodology based on the tenets of reducing waste and driving efficiency. It was derived from the Toyota Production System (TPS) [7, 8] and focuses primarily on its technical tools.

A case-based approach to quality improvement cannot be wedded to a particular quality improvement methodology. Organizations should have some latitude and resist being vehemently dogmatic, on which improvement methodology is employed. Of course, it is strongly suggested that an organization have a predominant methodology for quality improvement that is understood by the entire organization. However, to climb the quality tree, it must be conceded that, at times, additional methodologies may need to be incorporated into the strategy. Furthermore, we would caution that being resistant to ideas from other staff about their preferred improvement methodology may harm improvement culture in the long run.

Simplicity is crucial to the message for our frontline team members, who may not understand the complexities of improvement and safety science, as they are the agents driving change. Recall the aforementioned discussion about the apple tree (Fig. 1.1). Now realize that these apples need to reach their customers or our frontline team members. The more complex the bureaucracy or the language, the more likely that the apples will spoil and not reach the mouths of our frontline team members. This would be crippling, as they are hungry for the skills that will make them better problem-solvers (Fig. 1.2). We need to realize that improvement science, while having multiple theoretical models, can be simplified to a common local language that is inclusive and respectful of all methods while still facilitating change across the health system continuum.

Vignette 1.4

After the appropriate structure had been put in place with the necessary multi-disciplinary stakeholders, a clear reporting structure to executive leadership and the Board, and an involved executive sponsor, attention was turned toward traditional quality improvement methodologies. A key driver diagram with a global aim, SMART (specific, measurable, applicable, realistic, timely) aim, appropriate drivers, and interventions was created and then shared broadly throughout the organization. The key driver diagram and review of the CAUTI processes and outcomes were evaluated by the Chief Quality Officer on a monthly basis. Resources (educational, personnel, financial, etc.) were deployed to the micro-units in need to properly reinvigorate their teams. Small groups of frontline individuals were pushing back that they had competing priorities and were unable to do their core work. The CAUTI steering committee was appropriately worried that this would, once again, set back the improvement project.

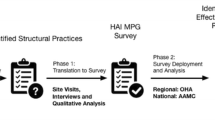

It is clear that operational success requires systems thinking and realignment which, in turn, requires a structured framework. Some frameworks are inherently complex, such as the Baldrige Framework for Performance Excellence [9] , and require considerable organizational and individual commitment and planning. Others appear to be simple like the TPS (Fig. 1.3) which emphasizes the development of individuals, with a focus on the frontline and customers, and the creation of teams of problem-solvers that readily bring problems to the surface. The authors are not advocating for one over another – they each have a role. It is important for the reader to understand the basic tenets of these frameworks. The reality is that the ability to do the latter (TPS) well takes considerable organizational commitment and alignment and probably has not been mastered perfectly by any health system at the time of writing of this text. Jamie Bonini, Vice President of Toyota Production System Support Center (TSSC), best described TPS as “an organizational culture of highly engaged people solving problems (or innovating) to drive performance” (personal communication). Implied in this statement is the importance of transparency, accountability, a focus on developing our frontline team members, and supporting a problem-solving culture. This cannot be achieved overnight. Frankel et al. [10] proposed a Framework for Safe, Reliable, and Effective Care (Fig. 1.4) which describes the culture and learning system domains as being foundational and crucial to the success of safety and quality systems.

IHI framework for safe, reliable, and effective care [10]. (Reprinted from www.IHI.org with permission of the Institute for Healthcare Improvement, ©2019)

Quality improvement efforts in a healthcare organization need to be cognizant of the organizational Culture (intentionally with a capital “C”). Culture is the shared norms of a system. There are hundreds of definitions of Culture. Indeed, each organization most likely uses some permutation of the aforementioned definition. The CAUTI vignette, which has been carried through this introductory chapter, has Culture as a key component. The authors and editors of this text have shared many examples of how quality improvement initiatives fail, or are not sustained, primarily due to the lack of appreciation of the importance of Culture. There is no quick fix or methodology to improve Culture. It is beyond the scope of our introductory chapter, in this case-based approach to quality improvement textbook, to expound upon Culture. However, it must be appreciated in these case vignettes that efforts to drive quality improvement, without an understanding and appreciation of Culture, will not be successful.

Vignette 1.5

It was found, when digging deeper into the CAUTI outcomes, that the operating rooms and emergency department did not espouse the same values and Culture with regard to CAUTI as that held by the inpatient units. One can immediately see the problem and how it can spiral into a bigger issue. If two of the three stakeholders had a different cultural approach to CAUTIs, then there would be no shared mental model. The emergency department and operating rooms did not feel ownership of the issue, as they believed that their care was transient and the patient was ultimately admitted to the inpatient unit. To break this cultural logjam, the Chief Medical Officer brought the leadership of these three areas together in a small group meeting. The objective of the meeting was to discuss, in an open forum, why two of the stakeholders were not appreciating their team’s role in CAUTIs. Contrary to one’s impression, the 1-hour meeting did not perseverate on the pathophysiology of CAUTIs nor on specific tactics and strategies to reduce CAUTIs. Rather, a significant portion of the meeting addressed the mission, vision, and values of the organization. By elevating the meeting to a shared understanding of the organization’s commitment to their patients, families, and community, the Chief Medical Officer was able to imbue the organization’s desired Culture to these teams. Of course, this broader realization did not happen overnight. The initial meeting with the Chief Medical Officer put in motion the goals of the three teams and laid out how their work on CAUTIs would be a microcosm of the bigger work and global aim.

A successful approach to those stakeholders that are recalcitrant, or do not see an issue as a “problem” to be owned, is to move the issue to a higher level and focus on the mission, vision, and values of the organization. This is not a quick solution, and the recalcitrant leader may need to be reminded frequently, perhaps at the start of each meeting on the topic, of their role in the organization and how that ties into the mission, vision, and values (Key Point Box 1.4).

Key Point Box 1.4 Mission, Vision, Values

Mission – the role of the organization

Vision – forward-looking statement of what the organization wants to achieve in the future

Values – principles and ideals that bring the organization together

It would be disingenuous to state that, immediately after this meeting, these groups were engaged. Culture change takes time – often years. Once the Chief Medical Officer had the small group meet, she further charged them to report back to her monthly with their CAUTI data. At subsequent meetings, the Chief Medical Officer made it clear that the three leaders were accountable for the CAUTI outcomes in the organization.

Vignette 1.6

The hospital’s Board had heard about the increase in CAUTIs and wanted this to be presented by the Chief Quality Officer at the next Board meeting. The Chief Quality Officer struggled with presenting the data as an absolute number of cases versus a rate (numerator/denominator). The Chief Quality Officer had also contemplated the best manner in which to show the executive leadership and Board other hospital acquired conditions. She believed that if the Board was engaged at present, and asking for data regarding CAUTIs, she should seize this moment and put CAUTIs in context with other hospital acquired conditions. She struggled with how to best show the Board the entirety of the information in an understandable and meaningful way.

Rates are often used in quality improvement and take various forms in their presentations. The most common is the number of events divided by a frequency. For CAUTI, the rate is usually expressed as the number of catheter-associated urinary tract infections divided by the number of catheter days. Some individuals (board members, executive leadership, or non-clinical leaders) may not be able to immediately grasp the significance of small changes in rates as having an impact on patients, especially as we near zero. Dr. Richard Brilli, Chief Medical Officer at Nationwide Children’s Hospital, has been a proponent on using actual event frequency data, as well as rates, to help organizations understand the scope of a problem [11]. It is much more tangible for leadership, Boards, and frontline team members to know that there were, for example, 17 CAUTIs in the past year and 3 in the past quarter. To tersely state a rate for this audience would not be providing them the full context. As we continue to climb the quality tree, outcomes are going to significantly improve, and the numerators (number of actual events) will continue to fall. Rates should also continue to drive down to zero. Dr. Brilli was among the first to stress the importance of zero as our goal for harm reduction. Tacit in this goal is that we may need to be agile in how we present our data – sometimes as an absolute number of events and other times as a rate.

When faced with an improvement project, it is crucial that the initiative is aligned with the organizational mission, vision, and values (Fig. 1.5). We have seen that, in our institutions and when working with other organizations, both the frontline and executive leadership need to be able to see how their work connects to the trajectory of the organization.

At Children’s National, under the leadership of our Executive Management and Board, we embarked upon a journey in which the accountable executives over Patient Care Services (Chief Operating Officer and Chief People Officer) crafted contemporary organizational values. These values are Compassion, Commitment, and Connection (Fig. 1.6).

The importance of explicitly stating the organizational core values, and using them as levers to drive engagement and improvement projects forward, cannot be understated (Fig. 1.5).

Vignette 1.7

Despite aligning organizational awareness around CAUTIs by using the Harm Index to demonstrate to the employees and Board that this issue was still pervasive, some employees were not making the connection to bundle compliance and the goals of the organization. Frontline employees were completing the CAUTI bundles approximately 50% of the time on average, and, when looking at various microsystems, the bundle compliance ranged from 30% to 70%. Therefore, the quality improvement team was not surprised that the organization was still having a CAUTI every 45 days. The CAUTI steering committee heard from frontline staff that they believed there was no connection of their work to the goals of the organization. The CAUTI steering committee began to change their messaging. The team began to include the “why.” The leaders of this work started each of their CAUTI meetings with a patient story that related back to the organizational mission, vision, and values. Often times, a non-CAUTI story was utilized. This tactic spread organically through the organization and, before long, patient safety stories were shared at the top of each pertinent meeting. The patient stories generally lasted about 2–3 minutes and were strategically used to connect the meeting, and work of the team, to the mission of the organization.

Starting each pertinent meeting with a safety story is hugely impactful. A safety story is a brief vignette of an event that occurred in the organization, region, or otherwise, told by a member of the committee. The story should be brief (90 seconds or less), and the chair of the committee should provide just a couple of minutes of discussion to connect the story, address open items, and move the meeting to the agenda items. An example of a patient safety story presentation would be: “I would like to start this meeting off with a patient story. The patient was on the hospitalist service on hospital day #3 when she spiked a fever. The child had multiple lines and was admitted for an aggressive respiratory infection. The child was pan-cultured and found to have a urinary tract infection with a Foley catheter, so this was deemed to be a CAUTI. The child was transferred to the ICU for urosepsis, and required aggressive antibiotic therapy for 3 days. She was then discharged home after a total hospital stay of 9 days. When reviewing the risk factors for the CAUTI, it was noted that the unit’s bundle compliance for CAUTI is only 60%. For this child, the CAUTI bundle was not performed each time for all elements. As a side note, the hospital census is high and the ICU is at full capacity” (Key Point Box 1.5).

Key Point Box 1.5 What Is a Bundle?

A bundle is a group of process interventions (almost always evidence-based) put into place for a specific metric, which has been demonstrated to improve outcomes.

The specifics of how to tell a patient story are important to share as the authors have often seen patient stories taking 10–15% of an allotted meeting or note stories that are not connected back to the meeting agenda. Other times, the stories are so profoundly impactful (e.g., patient death or egregious deviation from care) that a portion of the meeting must be used to immediately address some area(s) of concern identified in the patient story. Such a story is not effective if it did not achieve its goal of connecting the dots for the committee members and grounding the team in their work, but instead “hijacked” the agenda from the meeting’s intended purpose. A safety story should be a succinct vignette, preferably related to the organization in some manner and presented in 90 seconds or less, that is used to demonstrate organizational alignment and the work of those in the meeting. Additionally, the importance of patient and family participation on improvement committees cannot be overstated. We need to remember that, at some point, all healthcare providers will also be consumers of healthcare. We would want to be given the same respect and ability to be involved in our care or the care of our loved ones.

We are confident that this introduction has provided the reader an idea as to what to expect in the ensuing chapters. Quality and safety is the paramount priority of most organizations globally and unequivocally for healthcare organizations. Naturally, there is much information as to how to proceed, but the journey to zero harm requires careful planning and time. Success takes a shared vision, simple and measurable strategic objectives, leadership and frontline engagement, common operational language, perseverance, and the desire to succeed.

Thomas Nolan’s Framework for Execution [12] (Fig. 1.7) and the Toyota Production System Triangle (Fig. 1.3) are some of the simplest representations by which to drive improvement. Both will be discussed in the ensuing chapters. Nolan discussed the criteria necessary for breakthrough performance: (1) to define breakthrough performance goals; (2) to create a portfolio of projects that support these goals; (3) to deploy appropriate resources to ensure the success of these goals; and (4) to create the oversight and learning system to monitor and ensure success. High reliability, as discussed by Weick and Sutcliffe [13], is the goal for healthcare enterprises and their combined membership. It is not for the faint of heart, but it remains elusive until the many aforementioned criteria are attained. We will be discussing their various components in depth in this text.

Framework for execution. (Reprinted from www.IHI.org [12], with permission of the Institute for Healthcare Improvement, ©2019)

Editors’ Comments

Each chapter will be followed by a synoptic chapter summary by the editors to put the article into the broader context of the textbook and healthcare quality improvement overall. To simply reiterate the abstract would not be of value. Rather, this concluding section for each chapter will attempt to pull the chapter and textbook together and be forward-looking in nature for the reader.

This introductory chapter attempts to rekindle the burning platform in healthcare by pushing us to strive for zero harm. To do this, we implore readers to strive for zero harm. To increase the level of sophistication in quality improvement, the authors stress the importance of the Donabedian quality triad of structure, process, and outcomes. In beginning quality improvement projects and when evaluating those that are in sustain mode, it is crucial to ensure the project has the right structure and that process measures are being completed and sustained as expected with controls in place for accountability.

A key goal of this chapter is to also drive home the concept of absolute numbers of harm compared to a rate and how to engage an organization’s Board to understand and be able to participate in discussions regarding hospital-acquired conditions. Additionally, engagement of our frontline team members, our patients, and their families is needed for success. We need a common and simple operational language which everyone can understand and rally around.

Finally, Culture is important when evaluating why a quality improvement project has stalled or is not achieving the desired outcomes. Understanding your organizational Culture and ensuring its alignment with quality improvement efforts is compulsory, especially with stalled initiatives. Many times, Culture is not explicitly addressed and is evaded to avoid potentially difficult conversations. One must use the levers necessary to prioritize and highlight the role of Culture in quality improvement initiatives.

References

Institute of Medicine. To err is human: building a safer health system. Washington, DC: The National Academies Press; 2000. https://doi.org/10.17226/9728.

Institute for Healthcare Improvement. Boston, MA, 2019. http://www.ihi.org/. Accessed 30 Dec 2019.

Deming WE. The new economics for industry, government, education. 1st ed. Cambridge, MA: Massachusetts Institute of Technology, Center for Advanced Educational Services; 1994.

Langley GJ, Moen RD, Nolan KM, Nolan TW, Norman CL, Provost LP. The improvement guide. 2nd ed. San Francisco: Jossey-Bass Publishers; 2009.

Donabedian A. The quality of care: how can it be assessed? JAMA. 1988;260(23):1743–8.

Children’s Hospital Solutions for Patient Safety (CH-SPS). Cincinnati, OH. 2019. https://www.solutionsforpatientsafety.org/. Accessed 30 Dec 2019.

Ohno T, Bodek N. Toyota production system: beyond large scale. 1st ed. Portland: Productivity; 1988.

Toyota Production System Support Center (TSSC). 2019. http://www.tssc.com. Accessed 30 Dec 2019.

Baldrige Website. 2018. https://www.nist.gov/baldrige/publications/baldrige-excellence-framework/businessnonprofit. Accessed 30 Dec 2019.

Frankel A, Haraden C, Federico F, Lenoci-Edwards JA. Framework for safety, reliable, and effective care. White paper. Boston: Institute for Healthcare Improvement and Safe and Reliable Healthcare; 2017. p. 1–31. Available on IHI.org

Brilli RJ, McClead RE, Davis T, Stoverock L, Rayburn A, Berry JC. The preventable harm index: an effective motivator to facilitate the drive to zero. J Pediatr. 2010;157(4):681–3.

Nolan TW. Execution of strategic improvement initiatives to produce system-level results. IHI innovation series white paper. Cambridge, MA: Institute for Healthcare Improvement; 2007. Available on IHI.org

Weick KE, Sutcliffe KM. Managing the unexpected: sustained performance in a complex world. 3rd ed. Hoboken: Wiley; 2015.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Chapter Review Questions

Chapter Review Questions

-

1.

Describe how quality improvement strategies have evolved over past decades.

Answer: Initial quality improvement strategies focused on the low-hanging fruit, and, as improvements occurred, it became necessary to move to higher levels of sophistication and reliability. At present, organizations are on different parts of the quality journey, and, as such, their improvement strategies have differing levels of sophistication (Fig. 1.1 and 1.2).

-

2.

What is the difference between capacity building and capability building?

Answer: Capability building is the “ability,” or skill set, for improvement science. Capacity is the “time,” resources, or organizational ability, to improve. An individual may have capacity to lead improvement, but an improvement initiative will be stymied without capability.

-

3.

How does Culture influence quality improvement initiatives?

Answer: Culture drives improvement. Without attention to Culture, much improvement will be the result of the Hawthorne effect and will not be able to be sustained. The value of Culture development cannot be underestimated.

-

4.

What are the elements of the Donabedian quality triad?

Answer: Structure, Process, Outcome.

-

5.

How can an organization’s mission, vision, and values be used as levers for quality improvement?

Answer: It is crucial that staff appreciate and understand their role in quality and safety and how it aligns with the organization’s role. The mission, vision, and values help the frontline staff, manager, leader, and Board member connect their safety and quality work with organizational improvement efforts.

-

6.

How can patients and their families be incorporated into organizational quality improvement initiatives?

Answer: It is imperative to include the voice of the family and patient in organizational quality improvement. If we fail to include these stakeholders, then our work is not complete. It is quite easy to include patients and families by working with your Patient/Family Advisory Council, Volunteer Services, or other such liaisons in your organization.

-

7.

Describe the characteristics of the ideal system for continuous process improvement.

Answer: The purpose of this question is to get our readers to start thinking about the ideal system for continuous process improvement. The remaining chapters of this text provide further insights, and we will return to this very question throughout the text in the editor’s comments. For now, we will state that the ideal system for continuous process improvement understands this is difficult work that takes considerable organizational planning and foresight. Capability and capacity need to be built at the frontline level with significant senior leadership, and Board, commitment and visibility. The goal of this system is to develop processes and procedures that are clear, simple, and understandable and that occur reliably. The organizational culture needs to encourage bringing problems to the surface and, for the most part, local ownership of problem-solving.

-

8.

True or False: Healthcare systems are unique and complex, so few concepts from other industries are applicable to healthcare.

Answer: False. Healthcare has learned, and continues to learn, much from other industries. Specific examples are included throughout the chapter.

-

9.

Based on the discussions in this chapter, which of the following is important to carrying out a successful quality improvement project?

-

A.

Alignment with organizational goals and priorities.

-

B.

Inclusion of patients and/or their families.

-

C.

Assigned accountability and visible support of senior leadership.

-

D.

Supportive culture that permits transparency.

-

E.

All of the above.

Answer: E.

-

A.

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Godambe, S.A., Shah, R.K. (2021). Introduction: A Case-Based Approach to Quality Improvement. In: Shah, R.K., Godambe, S.A. (eds) Patient Safety and Quality Improvement in Healthcare. Springer, Cham. https://doi.org/10.1007/978-3-030-55829-1_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-55829-1_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-55828-4

Online ISBN: 978-3-030-55829-1

eBook Packages: MedicineMedicine (R0)