Abstract

The article presents a comprehensive analysis of the environmental aspects of the production and use of biofuels in transport. It is stated that the environmental impact occurs at all stages of production and processing of bioenergy raw materials. It is substantial during land use change and production intensification, and minimal greenhouse gas emissions are observed when lignocellulosic fuels are used. Life cycle analysis shows that battery electric vehicles have a better greenhouse gas saving than most biofuels. At the same time, a large-scale implementation of renewable energy sources is needed to reduce harmful emissions from electricity generation. It is established that the use of carbon-neutral synthetic biofuels is a promising way to achieve the complete decarbonisation of the transport sector.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Using of Biomass-Based Alternative Fuels in Automotive Industry

The existence of energy is a fundamental requirement for the development of all aspects of society. Energy is also needed to maintain the existence of ecosystems, life and human civilization. However, the use of fossil energy sources can cause a number of problems [1]. The energy from fossil fuels is non-renewable, and its overuse leads to a major energy crisis, which is now a major concern in the world. In this case, the demand for energy in transport grew faster than in most other economy sectors from 45 EJ in 1973 to 110 EJ in 2014 and increased its proportion in the total final consumption from 23 to 28% [2]. Due to the population growth, gross domestic product growth and rise in living standards, the demand for energy in the transport sector is expected to increase by about 40% by 2050 [3].

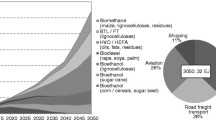

The use of conventional fossil fuels also contributes to the generation of pollutants that accelerate global warming, for example, the increase in carbon dioxide and other greenhouse gases [4–6]. According to different sources, the transport sector—road, air, and water transport—accounts for about 20% of the world’s greenhouse gas emissions (Fig. 1) and is considered the most difficult sector for decarbonisation [7].

The development and operation of automobile transport are determined by two distinct and contradictory trends. On the one hand, the attained level of motorization reflects the technical and economic potential for social development and helps to meet the social needs of the population, and, on the other hand, it increases the negative environmental impact. That is, the improvement of transport vehicles to support human life and activities does not only improve people’s transportation options, it also causes significant environmental pollution.

Studies on the socio-economic assessment of the effects of atmospheric pollution show that a significant proportion of the potential damage is attributable to the component related to the environmental impact on human health [10]. The analysis of the atmospheric pollution in cities with intense car traffic shows that nitrogen oxides (NOx) and carcinogenic hydrocarbons have the most dangerous effect on human body. Their proportion in the assessment of the environmental hazard of automobile engines is 95%. Particularly dangerous are their derivatives, nitrocarcinogens, which cause synergism and mutagenic properties. Some of the major carriers of carcinogens and nitrocarcinogens, which significantly enhance their aggressiveness, are carbon-based micro-fine solids [11].

However, unless cardinal measures are taken, the emissions will increase due to the growing demand for transport [12]. The total number of motor cars is expected to double by 2035 and reach 1.7 billion units [13]. The European Union is intended to reduce greenhouse gas emissions from transport by 60% by 2050, compared to 1990 [14].

Reducing greenhouse gas emissions and enhancing the energy security of states pose significant challenges for the transport sector in the coming decades.

Thus, at present, it is important to develop fuel technologies in road transport which would help to significantly improve the ecological and economic performance of vehicles using renewable alternative motor fuels.

It should be mentioned that modern systems based on fossil fuels provide a rather flexible energy supply for power plants, boilers and transport vehicles in liquid, gaseous and solid forms. Today’s energy systems are based on infrastructure and storages and meet the needs by means of long-distance transportation of fossil fuels by ships and pipelines globally and to the national or regional energy infrastructures, for example, coal, gas and oil storages. Hence, the global system is based on the large-scale storage and transportation of energy-intensive fossil fuels, which can usually flexibly meet the requirements at the right time and place. Though the power system based on fossil fuels is a reality, the current challenge is to create an equivalent or more flexible energy supply system with an increase in the proportion of renewable energy.

Although biomass-based alternative fuels have significant potential for reducing pollutants in the long run, in our opinion, the technological potential for fossil-fuel vehicles should be used more efficiently to improve the environmental situation.

At the present stage of the automotive industry development the main indicators of internal combustion engines are considered to be the mileage rating and toxicity of exhaust gases.

The ways to improve the environmental safety of vehicle engines both at the design stage and in operating conditions should be selected based on the comprehensive and complex assessment of fuel efficiency and pollutants emissions, taking into account both design and operational factors.

2 Technological Measures to Reduce Fuel Consumption

First of all, it is possible to decrease CO2 emissions by means of reducing fuel consumption. The technological measures aimed at reducing fuel consumption in traditional internal combustion engines can be roughly divided into improving a particular engine design, keeping engine revolutions within the energy-efficient performance range, and optimized energy management. These measures are complemented by the reduction in car weight, rolling resistance and air resistance along with the measures aimed at improving driving skills [15].

2.1 Improving Engine Design and Transmission Technology

As far as optimizing the combustion process is concerned, one should distinguish between diesel and gasoline engines. In the case of gasoline engines, it is possible to significantly save up to 20% of fuel when using direct-injection engines in combination with stratified charge or variable valve timing (VVT) technology, innovative cylinder cutout technologies and reducing the idle speed, especially in the adverse conditions of partial throttling [16]. However, because of higher NOx emissions, direct fuel-injection gasoline engines require that NOx emissions be cleaned by catalytic converters, in this case it is possible to obtain the composition of exhaust gases close to that of diesel engines emissions.

Diesel engines consume 15–20% less fuel than gasoline engines. However, CO2 emissions from the combustion of one liter of diesel are about 13% higher than from one liter of gasoline. The lower level of diesel consumption is due to a much higher compression ratio and direct fuel injection [15]. Despite burning with excess air, rapid fuel injection can still lead to localized starvation and hot spots, which leads to soot and NOx emissions. Therefore, the further progress of diesel engines involves improving the fuel injection processes in order to get more homogeneous mixtures and ultimately reduce emissions [17].

It should be also noted that a slight reduction of about 2% in fuel consumption can be obtained by improving the exhaust gas recirculation.

In the long run, the combustion processes in gasoline and diesel engines are expected to converge [18].

It is well known that both engine types achieve the best efficiency level in a certain performance range. This range can be provided by optimum transmission parameters. In this case, automatic gearboxes with a wider gear range (6 or 7 gears) and gear changes, supported hydraulically or electronically, can reduce fuel consumption by about 10% [19]. Automatic gearboxes can be further improved to use the continuously variable transmission (CVT), which can additionally save about 8% of fuel [20].

2.2 Energy Management and Hybridization

In urban conditions, the engine power of transport vehicles is not used for about 45% of the operation time. In such operating conditions, an automatic start-stop system which uses the flywheel to start and stop the engine can save about 25% of fuel [21].

A prospective direction is further hybridization (strong or parallel hybrid) when an electric motor with sufficient power for car self-feeding is installed next to a conventional internal combustion engine. This allows for three different operation methods: an internal combustion engine, an electric motor, and a combination of both.

The electric motor is usually designed for city driving, and the internal combustion engine—for motorways and other trips over longer distances. Hence, the internal combustion engine may not be used when the throttle is partially open: although the performance requirements are lower in this case, the internal combustion engine can still operate at a favorable efficiency level, and excess energy is used to recharge the battery. It also allows for the purposeful reduction of the internal combustion engine size, its weaknesses with a partially open throttle can be compensated by the electric motor. The parallel hybrid provides regenerative braking, that is, the braking energy is recovered and stored in the batteries.

Along with reduced emissions (except NOx), the advantages of a parallel hybrid over gasoline and diesel engines contribute to a potential reduction in fuel consumption from 25 to 34% [22].

The disadvantages of hybrid vehicles are their dual energy storage and dual engines that affect the weight and value of the vehicle.

2.3 Vehicle Design

Since the increase in the performance indicators of the internal combustion engine is almost exhausted, a promising direction for decreasing fuel consumption is to reduce the car weight and increase the aerodynamic properties of the body.

Expanding the use of light steels, aluminum, and plastics creates opportunities to reduce car weight without compromising safety and comfort. The authors of [23] state that the reduction of car weight by 10% leads to the decrease in fuel consumption by 5.6–8.2%. In the foreseeable future, up to 2030, it may be possible to reduce car weight by 28–30% [24].

Plastics are flexible materials with low thermal conductivity, high chemical resistance, good dielectric and optical properties, and high corrosion resistance. They can damp and suppress vibrations. This explains their widespread use in the automotive sector.

The modification of polymers, in particular, the structural and chemical modification with reactive compounds, is one of the effective methods of regulating the structure and properties of polymers as well as creating composites that combine the valuable properties of polymers and fillers, can be easily processed into products of complex shape and have special properties, characteristic of a particular filler. This combination significantly extends the application field of these materials.

At the same time, the increased production and use of plastics result in the accumulation of huge plastic wastes. Plastics and plastic fibers are not environmentally friendly, they have high carbon composition, cause environmental pollution and do not degrade. Hence, the problems of recycling plastic products and environmental issues require comprehensive scientific studies to produce environmentally friendly and biodegradable composite materials from renewable raw materials.

Composites containing natural fibers (NF) and natural polymers play a key role among different types of composites. At present, the most efficient way of making environmentally friendly composites is to use natural fibers as reinforcement.

Polymer composites reinforced with natural fillers were used to replace widespread materials in several industries, including the automotive industry.

Automobile foams and extruded polymers are also widely used nowadays [25]. In particular, about 150 plastic products with a wide range of physical characteristics are used in car showrooms, and foam production for the automotive industry worldwide is 1.7 million tonnes per year.

A promising trend is also the use of polymer nanocomposites based on natural fillers, which, due to their lower density, help reduce the weight of materials and generally meet the requirements of the automotive industry and in some cases even exceed them (Fig. 2).

The use of polymer restorative composites [26]

Nanocomposites are a class of polymer materials that have excellent mechanical, thermal and technological properties and can be used to replace metals in the automotive and other industries (Table 1). Due to the peculiarities of nanodimensional particles and a very high surface-to-volume ratio, they have a unique combination of multifunctional properties that are not characteristic of their conventional composite analogues [23].

These multifunctional nanocomposites not only have great mechanical properties, they also demonstrate an excellent combination of optical, electrical, thermal, magnetic and other physicochemical properties. It is believed that the interaction between nanoparticles and polymer matrices at the molecular level and the presence of the nanoparticle-polymer interface play a major role in influencing the physical and mechanical properties of nanocomposites. These composites also have distinct advantages (specific strength and modulus of elasticity) compared to fiberglass and mineral fiber, which make them more competitive in the automotive industry.

Parts made from nanocomposites provide rigidity, strength, durability and reliability at the metal level, and in some cases they even exceed them. They have high corrosion resistance, noise absorption, enhanced modulus of thermal resistance, and dimensional stability. Nanocomposites can replace metal and glass components in the near future. They can help the automotive industry to take a leading position in saving fuel and produce more durable vehicles of a higher quality.

The commercialization of polymer nanocomposites began in 1991 when Toyota Motor Co. was the first to introduce to the market nylon-6/clay nanocomposites used to manufacture timing belt covers as parts of engines for its Toyota Camry vehicles. About the same period, Unitika Co. from Japan introduced the nylon-6 nanocomposite for engine covers on Mitsubishi GDI3 engines made by injection moulding. These covers are 20% lighter than their counterparts and have excellent surface finish [27].

Elastomeric nanocomposites are also getting widespread in the automotive industry, especially for tire production. They have lower rolling resistance and weight and therefore demonstrate excellent fuel saving rates [28]. The main drivers for using these materials are the increasing demand for fuel utilization efficiency, strict automotive safety standards, increased durability and noise reduction. For example, replacing elastomer in the traditional inner liners for tires with nanocomposite inner liners leads to the reduction in fuel consumption by approximately 2%. Major tire manufacturers involved in the development and manufacturing of nanocomposites are Yokohama Tire Corp. (Japan), Pirelli SpA (Italy), Goodyear Tire & Rubber Co. (USA), Continental AG (Germany), InMat Inc. (USA) etc. The elastomeric nanocomposite tire models are also used by Goodyear UltraGrip Ice+, Continental EcoContact5, Michelin Energy Saver and Pirelli Cinturato P1.

Green nanocomposites or biodegradable nanocomposites (cellulose clay-reinforced bioplastics) are the next generation of materials used in automobiles. They have the potential to replace the existing non-biodegradable thermoplastic oil-based nanocomposites.

Despite the advantages of polymer composites reinforced with natural fillers, their wide use in the automotive industry still has some factors, mainly related to the economic production indicators [29], which impede their widespread commercial adoption. This trend can be improved by the increased productivity and environmental friendliness. For example, fillers can reduce the negative impact of non-biodegradable polymers [30]. In general, the market for polymer composites is strengthened by natural fillers for the automotive industry. It is a multi-billion business in which the manufacturers and engineers are in constant search in order to prepare more competitive materials, thereby increasing their profitability [31]. In particular, at present, the European market for polymeric materials contains 10–15% of wood plastics and composites made from natural fiber [32].

In addition, the use of natural fibers for the production of polymer composites creates the opportunities for general employment in rural and less developed regions, thereby helping to achieve the UN sustainable development goals, namely poverty eradication, promotion of the inclusive and sustainable industrialization, stimulation of innovations, creation of sustainable cities and communities, and responsible production and consumption. Therefore, natural fibers will play a vital role in the socio-economic development of society.

A significant fuel economy in ICE motor cars can be obtained by reducing the aerodynamic body resistance and rolling resistance. As shown in [33], due to these factors, the specific fuel consumption can be reduced by 12% by 2030, inter alia by improving the aerodynamic properties of cars by 4.4% and reducing the rolling resistance by 6.7%. Besides, the effect of the start-stop system use should be also taken into account, as it helps to reduce the engine idling losses by almost 60% [34].

3 Peculiar Features of Biofuels Production

The biofuels made from different biological raw materials should be highlighted among alternative renewable fuels. The obvious advantage of these fuels is a virtually inexhaustible raw materials base used for their production and excellent environmental qualities. Biofuels can technically replace oil in all modes of transport with the existing fueling infrastructure. Biomass resources can be also used to produce decarbonized synthetic fuels, methane and LPG. Therefore, some key factors can be singled out as the main prerequisites for the development of biofuels industry.

The first factor is the need to combat global climate changes caused by increased greenhouse gas emissions into the atmosphere, mainly of carbon dioxide CO2 as well as SO2 and NOx. The increase in carbon dioxide emissions into the atmosphere is significantly associated with the increase in global energy consumption, mainly with the use of fossil energy sources, such as gas, oil, coal, etc.

The second factor is the desire to improve the countries’ economic security and to reduce their strategic dependence on the foreign supplies of fossil fuels.

The third factor is the development of internal competition, diversification of countries’ economies, optimization of production cycles and supply chains, and the introduction of energy efficient and resource-intensive technologies.

At present, biomass ranks fourth in the global energy system, accounting for 10–14% or 51 EJ of the global energy supply [35]. The world market for biofuel production is constantly developing due to the existence of state programs for the development of bioenergy. In the coming decades, the contribution of bioenergy to the world fuel and energy production will continue to increase. Its growth is on average 3.3% per year [4].

Nowadays there are several predictable scenarios for the worldwide energy development and use. According to the World Energy Council (WEC) estimates, by 2050 energy consumption will increase more than twice compared to 1993, and over 40% of energy needs will be covered by renewable energy sources, among which the proportion of bioenergy will be 32%.

However, the development of current trends in the global biofuel market is accompanied by the contradictions between its participants at all levels—starting from groups of states and ending with individual economic entities and consumers. In this case, the economic, environmental and social effects of biofuel implementation remain controversial. These factors can be a significant impediment to the development of biofuels market and, therefore, require an in-depth analysis of all aspects of the impact of biofuels production both on the economies of individual states and the world as a whole.

Biofuels are defined as a kind of fuel produced from renewable organic biomass through physical and chemical processes with zero net CO2 emissions. Biomass is an organic material that can store chemical energy produced by photosynthesis; it may be timber, wood waste and many agricultural by-products [36].

Biofuels are an alternative to traditional oil-derived fuels. The ever-increasing demand for them in the long term can dramatically change the situation in the global energy market. At the same time, new vehicles capable of consuming both traditional fuels and mixtures containing over 80% of biofuel are increasingly being produced in the world. Nowadays, the rates of biofuels production increase are far behind the increasing demand for them.

At present, more than 40 countries of the world produce biofuels. The current leaders of biofuel production are the United States, Brazil and the European Union. About 85% of the world’s biofuel production is concentrated in these countries. The largest proportion in production (48%) is in the United States of America. The rapid development of China’s biofuels industry should be also highlighted [37].

In 2004, the increasing global demand for alternative energy types, rising oil prices and tax incentives contributed to the fact that many countries around the world started expanding their potential for biofuels production. The overall economic growth, production subsidies and legislative support helped to rapidly increase investments in the biofuels sector, especially in 2004–2007, and the share of biofuels in the total fuel consumption in several countries of the world.

Global biofuels production increased sevenfold—from 16 billion liters in 2000 to 110 billion liters in 2012. At the same time biofuels made up only 2.3% of the total amount of liquid (motor) fuel used. The rates in Brazil (20.1%), the United States of America (4.4%) and the European Union (4.2%) exceeded the world average.

Within seven years (from 2000 to 2007), the bioethanol fuel production tripled and exceeded 60 million liters, with Brazil and the United States accounting for the bulk of this increase. During the same period, the biodiesel production in the EU countries saw a more significant growth, resulting in the production increase from less than 1 billion liters to almost 11 billion liters, i.e. by 11 times.

The EU has three major biodiesel producing countries—Germany, France and Italy. France and Germany are the largest consumers of biofuels in the European Union.

It should be noted hat biofuels are important for two reasons. Firstly, biofuel is the only renewable energy source that can provide about 27% of the world’s transport fuel, which is currently made from fossil fuels [38]. The use of biofuels can lead to a reduction of 2.1 Gt of CO2 in the atmosphere per year. Secondly, biofuels production can create wealth and contribute to the sustainable improvement of human well-being both now and in the long run. In addition to greenhouse gas emission reduction [39], there is substantial evidence that bioenergy brings numerous benefits that can offset environmental issues related to fossil fuels, intensive food production and urbanization [40]. Besides, the biofuel industry development can promote agricultural development and benefit farmers through its utilization of waste from food crops, bioenergy crops and other biomasses. The examples range from pollution abatement in urban centers to improving the agricultural efficiency in rural areas, which benefit from the improved access to energy and poverty alleviation.

Nowadays about 90% of the world’s biofuel consumption is accounted for by liquid fuels—bioethanol and biodiesel. Other biofuels are also used, such as pure vegetable oil and compressed biomethane, although their market presence is quite limited. The world production of liquid biofuels (i.e. ethanol, biodiesel) has been growing rapidly in recent decades. According to the International Energy Agency estimates, in 2050 the share of biofuels in the transport sector will increase to 27% [41].

According to different expert estimates of bioenergy development prospects, there is a potential for the sustainable increase in the volumes of timber processing in Europe. The results of expert reviews and estimated figures in the European Forest Sector Outlook Study for the period 2010–2030 show that the use of wood biomass for bioenergy will nearly double by 2030 (from 435 million cubic meters in 2010 to 859 million cubic meters in 2030) [42].

At present, in the EU countries, the potential reserves that can be processed into energy are estimated at 277 million cubic meters of ground vegetation biomass and 308 million cubic meters of subsurface biomass, the possible total growth may be up to 913 million cubic meters in the long run. Thus, theoretically, the EU can cover its internal raw material needs for bioenergy production.

If the existing trends in bioenergy development in the EU continue, by 2030 the competition for wood biomass will significantly intensify, affecting biofuels markets both within the EU and in exporting countries. Wood biomass production technologies will be increasingly developed through the intensive use of land resources capacity during the long-term cycle of forest cultivation (intensification of forest use on woodlands) and short-term cycle of forest cultivation (establishment of plantations on non-forest lands).

If the automotive industry has been trying to replace gasoline engines with hybrid or fully electric engines for several years, then this process is just beginning for air and maritime transport. It should be noted that airlines switch their fleet to biofuels, and aviation companies try to develop electric airplanes in order to reduce greenhouse gas emissions and running costs.

According to the innovation degree, the biofuels made from biomass for use in automobile engines are divided into the first, second, third and fourth generations [43].

Table 2 shows the types of raw materials and end products of different generations of biofuels.

3.1 First-Generation Biofuels

First-generation biofuels include bioethanol, produced from the crops rich in sugar (sugar beet, sugar cane) and starch (corn, wheat, cassava), and biodiesel from oil crops (soybeans, sunflower, rapeseed, palm oil) or animal fats and pure vegetable oil. In most cases, these types of raw materials can be also used as foods and feeds [43].

Bioethanol is one of the most important products in modern bioeconomy. About 85% of the global production of liquid biofuels comes from it. In recent years, the worldwide bioethanol production has reached the level of about 106 million m3 per year (Fig. 3). The two largest manufacturers of this product, the United States and Brazil, account for about 90% of the total production, with the rest coming mainly from China, Canada, the EU and India.

Dynamics of the global ethanol and biodiesel production [44]

Fuel ethanol is obtained by means of fermentation of sugars (glucose, sucrose) with alcohol yeast Saccharomyces cerevisiae in an oxygen-free environment.

Ethanol increases the knock resistance of gasoline and its combustion efficiency. However, traditional 96% alcohol is not added to gasoline. The dehydrated ethanol is added instead, because it does not emulsify. Zeolites, azeotropic distillation with cyclohexane, and membrane technologies are used to dry alcohol.

At present, biodiesel is gradually becoming one of the most important fuels. By 2020, the share of biodiesel in the total motor fuel consumption can reach 20% in Europe, Brazil, India and China. In case of active state support, creation of a favorable investment environment and taxation system for the industry, this figure may be even higher. Nowadays, about 90% of the world biodiesel consumption is accounted for by Europe, but the biodiesel industry of the United States is the fastest growing industry in the world.

From the chemical point of view, biodiesel is a mixture of methyl (ethyl) esters of saturated and unsaturated fatty acids. At present, the largest volume of biodiesel is produced by the method of transesterification of vegetable oils and fats to esters and fatty acids.

The transesterification process is carried out through reaction of alcohol with triglycerides in the presence of a homogeneous catalyst, usually an acid, alkali or enzyme, to obtain glycerol and esters of fatty acids. Although methanol is mainly used in the industry, ethyl, propyl, butyl and amyl alcohols may be also used as esterification agents. The resulting reaction mixture is separated in separators or in settling tanks. As a result, a mixture of fatty acid methyl esters (biodiesel fuel) and glycerol phase (“black” glycerol) containing 45–50% of glycerol, unreacted methanol, saponification products of fats and other impurities are obtained. Refined glycerol is used for the production of detergents, and after deep purification it is used in pharmacy.

A number of authors treat biogas as the first generation of biofuels [43]. Biogas has a special status among all renewable energies, because it has manifold uses in different fields of the power industry. Biogas production is a well-established technology that uses a wide range of residues in the form of raw materials.

Biogas is produced as a result of anaerobic biodegradation of organic biomass, in which organic matter is decomposed by microbes in the absence of oxygen (Fig. 4). Biogas, generated as a product of the metabolic action of methanogenic bacteria, consists mainly of methane (55–75%) and CO2 (25–50%). Several methods have been proposed to extract CO2 from biogas, the most common being extraction with solvents, activated carbon adsorption, membrane filtration and cryogenic separation [45].

Scheme of biogas production [45]

Different types of raw materials are used for biogas production. These include agricultural crops, sewage sludge, solid plant waste, leaves, grass, seaweed, animal waste and microalgae.

Biogas is a valuable energy carrier, because it can be used for various purposes and with high efficiency. The use of biogas as a motor fuel provides a significant saving of fuel and energy resources. The experience of operating cars using biogas as a motor fuel proves the possibility of its use in traditional vehicle designs. Due to the simple, reliable and proven technology, biogas has all the necessary characteristics to become one of the most efficient and cost-effective fuels obtained from renewable sources.

Like natural gas, before it is used in the internal combustion engine, biogas is enriched (up to 95% of methane content), purified, dried and compressed. The purified biogas is usually delivered to fueling stations by special tank trucks or by pipelines.

It is worth noting that biomethane can be turned into renewable fuel—hydrogen.

The production of biomethane gives a higher energy yield per hectare than the production of bioethanol or biodiesel (Fig. 5). The production residues are nutrients and microelements that return to farmlands and increase their productivity. However, methane leaks can be a problem. Although methane is a valuable fuel, either in the form of biomethane or natural gas, it is also a greenhouse gas with a global warming potential 25 times higher than carbon dioxide. For this reason, special measures should be taken to minimize losses during production, storage and transportation.

Distance driven by a motor car with fuel obtained from 1 ha of cultivated land [46]

The main disadvantage in the production of first-generation biofuels is the need to use high-quality arable land, different heavy agricultural machinery, fertilizers and pesticides.

3.2 Second-Generation Biofuels

Second-generation biofuels are the next step in the processing of biological raw materials, allowing for the use of a wider range of biomass, the main component of which is lignocellulose. The global production of plant biomass is 200 × 109 tonnes per year. 90% of the biomass is accounted for by lignocellulose. The percentage composition of lignocellulose components may vary depending on the type of raw material, and each component of lignocellulose, if properly processed, can be used in biofuel production.

However, the processing of cellulosic raw materials is more complex than the processing of sugar or starch. Therefore, the production of second-generation biofuels requires more complex fuel extraction and processing technologies. It is worth noting that there may be competition between the potential use of cellulosic materials to produce liquid motor biofuels and solid biofuels to generate heat and electricity.

The commercial production of second-generation biofuels remains relatively low today. Support for policies to promote the production of advanced biofuels from lignocellulosic biomass-based raw materials, such as wood and agricultural residues, have encouraged the development of commercial pilot projects in Europe and the US.

In 2012, the production of modern biofuels in the USA from lignocellulosic raw materials reached 2 million liters. China made progress in the production of second-generation biofuels too and produced in 2012 about 3 million liters of ethanol from corn cobs for use in gasoline blends. At present, several demonstration plants with small volumes of final products operate in Europe.

Mainly biochemical and thermochemical methods are currently used to produce second-generation biofuels.

The biochemical methods are based on the hydrolysis of pre-treated lignocellulosic material with enzymes or acids into xylose C5 and glucose C6, which is followed by their fermentation into bioethanol [43].

The most effective and promising hydrolysis method of pre-treated lignocellulose is the enzymatic method, which, in general, does not produce any toxic by-products. It involves cellulases and hemicellulases of prokaryotic and eukaryotic microorganisms, mainly fungi.

Thermochemical biofuel production technologies have the advantage of producing hydrocarbons that are fully compatible with existing fuels, which is very important for infrastructure development and creating fuel blends (traditional fuel + alternative fuel). In addition, thermochemical processes allow the production of synthetic biofuels—gasoline and diesel.

Synthetic fuels have excellent consumer properties. Therefore, they can be used not only for modern internal combustion engines, but also for the future prospective engine designs. Methanol, dimethyl ether, methane and hydrogen can be obtained in this way too.

A promising type of synthetic gaseous fuel produced from synthesis gas is dimethyl ether (DME). Despite the fact that DME is inferior to traditional diesel in energy content, lubricity and viscosity, it has some undeniable advantages. High oxygen content and the absence of carbon-to-carbon bonds in the molecular structure of the ether result in its effective combustion in diesel engines. Compared to petrodiesel, DME has a higher methane number (55–60), low boiling (−25 °C) and ignition (235 °C) temperatures, and does not contain sulfur and its compounds, which in total contributes to the significant reduction of soot, nitrogen and sulfur oxides emissions in the exhaust gases, overall reduction of noise levels and increased engine life. In addition, this fuel has excellent starting characteristics at low temperatures.

The disadvantages of this fuel are low kinematic viscosity (leakage tendencies) and poor lubrication properties. Sealing may be also required, because dimethyl ether is a strong solvent for most rubber products.

One of the main areas of the biomass thermochemical conversion involves using the pyrolysis process, which results in the formation of pyrolysis gases and liquid fraction—bio-oil and solid coal. Bio-oil is mainly used for the production of transport biofuels.

Bio-oil is a thick dark brown resinous liquid with an acid-smoke smell, which is similar in appearance to the traditional fossil oil. Depending on the raw material, the modes of pyrolysis process and the presence of microorganisms, the color of the liquid may change and turn dark red-brown, dark green and almost black [47].

The high content of water in bio-oil complicates its flammability. The increased acidity of bio-oil causes corrosion of some systems during storage and use (tanks, pipelines, fittings, nozzles, etc.) and requires the use of anti-corrosion materials. In addition, bio-oil is instable and may change its properties over time (viscosity growth, phase separation, and the formation of polarized deposits), the same happens when it contacts warm air. Different physical and chemical methods are used to improve the quality of bio-oil.

At present, mainly the chemical upgrading of bio-oil and the co-processing of bio-oil with petroleum products at the oil refinery are used to obtain transport biofuels in the pyrolysis process [48].

The chemical upgrading of bio-oil involves its hydrotreatment to the minimum oxygen content and the hydrocracking of the heavy part of the upgraded liquid. After that, the distillation of the resulting mixture and its separation into gasoline and diesel fuels take place. The process scheme is shown in Fig. 6.

Scheme of turning biomass into liquid fuels by upgrading the bio-oil [48]

The studies conducted by BTG staff together with the scientists from the University of Twente showed that the biodiesel obtained by direct upgrading could be blended with traditional diesel in the proportion of 25% to 75% respectively, and the resulting mixture could be successfully used for fueling cars [49].

Nowadays, the co-processing of renewable and natural raw materials on standard oil refining equipment is of particular interest (Fig. 7). The co-processing is the simultaneous transformation of biogenic raw materials—bio-oil and intermediate petroleum products, such as vacuum gasoil (VGO)—using the existing refinery processing units.

Scheme of the fluid catalytic cracking unit for co-processing [48]

The co-processing in fluid catalytic cracking units is a new and promising way of converting bio-oil into renewable gasoline and diesel. Current studies are mainly aimed at unlocking the potential of this technology and show that co-processing can provide significant potential for using the existing processing infrastructure for biomass processing, mainly lignocellulosic raw materials, and increase the supply of biofuels to the market [50]. For example, in the United States of America, there are 110 fluid catalytic cracking units currently in operation, the use of which could provide the production of more than 8 billion gallons of biofuel (more than 30 billion liters) at the existing refineries. [51]

The authors of [52] carried out research and established the technical possibility of the direct use of crude bio-oil in the amount of up to 20% for co-processing. It is worth noting that the co-processing of bio-oil in combination with petroleum products does not require the construction of new plants. It reduces the dependence on fossil oil and can pave the way for the intensive introduction of biofuels to the market. The obtained biofuels have good operational characteristics and their use practically does not require changes in the fuel consumption infrastructure.

3.3 Third- and Fourth-Generation Biofuels

The definition of “third-generation biofuels” generally denotes the biofuels that do not compete with either feed grains or land. The most commonly accepted definition of third-generation biofuels is fuels produced from the algae-derived biomass [43].

Algae are the fastest growing plants in the world. They can double their weight several times a day, contain a record amount of oil and have no analogues in the plant world according to this indicator. Up to 40 harvests per year can be taken from one biofuel algae cultivation site, and about 80% of the organic matter generated on Earth every day is accounted for by algae. Theoretically, more than 15,000 L of lipids per year can be obtained from 1 ha of phytoplantation.

Microalgae—both the simplest unicellular and large seaweeds—are used for industrial processing. The former are used to produce biodiesel and hydrogen, the latter—to produce bioethanol, biomethane and liquid synthetic fuels by the Fischer-Tropsch process.

The peculiarity of algae production is the ability to change the quantitative and qualitative composition of lipids (variability), depending on the culture medium, light and temperature. As there are many lipids in cell walls, it is possible to remove them by non-toxic solvents without disrupting cells’ viability. Lipids can be also extracted by centrifugation, which, after their separation, allows the biomass to be placed in a nutrient medium for the re-accumulation of hydrocarbons. It is especially important that algae can be cultivated in all conditions of all climatic zones. Carbon dioxide is also used for algae cultivation. It is passed through the culture medium, which reduces its content in the atmosphere and contributes to the global warming slowdown.

In addition to algae cultivation in open ponds, there are technologies for growing them in bioreactors, which is a better method to perform research and implement new and innovative production projects. Although these systems are more expensive in production and operation, they allow for the creation of a controlled environment to optimize the growing process: temperature, pH, gas level, uniform mixing, and sufficient light. Besides, bioreactors can provide for the cultivation of certain algae species without the competitive effect of other species, which is rather problematic in open ponds.

In general, microalgae biodiesel has two major advantages over the production of vegetable oil biodiesel. First, algae contain a large amount of polyunsaturated fatty acids that allow biodiesel not to lose its fuel properties at low temperatures, so diesel engines can work in winter. Second, the yield of fuel from microalgae is 20–30 times higher than from vegetable oil crops when grown on the same area.

Most third-generation biofuels are planned to be produced by converting the organic matter into fuel. However, there is an alternative approach based on the fact that some algae inherently produce ethanol that can be collected without destroying the plant itself. Thus, the photosynthesis accumulation of solar energy, CO2 deposition and ethanol production occur during one process [53].

The production of molecular hydrogen by microalgae is currently at the stage of experiments and pilot projects. It is an absolutely clean fuel, characterized by the high calorific value of 143 kJ/g. It has high energy intensity, which is 3–5 times higher than the same indicator of gasoline and oil, and universal energy properties: reducing agent, energy carrier and fuel. The chemical and electrochemical methods for producing H2 are not economical, so it is more rational to use the microorganisms capable of releasing hydrogen. Aerobic and anaerobic chemotrophic bacteria, purple and green phototrophic bacteria, cyanobacteria, various algae and some protozoa have this capability. Their use is of particular interest as they are more efficient in converting solar energy than higher plants.

The long-term benefits of hydrogen fuel as one of the substitutes for petroleum products were proved by the innovative programs, approved by the governments of some states, and a larger fleet of hydrogen vehicles and number of gas stations.

Thus, at present, algae are the most dynamic and high-energy plants. They can become the basis for the large-scale production of motor biofuels, thereby creating a basis for sustainable energy development of the future.

Hydrogen is considered to be a promising alternative in the long run (by 2030). Hydrogen produced from biomass, which can be used to drive motor vehicles with fuel cells or internal combustion engines, is sometimes considered to be another type of third-generation biofuels.

At present, there are all prerequisites to believe that hydrogen, just like biomass, can compete with fossil fuels. The transition from an oil-based energy system to a hydrogen economy requires the construction of many new hydrogen plants and gas stations. The new infrastructure should cater to the emerging demand for hydrogen and use the existing infrastructure, for example, gas pipelines and railways, to minimize the set price.

The early introduction of a certain hydrogen technology can dominate the market, provided there is appropriate infrastructure. For example, if natural gas became the dominant fuel for hydrogen production, a more complex pipeline network could be built to facilitate the transportation of gas for hydrogen production. The same system could be used to transport synthesis gas produced by coal or biomass gasification. In this case, it would be possible to reduce the costs of hydrogen production and make the hydrogen-based gas technology dominant [54].

The designs of hydrogen infrastructure and systems should comply with the existing infrastructure for the transportation of natural gas, coal, biomass, water and maybe other renewable energy sources [55].

The choice of raw materials for hydrogen production can also depend on time and prices. If the demand for natural gas increases, prices will rise and alternative technologies can become competitive [56].

The latest achievement in biofuels production is the fourth-generation biofuels. The production of this fuel type uses special living microorganisms that over time will be able to produce biofuel products with photosynthetic cells (more precisely, several cycles of photosynthesis). The microorganisms will use carbon dioxide to support their life processes [57]. It is believed that metabolic engineering of algae for biofuels production has great potential for producing sustainable and clean energy.

There are special electrotrophic microorganisms capable of using electric current to convert carbon dioxide from air or seawater into organic molecules. These microorganisms can be combined with any source of energy: nuclear and thermal power plants, renewable energy. Such developments in the field of alternative energy will help to minimize the consumption of organic natural resources and will lead humanity to a new and productive stage of the energy-efficient development [58].

Summarizing the analysis, it can be concluded that the above-mentioned fuel generations have their advantages and disadvantages (Table 3) and still have considerable potential for improvement.

3.4 Economic Aspects of Biofuels Production

The production cost of biofuels is the cost of raw material resources plus production costs, including capital cost of chemicals, enzymes, energy and operating costs. With the exception of ethanol from sugar cane in Brazil, the production costs of all first-generation biofuels in each country are substantially subsidized [59]. Higher costs of edible crops have made the first-generation biofuels (except Brazil) more expensive.

Due to the rapidly increasing demand for raw materials for biofuel production, the prices for some raw materials, such as corn in the the USA, have risen sharply. In view of this, the production of second-generation biofuels from low-cost raw materials is promising [33]. Based on the data from different studies, the comparison of the cost of different generations of biofuels and the cost of conventional fuels is shown in Fig. 8.

According to Fig. 8, corn ethanol has the minimum cost, and algae biodiesel has the maximum cost. In [49, 59], it is reported that the capital cost per unit of production capacity decreases with the increase in the capacity of processing plants. Usually the reduction of these costs is enough to offset the increase in biomass costs, resulting from the increased average transportation distances associated with larger production scales. Large production scales are more significant for the thermochemical process [59]. Ajanovic and Hass [62] report that under exisitng political conditions, mainly excise tax exemption, the economic prospects of first-generation biofuels are quite promising in Europe, but the main problems of this generation of biofuels are the lack of land available for growing raw materials and modest environmental performance. The commercial production of the first- and second-generation biodiesel is practiced in many countries (Table 4).

An important indicator in the biofuels production is the net energy ratio (NER). This ratio determines the ratio of the amount of produced energy in MJ to the amount of consumed energy in MJ and indicates the commercial feasibility of the process. The values of net energy ratio for different fuels are shown in Fig. 9. In this case, the NER value less than 1 indicates that the production process is commercially unprofitable.

The authors of [65] studied the NER of the small-scale production of rapeseed and soybean biodiesel. They found that biodiesel made from soybeans was more energy efficient than rapeseed biodiesel because of the lower need for nitrogen fertilizers. However, rapeseed was a more productive raw material due to its higher oil content. The work [66] compared net energy consumption with greenhouse gas emissions of algae (Nanochloropsis) with soybean biofuels and fossil fuels, and found that algae biodiesel had 5% less greenhouse gas emissions than soybean biodiesel. Besides, it was noted that the NER of algae biodiesel was 43% lower than the NER of soybean biodiesel. Figure 6 shows that the NER for second-generation bioethanol is close to the NER of fossil fuels. The authors of [67] obtained the highest NER for cellulosic ethanol. Due to lower NER values (<1), the authors of [68] conclude that horizontal tubular photobioreactors (PBRs) and plane-type photosynthetic bioreactors are currently commercially unsuitable.

4 Biofuel Influence on Global Climate Change Mitigation

Although in the context of general power demands the biofuel production is small like before, at the same time it is quite significant in comparison with the modern level of agricultural production. In connection with this, possible ecological and social consequences of further increase of biofuel production should be recognized.

For instance, greenhouse gas emission reduction is among the specific goals of biofuel production support policy. An unpredicted negative influence on the land and water resources, as well as on the biodiversity, is regarded as a side effect of agricultural production as a whole, but it triggers special concern in regards to the biofuel. The degree of such influence depends on the way the raw materials for biofuel are conveyed and processed, on the scale of production, and especially on the discovered influence on the change of the nature of land use, intensification and international trade.

In many specialists’ opinion, the replacement of fossil fuel with the fuel produced from biomass will make a significant positive impact on climate due to emission reduction of greenhouse gases, which constitute one of the reasons of global warming [69]. Bioenergy crops are capable of reducing and compensating greenhouse gas emissions by way of directly eliminating carbon dioxide from air during the process of their growth and accumulating it in their biomass and soil. Many of such crops are used not only for biomass production but also for the production of by-products, such as protein for animal feeds; this saves energy which would be spent on the production of feeds by means of other methods.

Regardless of such possible benefits, scientific investigations have proved that various kinds of biofuel differ significantly by greenhouse gas balance if compared with fossil fuels. Depending on the method of raw materials production and fuel manufacturing process, some crops can produce even more greenhouse gases than fossil fuel does [70]. For example, nitrogenous fertilizers emit nitrogen oxide. Moreover, greenhouse gases are also emitted at other stages of production of bioenergy crops and biofuel: in the process of production of fertilizers, pesticides and fuels used in agriculture, in the process of chemical processing, transportation and distribution up to their end use.

Greenhouse gases can also be emitted due to direct or indirect changes in the nature of land use caused by the expansion of biofuel production: for example, carbon release from the soil accumulated by woods or meadows, as a result of repurposing lands for cultivation of crops. For instance, if maize, which is cultivated for ethanol production, can reduce greenhouse gas emission approximately by 1.8 tons of carbon dioxide per hectare per year, and millet (potential second generation bioenergy crop) can achieve reduction by 8.6 tons per hectare per year, then the conversion of meadowland to the production of such crops can yield 300 tons of carbon dioxide per hectare, while in case of forests it constitutes from 600 to 1000 tons per hectare [71].

A life-cycle analysis is an analytical tool used for the calculation of balances of greenhouse gases. The balance of greenhouse gases is obtained as a result of comparing all greenhouse gas emissions during all stages of biofuel production and usage with all the greenhouse gases emitted during the production and usage of equivalent amount of energy of the respective fossil fuel.

With the help of a reliable, albeit complex, method, a thorough analysis of each chain link of value creation is carried out aiming at the assessment of greenhouse gas emissions (Figs. 10, 11).

The assessment of greenhouse gas balance starts from the determination of boundary conditions for a specific biofuel system, which is compared with the corresponding reference system, and in most cases, it is gasoline. Some kinds of raw materials for biofuel are also used for the production of by-products, such as seed cake, livestock feed, etc. In such cases, “eliminated” emissions of greenhouse gases are considered, which are compared with analogical stand-alone products or assessed based on the distribution method (for example, based on energy store or market price).

Greenhouse gas balances differ significantly for various crops and locations, and depend on the methods of raw materials production, treatment processes and application. Resources which were put in, such as nitrogenous fertilizers, and the way of electrical energy obtainment (for example, from coal or oil, in the form of nuclear energy), which are used in the process of raw materials treatment for their conversion to biofuels, can cause the varying degree of greenhouse gas emissions and also be different in various areas (Fig. 12; Table 5).

The majority of currently existing investigations on biofuel conducted with the use of life-cycle analysis were dedicated to grain and oil crops in the European Union and the United States of America, as well as to sugarcane ethanol in Brazil.

Taking into consideration a big variety of kinds of biofuel, raw materials and technologies of production and treatment, one can expect the obtainment of an equally wide range of results during the calculation of emission reduction which is observed in reality.

The majority of investigations show that the production of the first generation biofuel from the existing raw materials will lead to emission reduction in the range of 20–60% if compared with fossil fuel under the condition of using the most effective systems (calculations exclude carbon emissions as a result of the change of land use nature). Brazil, which has a long-time experience in sugarcane ethanol production, demonstrates higher values of emission reduction.

The second generation biofuel, which still has a small commercial value, usually provides with 70–90% reduction of emissions in comparison with fossil diesel fuel and gasoline and also does not take into account carbon release due to the change of land use nature.

Some of the latest investigations show that the most distinct differences in the obtained results emerge due to the selection of different methods of by-products distribution and different assumptions about nitrogen oxide emissions and carbon release resulting from the change of land use nature. It is worth mentioning that a wide range of different methods is used for the execution of life-cycle analysis and, as mentioned above, some of them do not take into account a complex issue of changes in the land use structure. Measurement parameters and the quality of data used in the assessments must comply with the established standards. At the moment, there are efforts made, including also the ones within the framework of the Global Bioenergy Partnership, intended for the development of an approved assessment methodology for the balances of greenhouse gases. Of no less importance is the development of an agreed approach to the assessment of a wider ecological and social influence of bioenergy crops in order to provide with transparency and compliance of the results within a wider range of systems. This can be done if strict requirements are put to picture completeness and accuracy during the calculation.

5 Biofuel Production Influence on the Land and Water Resources as Well as on Biodiversity

Intensification of systems for agricultural production of raw materials for biofuel and repurposing of the currently available and new croplands will have ecological consequences which extend beyond the scope of influence on the greenhouse gas emissions. The nature and severity of these consequences depend on such factors as the scale of production, kinds of raw materials, methods of cultivation and land use, location, and ways of further processing.

At the moment, there are not enough data on the impact which is directly connected with the intensified biofuel production, but the majority of problems in this field are similar to the problems observed in agricultural production:

-

depletion and contamination of water resources;

-

soil degradation and nutrient depletion;

-

loss of natural and agricultural biodiversity.

5.1 Impact on Water

In many situations, it is the water shortage instead of land one that can be found to be the main limiting factor for the biofuel raw materials production [76, 77]. Currently, around 70% of fresh water in the world is spent on agricultural needs [78]. Many countries feel an increasing deficiency of water resources for agriculture as a result of an increase of competition with domestic and industrial uses. Besides, the load on already insufficient resources will increase further because of expected consequences of climatic changes, such as the reduction in the amount of precipitations and river flows in some of the main regions (including the Middle East, North Africa and South Asia).

At present, in the whole world the biofuel production uses approximately 100 km3 (or 1%) of all the water absorbed by agricultural crops, as well as approximately 44 km3 (or 2%) of all the water used for irrigation [79]. It is worth mentioning that water quantity and quality are the key factors influencing ecological sustainability in biofuel production [70, 80].

In order to achieve industrial capacities during the cultivation of many crops currently used for biofuel production, such as sugarcane, oil palm and maize, relatively much water is needed, thus, such crops are more suitable for tropical regions with a high level of precipitations or for the places where artificial irrigation is possible.

Even for perennial plants, such as jatropha and pongamia, which can be cultivated in semi-arid regions on marginal or degraded lands, irrigation may become necessary during a dry and hot summer. Moreover, the process of raw materials conversion to biofuel can require a lot of water. However, it is the irrigated production of the main kinds of raw materials for biofuel that will make the greatest impact on the local balance of water resources. Many regions producing sugar on the irrigated lands in South Africa and East Africa, as well as in the north-east of Brazil, have practically depleted the hydrological capabilities of the river basins in use. This is the case of the river basins of Awash, Limpopo, Maputo, Nile and San Francisco.

Even if the potential for expansion of the irrigated areas can seem high in some regions due to the availability of water and land resources, the actual capacities of biofuel production growth in the irrigated conditions on the available or new irrigated lands are limited with the demands to infrastructure, water supply provision, and the existing land-tenure systems which can be non-compliant with the systems of industrial production.

The highest potential for expansion is present only in Latin America and in Africa, to the south from Sahara. However, judging by predictions, in the last-mentioned region the level of water consumption for irrigation, which used to be low so far, will gradually increase.

The expansion of the production of agricultural crops for biofuel will influence both the quality and the quantity of water. The conversion of pasture lands and forests to maize fields, for example, can enhance such problems as soil erosion, sedimentation and drain of excessive nutritional chemicals (nitrogenous and phosphatic ones) to the surface waters, as well as infiltration of the surplus of applied fertilizers to the underground waters. An excess of nitrogen in the Mississippi river system is the main reason of emergence of the oxygen-free “dead area” in the Gulf of Mexico where a lot of species of marine fauna cannot exist.

An important water quality issue related to the increase in the cultivation of bioenergy crops is the contamination with nutritional chemicals as a result of surface runoff and infiltration to the subsoil waters. The paper [81] states that after the substitution of maize-soybean crop succession with constant maize planting for the production of ethanol in the United States of America the problems will escalate due to the wider application of nitrogenous fertilizers and their drain.

What concerns the stages of distribution and storage, then, as ethanol and biodiesel decompose under the influence of microorganisms, they have less negative impact on the soil and water resources during the drain and spillage than the fossil fuel.

In Brazil, where sugarcane for ethanol production is cultivated mainly under the conditions of rain watering, water availability is not a limiting factor, however a bigger concern is triggered by water contamination related to the application of fertilizers and agrochemicals, soil erosion, sugarcane washing and other stages of ethanol production process [82]. A big part of factory drains water (vinasse) is used for irrigation and fertilization of sugarcane plantations, reducing in such a way the water demand and the risk of eutrophication.

Pesticides and other chemicals can get washed away to water bodies and deteriorate water quality. The need in fertilizers and pesticides differs significantly for maize, soybean and other biofuel raw materials. Among the main kinds of biofuel raw materials, the highest application rate of fertilizers and pesticides per hectare is peculiar for maize. The production of biofuel from soybean and other, not much fertilized and quite diverse, biomass in prairie regions demands per unit of produced energy only a small portion of nitrogen, phosphorus and pesticides used for the production of biofuel from maize and, correspondingly, does not make such a negative impact on water quality [83].

At the same time, the above mentioned problems related to the quantity and quality of water for bioenergy crops production can be controlled by way of a proper selection of agricultural crop species and optimal management (for example, of harvest gathering speed, irrigation, corresponding plant food and filter strip) which raises the possibility of balancing bioenergy production and water resources conservation [84]. Applying the modern technologies of waste water treatment, organic impurities and waste can be effectively fought with. Fermentation systems can decrease the biological oxygen demand in the waste waters more than by 90%, that is why water can be re-used in the production process, while methane can be absorbed by a purification system and used for electrical power generation.

5.2 Impact on Soil

A negative impact on the soil is made both by changes in the land use structure and the intensification of agricultural production on the existing croplands, but such impact is dependent to a significant extent on the agricultural technologies for all the crops with no exceptions. Unacceptable techniques of agricultural crop cultivation can reduce the content of organic substances in the soil and increase its erosion due to the removal of a constant soil mantle.

Soil erosion is a very common and serious problem which is an important issue in the production of bioenergy crops as erosion deteriorates soil quality and hereby decreases the production capacity of natural and agricultural ecosystems. Soil erosion can be caused by three main ways: expansion of maize areas, elimination of plant remains, and change of land use. The expansion of maize areas due to the increase of demand for ethanol can cause serious adverse consequences for soil management [76].

The elimination of plant remains can deteriorate soil nutrient content and increase greenhouse gas emission due to the loss of soil carbon. On the other hand, conservation tillage, crop successions and other improved farming methods under favourable conditions can reduce the negative impact or even improve the state of environment along with the expansion of production of biofuel raw materials [85].

Cultivation of perennial plants, such as palm, fast-growing coppice crops, sugarcane or millet, instead of annual crops, can improve soil condition due to the boost of soil mantle and the increase of organic carbon level. If, in addition to this, tillage treatment is refused from and a lesser amount of fertilizers and pesticides is applied, then a positive influence on the biodiversity can be achieved.

The kinds of raw materials differ from each other by the impact on soil, needs in nutrients and the necessary degree of soil preparation. In particular, the sugarcane makes less impact on soil than rapeseed, maize and other grain crops. The quality of soil is maintained due to the recirculation of nutrients contained in the waste of sugar plants and distilleries, but the expansion of bagasse usage as an energy source during ethanol production reduces the recirculation.

Extensive production systems require re-use of waste for nutrient recirculation provision and soil conservation; in case of herbaceous crops and maize, as a rule, only 25–33% of crop waste can be gathered without environmental damage [86]. Under the conditions of increased demand for energy leading to the creation of crop waste market and in the absence of a proper process organization, such waste is used for the production of different kinds of biofuel that can potentially have a harmful influence on the soil quality, especially on its organic composition.

It has been established in the paper [83] that soybean production for biodiesel fuel in the United States of America requires much less fertilizers and pesticides per unit of generated energy than maize processing. However, the authors of the research state that both kinds of raw materials require a bigger amount of applied resources and the availability of higher-quality lands in comparison with the second-generation raw materials like millet, woody plants or different combinations of meadow grasses and graminaceous plants.

Perennial lignocellulosic crops, such as eucalyptus, poplar, willow or grass plants, do not require such an intense processing and demand less fossil fuel to be used as an input resource; besides, they can be cultivated on poor lands, and thereupon the content of soil carbon and soil quality, as a rule, improve in the course of time.

5.3 Impact on Biodiversity

Biofuel production can make a certain positive impact on the natural and agricultural biodiversity, for example, due to the restoration of degraded lands; however, its influence is mainly negative, for instance, in the cases when natural landscapes are to be repurposed for the production of energy crops or during marshland reclamation. In essence, during the expansion of croplands, natural biodiversity is under the threat of habitat loss, while agricultural biodiversity can suffer from a large-scale transition to monocropping which means the use of a narrow gene pool, and this leads to a reduction in the use of traditional breeds.

The first way which leads to biodiversity loss is the habitat disappearance resulting from repurposing of the lands, like, for instance, the use of forests or meadows for energy crop processing. It is known that many of the current-day energy crops are more suitable for tropics. This increases economic stimuli in the countries, which have favourable opportunities for biofuel production, to the conversion of natural ecosystems to plantations for the production of bioenergy raw materials (for example, oil palm) leading to a reduction of natural biodiversity in such regions.

Regardless of the fact that oil palm plantations do not need a big amount of fertilizers or pesticides even on poor soils, their expansion will lead to the reduction of tropical forest areas. In information coming from some countries it is stated that, as a result of land conversion to the production of raw materials for biofuel, a habitat loss is happening [87], but the data and analysis results which are necessary to make an assessment of the degree and consequences of such loss are still absent.

The paper [88] considers how a price increase on the goods which is caused by an increased demand for biofuel can influence land use and production intensification in Brazil. The authors have found out that the expansion of agricultural production due to the increase of prices can threaten the regions with a big diversity of bird species.

The second main way is the loss of agricultural biodiversity caused by the intensification of production on croplands which shows itself in genetic uniformity of crops. Most of the plantations of raw materials for biofuel are used for the cultivation of a crop of one kind. The concerns are voiced for a low level of genetic diversity of grass plants used as raw materials, such as sugarcane, which enhances the susceptibility of these crops to new pests and diseases.

For such a crop as jatropha, vice versa, an extremely high degree of genetic diversity is peculiar, a big part of which is not perfected, and this creates a wide range of genetic characteristics, reduces the commercial value of this crop.

What concerns the second-generation raw materials, it should be mentioned that some of the popularized kinds are classified as invasive, and this causes new problems in the sphere of their control and avoidance of unforeseen consequences. Moreover, a lot of ferments necessary for processing of such kinds are genetically modified with the aim of increasing the performance, and they must be handled very carefully, with the application of industrial technologies which ensure their isolation.

A positive impact on biodiversity was observed on degraded or marginal lands where new combinations of perennial species were implemented in order to restore functions of ecosystems and to increase biodiversity. Experimental data obtained on the investigated areas of degraded or derelict lands [89] indicate that low-cost, local perennial meadow plants do a wide range of ecosystem favours including the provision with habitats for wild fauna and flora, water filtration and carbon capture; they are characterized by high values of energy net increase (amount of energy released during combustion), by ability of a more significant reduction of greenhouse gas emissions, and less agricultural pollution in comparison with maize for ethanol production and soybean for biodiesel production; they increase their efficiency as the number of species grows.

Besides, the authors of this research have also found out that millet can produce a heavy yield on fertile soils, especially with the application of fertilizers and pesticides, but its yielding ability on poor soils is significantly lower than that of various local perennials.

5.4 Use of Marginal Lands

The marginal lands are usually areas degraded in a technogenic way, eroded or depleted in organic matter content, which are not profitable or convenient for agricultural crop cultivation for the production of food items, or naturally inappropriate territories like saline lands, marshes, wastelands, subacid or acid soils. Moreover, former or reclaimed industrial areas can also be marginal lands. And although these inappropriate lands may have a low fertility potential for producing heavy yields, they can still possess a high potential for producing the biomass for bioenergy production [90].

Marginal or degraded lands are quite often characterized by a shortage of water (which restraints the growth of plants and decreases the nutrient availability), as well as low fertility and high air temperatures. Typical problems of such areas are: degradation of vegetation mantle, water and wind erosion, salinization, soil compaction and soil crust formation, as well as depletion of nutrient stock. In some places, soil pollution, degleyfication, alkalization and bogging can happen as well.

Biofuel crops that are capable of sustaining the conditions in which food crops do not survive allow to use for cultivation the land which is currently providing with minor economic benefits [91].

Possible “candidates” for such a role are: cassava, castor-oil plant, sweet sorghum, jatropha and pongamia, as well as drought-resistant tree crops, such as eucalyptus. However, it is important to mention that quite often marginal lands provide with sources of the means of existence for low-income village dwellers and, in many cases, women. It will depend on the nature and reliability of the poor population’s land title if they are going to gain or lose from the implementation of biofuel production on marginal lands.

Quite often one can hear statements that there are considerable areas of marginal lands which could be brought to use in biofuel production, and this would smoothen the competition with food crops and provide the poor farmers with a new source of income.

Although such lands are less productive and tend to have higher risks, their use in the form of bioenergy plantations can give additional benefits like restoration of degraded vegetation, carbon capture and the provision with local ecological services. However, the issue of appropriateness of such lands for sustainable production of biofuel is underinvestigated in most of the countries.

Cultivation of any crops on marginal lands with a low moisture content and poor nutritive properties will cause a decrease in yielding ability.

Drought-resistant jatropha and sweet sorghum are not an exclusion, and in order to ensure commercially acceptable yielding ability levels, the plant and tree species should not be subject to stress exceeding certain limits; in fact, a favourable impact on such species will be made by an introduction of a moderate amount of additional resources.

Perfected crops can provide with a potential for development in a long-term perspective, but in order to guarantee yielding ability that will be economically significant, a sufficient amount of nutritive substances and water will be needed, as well as the proper regulation; this means that even durable crops cultivated on marginal lands will still compete to some extent with food crops for such resources as nutritive substances and water [92].

6 Sustainability Criteria and Compliance Therewith

Although numerous and diverse ecological consequences of bioenergy development, in fact, do not differ from the consequences of other farming methods, the question about the best way to assess them and consider in agricultural practice is still in the agenda.

Existing methods of assessment of environmental impact and long-term ecological consequences can be successfully used as a basis for the analysis of biophysical factors. There also exists an enormous amount of technical solutions based on the experience of agriculture development in recent years. Among new investigations in the bioenergy field are: basic analytical solutions in the domain of bioenergy, food security and analysis of bioenergy development consequences, work regarding a complex influence on environment, including acidification of soil, excessive application of fertilizers, biodiversity loss, air pollution and toxicity of pesticides [93], as well as the work dedicated to the criteria of social and ecological sustainability, including the boundaries of disafforestation, competition with food production, negative impact on biodiversity, soil erosion and nutrient depletion. Biofuel sector is characterized by the availability of a wide range of activity subjects with different interests. In combination with the sector’s quick development, this led to the appearance of numerous initiatives directed at the provision of a sustainable development of bioenergy.