Abstract

TEM characterization of the deformation micromechanisms in the case of AD730TM disk superalloy has been performed in order to identify the relevant parameters controlling its creep behavior at 700 °C under 600 or 850 MPa. The creep behavior has been investigated for different microstructures resulting from different heat treatments: a coarse grain (CG) and a fine grain microstructures (FG). The specific influence of the primary γ′ precipitates, which are only present in the fine grain microstructure, is of main focus. TEM observations indicate that, in the first stage of the creep deformation, primary γ′ precipitates may act as dislocation sources. The stability of this phase was confirmed using samples aged at 850 °C for several hundreds of hours. TEM spectroscopy has been used to characterize the local chemical composition after aging. A clear evolution of these primary γ′ precipitates has been evidenced and a dissolution of the secondary γ′ precipitates during aging. The presence of these primary γ′ precipitates induces a strong localization of the deformation. Its detrimental effect on the creep properties in the case of polycrystalline Ni-based superalloy at high temperature may be concluded.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

The enhancement of efficiency in gas turbines requires the design of new superalloys capable of withstanding higher temperature with a reasonable cost. In this context, the superalloy AD730TM has been developed by Aubert & Duval to be a cost-effective superalloy for high temperature (up to 700 °C) rotating components. Its development was based on thermodynamical calculations made for similar alloys (Udimet 720Li, René 88DT), as the design of new superalloys often relies on incremental changes in compositions of existing alloys [1,2,3,4]. As the γ/γ′ Ni-based superalloys are designed for aeronautic applications, efforts have been made to give a better understanding of their behavior during actual service conditions. It is well known that, in the case of polycrystalline Ni-based superalloys, the thermo-mechanical treatments and service conditions may be at the origin of microstructure evolutions which are essential to be identified, as the mechanical properties are highly dependent on microstructural parameters. The effect of the microstructure on the creep behavior, and more generally, on strengthening mechanisms, has been extensively studied in the case of Udimet 720Li and René 88DT superalloys, as well on other similar polycrystalline superalloys such as N18 and NR3 [3, 5,6,7,8,9,10,11,12,13,14]. These papers have pointed out that γ′ precipitation is the main creep controlling parameter of this type of superalloys in the temperature range 650–800 °C. Due to its recent development, the creep deformation micromechanisms in the range 600–850 MPa at 700 °C and the microstructural stability after heat treatment at higher temperature, in the case of the AD730TM nickel-based superalloy, have not been widely studied. Recent work carried out on this superalloy has pointed out the increase of the ductility and the decrease of the time to failure during creep at 600 MPa/700 °C or 850 MPa/700 °C in a fine grain microstructure superalloy in comparison with a coarse grain microstructure [14, 15]. The major difference between both microstructures is the presence of primary γ′ precipitates in the fine grain microstructure. These primary γ′ precipitates are usually considered as a stable phase and not considered to be key in controlling the creep deformation mechanisms, their usefulness being to keep a fine grain size during forging operations and subsequent sub-solvus heat treatments. This paper is aimed at analyzing the influence of these primary γ′ precipitates on the creep deformation mechanisms at 700 °C and to check the stability of these primary γ′ precipitates using transmission electron microscopy (TEM) characterization.

Experimental

The chemical composition of the material studied is given in Table 1 and is compared to the reference disk superalloys Udimet 720Li (U720Li) and INCONEL 718 plus (718Plus).

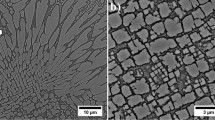

AD730TM classical microstructure consists of γ′-particles embedded in a γ-matrix phase, which exist in this alloy as primary γ′ (size typically in the 1–10 μm range) present mainly at grain boundaries and secondary γ′ (size in the 50–500 nm range) or occasionally very fine tertiary γ′ (size < 50 nm) both present within the grains. The primary γ′ particles are formed during the solidification of the ingot (actually, during cooling from ingot homogenization) and kept during forging operations. The presence of primary, secondary, and tertiary γ′ particles depends on the solution heat treatment. When the samples are sub-solvus solution heat-treated at 1080 °C for 4 h, cooled in air (cooling rate of ~ 100 °C/min) and then heated at 730 °C for 8 h, a fine grain microstructure (FG) is obtained. The grain size is around 10 μm. When the samples are super-solvus solution heat-treated (in accordance with the sequence developed by D. Locq at ONERA [16]) at 1120 °C for 2 h, cooled in air, then heat-treated at 1080 °C for 4 h, cooled in air and finally heated at 760 °C for 16 h, the specimen exhibits a coarse grain microstructure (CG). The primary γ′ particles are present only in the case of sub-solvus heat treatment, i.e., for the fine grain microstructure (FG). For simplicity, the investigated samples will be noted in the following as FG and CG for fine grain and coarse grain references, respectively.

The samples have been creep tested using cylindrical specimens having a 4.5 mm gauge diameter and a 14 mm gauge length. Before creep tests, specimens were mechanically polished up to a 4000 grade SiC paper (final polishing parallel to the loading axis) to remove machining scratches as well as the surface deformed layer due to machining. Tensile creep tests were performed under constant load at 700 °C with a ±1 °C temperature accuracy. After heating, a 3 h soak time at maximum temperature was used to homogenize the temperature within the specimens, grips, and creep frame before applying the load. Strain measurements were performed thanks to Linear Variable Displacement Transducer (LVDT) following the relative displacement of specimen heads. Different interrupted creep tests have been performed in order to make the observation of dislocations easier and to analyze the deformation micromechanisms for different creep deformation strains. The creep tests were interrupted by cooling down the specimen to room temperature under load, in less than 2 h. Two creep conditions were used: 700 °C/600 MPa and 700 °C/850 MPa.

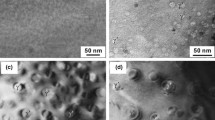

In order to investigate the effect of aging on primary γ′ particles in the FG microstructure, some specimens were previously aged at 850 °C for 100 h prior to similar creep tests and other ones have been aged for 350 h at 850 °C under 50 MPa in order to investigate the effect of the aging duration at 850 °C.

The TEM foils were extracted from foils cut normally to the tensile axis and prepared using standard preparation techniques (mechanical polishing and twin-jet electropolishing).

TEM conventional experiments were done using a JEM2010 transmission electron microscope operating at 200 kV. These conventional TEM observations have been used to identify the deformation micromechanisms. The characterization of the dislocations has been undertaken using TEM using two-beam conditions (and sometimes using weak beam conditions). The Burgers vectors of the dislocations have been determined using the familiar criteria for dislocation invisibility. Energy Dispersive X-Ray Spectroscopy (EDXS) analyses have been performed on a CM20FEG TEM equipped with a Brüker SDD detector.

Results and Discussion

TEM observations after interrupted creep tests have been performed for all specimens. In the FG or the CG microstructures, the observed intragranular deformation micromechanisms are similar. The observed deformation mechanisms are in agreement with the usual mechanisms observed in similar polycrystalline Ni-based superalloys [4,5,6,7,8,9,10,11,12,13]. They consist of coupled perfect dislocations, with numerous rather straight segments indicating the occurrence of precipitate shearing by perfect a/2 <110> dislocations as illustrated in Fig. 1a. Bright field imaging is used in this case in order to obtain an overview of the dislocations. Using this diffraction condition, the tertiary precipitates are not well imaged. Some large secondary precipitates are observed with a size ranging from 300 to 400 nm. Another typical mechanism observed in the CG specimen is illustrated in Fig. 1b. The observed fault and Shockley a/6 <112> dislocations are in agreement with the mechanism proposed by Condat and Décamps [15].

TEM observations in the CG specimen after interrupted test at 700 °C/600 MPa and 0.15% creep strain. a Coupled perfect dislocations are observed, b faults and partial dislocations are observed in accordance with the Condat and Decamps mechanism [15]

Similar deformation mechanisms involving perfect a/2 <110> or partial a/6 <112> dislocations are observed in the FG specimen as illustrated in Fig. 2a, b. These TEM micrographs correspond to a whole fine grain. These observations are carried out in a specimen after interrupted creep test at 850 MPa and 0.6% strain. These experimental conditions explain the higher density of dislocations in comparison with the previous observations. Nevertheless, the creep deformation mechanisms observed within the grains are the same in terms of dislocation characteristics. It is worth mentioning that a primary precipitate is observed in the middle of the grain (cf. Fig. 2a) and is encircled by dislocations.

Other examples of deformation mechanisms observed after creep testing at 700 °C/600 MPa in the CG and FG microstructure are presented in Fig. 3a, b. Here, perfect dislocations are observed. The prevalent mechanism is precipitate by-passing revealed by the presence of numerous curved dislocation segments. It is worth mentioning, that similar characteristics have been observed after creep tests at 700 °C/850 MPa for both specimens. The density of dislocations observed after creep testing at 850 MPa for similar strain is higher than after test at 600 MPa.

To summarize all these experimental results, the creep controlling deformation mechanisms involve perfect and partial dislocations. Both γ′ precipitate shearing and γ′ precipitate by-passing are observed. The only difference between the CG and the FG microstructures relies on the presence of the primary precipitates. The comparison between the CG and the FG microstructures suggests that the increase of the ductility during creep at 600 MPa/700 °C or 850 MPa/700 °C for the FG microstructure is attributed to these primary precipitates. This hypothesis may be confirmed by the observations illustrated in Figs. 4 and 5. Some primary γ′-precipitates are observed after creep tests interrupted at different deformation strain. In the case of interrupted creep test at 0.2% strain, some dislocations are present within the primary γ′-precipitates (see Fig. 4a). In some cases (see Fig. 4b) dislocations are located around the primary γ′-precipitates. These dislocations are clearly emitted from this γ′-precipitate. When the strain is increased, the primary γ′-precipitates are full of dislocations, indicating a strong localization of the plasticity as illustrated in Fig. 5.

TEM observations after interrupted test at 700 °C/600 MPa and 0.2% deformation strain in the FG specimen. a General overview, note the absence of dislocations out of to the primary precipitate, b observation of another primary γ′ precipitate. Some dislocations are observed around the precipitate and appear to be emitted from it

The comparison between the FG creep tested from 0.2% to 9% strain specimens (from Figs. 4 and 5) leads to the following scenario: When the strain increases, an increase in the dislocation density has been observed within the primary precipitates. When the primary precipitates begin to be saturated with dislocations, the dislocations are emitted within the grain, so that intragranular deformation may occur (see Fig. 4b). This results in a strong localization of the plasticity (see Fig. 5), which could be detrimental for the creep resistance.

As these primary precipitates appear to strongly influence the creep properties, the stability of these particles has been particularly investigated. In order to enhance the high-temperature effect, the temperature of 850 °C has been chosen for (over-)aging. TEM observations of the primary γ′ precipitates are presented in Fig. 6. In the aged specimen, the nucleation of small particles (with a size around 20 nm after 850 °C for 350 h) is visible inside these precipitates (Fig. 6). Such precipitation has been already mentioned in the literature in other similar polycrystalline superalloys [5, 17–19]. A chemical composition similar to the γ-phase has been revealed using TEM EDX spectroscopy (not shown in this chapter). This local chemical composition deviates from the stoichiometric composition expected for an L12 ordered structure. This structural evolution indicates a possible increase in the capability for these primary phases to develop plasticity. In addition, in the FG-350 h specimen, some areas where no secondary γ′ precipitates are observed in the vicinity of primary precipitates. The absence of all the γ′-partitioning elements in such area has been pointed out using TEM EDX experiments, as an evidence of the γ′-phase dissolution. This dissolution may offer large γ-channels for the propagation of dislocations.

As the nucleation of the dislocations is observed to occur very often within/from the primary γ′ precipitates, the heterogeneous distribution of the dislocations illustrated in Fig. 7 suggests the following conclusions: The dislocations are emitted from the primary γ′ precipitates within the grain. Due to the dissolution of some secondary γ′-precipitates the propagation of the dislocations is easy. When these dislocations enter again the areas where some γ′ secondary precipitates are present, their propagation seems to be impeded. This leads to a strong localization of the deformation. It is important to note that straight dislocations are observed in the primary precipitates (as illustrated in Fig. 4a). These dislocations may result from the forging sequence prior to the creep test. These dislocations may contribute to the activation of mobile dislocations during creep.

Conclusions

The TEM characterizations of specimens of AD730TM Ni-based superalloy have revealed the influence of the primary γ′-precipitates in the first stages of the creep deformation mechanisms at 700 °C/600 MPa or 700 °C/850 MPa. These primary precipitates act as dislocation sources. Their presence may be correlated to the increase in the creep strain rate in the fine grain microstructure containing these primary precipitates in comparison with the coarse grain microstructure in the dislocation creep domain. Then, a strong microstructural evolution after aging at 850 °C has been observed with the precipitation of near-γ-phase within the primary precipitates. The dissolution of secondary γ′-precipitates close to primary particles has been observed. All these microstructural features induce a strong evolution in the distribution of the dislocations. It results in a strong localization of the deformation, which should influence the creep properties of such polycrystalline Ni-based superalloys at high temperature. As a summary, it is shown that primary particles are key in controlling the creep strain rate since they serve as dislocation sources and are not stable at high temperature.

References

Jackson MP, Reed RC (1999) Heat treatment of UDIMET 720Li: the effect of microstructure on properties. Mater Sci Eng A 259 (1): 85–97. https://doi.org/10.1016/s0921-5093(98)00867-3.

Devaux A, Picqué B, Gervais MF, Georges E, Poulain T, Heritier P (2012) AD730 TM - A new nickel-based superalloy for high temperature engine rotative parts. Superalloys 2012 911–919. https://doi.org/10.1002/9781118516430.ch100.

Devaux A, Helstroffer A, Cormier J, Villechaise P, Douin J, Hantcherli M, Pettinari-Sturmel F (2014) Effect of aging heat-treatment on mechanical properties of AD730TM superalloy. 8th Int Symp Superalloy 718 Deriv 521–535. https://doi.org/10.1002/9781119016854.ch41.

Devaux A, Berglin L, Thebaud L, Delattre R, Crozet C, Nodin O. (2014) Mechanical properties and development of supersolvus heat treated new nickel base superalloy AD730 TM. MATEC Web Conf 14 01004. https://doi.org/10.1051/matecconf/20141401004.

Flageolet B (2005) Effets du vieillissement du superalliage base nickel pour disques de turbines N18 sur sa durabilité en fatigue et en fatigue-fluage à 700°C. Ph.D Thesis, Poitiers University.

Billot T (2010) Comportement et endommagement en fatigue et fatigue-fluage à haute température de différents états microstructuraux du superalliage base-nickel Udimet 720, PhD Thesis, Poitiers University.

Raujol S, Pettinari F, Locq D, Caron P, Coujou A, Clement N (2004) Creep straining micro-mechanisms in a powder-metallurgical nickel-based superalloy. Mater Sci Eng A 387–389 678–682. https://doi.org/10.1016/j.msea.2004.02.091.

Viswanathan GB, Sarosi PM, Henry MF, Whitis DD, Milligan W.W, Mills M.J (2005) Investigation of creep deformation mechanisms at intermediate temperatures in René 88 DT. Acta Mater 53 (10): 3041–3057. https://doi.org/10.1016/j.actamat.2005.03.017.

Kozar RW, Suzuki A, Milligan WW, Schirra J.J, Savage M. F, Pollock T. M (2009) Strengthening Mechanisms in Polycrystalline Multimodal Nickel-Base Superalloys. Metall Mater Trans A 40 (7): 1588–1603. https://doi.org/10.1007/s11661-009-9858-5.

Hoffelner W, Kny LE, Stickler R, McCall WJ (1979) Effects of aging treatments on the Microstructure of the Ni-base superalloy IN-738. Materwiss Werksttech 10 (3): 84–92. https://doi.org/10.1002/mawe.19790100307.

Wlodek ST, Kelly M, Alden DA (1996) The Structure of Rene’ 88DT. Superalloys 1996 (Eighth Int Symp 129–136. https://doi.org/10.7449/1996/superalloys_1996_129_136.

Giraud R, Hervier Z, Cormier J, Saint-Martin G, Hamon F, Milhet X, Mendez J (2013) Strain effect on the γ′ dissolution at high temperatures of a nickel-based single crystal superalloy. Metall Mater Trans A Phys Metall Mater Sci 44 (1): 131–146. https://doi.org/10.1007/s11661-012-1397-9.

Shahriari D, Sadeghi MH, Akbarzadeh A (2009) γ’ Precipitate dissolution during heat treatment of nimonic 115 superalloy. Mater Manuf Process 24 (5): 559–563. https://doi.org/10.1080/10426910902746820.

Masoumi F, Jahazi M, Shahriari D, Cormier J (2016) Coarsening and dissolution of γ′ precipitates during solution treatment of AD730TM Ni-based superalloy: Mechanisms and kinetics models. J Alloys Compd 658 981–995. https://doi.org/10.1016/j.jallcom.2015.11.002.

Décamps B, Morton AJ, Condat M (1991) On the mechanism of shear of γ′ precipitates by single (a/2) ⟨110⟩ dissociated matrix dislocations in Ni-based superalloys. Philos Mag A 64 (October 2014): 37–41. https://doi.org/10.1080/01418619108204866.

Locq D (2014) Etude du superalliage C&W A&D AD730. Rapport Interne - ONERA

Oblak JM, Doherty JE, Giamei AF, Kear BH (1974) Met Trans (5):1252–1255. https://doi.org/10.1007/BF026444342

Cadel E, Lemarchand D, Chambreland S, Blavette D (2002) Acta Mat 5(5):957–966. https://doi.org/10.1016/S1359-6454(01)00395-0

Laurence (2016) Ph.D. thesis, Ecole Nationale Supérieure de Mécanique et Aérotechnique – France

Thébaud L (2017) Ph.D. thesis, Universié de Poitiers, France

Vultos W (2019) Ph.D. thesis, Université de Toulouse, France

Acknowledgements

Authors are grateful to Aubert & Duval—Group Eramet, and more specifically Dr. Alexandre Devaux, for providing the material and for stimulating discussions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Pettinari-Sturmel, F. et al. (2020). Contribution of Primary γ′ Precipitates in the Deformation Creep Mechanisms in the Ni-Based Polycrystalline AD730TM Superalloy. In: Tin, S., et al. Superalloys 2020. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-51834-9_59

Download citation

DOI: https://doi.org/10.1007/978-3-030-51834-9_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-51833-2

Online ISBN: 978-3-030-51834-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)