Abstract

This paper presents an investigation into the mechanical properties of bitumen and asphalt mixture modified with polymer additives. Two polymer additives used in the study are SBS (Styrene-Butadiene-Styrene) and EVA (Ethylene-Vinyl Acetate). Penetration test, softening point test and elastic recovery test were performed on the base bitumen and the SBS polymer modified bitumen with different additive contents. In addition, the complex modulus tests were conducted in order to characterize the linear viscoelastic behaviour of the base bitumen, SBS polymer modified bitumen and the EVA modified asphalt mixture. The experimental results showed that the polymer modification improved the hardness and the elastic recovery of bitumen. The extent of the improvements varied as a function of polymer content. The changes in the complex modulus (both norm and phase angle) of polymer modified bitumen and asphalt mixture were observed. The Time Temperature Superposition Principle (TTSP) was shown to be applicable for the complex modulus of the base bitumen. But the polymer modified bitumen and asphalt mixture respected only the Partial Time-Temperature Superposition Principle (PTTSP). The PTTSP was also verified for the complex Poisson’s ratio of an EVA modified asphalt mixture. Despite the changes in the rheological properties, the shift factors used to build the complex modulus master curves of both original and polymer modified bitumen were very similar.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Polymer modification

- Bitumen

- Asphalt mixture

- Complex modulus

- Partial time-temperature superposition principle

- Complex Poisson’s ratio

1 Introduction

Following the rapid development, increased traffic loading and traffic volumes require higher quality and sustainable pavements. In order to enhance the mechanical properties and the long term behaviour of asphalt pavements, the polymer additives are often used to modify asphalt binders (and thereby the asphalt mixtures) by mechanical mixing or chemical reaction. It is well known that the pure bitumen is a viscous and temperature sensitive material. Many authors have shown that the viscoelastic behaviour of bituminous binders and the bituminous mixtures respects the Time Temperature Superposition Principle (TTSP) [1, 2]. Polymer modification of bitumen was reported to improve the properties of bitumen, such as higher fatigue and cracking resistance, higher stiffness at high temperatures… [3, 4]. In this paper, the mechanical properties of some bitumen and asphalt mixtures modified with SBS (Styrene-Butadiene-Styrene) and EVA (Ethylene-Vinyl Acetate) are investigated. The main research objective is to study if the TTSP can be applied for the polymer modified bitumen (PMB) and mixtures and how the linear viscoelastic behaviour changes from original bitumen to the PMB.

2 Materials and Experimental Program

The tested materials and experimental program are presented in Table 1. Two original bitumen of 60/70 penetration grade, called B1 and B2, were used in this study. The B1 and B2 were then mixed with SBS at different contents (see Table 1) to produce the PMB. An asphalt mixture dosed at 5.6% EVA modified bitumen by weight of aggregates was also tested.

The penetration, softening point, elastic recovery and complex modulus test were performed on the original bitumen and the PMB. The complex modulus tests were conducted at different temperatures and frequencies to characterise the linear viscoelastic behaviour of binders and mixture. The Dynamic Shear Rheometer (DSR) was used to perform the complex modulus tests on B2 and B2 + SBS. The complex modulus tests on B1 and B1 + SBS were carried out by the Metravib’s DMA (Dynamic Mechanical Analyzer) [5]. The test using DSR measures the shear complex modulus G* and one with Metravib’s DMA measures the complex modulus E* (with hypothesis E* = 3G* at high temperature) of bitumen. It should be noted that the complex modulus test on asphalt mixture is set up to obtain two parameters: E* and the complex Poisson’s ratio ν* [1, 2, 6].

3 Test Results and Analysis

The results of the penetration, softening point, elastic recovery tests on B2 and B2 + SBS were presented in Fig. 1. It can be seen that the SBS modification improved the hardness and the elastic recovery of bitumen. The penetration decreases, the softening point and the elastic recovery increase with the increase of the SBS content.

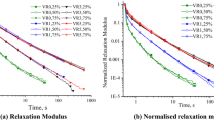

Figure 2 presents the master curves of |E*| and |G*| (norm of complex modulus) at the reference temperature Tref = 45 °C. The experimental results on both original bitumen B1 and B2 show that the SBS modification enhances the complex modulus of bitumen at high temperature/low frequency. But at low temperature/high frequency, the difference in modulus between B2 and B2 + SBS is not clearly observed. The complex modulus of B1 is even higher than one of B1 + SBS. In the case of phase angle (Fig. 3a), the experimental result shows a decrease in phase angle from original bitumen (B1) to PMB (B1 + SBS) at high temperature. The shift factor aT used to build the master curves of complex modulus (both norm and phase angle) is presented in Fig. 3b. It can be seen that the shift factor is very close for each group: B1 and B1 + SBS, B2 and B2 + SBS. It means that the SBS modification affects the complex modulus but does not have influence on the shift factor aT of the original bitumen. So the thermal sensibility which is characterised by the shift factor is kept from original bitumen to PMB.

Figure 4 presents the results of complex modulus tests on B1 + SBS and EVA asphalt mixture in Cole-Cole diagram. It is found that the isotherms of E* in Cole-Cole diagram do not form a unique curve but make some “commas”. It means that the polymer modification has effects on the rheology properties of bitumen and especially for asphalt mixture. The TTSP is not validated for PMB and asphalt mixture using the EVA modified bitumen. However, the results in Fig. 2 and 5a show that the master curves of PBM and asphalt mixture can be still plotted and observed. We call that the Partial Time-Temperature Superposition Principle (PTTSP). The polymer modified bitumen and asphalt mixture respected only the PTTSP. When the bituminous materials are thermo-rheologically simple, two master curves (both |E*| and the phase angle) can be plotted. The term “Partial” means the material is not thermo-rheologically simple but we can still plot and obtain only one smooth master curve for this material: the master curve of |E*|. The commas appear in the master curves of the phase angle that does not allow observing a smooth master curve of phase angle (Fig. 3a).

The results of ν* of asphalt mixture were presented in Fig. 5a (the master curve of norm of ν*) and Fig. 5b (Cole-Cole diagram). It is interesting that the complex Poisson’s ratio varies from 0.25 to 0.5 as a function of the reduced frequency (Fig. 5a). The master curve of ν* is obtained using the same shift factors aT that has been used for the E* master curve of asphalt mixture. It is observed that the “commas” are formed in Cole-Cole diagram of ν*. The ν* is also effected by the polymer modification and respected only the PTTSP.

4 Conclusions

From the presented experimental study and analysis, the following conclusions can be drawn:

-

Increasing the SBS content in the PMB enhances the hardness and the elastic recovery of bitumen such as: decrease of the penetration and the phase angle at high temperature; increase of the softening point, the elastic recovery and the complex modulus at high temperature. At low temperature, effect of SBS modification on the complex modulus is not clearly observed.

-

The TTSP and PTTSP are verified for the original bitumen and PBM respectively. The master curve can be plotted for the norm E* and ν* of EVA modified asphalt mixture but the EVA asphalt mixture respects only the PTTSP.

-

The shift factors aT used to build the complex modulus master curves of original and polymer modified bitumen were close together.

References

Perraton, D., Di Benedetto, H., Sauzéat, C., Hofko, B., Graziani, A., Nguyen, Q.T., Pouget, S., Lily Poulikakos, D., Tapsoba, N., Grenfell, J.: 3Dim experimental investigation of linear viscoelastic properties of bituminous mixtures. Mater. Struct. 49(11), 4813–4829 (2016)

Nguyen, Q.T., Di Benedetto, H., Sauzéat, C, Nguyen, M.L., Hoang, T.T.N.: 3D complex modulus tests on bituminous mixture with sinusoidal loadings in tension and/or compression. Mater. Struct. 50(1) (2017)

Isacsson, U., Zeng, H.: Low-temperature cracking of polymer-modified asphalt. Mater. Struct. 31(1), 58–63 (1998)

Alataş, T., Yilmaz, M.: Effects of different polymers on mechanical properties of bituminous binders and hot mixtures. Constr. Build. Mater. 42, 161–167 (2013)

Nguyen, Q.T., Nguyen, M.L., Di Benedetto, H., Sauzéat, C., Chailleux, E., Hoang, T.T.N.: Nonlinearity of bituminous materials for small amplitude cyclic loadings. Road Mater. Pavement Design 20(7), 1571–1585 (2019)

Perraton, D., Di Benedetto, H., Sauzéat, C., Nguyen, Q.T., Pouget, S.: Three-dimensional linear viscoelastic properties of two bituminous mixtures made with the same binder. J. Mater. Civ. Eng. 30(11) (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Nguyen, Q.T. et al. (2022). Mechanical Properties of Bitumen and Asphalt Mixture Modified with Polymer Additives. In: Di Benedetto, H., Baaj, H., Chailleux, E., Tebaldi, G., Sauzéat, C., Mangiafico, S. (eds) Proceedings of the RILEM International Symposium on Bituminous Materials. ISBM 2020. RILEM Bookseries, vol 27. Springer, Cham. https://doi.org/10.1007/978-3-030-46455-4_168

Download citation

DOI: https://doi.org/10.1007/978-3-030-46455-4_168

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-46454-7

Online ISBN: 978-3-030-46455-4

eBook Packages: EngineeringEngineering (R0)