Abstract

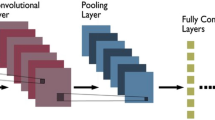

In smart manufacturing industry, health analysis and forecasting of degradation starting point has become an increasingly crucial research area. Prognostics-aware systems for health analysis aim to integrate health information and knowledge about the future operating conditions into the process of selecting subsequent actions for the system. Developments in smart manufacturing as well as deep learning-based prognostics provide new opportunities for health analysis and degradation starting point forecasting. Rotating machines have many critical components like spinning, drilling, rotating, etc. and they need to be forecasted for failure or degradation starting times. Moreover, bearings are the most important sub-components of rotating machines. In this study, a convolutional neural network is used for forecasting of degradation starting point of bearings by experimenting with Nasa Bearing Dataset. Although convolutional neural networks (CNNs) are utilized widely for 2D images, 1-dimensional convolutional filters may also be embedded in processing temporal data, such as time-series. In this work, we developed one such autoencoder network which consists of stacked convolutional layers as a contribution to the community. Besides, in evaluation of test results, L10 bearing life criteria is used for threshold of degradation starting point. Tests are conducted for all bearings and results are shown in different figures. In the test results, proposed method is found to be effective in forecasting bearing degradation starting points.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lee, J., Wu, F., Zhao, W., Ghaffari, M., Liao, L., Siegel, D.: Prognostics and health management design for rotary machinery systems—reviews, methodology and applications. Mech. Syst. Signal Process. 42(1), 314–334 (2014)

Shi, G., Dong, P., Sun, H.Q., Liu, Y., Cheng, Y.J., Xu, X.Y.: Adaptive control of the shifting process in automatic transmissions. Int. J. Automot. Technol. 18(1), 179–194 (2017)

Sikorska, J.Z., Hodkiewicz, M., Ma, L.: Prognostic modelling options for remaining useful life estimation by industry. Mech. Syst. Signal Process. 25(5), 1803–1836 (2011)

Vachtsevanos, G.J., Lewis, F., Hess, A., Wu, B.: Intelligent Fault Diagnosis and Prognosis for Engineering Systems, pp. 185–186. Wiley, Hoboken (2006)

Zhang, Y., Jiang, J.: Bibliographical review on reconfigurable fault-tolerant control systems. Ann. Rev. Control 32(2), 229–252 (2008)

Yang, B.S.: An intelligent condition-based maintenance platform for rotating machinery. Expert Syst. Appl. 39(3), 2977–2988 (2012)

Liu, R., Yang, B., Zio, E., Chen, X.: Artificial intelligence for fault diagnosis of rotating machinery: a review. Mech. Syst. Signal Process. 108, 33–47 (2018)

Zhao, R., Yan, R., Chen, Z., Mao, K., Wang, P., Gao, R.X.: Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 115, 213–237 (2019)

Jia, F., Lei, Y., Lin, J., Zhou, X., Lu, N.: Deep neural networks: a promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 72, 303–315 (2016)

Ren, L., Cui, J., Sun, Y., Cheng, X.: Multi-bearing remaining useful life collaborative prediction: a deep learning approach. J. Manuf. Syst. 43, 248–256 (2017)

Qiu, H., Lee, J., Lin, J., Yu, G.: Robust performance degradation assessment methods for enhanced rolling element bearing prognostics. Adv. Eng. Inform. 17(3–4), 127–140 (2003)

Masci, J., Meier, U., Cireşan, D., Schmidhuber, J.: Stacked convolutional auto-encoders for hierarchical feature extraction. In: International Conference on Artificial Neural Networks, pp. 52–59. Springer, Heidelberg, June 2011

Hinton, G.E., Osindero, S., Teh, Y.W.: A fast learning algorithm for deep belief nets. Neural Comput. 18(7), 1527–1554 (2006)

Taylor, G.W., Hinton, G.E., Roweis, S.T.: Modeling human motion using binary latent variables. In: Advances in Neural Information Processing Systems, pp. 1345–1352 (2007)

Vincent, P., Larochelle, H., Lajoie, I., Bengio, Y., Manzagol, P.A.: Stacked denoising autoencoders: learning useful representations in a deep network with a local denoising criterion. J. Mach. Learn. Res. 11, 3371–3408 (2010)

Poultney, C., Chopra, S., Cun, Y.L.: Efficient learning of sparse representations with an energy-based model. In: Advances in Neural Information Processing Systems, pp. 1137–1144 (2007)

Bengio, Y., LeCun, Y.: Scaling learning algorithms towards AI. Large-Scale Kernel Mach. 34(5), 1–41 (2007)

Kingma, D.P., Welling, M.: Auto-encoding variational Bayes. arXiv preprint arXiv:1312.6114 (2013)

Hasani, R.M., Wang, G., Grosu, R.: An automated auto-encoder correlation-based health-monitoring and prognostic method for machine bearings. arXiv preprint arXiv:1703.06272 (2017)

Medjaher, K., Tobon-Mejia, D.A., Zerhouni, N.: Remaining useful life estimation of critical components with application to bearings. IEEE Trans. Reliab. 61(2), 292–302 (2012)

Qiu, H., Lee, J., Lin, J.: Wavelet filter-based weak signature detection method and its application on roller bearing prognostics. J. Sound Vib. 289, 1066–1090 (2006)

Bogh, D., Crowell, J.R., Stark, D.: Bearings for IEEE 841 motors. IEEE Trans. Ind. Appl. 39(6), 1578–1583 (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Arslan, A.T., Yayan, U. (2020). Convolutional Auto-Encoder Based Degradation Point Forecasting for Bearing Data Set. In: Hemanth, D., Kose, U. (eds) Artificial Intelligence and Applied Mathematics in Engineering Problems. ICAIAME 2019. Lecture Notes on Data Engineering and Communications Technologies, vol 43. Springer, Cham. https://doi.org/10.1007/978-3-030-36178-5_71

Download citation

DOI: https://doi.org/10.1007/978-3-030-36178-5_71

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36177-8

Online ISBN: 978-3-030-36178-5

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)