Abstract

Fresh Market Wastewater (FMWW) is rich with high amounts of suspended solids, organic and inorganic compounds, nutrients, gases and some elements which come from fish entrails and seafood preparation sales, meat cutting, poultry slaughtering, fruits and vegetables sales. The excess of these parameters are harmful to the aquatic life since the FMWW is usually discharged into the drainage systems without any treatment or partial treatment. The FMWW technologies are developed due to some technical factors influencing the designation and construction. There are several projects of fresh market treatment technologies used on site area in small scale which could be replicated to other fresh market, and some case study have been tested in laboratory batch experiments. All the projects exhibited an efficiency to reduce critical parameters in FMWW and give positive impacts to the locals and responsible parties.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

The origin of fresh market is rooted in periodic marketing (typically for a few hours in the morning once every three to five days). Fresh market is the public market for locals to get their fresh foodstuffs such as vegetables, fruits, fish, seafood, chicken and meat. Fresh market has regular customers and is well known as a supplier of good quality raw food. The sellers did not use frozen method for their foodstuff. The customers can bargain with the sellers and compare with the supermarket which has fixed price and usually, the price at fresh market is still affordable (Sze-ki 2008). Unfortunately, the fresh market wastewater (FMWW) generated from fish entrails and seafood preparation sales, meat cutting, poultry slaughtering, fruits and vegetables sales affects negatively on the aquatic life and human health due to the improper disposal into the environment (Zulkifli et al. 2012; Godos et al. 2012). The removal of organic compounds and nutrients is the major requirement during the treatment process of FMWW to meet the acceptable limit before the final discharge to the environment and natural water systems (Jais et al. 2016; Apandi et al. 2019). The current chapter reviewed the advantages and disadvantages of the different FMWW treatment technologies.

4.2 Fresh Market Wastewater Composition and Characteristics

The fresh market wastewater contains suspended solids, organic and inorganic compounds, nutrients, gases and some elements in the wastewater (Apandi et al. 2018). The suspended solids are divided into non-filterable/suspended either settleable or non-settleable and filterable (colloidal or dissolved). The suspended solids in FMWW could increase the turbidity which prevents the light penetration and causes the fish’s gills to get plugged up. The silting decreased the depth of river or lake. Moreover, it reduces the lifetime of lakes and blocks the fish to free swim into deeper area. The organic compound such as biodegradable organic which consists of Oil and Grease (O&G), protein increase Biochemical Oxygen Demand (BOD) and blocking oxygen in atmosphere to enter the water (Maizatul et al. 2017). The pollution by fat traps the trash and other materials causing odour, attracting flies and mosquitoes that come out with other disease vectors. The surfactants in fresh market wastewater are refractory organics that come from detergent which had been used for floor cleaning (Zulkifli et al. 2012; Apandi et al. 2017; Jais et al. 2018).

Nutrients are inorganic compounds and are divided into dissolved inorganics (calcium, sodium and sulphate) and nutrients (nitrogen and phosphorus). These compounds are coming from the fresh food itself, the preservatives to maintain the freshness of the fresh food and from water usage. The nutrients are harmful to aquatic life causing the algal blooms and eutrophication. The gases such as nitrogen, oxygen, carbon dioxide and ammonia can be toxic to humans and aquatic life. The elements such as zinc (Zn2+) and iron (Fe2+) from fresh food even in small quantities can be toxic and hazardous to fish and plant in the river or lake where the wastewater flows to the drainage and flows into the river or lake without treatment (Jais et al. 2015, 2016).

The compounds in several FMWW samples investigated in the literature are illustrated in Table 4.1. Zulkifli et al. (2012) and Jais et al. (2015) revealed that the values of Total Suspended Solids (TSS) were between 60 and 900 mg/L which is higher compared to the standard (50–100 mg/L). BOD ranged from 68 to 293 mg/L, while Chemical Oxygen Demand (COD) ranged from 381 to 1440 mg/L which exceeded the permissible standard (20–50 mg/L and 50–100 mg/L, respectively). Moreover, the O&G is available in the range of 5.2–72 mg/L. The Total Nitrogen (TN) was in the range of 36.9–72.9 mg/L while phosphate (PO4) was ranged from 1.61 to 44.5 mg/L.

4.3 Technical Factors Influencing Designation of the Treatment System

The factors which need to be considered to design and implement the treatment systems for FMWW include fresh market wastewater content, volume, space area availability, compliance with the environmental standards and regulation on the country as well as compliance with engineering standards for design and construction. The fresh market wastewater usually contains solid wastes and liquid wastes as well as O&G. Therefore, the pretreatment is needed for separating the solids particles and wastewater (Shahbuddin et al. 2018). Fresh market produces huge amount of wastewater quantities since the daily operation of fresh market. Some of fresh markets operating half-day from early morning to afternoon (7 am to 1 pm), while some from early morning to evening (7 am to 6 pm). The estimation of wastewater volume produced per stall per day is 30 litres. The designation of treatment system needs to be sized according to the expected volume of wastewater. The retention time also needs to be considered to ensure the process of wastewater treatment works effectively (Jais et al. 2016). The space area around the fresh market is needed to implement the treatment system. The dimensions of the structure must be suited to the available space (Karia and Christian 2006). Moreover, the effluent or sludge quality must meet the relevant environmental standards before final disposal into the rivers or lakes (Karia and Christian 2006; Jais et al. 2016). On the other hand, the system should be designed and constructed according to the engineering standard, for example the concrete strength and suitable maintenance (Karia and Christian 2006).

4.4 Fresh Wastewater Treatment System

The wastewater treatment system is designed under several stages which are preliminary treatment system, primary treatment system, secondary treatment system and tertiary or advanced treatment system. Preliminary treatment system is a method to remove large inorganic particulate contents of wastewater or floating materials that disturb the operation in primary and secondary treatment of wastewater. The preliminary treatment system includes bar screen for screening large floating materials while grit chamber for heavy suspended solids. Some of the preliminary treatment systems have skimming tank to trap oil and grease which is suitable for fresh market wastewater. The primary treatment system aims for the separation of solids through sedimentation or settling process in sedimentation tank. The wastewaters are left in the tank for several hours to allow the particles to settle at the bottom of the tank. The settleable suspended solids which are called as sludge are then removed or drawn from the tank. This sludge may reduce 60–70 % of fine settleable suspended solids which include about 30–32 % of organic suspended solids (Karia and Christian 2006).

After primary treatment, the biological treatment known as a secondary treatment system is needed to remove colloidal and soluble organic matter present in wastewater. Biological process is employed in this stage. The activated sludge process (an aeration basin with return sludge activity) or trickling filter (a basin with fixed-filter media filter) and secondary settling tank take place in this stage. During the process, the aerobic microorganism needs oxygen to absorb the organic matter from wastewater. Other biological treatments provided for secondary treatment system to cater specific needs are waste stabilization ponds (also known as oxidation ponds), oxidation lagoons (aerated lagoons), oxidation ditches (extended aeration system), Rotating Biological Contractor (RBC), Up-flow Anaerobic Filter (UAF) and Up-flow Anaerobic Sludge Blanket (UASB) (Karia and Christian 2006).

The tertiary or advanced treatment system is needed if the effluent quality of secondary treatment system is unsuitable for final disposal requirement into the rivers or lakes. The tertiary treatment usually focused on the removal of microorganisms, nutrients, elements and gases. The different techniques can be used for tertiary treatment as in Table 4.2.

4.5 Type of Treatment Technologies

The selection of treatment system is depending on the pollution level and level of treatment required to bring the raw wastewater quality to the permissible level of treated wastewater which is safe for disposal or acceptable for specific reuse and recycling. Nowadays, there are three types of treatment technologies suitable for fresh market wastewater which are anaerobic pond, Up-flow Anaerobic Sludge Blanket (UASB) and anaerobic reactor.

4.5.1 Treatment Technologies Implemented on Site Area

There are several treatment technology projects related to fresh market wastewater implemented on site area which are located at

-

(a)

Five fresh markets in Kuala Lumpur, Malaysia (Pasar Harian Selayang, Pasar Borong KL, Pasar Jalan Klang Lama, Pasar Air Panas and Pasar Sentul)

-

(b)

Muntinlupa City Public Market, Muntinlupa City, Metro Manila, Philippines

-

(c)

San Fernando Public Market, San Fernando Cist, La Union, Philippines

-

(d)

Santa Ana Public Market, Manila City, Metro Manila, Philippines.

In Malaysia in 2016, the Department of Civil Engineering and Urban Transportation implemented five wastewater treatments in fresh market in Kuala Lumpur. The sources of wastewater discharge are from wet market activities, discharge from food stalls within the market vicinity and cleaning the market daily after operations. The project locations are Pasar Harian Selayang, Pasar Borong KL, Pasar Jalan Klang Lama, Pasar Air Panas and Pasar Sentul while the receiving rivers of wastewater are Jinjang River (Pasar Harian Selayang and Pasar Borong KL), Klang River, Bunus River and Gombak River, respectively (KLCH 2016).

The membrane biofilter was chosen for the fresh market wastewater. The processes of water treatment plants are demonstrated in Fig. 4.1.

Raw fresh market wastewater flows into the intake sump. In this stage, the wastewater flows to the coarse and fine screen to prevent rubbish and debris to enter the sump. There are three submersible pumps for duty and standby. The basin depth is 5.0 m which is controlled by ultrasonic level sensor. From inlet sump, the wastewater will flow into inline macerator to grind large solids into small particles with size 4–5 mm. Next, the fresh market wastewater flows to rotating drum screen to screen the small particles with the size of 0.5 mm before flowing into oil and grease removal tank. The purpose of this tank is to remove floating free oil with the disposal of oil and grease had been recycled for fuel oil by licensed contractor registered with Department of Environment Malaysia. The stabilizing basin is vital to store effluent with supplied oxygen. The three submersible pumps were used, and the basin depth was controlled by ultrasonic level sensor with maximum depth of 3.5 m with hydraulic retention time of three to four hours to homogenize the pollutant loading. The diffuser membrane material by Ethylene–Propylene–Diene Monomer (EPDM) was used with 1–3 mm bubble size, and air flow rate is 5–8 m3/h. The fresh market wastewater from stabilizing basin will flow into aeration basin. This basin is important to remove suspended solid, COD and BOD with the presence of bubble diffuser to increase biological oxidation process. The oxidized effluent will decant into membrane biofilter basin by outlet opening. The basin depth is 3.5 m with hydraulic retention time of four to five hours and rate of aeration is 12.5 m3/min.

The next process is wastewater flow into membrane bioreactor basin. The set packages of membrane bioreactor are used in this stage with hooked up to the permeate suction pipe plastic hose, and the water sucked is through the membrane in membrane bioreactor by permeate pump. Three self-priming pumps/trains were used for duty or standby in this stage. Next, the wastewater is re-supplied to the bottom membrane bioreactor through diffuser located underneath the membrane bioreactor package. The air bubble blows through membrane and loosen the dirt with drop down which accumulates as sludge. The membrane material is high-density polyethylene with hollow fibre type. The size of membrane bioreactor is 0.4 µm with allowable pH range of 2–13 and optimum temperature of 13–35 °C for operating condition. Finally, the wastewater flows to treated water basin. This basin is used to store the wastewater before discharge into outlet drain which is used in the backwash operation. This stage was controlled by float sensor with the basin depth of 3.5 m (KLCH 2016).

Figure 4.2 shows the installation process while Fig. 4.3 shows the maintenance process for membrane bioreactor. Sludge digesting basin is needed to store accumulated sludge in which the interval of sludge desludging depends on effluent quality. The basin depth is 3.5 m. The sludge disposal is collected and transferred to Jinjang Transfer Station. Washing basin is used during membrane bioreactor cleaning. The membrane bioreactor frame is soaked into this basin. Chemical tank contains sodium hypochlorite and oxalic acid which was supplied to the basin using chemical dosing metering pump. The depth of washing basin is 3.5 m. The monitoring work needs to be conducted to maintain good effluent quality by checking the control panel, data collection and water flow rate and gauge.

The summary of influent and effluent water quality was recorded with the data collected on 22 January 2016 as shown in Table 4.3.

Muntinlupa City Public Market in Muntinlupa City, Metro Manila, Philippines is the largest public market in the metropolitan area with 1448 stalls and 24 h operating per day. The sewage, grease and wastewater from washing the meat and fishes that discharge to a septic tank produce odour that is uncomfortable to the customers. The partially treated fresh market wastewater then flows to the Laguna Lake which is main inland sources of drinking water and freshwater fish at Manila. A sewage treatment system for this fresh market wastewater was constructed and implemented by the government and Philippine Sanitation Alliance (PSA)’s precursor, to reduce the amount of pollution flow into the Laguna Lake, to clean up surrounding area and to build the small scale of wastewater treatment system that could be replicated in other markets (PEN 2008; CAP 2011).

The system in Muntinlupa City Market consists of several process flows as shown in Fig. 4.4. The system was located under the parking lot due to limited ground space and was designed to treat up to 210 m3 of fresh market wastewater per day. The bar screen is located at each main inlet area to filter large floatable debris such as garbage, fish or meat trimming before flowing to the lift station which is a simple chamber containing aired automatic pumps to collect wastewater to the equalization tanks. This equalization tank is the point that wastewater retention and allows relatively constant flow of wastewater to proceed to the next chamber. After that, the wastewater flows to the anaerobic baffled reactor which is the main treatment technology used for this project. This multi chambered (this project used four chambers anaerobic baffled reactor) is closed without natural air and the wastewater flows slowly up and back down in the pipes, through the identical chambers, each time entering the chamber at bottom, where it passes through the accumulated sludge. The settleable solids in the sludge and anaerobic bacteria in the sludge degraded the harmful organic and chemical components in wastewater (PEN 2008; CAP 2011).

The up-flow anaerobic sludge blanket is a single tank with baffled near the top of wastewater level in which the wastewater flows upward through the blanket, and the sludge was settling using gravity with the aid of flocculant. The sludge then decomposes by anaerobic bacteria. The degradation is methanogenic (methane produced) and produces carbon dioxide. The bubbles rise upward and provide natural mixing to the wastewater above the sludge layer. The baffles guide the gas bubbles towards the top and centre of the tank which is known as ‘gas cap’. Indirectly, the gas caps prevent remaining particles to enter the next tank. This tank can reduce 50–70 % BOD, COD and TSS (PEN 2008; CAP 2011).

The sequencing batch reactor is the chamber that treats fresh market wastewater in batches and not continuously with activated sludge process which consists of open-air tank. The aeration from air injection pipes at the bottom tank with specific rate increases aerobic bacteria growth rate. These bacteria consume organic compound and nutrients present in wastewater, were clumped together and suspended in the tank. The process reduced the amount of BOD and COD (PEN 2008; CAP 2011).

The stages for sequencing batch reactor are

-

i.

Filling—filled with pre-treated from up-flow anaerobic sludge blanket,

-

ii.

Reaction—bacteria react with the aerated wastewater, then flocs,

-

iii.

Settling—when aeration stopped, the flocs are allowed to settle and give clear effluent,

-

iv.

Decanting—effluent pumped out of the tank from the top of wastewater (it does not disturb the sludge blanket at the bottom),

-

v.

Idling—the sequencing batch reactor idles until for the next cycle and,

-

vi.

Sludge wasting—the excess sludge is periodically removed from the tank.

The cocopeat filter was used for this site for about one year as demonstration. The treated wastewater is dripped through the cocopeat, to ensure the wastewater is clean for reusing or for discharging the effluent. The effluent was reused for toilet flushing for about a year and now currently used for cleaning the streets.

San Fernando Public Market in San Fernando City at La Union, Philippines runs a small-scale wastewater treatment system. The main city market with 700 stalls (sometimes up to 900 stalls on the market days of Wednesday, Saturday and Sunday). The wastewater from septic tank then flows to the drainage canal which pose a significant threat to the coastline city. Thus, the wastewater polluted the nearby beaches and threatened human health in the surrounding area. The newly constructed sewage treatment system was used to clean up the coastline at San Fernando City with technical assistance from the United States Agency for International Development (USAID) funded Environmental Cooperation-Asia project (PEN 2008; CAP 2011).

The flow process of wastewater treatment system at San Fernando Public Market is illustrated in Fig. 4.5. The chlorination tank consists of a tank and supplied chlorine to kill the remaining pathogens or bacteria in the wastewater. After dissipation, the effluent can be recycled for toilet flushing or discharged.

Sta. Ana Public Market in Manila City, Metro Manila, Philippines which is alongside the Pasig River has 220 stalls. This public market discharges the partially treated wastewater to the river, thereby increasing the pollution in Pasig River which is known as the most polluted river in the world. The river is considered as ‘biologically dead’ due to the combination of this public market wastewater and domestic wastewater. Thus, PSA, Rotary and government worked together to clean the river by constructing a sewage treatment system for this public market wastewater. This wastewater treatment system also can be used as a model that can be replicated in other public markets along the river (PEN 2008; CAP 2011).

Figure 4.6 shows the treatment flow for Sta. Ana Public Market. The grease trap is a simple tank consisting of one or two chambers, with a position deep below the anticipated wastewater level. The floating grease was trapped while the wastewater will exit through the pipes (Rahmat et al. 2018; Al-Gheethi 2019).

4.6 Treatment Technologies in Case Study in Laboratory Experiment

There are several case studies of fresh market wastewater treatment technology using laboratory batch experiment which are

-

(a)

Effective microorganisms for preliminary treatment.

-

(b)

Phycoremediation process by microalgae Scenedesmus sp.

-

(c)

Sequencing batch reactor.

-

(d)

Modified sand filtration for preliminary treatment.

Shahbuddin et al. (2018) use effective microorganisms to treat fresh market wastewater during preliminary treatment. Effective microorganisms are nature-based solution for sustainable water management and popular media due to its low operational cost and synergistic effects to the environment. The effective microorganisms are widely applied in many countries as a method for wastewater treatment. The effective microorganisms are antioxidant, able to inhibit harmful bacteria substance and enhance the proliferation of beneficial microorganisms and fungi to restore and balancing natural system.

The wastewater sample from Selayang Public Market located at Bandar Baru Selayang, Selangor were collected for the study. This fresh market wastewater was discharged directly to the river with intersection of the most critical sources of untreated wastewater from two rivers, Batu River and Jinjang River. The wastewater samples were collected for one hour interval starting from 7 am to 12 pm by using 2 L clean plastic sampling bottles and preserved by adding sulphuric acid (H2SO4) to reduce the pH to 2 or less. The parameters from fresh market wastewater that were tested are pH, DOBOD5, CODTSS and ammoniacal nitrogen (NH3−N). The wastewater samples were mixed by adding all of the samples in each interval, in a beaker with magnetic stirrer. 100 mL of effective microorganisms were then added into 1 L of wastewater sample.

As the result, flow rate at 8 am show highest amount with 0.015 m3/s and lowest at 10 am, and it can be assumed the peak hour of this market activities is at 8 am The highest BOD5, COD, TSS and NH3−N is 423 mg/L, 1566 mg/L 933.3 mg/L and 0.14 mg/L, respectively, with the range of pH and DO are 6.79–7.18 and 7.38–7.53 mg/L. Shahbuddin et al. (2018) revealed the bacteria existed in the wastewater is not tolerant in lower dissolved oxygen level which they need to survive and decompose the organic compound. The nitrogen is vital for plants and animals in the formation of protein for cell growth.

Table 4.4 shows the data collected during preliminary treatment by effective microorganisms. There are no significant changes in DO using effective microorganisms. However, the effective microorganisms are successful to reduce BOD5 with 66.8 %, COD with 19.1 %, TSS with 57.1 and 85.71 % reduction for NH3−N. Hence, this preliminary treatment is good to protect membrane for filtration in treatment plant.

Jais et al. (2015) used phycoremediation by microalgae to treat fresh market from Parit Raja Public Market, Batu Pahat. Microalgae are widely used as a medium to treat wastewater such as municipal wastewater, industrial wastewater and animal wastewater. However, the lacking relevant information about wet market wastewater treatment using microalgae led to this study. 10 L of wastewater was collected around 9 am. The characteristics of wastewater such as turbidity, BOD, COD, TSS, TN, Total Phosphorus (TP), O&G, Zn and Fe were collected. Microalgae Scenedesmus sp. were chosen as a phycoremediate agent to treat wastewater. The culturing of microalgae was done using Bolts Basal Medium (BBM). To get the optimum concentration of microalgae to phycoremediate wastewater, five sets of wastewater samples were prepared with adding different microalgae Scenedesmus sp. concentration (6.50 × 105, 49.88 × 104, 34.75 × 104, 19.63 × 104 and 4.50 × 104 cell/ml). Nutrients and elements amount were measured on zeroth, second, fourth, sixth and eighth day for each sample. The efficiency removal in percentage was used to determine the efficiency of phycoremediation process.

The fresh market wastewater characteristics at Parit Raja Public Market are turbidity (66.0 ± 8.9 NTU), BOD (89 ± 3.61 mg/L), COD (456 ± 8.19 mg/L), TSS (132.3 ± 1.7 mg/L), TN (36.9 ± 0.5 mg/L), TP (1.61 ± 0.13 mg/L), oil and grease (5.22 ± 0.07 mg/L), Zn (0.312 ± 0.0021 mg/L) and Fe (1.071 ± 0.0010 mg/L). Microalgae are known as sequester elements due to their ability to remove elements in wastewater by absorbing the elements for their growth. Nitrogen and phosphorus are primary concern to remove by phycoremediation in these wastewater samples. Highest efficiency removal of nutrients and elements by different initial microalgae concentrations are as in Table 4.5. 6.50 × 105 cell/mL of microalgae absorbed maximum amount of TN by eliminating 74.77 % from wastewater while the TP was reduced up to 82.17 % removal by initial concentration, 34.75 × 104 cell/mL of microalgae. 49.88 × 104 cell/mL of microalgae can remove 65.76 % of Fe while 6.50 × 105 cell/mL removed 84.14 % of Zn. As conclusion, the microalgae Scenedesmus sp. have good ability to remove nutrients and elements within 8 days experiment, and concentration 49.88 × 104 cell/ml of microalgae Scenedesmus sp. was chosen as the most efficient concentration due to the highest efficiency removal of nutrients and elements (Jais et al. 2015).

Danial et al. (2016) used a sequencing batch reactor to remove nutrients from greywater at Peladang Public Market, Skudai. Bio. The sludge was obtained from wastewater treatment plant (Taman Harmoni Wastewater Treatment Plant) as inoculum. Sequencing batch reactor was built by fabricated transparent glass cylinder with a total volume of 4 L of wastewater. The system was operated under alternating anoxic-aerobic condition within 28 days with activated sludge process (MLSS) maintained at 3000–5000 mg/L. The sequencing batch reactor was equipped with two peristaltic pumps with (35 L/min of air feeding) mechanical agitator (30 rpm) to mix well with three cycles per day (1.2 days of hydraulic retention time). The pH was set at a range of 7.0–7.5 with natural room temperature.

The system of this sequencing batch reactor consisted of four steps:

-

(1)

Filling—the filling process is done within half an hour, and the air pump was stopped to promote anoxic condition and continued for two hours after feeding.

-

(2)

React—the aeration using mechanical agitator and air pump automatically occurred for four hours and offed for one hour.

-

(3)

Settling—sedimentation or clarification.

-

(4)

Draw—decanting occurs when 1000 mL of supernatant was removed from the sequencing batch reactor within half an hour.

The characteristics of wastewater are COD was 1708 mg/L, TSS was 140 mg/L, TN was 66 mg/L, TP was 288 mg/L, while NH4−N was 98 mg/L. The maximum effluent of COD is 97 mg/L which reduces up to 94 % using the sequencing batch reactor. The TSS also removed 71 %. The efficiency removal of TN, TP and NH4−N are 88 %, 67 % and 93 %, respectively. It is proven that sequencing batch reactor effectively removes nutrients and promotes biodegradation of organic matter for fresh market greywater.

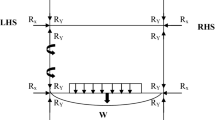

The study of modified sand filtration as a preliminary treatment for fresh market wastewater was conducted by Saad et al. (2016). Sand filtration is one of the oldest wastewater treatment technology which is of low cost and maintenance and high treatment efficiency. The four sand filtration systems were constructed in transparent plastic column with the size 260 mm of height, 80 mm of top diameter and 24 mm for bottom diameter. A hole at the bottom is presented as a channel for effluent disposal. There are three media used in this study which are fine sand, coarse sand and activated carbon (rice husk and coconut shell) with 0.06 mm, 2.00 mm, and 0.08 mm in their effective size, respectively. Four types of sand filtration were used in this study such as (a) sand filtration, (b) sand filtration with coconut shell, (c) sand filtration with rice husk and (d) sand filtration with rice husk and coconut shell (Fig. 4.7).

The characteristics of wastewater are BOD 137.03 mg/L, COD 350.27 mg/L, TSS 126.4 mg/L and NH3−N 45.81 mg/L while efficiency removal of four types of treatment system is recorded in Table 4.6. The sand filtration with the presence of rice husk indicates 86.2 and 84.4 % of BOD and COD removal,respectively. It shows that organic matter from fresh market wastewater was removed. The TSS and NH3−N in wastewater also indicated removal as 63.0 and 87.6 %, respectively. Overall result is successful in efficiency reduction up to 30 % except TSS using sand filtration. This study revealed that sand filtration with addition of activated carbon (rice husk) shows potential in eliminating the amount of organic compound and nutrients. Therefore, the addition of activated carbon in filtration method can be one alternative preliminary treatment system for fresh market wastewater.

4.7 Impact and Challenges

The several projects of wastewater treatment system at fresh markets area are still operating and maintained. The treatment system is still functioning properly and serves as a significant model. The Muntinlupa market, for example showed an innovative project since the system is underground due to the limited space. The volume of wastewater treated is also a reasonable sum. The cost of operating and maintaining is also lower compared to the conventional systems. The treated wastewater usage as toilet flushing and street cleaning also saves money on water bills. The combination of aerobic and anaerobic treatment process allows the amount of BOD, COD and TSS meet to allowable standard after treatment. However, the treatment system still faces challenges. For example, in Muntinlupa Public Market, several pumps broke down and need to be replaced which takes time. In San Fernando Public Market, the treatment system is always and easily clogged with the trash and grease due to poor design and construction (PEN 2008). Overall, the several wastewater treatment systems that had done successfully improved the wastewater quality by eliminating the largest and highest parameter strength of wastewater into important water bodies such as Jinjang River, Klang River, Bunus River, Gombak River, Pasig River, Laguna Lake and coastlines in Philippines.

References

Al-Gheethi A (2019) Establish in-house: a pre-treatment method of fat, oil and grease (FOG) in kitchen wastewater for safe disposal. Int J Integr Eng 11(2)

Apandi NM, Mohamed RMSR, Latiffi NAA, Rozlan NFM, Al-Gheethi AAS (2017) Protein and lipid content of microalgae Scenedesmus sp. biomass grown in wet market wastewater. In: MATEC web of conferences, vol 103. EDP Sciences, p 06011

Apandi N, Mohamed RMSR, Al-Gheethi A, Latiffi A, Arifin SNH, Gani P (2018) Phycoremediation of heavy metals in wet market wastewater. In: IOP conference series: earth and environmental science, vol 140, no 1. IOP Publishing, p 012017

Apandi N, Mohamed RMSR, Al-Gheethi A, Gani P, Ibrahim A, Kassim AHM (2019) Scenedesmus biomass productivity and nutrient removal from wet market wastewater, a bio-kinetic study. Waste Biomass Valoriz 10(10):2783–2800

CAP (2011) 17 Philippines case studies. https://www.susana.org/en/knowledge-hub/resources-and-publications/library/details/1329, Accessed 15 Dec 2018

Danial O, Salim MR Salmiati (2016) Nutrient removal of grey water from wet market using sequencing batch reactor. Malays J Anal Sci 20(1):142–148

Godos I, Vargas VA, Blanco S, Gonzalez MCG, Soto R, Garcia-Encina PA, Becares E, Munoz R (2012) A comparative evaluation of microalgae for the degradation of piggery wastewater under photosynthetic oxygenation. Biores Technol 101:5150–5158

Jais NM, Mohamed RMSR, Apandi WA, Matias-Peralta H (2015) Removal of nutrients and selected heavy metals in wet market wastewater by using microalgae Scenedesmus sp. Appl Mech Mater 773–774:1210–1214

Jais NM, Mohamed RMSR, Al-Gheethi AA, Kassim MAH (2016) The dual roles of phycoremediation of wet market wastewater for nutrients and heavy metals removal and microalgae biomass production. Clean Technol Environ Policy 1–16

Jais NM, Mohamed RMSR, Apandi N, Al-Gheethi AA (2018) Heavy metals removals from wet market wastewater by phycoremediation technology. In: IOP conference series: earth and environmental science, vol 140, no 1. IOP Publishing, p. 012060

Karia GL, Christian RA (2006) Wastewater treatment: concept and design approach. Prentice Hall of India, New Delhi

KLCH (Kuala Lumpur City Hall) (2016) Training wastewater treatment plant. https://www.seisakukikaku.metro.tokyo.jp/en/diplomacy/pdf/1610-07-economic-e.pdf, Accessed 13 Dec 2018

Maizatul AY, Mohamed RMSR, Al-Gheethi AA, Hashim MA (2017) An overview of the utilisation of microalgae biomass derived from nutrient recycling of wet market wastewater and slaughterhouse wastewater. Int Aquat Res 9(3):177–193

PEN (2008) Philiphine sanitation sourcebook and decision aid. https://esa.un.org/iys/docs/san_lib_docs/philippines_sanitation.pdf, Accessed 13 Dec 2018

Rahmat SN, Abduh AAAS, Ali AZM, Razi MAM, Adnan MS (2018) Field performance of a constructed litter trap with oil and grease filter using low-cost materials. Int J Integr Eng 10(2)

Saad FNM, Jamil MN, Odli ZSM, Izhar TNT (2016) Study on modified sand filtration towards water quality of wet market waste water. In: MATEC web of conferences 7 01104

Shahbuddin M, Raus RA, Ramli NA, Adel N, Jami S, Zainuddin Z (2018) The use of effective microorganisms (em) for pretreatment of wet market wastewater. In: International Conference on Bioengineering 2018. https://www.researchgate.net/publication/328064087_The_Use_of_Effective_Microorganisms_EM_for_Pretreatment_of_Wet_Market_Wastewater, Accessed 11 Dec 2018

Sze-ki LUI (2008) An ethnographic comparison of wet markets and Supermarkets in Hong Kong 2:1–52

Zulkifli AR, Roshadah H, Tunku Khalkausar TF (2012) Conference: Control of water pollution from non-industrial premises. Bayview Hotel, Langkawi Kedah. (5.30–5.45 pm)

Acknowledgements

The authors gratefully acknowledge the Ministry of Higher Education of Malaysia for the financial support under the Prototype Research Grant Scheme (PRGS) vot No. G004 and My PhD.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Jais, N.M., Miswan, M.S., Radin Mohamed, R.M.S., Al-Gheethi, A.A.S. (2020). Treatment Technologies of Fresh Market Wastewater. In: Al-Gheethi, A., Radin Mohamed, R., Noman, E., Mohd Kassim, A. (eds) Prospects of Fresh Market Wastes Management in Developing Countries. Water Science and Technology Library, vol 92. Springer, Cham. https://doi.org/10.1007/978-3-030-42641-5_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-42641-5_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-42640-8

Online ISBN: 978-3-030-42641-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)