Abstract

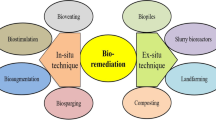

The term “environmental biotechnology” has been coined to describe the use of biological systems, ranging from bacteria to plants, to achieve environmental remediation, pollution prevention, detection, and monitoring of contaminants, and more recently transforming waste to produce energy, biopolymers, and other benefits. Latin-American countries have a privileged location to develop ingenious and sustainable alternatives in environmental biotechnology. An advantage to do innovation in tropics is their biodiversity. Useful compounds can be produced in laboratory settings and/or full-scale operations. However, waste (solid, liquid, or gaseous) released into natural and confined (end of pipes) environments are normally mixtures of different chemical compounds and often microorganisms are part of this waste. Waste valorization can conduce to obtain more rentable by-products in bioremediation. To conduct the bioremediation join to valorization, many processes need to be implemented. Coupled biological processes can increase the efficiency and value to end products. In this chapter, different alternatives to valorize organic wastes under the anaerobic digestion-based biorefinery concept were reviewed. Advantages and challenges of developing countries to use environmental biotechnology and to solve waste problems were also analyzed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

9.1 Introduction

Anaerobic digestion (AD) is defined as a biological process that converts organic matter into biogas (energy) and nutrient-rich digestate. This process can be seen as a promising alternative for agro-industrial waste management with low environmental impact, and opportunities for value recovering in a simple, economic, and profitable fashion. However, AD does not guarantee a completely safe environmental treatment for products generated in the process (i.e., biogas, solid digestate, and liquid effluent).

The biogas, which is a gas mixture mainly composed of methane (40–70%), has a greenhouse effect equivalent to twenty-five times carbon dioxide effect whether it is emitted directly into the atmosphere (Sawatdeenarunat et al. 2016). Ideally, methane can be used in the process of thermal utilization (e.g., lighting, heating, power generation, etc). Otherwise, burnt it would be an option. Alternatively, biogas might be converted into methanol, which is the source of many high-value industrial chemicals (e.g., anhydride, ethylene, polyols, and other aromatic compounds), under the concept of anaerobic biorefinery (Sawatdeenarunat et al. 2016).

On the other hand, there is a liquid effluent with different amounts of organic matter that depends on the efficiency of AD. This liquid effluent could promote eutrophication in soils and water bodies where is poured. High concentration of nutrients, such as nitrogen, phosphorus, and potassium can be commonly found in liquid effluents that may promote eutrophication. Environmental issues related to ferti-irrigation require regulations and careful handling. Within the safe handling of anaerobic effluents, the use as fertilizer and/or amendment is commonly suggested. In the situation that mentioned uses are not possible, processes of nutrient removal can be considered.

Finally, AD plants generate large amounts of solid digestate that need to be utilized or disposed in an environmental friendly fashion since this matter can be source of contamination due to nutrient runoff (Vasco-Correa et al. 2018). This stream mainly consists of suspended solids and undigested residues. The composition of solid residues varies depending on the substrate type and operating conditions. High concentration of nutrients useful for fertilization can be found. Nevertheless, the concentration of pathogens is the major problem related to this stream. Since AD does not guarantee the elimination of pathogens, the digestate may be converted into the source of contamination for crops that can affect food safety. From this viewpoint, the digestate should be sanitized before its use as fertilizer.

In view of the above, when AD is coupled to other processes, not only the risk of environmental contamination is decreased but also opportunities for recovery and products of added value are generated. This ultimately contributes to the process of sustainability. In this chapter, the current state of AD is presented. In addition, a brief description of compatible technologies with AD and possible models for the integration of processes are included. Thus, a wide variety of high-value bio-based energy and products via biorefinery approach are described. Finally, challenges and perspectives for products of added value around the AD process are considered.

9.2 Current State of Anaerobic Digestion

9.2.1 Worldwide State

Countries that have the greatest AD technology establishment, contexts in which those technologies are used, offering of anaerobic technologies, offering of compatible processes with AD, information from reputable suppliers, and recommended coupling systems are included herein. Additionally, regulations and/or norms from developed countries are considered.

Biogas production has shown a fluctuating behavior over time. It gained a great acceptation in the first half of the twentieth century, followed by a decreasing trend after the 1950s due to the low price of fossil fuels and their accessibility. With the energy crisis in the 1970s, biogas obtained importance as renewable energy. Nonetheless, the high cost of digesters, issues related to design, lack of knowledge, and the inability for proper management were responsible for affecting its growing establishment (Vasco-Correa et al. 2018).

Anaerobic digestion (AD) is a promising biotechnology to convert organic substrates such as high solid feedstocks (animal manure, food wastes, municipal solid wastes, and lignocellulosic biomass), municipal and industrial wastewater to biogas while stabilizing waste (Sawatdeenarunat et al. 2016; Vasco-Correa et al. 2018). The establishment of AD worldwide varies enormously, from small-scale household digesters in developing countries to large farm-scale or centralized digesters in developed countries. Differences in the implementation of this technology are mainly related to a complex set of conditions that include economic and environmental implications, stimulus from polices and incentives in agricultural systems, waste management and renewable energy production (Vasco-Correa et al. 2018).

Over 14,000 commercial AD plants operate in Europe while 9000 plants only work in Germany (Sawatdeenarunat et al. 2016). Europe is a leader in AD technology and its implementation is driven by the establishment of strict environmental regulations for waste disposal (Vasco-Correa et al. 2018). Asia accounts for the largest amount of digesters installed, but most of them are small-scale household digesters used in rural areas for cooking and lighting. China has more than 43 million digesters, and India has about 4.7 million units. The USA, on the other hand, has about 2200 operational AD plants with growing interest in this technology (Vasco-Correa et al. 2018; Serfass 2017).

Two models of digesters are commonly used in Europe; the centralized or joint systems, and the farm-scale digesters. Denmark, for instance, is a pioneer in the development of the first type of digesters with capacities up to 8000 m3. About 150 biogas plants, containing 20 centralized AD systems, are known in this country. Farm-scale plants have capacities from 200 to 1200 m3, and they are usually located in swine farms that co-digest animal manure from 1 to 3 farms with agricultural residues and other organic matter. Germany excels with this sort of plants; about 9000 units and great interest to increase the number of these units are highlighted (Vasco-Correa et al. 2018; Wilkinson 2011). The USA has 247 farm-scale anaerobic digesters, 1269 wastewater treatment plants, 39 industrial AD plants, 645 plants at landfills, and potential for about 13,500 new biogas systems (Serfass 2017). Canada has about 100 biogas plans and various initiatives to reinforce the use of this technology (Vasco-Correa et al. 2018).

Among the renewable energy sources, biomass is used in developing countries. Biomass (e.g., firewood, crop residues, and cattle dung) is considered as a primary energy source for heating and cooking. In developed countries, the use of biogas for combined heat and power generation or transportation fuels is well established (Sawatdeenarunat et al. 2016). Nonetheless, biogas production alone may not be economically competitive due to the volatility of market and price index of fossil fuels, leading to explore alternative products and to adopt other approaches like the biorefinery concept. Many studies have discussed about this topic, but limited studies focused on anaerobic biorefinery have been reported (Sawatdeenarunat et al. 2016; Hagman et al. 2018; MacLellan et al. 2013; Surendra et al. 2015).

9.2.2 Latin America Landscape

In this section, the relationship between AD and agricultural vocation of Latin America countries is included. As well as, regulations and/or norms in these countries are taking into account.

In overall, the application of waste-to-energy (WtE) technologies used to manage and treat organic residues have been developed and implemented in Latin America and Caribbean countries. However, a lot of effort is still needed to significantly contribute and generate impact in the region. Household organic wastes, forest, and agricultural residues, for example, should be seriously recognized as valuable sources of energy since most of them are largely unused (Silva-Martínez and Sanches-Pereira 2018).

As early mentioned, Asia and other developing regions such as Latin America are focused on the use of small-scale digesters (Garfí et al. 2011, 2016, 2019); most household units with capacities between 2 and 10 m3 are usually located in rural areas. Among the most common digesters used, the following types can be found: Chinese fixed dome digester, Indian floating drum digester, and tube digester. These designs do not have mechanical mixing and heating systems (Vasco-Correa et al. 2018). The latter digester has successfully treated agricultural manure since 1980 when the first plastic tubular digester was introduced in Colombia (Silva-Martínez and Sanches-Pereira 2018; Garfí et al. 2019). In Latin America and Caribbean countries, the first small-scale biodigesters were installed in the 1970s. Most countries in the region implemented this technology for the following decade, and the process had major interest in the 1990s and early in the twenty-first century (Silva-Martínez and Sanches-Pereira 2018).

In countries like Colombia, Mexico, Nicaragua, Caribbean Islands, and Central America (i.e., Costa Rica and Honduras), AD technology has been implemented, and it has also adapted to harsh weather conditions (e.g., Bolivia, Peru, Chile, Ecuador, and Argentina). Brazil has registered the use of “Sertajeno” digester type based on the Indian model, but it was abandoned for operational problems. In Caribbean countries, the AD technology was introduced by “Deutsch Gesellshaftfur Technische Zusammenarbeit,” a German organization (Silva-Martínez and Sanches-Pereira 2018).

Government programs and/or nonprofit international organizations (e.g., Stichting Nederlandse Vrijwilligers-SNV founded in the Netherlands) have supported the implementation of national biogas systems in Latin America (Vasco-Correa et al. 2018). In rural areas of Central and South America, for instance, more small-scale digesters (e.g., tube plastic digesters) have been developed and implemented (Vasco-Correa et al. 2018; Silva-Martínez and Sanches-Pereira 2018; Garfí et al. 2011, 2016, 2019; Cutz et al. 2016). Additionally, the Network for Biodigesters in Latin America and the Caribbean (RedBioLAC) was created in 2009 with the purpose of sharing information and to support this technology (Vasco-Correa et al. 2018; Silva-Martínez and Sanches-Pereira 2018).

Although AD has received less attention, Latin America can benefit from small-scale digesters. Successful implementation has been reported in the last few years for heating and cooking purposes. Interestingly, AD for wastewater treatment has operated for several decades. However, the biogas is not fully used. Mexico has tried to develop projects and to use biogas for energy production (Vasco-Correa et al. 2018). Interest in large-scale biodigesters and second-generation biofuels is gaining ground in the region, seeking out their development and implementation (Silva-Martínez and Sanches-Pereira 2018).

Large-scale anaerobic digesters have not been widely implemented for various reasons. Among these, the following can be mentioned: Related costs, system technical complexity, and maintenance demand. Argentina, Chile, and Brazil, on the other hand, have implemented Continuous Stirred Tank Reactors (CSTR), Upflow Anaerobic Sludge Blanket (UASB), and cover lagoons (Silva-Martínez and Sanches-Pereira 2018). Some reports indicate the construction of large-scale plants in Puerto Rico (Voegele 2018).

9.3 Bioprospecting in Tropical Countries

Several alternatives for valorization of organic wastes are biological processes, therefore it is fundamental to have microbial resources in a sustainable way for their implementation. In this sense, it is interesting to consider the potentialities of bioprospecting in tropical countries characterized by their wide biodiversity, especially (Bull et al. 2000; Sanabria 2014).

The use of pure cultures has allowed researchers to know microorganisms in detail, and to control their harmful effects and use them for beneficial applications (i.e., pharmaceutical medicine and disease control) (Bull et al. 2000). Bioremediation has ever used microbial communities capable of transforming pollutants into less environmentally harmful chemical compounds (Sanabria 2014). Lately, when combining the need to control pollution and the use of pure cultures, several pieces of research have aimed at searching for useful and specific microorganisms from consortia, focusing on media enrichment. This method consists in successively passing a group of organisms to the same culture media, decreasing the population to gain a pure culture from a single colony. However, when comparing the number of microorganisms and the applications derived from them, the number of results seems out of proportion. This might be related to the chemical complexity of the pollutants and the limited understanding of the ecological relationships between the species involved.

Furthermore, in the case of Latin America and especially Colombia, there is an actual challenge in microbiology and biotechnology laboratories for design, acquisition, and operation of special devices such as reactors. The directed prospection strategy, in continuous or semicontinuous systems, differs in that microorganisms are never taken out of the bioreactor, in such a way that the consortia obtained is the same product of the continuous feed. For this condition, the supplied media must be continuously adjusted to obtain the desired metabolic outcome. This strategy allows the expansion of the microbial diversity range, and to find microorganisms and combined biochemical processes adapted to the stressful conditions of residues. Thus, they can generate products with high-added value. One of the biggest challenges toward the transformation of wastes is their complexity due to the convergence of organic and inorganic pollutants.

Consortia design can be used as separation strategy, focusing on one or more reactors and coupled processes. In the process, it is possible to obtain pure cultures of microorganisms that have been previously described as non-cultivable (Hu et al. 2013). The use of mixed cultures and low-cost substrates such as waste can reduce the production cost, which may generate an actual interest in decreasing the impact of pollutant discharge. Recent studies have shown that cellular content of PHA in mixed cultures from activated sludge can achieve 67 and 78.5% of its dry cell weight (Liu et al. 2011; Serafim et al. 2004), such values flanking those obtained with pure cultures using high-cost raw material.

Mixed Culture Biotechnology (MCB) was firstly defined by Kleerebezem and Loosdrecht (2007). With the use of undefined mixed cultures, process development in MCB can only be based on natural/ecological selection by manipulating the operation of the bioprocess or varying the source of the natural inoculum which is useful for the transformation of substrates into valuable products. This combination of approaches has been used to improve the production of bio-based fuels, chemicals, and materials.

In this approach, energy flows and stoichiometry play an important role (Rodríguez et al. 2006), and genetic changes will no longer be needed (Agapakis et al. 2012). The success of consortia is represented in the naturally established biodiversity and temperature. Surely, if tropical countries possessing the largest diversity on the planet (many of them in conditions of delayed development) could indeed take advantage of this, they will have better options for competitiveness and development.

9.3.1 Processes That Can Be Coupled to Anaerobic Digestion

In this section, the main concepts and current state of technologies that can be coupled to AD for treatment and valorization of the different effluents are described. Alternatives with added value through obtaining of energy, chemical, and materials are included.

9.3.1.1 Biogas

Biogas Upgrading

The presence of hydrogen sulfide (H2S) in biogas due to the digestion of sulfur-rich substrates can be detrimental to combined heat and power units. Higher concentrations than 250 ppm are worrying. Thus, the hydrogen sulfide and other impurities such as CO2, ammonia, moisture, and particulates should be removed prior to the use of biogas, achieving greater methane content than 95%.

Upgrading processes at commercial-scale plants have been applied (e.g., pressure swing adsorption, water pressure absorption, alkaline absorption, biological filtration, micro-aeration). However, associated costs and economic benefits must be addressed.

Compression and Liquefaction

Among the possible uses of the upgraded biogas, energy production (i.e., heat, electricity, or mechanic work) and biogas injection into a natural gas distribution grid can be mentioned. In these processes, the biogas pressure must be increased (Morini et al. 2009), which (including upgrading process) consumes about 20% of the energy contained in raw biogas (Budzianowski et al. 2017).

The natural gas infrastructure might be used for biogas compression. However, some problems can emerge due to the different physical properties of gasses. The surge, for instance, is one of the main problems detected in biogas compression. It is known as compressor instability and is characterized by the time variation of pressure ratio and mass flow rate, which affects the compressor operating range, performance, and reliability. Experimental and modeling strategies have been proposed to study compressor instabilities and to set up devices that avoid compressor operation beyond the surge line (Morini et al. 2009).

The conversion of biogas in liquefied natural biogas (bio-LNG) can be seen as other interesting option. High energy density, in comparison to compressed biogas, guarantees similar ranges to those values obtained with diesel oil (Baccioli et al. 2018).

The liquefaction technology for small-scale systems is recently available in the market but is characterized by an elevated specific energy consumption (0.7 kWh/Stm3). This highly increases the electric demand of the plant and generates new opportunities in system management (Baccioli et al. 2018). Nonetheless, it is an attractive energy vector with volumes about 600 times less than natural gas volumes at standard conditions, making easy to store and ship (Pasini et al. 2019). Several types of refrigeration cycles can be implemented, but the reverse Joule-Brayton cycle could be the most promising technology for small-scale systems (Baccioli et al. 2018).

Heat and Power Generation

Biogas was initially considered as nuisance because of the odor problems and methane emissions. Flaring has always been a cheap and simple solution. For years, biogas has been intentionally produced from biosolids to generate energy in the form of heat and power. Biogas can be converted into CNG through five steps. After each step, the biogas can be used against a high energy efficiency and/or high energy value. The first step is to dry the gas, making it suitable for simple boilers, for instance. The next step is desulphurization, followed by siloxane removal. After this stage, the gas can be used in a CHP or used to produce electricity at the highest efficiency with gas turbines. In a subsequent step, CO2 can be removed from the biogas, resulting in almost pure methane with the same quality of natural gas. This gas can be injected into a local gas grid after increasing its calorific value with propane. Finally, the gas can be pressurized to 220 bar, allowing to use it as vehicle fuel and being substitute for CNG.

Combined Heat and Power (CHP) is a highly fuel-efficient energy technology, in which usable heat and energy (usually electricity) are simultaneously generated in a single stage. In this process, the excess of heat produced during the conversion of thermal energy into electricity is captured and let available for use. In such a way, CHP can increase the overall efficiency of fuel use up to 89% compared to 55% for the best conventional electricity generation (Coolkeeragh 2007). Most new CHP schemes use natural gas, but a significant portion is dual fuel, and it can burn alternative and renewable fuels, such as biofuels or biogas.

Methane Reforming

It is an important industrial process for H2 and/or syngas production. Fossil natural gas is the main source of methane for the reforming process. However, biomethane might be a renewable option for supplying this demand. Methane reforming can be conducted through three ways (Julio and Barbosa 2013):

-

(a)

Steam methane reforming. Almost half of the world’s hydrogen demand is produced through the steam methane reforming process (Ewan and Allen 2005), which requires high temperatures (800–900 °C) and pressures (15–30 bar). In this process, two reactions are performed:

$$ {\mathrm{CH}}_4+{\mathrm{H}}_2\mathrm{O}\leftrightarrow \mathrm{CO}+{3\mathrm{H}}_2 $$(9.1)$$ \mathrm{CO}+{\mathrm{H}}_2\mathrm{O}\leftrightarrow {\mathrm{CO}}_2+{\mathrm{H}}_2 $$(9.2)The reactor output includes H2, CO, CO2, H2O, and non-reacted CH4.

-

(b)

Dry methane reforming. This process has the advantage of consuming both CH4 and CO2 (two intensive greenhouse gasses) by the following reaction:

$$ {\mathrm{CH}}_4+{\mathrm{CO}}_2\leftrightarrow 2\mathrm{CO}+{2\mathrm{H}}_2 $$(9.3)Chemical promoters (i.e., Mg, K, and other alkali compounds) are used with catalysts in order to avoid coke formation.

-

(c)

Partial catalytic methane oxidation. In this process, an amount of O2 under stoichiometric ratio is used, allowing the partial oxidation of methane and the production of CO and H2. The following reaction is carried out:

$$ {\mathrm{CH}}_4+1/{2\mathrm{O}}_2\leftrightarrow \mathrm{CO}+{2\mathrm{H}}_2 $$(9.4)When the process is not controlled, the increase of oxygen may lead to the total oxidation of methane, producing CO2 and H2O as shown by the following reaction:

$$ {\mathrm{CH}}_4+{2\mathrm{O}}_2\leftrightarrow {\mathrm{CO}}_2+{2\mathrm{H}}_2\mathrm{O} $$(9.5)The above reaction is not desirable since it does not produce H2. However, the released heat may be used as energy source for steam reforming in a coupled configuration based on the following reaction:

$$ {2\mathrm{CH}}_4+{\mathrm{H}}_2\mathrm{O}+1/{2\mathrm{O}}_2\leftrightarrow 2\mathrm{CO}+{5\mathrm{H}}_2 $$(9.6)This process is named autothermal reforming.

Biological Processes

Biological conversion of methane to methanol using methanotrophic bacteria is a promising alternative since the whole process takes place at ambient pressure and temperature. Large amounts of energy are not required as compared to the thermochemical processes (Ghaz-Jahanian et al. 2018). Other value-added products such as lactic acid, succinic acid, carotenoids, and fatty acids may be obtained by the biological conversion of methane using engineered microorganisms (e.g., methanotrophs, ammonia-oxidizing bacteria, and acetogens) (Hwang et al. 2018; Ge et al. 2014).

9.3.1.2 Liquid Effluent

Valorization of Volatile Fatty Acids (VFAs)

In addition to biogas, AD may produce other intermediary and valuable products such as solvents and volatile fatty acids (VFAs), which can be marketed along with methane (Dogan et al. 2009). Moreover, the conversion of organic solid wastes into VFAs can be achieved by the acidogenic step within the AD process. The VFAs can be extracted and turned into valuable products such as methyl or ethyl esters for commercial purposes.

Among the main VFAs produced as a result of hydrolysis and acidification of the OFMSW, acetic acid and butyric acid can be found. As well as, ethanol as the main alcohol is obtained. These variations of by-products formation from acidification depend on the nature of feed and pH variations in the reactor. The pH has been considered as the most important parameter affecting product formation and product spectrum in the acidogenesis phase (Dogan et al. 2009).

Acidogenesis pathways using glucose as substrate can be seen in the Eqs. (9.7–9.10). It is clear that pH and hydrogen partial pressure could determine the choice of acidogenesis pathway. Firstly, ethanol-type acidogenesis is chosen at low operating pH for reducing VFAs production so as to avoid further pH decrease. Secondly, since the ethanol-type acidogenesis does not produce hydrogen, the acidogenesis pathway will shift to ethanol-type from acetic and butyric acid-type in order to avoid further increasing hydrogen partial pressure (Li et al. 2011). This shift easily occurs when pH is lower than 5.7 (Gottwald and Gottschalk 1985).

A study on mesophilic acidogenesis of protein-rich organic wastes revealed that VFAs were dominant products compared to lactic acid and alcohols. Among all VFA products, acetic and butyric acid accounted for 30–50% and 25–40% of VFA carbon, respectively; followed by propionic acid (10–15%), iso-valeric acid (10–15%), caproic acid (5–10%), and iso-butyric acid (3–6%) (Lü et al. 2008).

A liquid stream rich in VFAs can be effectively used as carbon source to remove nutrients in a biological nutrient removal (BNR) process. Producing a liquid with high VFAs concentration can also be desirable if the goal is, for example, to feed microbial fuel cells for direct bioelectricity generation. Likewise, the production of butanol as clean fuel could soon be of great interest since this alcohol has better energetic properties compared to ethanol. Its production and that of other solvents can also be triggered by a combination of high carboxylic acid concentrations, especially butyric and low pH values (Hüsemann and Papoutsakis 1988).

Algal Production

Effluents from AD plants that treat nitrogen-rich substrates (e.g., swine and poultry manure) are rich in nutrients such as nitrogen and phosphorus (Magrí et al. 2017). However, further treatment is needed prior to their disposal to the environment. Alternatively, this nutrient-rich source can be incorporated into an algal production system, providing biomass used for biofuel production (e.g., biodiesel, biomethane, biohydrogen), animal feed, and so on (Sawatdeenarunat et al. 2016; Hagman et al. 2018). Algal bioenergy seems to have a promising future as solution to the global energy crisis and climate change. Algal biomass for bioenergy and biomaterial production offers some benefits, such as no competition with food crops for land or fresh water resources (Daroch et al. 2013), and great potential as AD feedstock in a recycling operation (Hagman et al. 2018).

Nutrient Valorization as Fertilizer

Phosphorus as struvite (MgNH4PO4) can be obtained from anaerobically digested animal manure. This compound has a great potential as biofertilizer (Sawatdeenarunat et al. 2016; Hagman et al. 2018). Large amounts of dairy manure and the global interest in AD of such organic matter suggest an important market for the production of struvite (Tao et al. 2016). The technical and economic feasibility of recovering nutrients through precipitation of struvite from wastewater treatment plants has been reported (Sawatdeenarunat et al. 2016; Hagman et al. 2018; Shu et al. 2006). Struvite crystals can be directly land-applied for crop cultivation. Among the advantages of its use as solid fertilizer, the following can be mentioned: easy application, low transportation cost, reduced bulky storage, avoided odor, and pathogen contamination issues (Tao et al. 2016).

9.3.1.3 Solid Digestate

Products from AD can vary according to the substrate characteristics. Digestate fiber, for instance, is obtained when lignocellulosic substrates are used. Substrates of nonfibrous nature (e.g., manure, domestic or industrial wastewater) generate digestate sludge which has potential as fertilizer. However, the pathogen content in such stream can limit that use, suggesting a subsequent disinfection step.

Disinfection

Solar energy represents a promising alternative for the disinfection of water used for human consumption (Sanabria et al. 2005). This treatment may be applicable to sludges obtained from AD. The Research Group of Advanced Oxidation Processes for Chemical and Biological Treatments from the Universidad del Valle-Colombia, for example, has made important efforts to inactivate E. coli through homogeneous (Sambusiti et al. 2016) and heterogeneous (Arancon et al. 2013) catalytic operations that include the use of sun radiation as energy source.

Saccharification

When lignocellulosic substrates are processed in AD, the biomass size and hemicellulose content are mainly reduced, resulting in an accumulation of cellulose and lignin (Sambusiti et al. 2016). This action destabilizes the recalcitrant biomass structure, allowing cellulose solubilization and glucose production in downstream processes (e.g., saccharification). However, even if amorphous cellulose is a suitable substrate for fermentation, digested fibers still present recalcitrant physicochemical characteristics (i.e., cellulose crystallinity, and lignin content) that negatively influence their enzymatic/microbial accessibility for further conversions (Sambusiti et al. 2016). From these observations, it is suggested to perform pretreatments (physical and/or chemical) followed by saccharification (chemical or enzymatic).

Cellulose can be used as an initial substrate to synthesize cellulose derivatives such as cellulose esters (e.g., cellulose nitrate, cellulose acetate), which are needed to produce optical media, filtration membranes, food and medical purposes. Cellulose ethers such as methylhydroxyethyl cellulose and carboxymethyl cellulose are commonly used as building materials and milk stabilizers, respectively (Surendra et al. 2015).

Composting

Composting is a common and mature biological technology mainly used to stabilize organic waste and to convert such matter into compost for recovery. Notwithstanding, this compost is a relatively low-value product (Sawatdeenarunat et al. 2016; Arancon et al. 2013). This technology has been considered as option for recycling the surplus of manure in livestock production systems, offering stabilized and sanitized end products for agriculture (Bernal et al. 2009).

Within this aerobic biological degradation technology, organic matter is processed to produce a stabilized material that no longer consumes oxygen or generates toxic metabolites (O’Callaghan 2016). However, management of pathogens has been suggested when animal-derived wastes are used (O’Callaghan 2016; Bezanson et al. 2014).

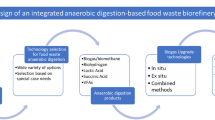

9.4 Biofactory Model-Based on Anaerobic Digestion

AD can be considered as a centerpiece of the biorefinery approach. This technology is used for waste remediation, biological pretreatment of biomass, and for producing bioenergy and bio-based products (Surendra et al. 2015). Figure 9.1 depicts the scheme of AD-based biorefinery concept.

Proposed AD-based biorefinery for producing biofuels and bio-based products modified from Surendra et al. (2015)

Operating under optimal conditions (solids retention time, temperature, and pH), plant solubles and hemicellulose can be converted to biogas while cellulosic matter in the digested fiber can be turned into soluble glucose by enzymatic saccharification. Digestate fiber (i.e., solid residue with lignocellulosic matter), which is considered as a low-value product, can be potentially used as feedstock for biofuel and bio-based product generation. This fiber has been mostly used as soil additive or animal bedding. Monomeric sugars can be used as a source of biofuels (e.g., ethanol, butanol), organic acids and biopolymers (e.g., bioplastic). The insoluble solid residue (i.e., lignin and residual fiber) after enzymatic hydrolysis can be combusted for heat and electricity generation. This residue can be also processed into different bio-based products (e.g., lignin-derived products such as lignosulfonates are used as plasticizers in making concrete, binders in animal feeds, and solid fertilizer pelletization).

The liquid phase after separation of the solid residue from digestate or digester effluent is mainly composed of nutrients (i.e., nitrogen and phosphorous) (Sawatdeenarunat et al. 2016). This effluent can be used for macro- and microalgae production, providing nutrient removal and algal biomass that can be further treated for generation of other biofuels and bio-based products (Sawatdeenarunat et al. 2016; Surendra et al. 2015).

For volatile fatty acid (VFAs) production through AD, the operating conditions and substrate type have an important interactive effect on VFAs’ yield and composition. Thus, the operating conditions should be adjusted taking into account both substrate type and the VFA of interest (Surendra et al. 2015). These compounds can be further processed into biogas, biologically/chemically converted into alcohols-based fuels, or they can be used in microbial fuel cells to produce electricity. Additionally, VFAs have great potential as carbon source in the biological nutrient removal during wastewater treatment and lipid production with oleaginous microorganism (e.g., microalgae, yeasts, molds) during biodiesel generation (Surendra et al. 2015).

To sum up, AD can operate as a biological pretreatment technology coupled to other process units that involve the generation of high-value products (e.g., bioplastics, bioethanol, biobutanol, fungal protein, carboxylates precursors for solvents and/or fuels).

9.5 Challenges and Perspectives

Although the biorefinery concept has received attention in the last decade, much work is still on the road before a coupled system can efficiently prosper. AD system is mostly conceived as a method for reducing organic waste and producing energy. However, fluctuations in energy prices and environmental issues encourage the exploration of other sources of revenue and organic waste treatment. A techno-economic analysis of an anaerobic biorefinery that considers local situations would be worthy before its establishment.

Differences in the implementation of AD worldwide are mostly related to policy drivers, socioeconomic barriers, existing infrastructure, technology availability, and reliability (Vasco-Correa et al. 2018). It is highlighted that AD could be feasible at different scales, from small-scale household digesters to large-centralized biogas plants. The use of biogas at small scale can generate environmental, health, and social benefits related to burn cleaner fuel and stabilizing residues. In addition, the reduction of deforestation and the production of fuels and fertilizers may be simultaneously achieved.

9.6 Opportunities for Tropical and Developing Countries: Colombian Case

There are clear opportunities to implement AD for a developing country such as Colombia:

-

1.

There is a huge amount of organic waste that is not environmentally safe managed and disposed as can be seen in Table 9.1.

-

2.

Tropical conditions benefit biological processes: Climate ~ 24–30 °C, availability of natural and renewable resources (e.g., water, sun, etc.).

-

3.

The necessity of diversification of energy sources due to climate change.

-

4.

Positive social and financial conditions to invest in environmental projects.

-

5.

International commitment to reduce greenhouse gasses. Colombia established an international commitment to reduce 20% of its projected emissions of greenhouse gasses by 2030.

9.7 Challenges

Developing countries face some barriers for the implementation of AD, which can be mainly economic, regulatory, and institutional (Beck and Martinot 2004). Strategic actions are required in order to pave the road for a successful implementation.

To facilitate and make attractive the use of biogas as a renewable energy, a well-established policy that supports and promotes the development and use of renewable energy sources is required. As well as, the design, enforcement of instruments, and lines of action to implement unconventional energies are needed. To harness the benefits from biomass, an integral policy for the use and development of biomass is essential. It is also important to make feasible opportunities for technified rural development.

Barriers to overcome in the renewable energy sector (UPME 2015):

-

1.

Wrong incentives, subsidies to conventional sources.

-

2.

High costs and financing difficulties.

-

3.

Market barriers, rules adjusted to conventional sources.

-

4.

Imperfect competition, strong oligopolies based on conventional sources.

-

5.

Externalities those are not valued and internalized.

-

6.

Lack of information on renewable resources.

-

7.

Lack of human capital with knowledge about technologies.

-

8.

Technological prejudice, inclination for conventional technologies.

-

9.

Increased transaction costs, research, negotiation, and execution.

-

10.

Regulatory and institutional factors, schemes around the conventional.

There are also barriers to the biomass sector (UPME 2015):

-

1.

The complexity of the regulatory framework and market mechanisms available to procure surplus delivery and marketing by small producers, even assuming the possibility of accessing the figure of cogenerator.

-

2.

The absence of a tradition or knowledge among agricultural and agro-industrial sectors in order to take advantage of the energy potential they have with special reference to the case of their waste.

-

3.

The high investment costs required to develop new cogeneration projects, and the lack of possible associated financing schemes.

-

4.

The absence of signals from the market to encourage this type of project, as integral projects for the efficient use of waste and mitigation of environmental pollution.

-

5.

The absence of industrial clusters in which the excess of heat produced by some industries could be used by another.

-

6.

The untapped opportunity to generate electricity from some resources that are available in rural areas not interconnected or with deficient provision of electricity.

References

Agapakis CM, Boyle PM, Silver PA (2012) Natural strategies for the spatial optimization of metabolism in synthetic biology. Nat Chem Biol 8(6):527–535

Arancon RAD, Lin CSK, Chan KM, Kwan TH, Luque R (2013) Advances on waste valorization: new horizons for a more sustainable society. Energy Sci Eng 1(2):53–71

Baccioli A, Ferrari L, Marchionni A, Desideri U (2018) Biogas upgrading and liquefaction in an anaerobic digester plant. Energy Procedia 148:655–662

Beck F, Martinot E (2004) Renewable energy policies and barriers. Encycl Energy 5:365–383

Bernal MP, Alburquerque JA, Moral R (2009) Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour Technol 100(22):5444–5453

Bezanson GS, Ells T, Prange R (2014) Effect of composting on microbial contamination and quality of fresh fruits and vegetables - a mini-review. Acta Hortic 1018:631–638

Budzianowski WM, Wylock CE, Marciniak PA (2017) Power requirements of biogas upgrading by water scrubbing and biomethane compression: comparative analysis of various plant configurations. Energy Convers Manag 141:2–19

Bull AT, Ward AC, Goodfellow M (2000) Search and discovery strategies for biotechnology: the paradigm shift. Microbiol Mol Biol Rev 64(3):573–606

Coolkeeragh (2007) Welcome to the Coolkeeragh ESB Website - Transforming the electricity market. Coolkeeragh ESB, 13 October. [Online]. https://web.archive.org/web/20071013231606/http://www.coolkeeraghesb.co.uk/index.htm

Cutz L, Haro P, Santana D, Johnsson F (2016) Assessment of biomass energy sources and technologies: the case of Central America. Renew Sustain Energy Rev 58:1411–1431

Daroch M, Geng S, Wang G (2013) Recent advances in liquid biofuel production from algal feedstocks. Appl Energy 102:1371–1381

Dogan E, Dunaev T, Erguder TH, Demirer GN (2009) Performance of leaching bed reactor converting the organic fraction of municipal solid waste to organic acids and alcohols. Chemosphere 74(6):797–803

Escalante H (2011) Atlas del to energético de la biomasa residual en Colombia. Universidad Industrial de Santander, Bucaramanga, Colombia

Ewan BCR, Allen RWK (2005) A figure of merit assessment of the routes to hydrogen. Int J Hydrog Energy 30(8):809–819

Garfí M, Ferrer-Martí L, Perez I, Flotats X, Ferrer I (2011) Codigestion of cow and guinea pig manure in low-cost tubular digesters at high altitude. Ecol Eng 37(12):2066–2070

Garfí M, Martí-Herrero J, Garwood A, Ferrer I (2016) Household anaerobic digesters for biogas production in Latin America: a review. Renew Sustain Energy Rev 60:599–614

Garfí M, Castro L, Montero N, Escalante H, Ferrer I (2019) Evaluating environmental benefits of low-cost biogas digesters in small-scale farms in Colombia: a life cycle assessment. Bioresour Technol 274:541–548

Ge X, Sheets JP, Yang L, Li Y, Yu Z (2014) Biological conversion of methane to liquid fuels: status and opportunities. Biotechnol Adv 32(8):1460–1475

Ghaz-Jahanian MA, Khoshfetrat AB, Hosseinian Rostami M, Haghighi Parapari M (2018) An innovative bioprocess for methane conversion to methanol using an efficient methane transfer chamber coupled with an airlift bioreactor. Chem Eng Res Des 134:80–89

Gottwald M, Gottschalk G (1985) The internal pH of Clostridium acetobutylicum and its effect on the shift from acid to solvent formation. Arch Microbiol 143(1):42–46

Hagman L, Blumenthal A, Eklund M, Svensson N (2018) The role of biogas solutions in sustainable biorefineries. J Clean Prod 172:3982–3989

Hu B et al (2013) Enrichment of an anammox bacterial community from a flooded paddy soil. Environ Microbiol Rep 5(3):483–489

Hüsemann MHW, Papoutsakis ET (1988) Solventogenesis in Clostridium acetobutylicum fermentations related to carboxylic acid and proton concentrations. Biotechnol Bioeng 32(7):843–852

Hwang A, Nguyen A, Nguyen T, Nguyen Thanh L, Lee O, Yeol Lee E (2018) Biological conversion of methane to chemicals and fuels: technical challenges and issues. Appl Microbiol Biotechnol 102(7):3071–3080

Julio J, Barbosa AL (2013) Avances en las Tecnologías de Reformado de Metano: Estudio de Rutas Catalíticas para la Obtención de Hidrógeno y Gas de Síntesis. Cienc E Ing Al Día 8(1):16

Kleerebezem R, van Loosdrecht MC (2007) Mixed culture biotechnology for bioenergy production. Curr Opin Biotechnol 18(3):207–212

Li S-Y, Srivastava R, Suib SL, Li Y, Parnas RS (2011) Performance of batch, fed-batch, and continuous A-B-E fermentation with pH-control. Bioresour Technol 102(5):4241–4250

Liu Z et al (2011) Optimization of polyhydroxybutyrate (PHB) production by excess activated sludge and microbial community analysis. J Hazard Mater 185(1):8–16

Lü F, Chen M, He P-J, Shao L-M (2008) Effects of ammonia on acidogenesis of protein-rich organic wastes. Environ Eng Sci 25(1):114–122

MacLellan J, Chen R, Kraemer R, Zhong Y, Liu Y, Liao W (2013) Anaerobic treatment of lignocellulosic material to co-produce methane and digested fiber for ethanol biorefining. Bioresour Technol 130:418–423

Magrí A, Giovannini F, Connan R, Bridoux G, Béline F (2017) Nutrient management from biogas digester effluents: a bibliometric-based analysis of publications and patents. Int J Environ Sci Technol 14(8):1739–1756

Morini M, Pinelli M, Venturini M (2009) Analysis of biogas compression system dynamics. Appl Energy 86(11):2466–2475

O’Callaghan K (2016) Technologies for the utilisation of biogenic waste in the bioeconomy. Food Chem 198:2–11

Pasini G, Baccioli A, Ferrari L, Antonelli M, Frigo S, Desideri U (2019) Biomethane grid injection or biomethane liquefaction: a technical-economic analysis. Biomass Bioenergy 127:105264

Rodríguez J, Kleerebezem R, Lema JM, van Loosdrecht MCM (2006) Modeling product formation in anaerobic mixed culture fermentations. Biotechnol Bioeng 93(3):592–606

Sambusiti C, Monlau F, Barakat A (2016) Bioethanol fermentation as alternative valorization route of agricultural digestate according to a biorefinery approach. Bioresour Technol 212:289–295

Sanabria J (2014) Environmental biotechnology research: challenges and opportunities in Latin America. J Agric Environ Ethics 27(4):681–694

Sanabria J, Dierolf C, Mora LE (2005) Nuevas tecnologías para la desinfección de aguas y microorganismos emergentes. Presented at the Seminario Internacional: Visión Integral en el Mejoramiento de la Calidad del Agua, Universidad del Valle, Instituto Cinara

Sawatdeenarunat C et al (2016) Anaerobic biorefinery: current status, challenges, and opportunities. Bioresour Technol 215:304–313

Serafim LS, Lemos PC, Oliveira R, Reis MAM (2004) Optimization of polyhydroxybutyrate production by mixed cultures submitted to aerobic dynamic feeding conditions. Biotechnol Bioeng 87(2):145–160

Serfass, P (2017) Avoiding the legal ‘third rail’ of energy generation. Presented at the NACWA Law Seminar, Savannah, GA, November 15

Shu L, Schneider P, Jegatheesan V, Johnson J (2006) An economic evaluation of phosphorus recovery as struvite from digester supernatant. Bioresour Technol 97(17):2211–2216

Silva-Martínez R, Sanches-Pereira A (2018) Organic waste to energy in Latin America and the Caribbean (LAC): state-of-the-art literature review. European Biomass Conference and Exhibition, Copenhagen

Surendra KC, Sawatdeenarunat C, Shrestha S, Sung S, Khanal S (2015) Anaerobic digestion-based biorefinery for bioenergy and biobased products. Ind Biotechnol 11:103–112

Tao W, Fattah KP, Huchzermeier MP (2016) Struvite recovery from anaerobically digested dairy manure: a review of application potential and hindrances. J Environ Manage 169:46–57

UPME (2015) Integración de las energías renovables no convencionales en Colombia. Ministerio de Minas y Energía, Bogotá (Colombia)

Vasco-Correa J, Khanal S, Manandhar A, Shah A (2018) Anaerobic digestion for bioenergy production: global status, environmental and techno-economic implications, and government policies. Bioresour Technol 247:1015–1026

Voegele E (2018) Organic power to install 2 MW AD plant in Puerto Rico. Biomass Magazine, 09 February. [Online]. Available http://biomassmagazine.com/articles/15045/organic-power-to-install-2-mw-ad-plant-in-puerto-rico

Wilkinson KG (2011) A comparison of the drivers influencing adoption of on-farm anaerobic digestion in Germany and Australia. Biomass Bioenergy 35(5):1613–1622

Acknowledgments

The authors gratefully acknowledge the support from Universidad del Valle and Universidad Nacional de Colombia-Sede Palmira to perform this work. Additionally, the authors acknowledge support from the Administrative Department of Science and Technology of Colombia (COLCIENCIAS).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Clavijo-Salinas, J.C., Fuertez, J., Cadavid-Rodríguez, L.S., Sanabria, J. (2020). Compatible Technologies to Anaerobic Digestion for the Integral Valorization of Organic Waste. In: Zakaria, Z., Boopathy, R., Dib, J. (eds) Valorisation of Agro-industrial Residues – Volume I: Biological Approaches. Applied Environmental Science and Engineering for a Sustainable Future. Springer, Cham. https://doi.org/10.1007/978-3-030-39137-9_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-39137-9_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39136-2

Online ISBN: 978-3-030-39137-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)