Abstract

Archaeological sites comprise fundamental elements of the national and international cultural heritage, and their structural safety is an issue of paramount importance. The archaeological sites usually include various sensitive engineering structures and monuments such as temples, buildings and masonry retaining walls that may be threatened by a range of natural hazards, leading to structural failures. The current paper is involved with the investigation of real-time measuring systems utilized for the transformation of archaeological sites into “smart”, from a structural safety point of view. More specifically the application of advanced monitoring technologies is presented and discussed, from the laboratory (small scale) to the archaeological site of the Acropolis of Athens (large scale), aiming to generate new knowledge towards structural risk reduction of archaeological sites. The research presented includes two sections, one presenting the monitoring tools utilized, and the examination of their operation at the laboratory and another focusing on their application at the archaeological site of Acropolis of Athens. The monitoring tools are Fibre Bragg Grating sensors, capable of recording strain, acceleration and temperature levels in real-time. Characteristic recordings of the monitoring scheme are shown and conclusions after the exploitation of the real-time data are presented and discussed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Cultural heritage preservation

- Smart structures

- Structural monitoring

- Optical fibre sensors

- Acropolis of Athens

1 Introduction

Smart instrumental monitoring is a rapidly growing scientific area, applied initially to structures and infrastructures of national and economic importance and of high risk of failure such as important buildings, energy systems, long lifelines and others, aiming to their “smart” transformation [1, 2]. More specifically, structures and infrastructures are instrumented with sensors and devices, providing important real-time information. Furthermore, remote hazard assessment (i.e. assessment of the loading conditions) can be achieved, alongside with early detection of probable damages and/or failures, contributing thus to optimal risk management and to the overall safety of the structures and infrastructures. On the other hand, in-situ damage detection is not always feasible and can be particularly expensive. Designing smart structures and infrastructures utilizes innovative technologies that can be implemented during construction and/or operational phase, while in parallel early warning systems can be developed, to be activated in the case of exceeding of predefined limits, leading thus to self-control of an area under examination. Due to the historical significance, complexity, and potential overall risk of the archaeological sites, the quantitative assessment of geological and meteorological hazards and the estimation of their structural vulnerability are considered necessary and may contribute to preservation and early/preventive intervention on them. It should also be noted that the archaeological sites usually attract huge numbers of visitors/tourists, and a potential structural failure, or insufficient risk management may have a direct impact on their safety. Figure 1 presents a typical crowd of tourists at the Acropolis of Athens during visiting hours.

The transformation of archaeological sites into “smart archaeological sites” can also provide new information on instrumented or even inaccessible locations, supporting necessary restoration works. Furthermore, experience and new knowledge can be developed regarding (a) particularly demanding installation procedure of sensors and devices and networks support/repair on archaeological sites, focusing on the minimization of potential disturbance on them, and (b) structure-related data exploitation via advanced Information and Communication Technologies.

2 Smart Monitoring Utilizing Optical Fibre Sensors

Over the last decade there has been a gradual replacement of the conventional methods of structural instrumentation and monitoring via the application of optical fibre sensors [3, 4]. The optical fibre sensors combine precision (microstrains) with resistance to mechanical stress and multiplexing of signals with a relatively low cost, which is constantly decreasing. An important advantage is that they are portable systems that can be placed in various positions, on almost any structure, monitoring the hazard(s) (i.e., the loading conditions) along with the structural response/distress on critical locations.

Furthermore, in an environment where various networks of sensors have been deployed, the need for intelligent management and processing of the recorded and transmitted data has emerged. Integral part of the data processing is the combination (i.e., data fusion between heterogeneous networks) [5] and the support of additional meta-data in order to efficiently handle the available measurements. Regarding the intelligent management, several different architectures have been proposed. Furthermore, smart structures and infrastructures can be supported effectively via the digital representation of their physical and functional characteristics, especially on critical locations. In addition, by combining data obtained via optical fibre sensors with numerical modelling simulations, useful conclusions can derive related to the mechanical properties of the constructions and/or their behaviour due to various loading conditions [6].

2.1 The Use of Optical Fibre Sensors at the Laboratory

Fibre Bragg Grating (FBG) sensors have been studied at laboratory environment at (a) the APS 400 Electro Seis one degree of freedom earthquake simulator, utilized for the creation of the create seismic motion, and (b) a geotechnical centrifuge. More specifically, FBG sensors recording strain have been studied and one FBG single axis acceleration sensor, suitable for low frequency measurements of small vibrations. In Fig. 2 equipment used at the laboratory is shown and more specifically (a) the earthquake simulator used for the seismic loading impose, (b) the optical fibres’ interrogator, (c) the optical fibres recording strain, (d) the single axis optical fibre acceleration sensor, (e) the software used for optical fibre recordings acquisition (i.e. wavelength), (f) the data acquisition (DA) card for the system operation, and (g) the QCN sensor for real-time recordings of the acceleration applied. In addition, software in LabView environment has been used for the control of the earthquake simulator.

Laboratory equipment: (a) earthquake simulator used for the seismic loading impose, (b) optical fibres’ interrogator, (c) optical fibres recording strain, (d) single axis optical fibre acceleration sensor, (e) software for optical fibre recordings acquisition, (f) data acquisition card for the system operation (g) QCN sensor for real-time acceleration recordings.

The FBG single axis acceleration sensor and the QCN sensor were attached on the earthquake simulator and seismic loading was imposed for a time period of approximately 200 s. In Fig. 3 the test set up is shown and in Fig. 4 indicative recordings via the FBG acceleration sensor and the QCN sensor. It should be noted that the QCN sensor recordings are in m/s2 (i.e. acceleration), while the initial recordings via the FBG acceleration sensor are in nm (i.e. wavelength) and further processing is required for their transformation into acceleration.

For the transformation of the FBG acceleration recordings from wavelength into acceleration, the Equation Accel = Δλ * S has been used, taking also into account the specific characteristics of the FBG acceleration sensor. More specifically Accel is the acceleration (g), Δλ is the wavelength shift (i.e. Measured wavelength - Centered wavelength) and S the sensitivity of the specific sensor (g/nm), equal to 17.03 for the current type of sensor. In Fig. 5, a comparison of the recordings via the QCN sensor and the FBG acceleration sensor in m/s2 are shown, after the transformation of the wavelength measurements into acceleration measurements. The comparison shows that the results are in good coherence, with the FBG acceleration sensor measuring slightly higher values. This analysis at the laboratory will be used for the transformation of the FBG sensor’s wavelength recordings in the field into acceleration recordings, as presented in the following section.

Concerning the use of optical fibre sensors in the geotechnical centrifuge, strain measurements were made possible via optical fibre sensors in the drum geotechnical centrifuge of ETH Zurich, aiming to investigate the behaviour of scaled geotechnical models. The test set up and the physical modelling has been presented in Kapogianni et al. 2017. In Fig. 6 the indicative physical modelling is shown and in Fig. 7, characteristic strain recordings in real-time, and more specifically strain recordings up to 50 g and 100 g level (b).

The physical model tests described in the above showed that the FBG sensors can successfully be used at the laboratory, during various loading scenarios and for different test setups. The setup and test series have been used in order to draw conclusions related to the measuring systems, for further application in the field, and in order to identify the behaviour of the physical models [7]. The application of the measuring systems for the development of smart structures, focusing on archaeological sites is described in what follows, focusing on the archaeological site of the Athenian Acropolis.

2.2 The Use of Optical Fibre Sensors at the Archaeological Site of Acropolis

The archaeological sites usually include various sensitive engineering structures and monuments, such as temples, buildings and masonry retaining walls that are subjected to various loadings, leading to damages and structural failures. Since archaeological sites comprise fundamental elements of the national and international cultural heritage, a serious damage and especially a total failure of a structure and/or monument is practically irreversible, and thus unacceptable. Furthermore, a failure at an archaeological site may lead to injuries of visitors and/or employees, or even to fatalities. For the evaluation of the structural risk of an archaeological site, quantitative hazard assessment and realistic evaluation of the structural vulnerability are required. Smart structural monitoring can provide important real-time information (records) on both the actual hazard(s) and the corresponding vulnerability, in terms of structural response and distress. In the current study FBG optical fibre sensors have been attached on the Acropolis Circuit Wall, recording temperature, strain and acceleration levels in real-time since 2016 to date [8]. The area selected for the installation was near to a pre-existing accelerographic array, at the highest part of the South Wall [9].

The first fortified Wall was built at the Acropolis Hill during the Mycenaean period (1200 BC), called the ‘Cyclopean’ Wall, surrounding the top of the Hill. This Wall with minor modifications was preserved until 480 BC, when it was severely damaged during the invasion of the Persians. The Acropolis was fortified again by Themistocles on the north side (Themistoclean Wall) followed by Kimon on the south side (Kimonion Wall). In the northern part of the Wall, architectural elements of the damaged temples and more specifically the Pre-Parthenon were also incorporated (Fig. 8). The Wall of Acropolis has suffered the actions of extreme weather conditions, various types of loading, e.g. earth pressures due to the backfill and seismic loading, as well as the human interference, leading to structural damages such as cracks, block falls and displacements [10].

Nowadays, the Circuit Wall is a masonry wall comprising mainly irregular mixed courses made up of marble and small stones. The geometrical properties of the Wall (i.e. height and width) vary substantially around the Acropolis Hill, with the southern part of the Wall being of the greatest height (~18 m). It retains a large volume of poorly compacted backfill material and has exhibited in the past some serious structural damages and detachments, while notable cracks have currently been observed at its south-east corner (Fig. 8). Additional mechanical stress is observed also due to the fact that heavy materials used for the restoration works undertaken at the Acropolis Hill are often transported via the south-east corner, increasing thus the risk for further damages and/or failures. Such recent restoration works undertaken at the south Circuit Wall can be seen in Fig. 9, and more specifically at the Choragic Monument of Thrasyllos (320/319 BC). In parallel the limestone on which the Wall is founded in noted in Fig. 9.

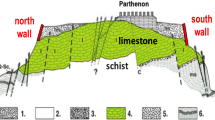

Concerning the geological prevailing conditions, the Acropolis Hill is composed mainly by limestone standing on a slate system of marls and sandstones [11]. The Athenian slate is visible on the main entrance of the archeological site and less in other positions while the limestone is visible on the Hill, when is not covered by artificial embankments, which have been built in order to create the surface level of the hill. The embankments are thicker on the south side and held around the Walls and the limestone karstification has leaded to cavities which facilitate the water flow, further erosion and rock fall phenomena. In Fig. 10 the south-east view of the Acropolis Hill is noted, a geological section [12], and parts of the monitoring array installed on the south Wall. It should be noted that due to the aforementioned structural problems and the heterogeneous and anisotropic nature of the Wall surface, long gauge Fibre Bragg Grating (FBG) optical fibre sensors and more specifically FBG Smart Rods, have been selected for installation on the south Circuit Wall. Furthermore, numerical analysis (utilizing the finite element method), regarding the behaviour of the Circuit Wall has been made [13].

By locating the FBG sensors some distance from the neutral axis of the Smart Rod, the Smart Rod curvature can be calculated, as can the curvature of a structure to which Smart Rod is fixed. The Smart Rods used in the current study have high resistance in erosion, and sensors installed on them can provide reliable measurements without necessary periodic calibration. In Fig. 11 a typical Smart Rod cross-sectional viewing angle is shown. Furthermore, one Fibre Bragg Grating single axis acceleration sensor Smart Accel – LF, suitable for low frequency measurement of small vibrations, has been attached on the South Wall (Fig. 11). The Accel - LF sensor consists of a robust, sealed metal body including armoured cables and has been placed perpendicular to the Wall, connected in series and in parallel to the rest of the optical fibre array.

3 Recordings at the Acropolis Circuit Wall

In the current section characteristic recordings utilizing the FBG strain, temperature and acceleration sensors are shown, during the 15th of January 2018, for approximately a 9-hour period. The initial, reference recording is at 06:45 pm. More specifically in Fig. 12(a) strain variation (in μstrain) recorded by two strain sensors (with the designation S2_IN and S2_OUT) located at the same Smart Rod can be seen. Even though they are mounted on the same Smart Rod, small variations are noted. Furthermore, the temperature variation (in °C) during the 9-hour period of time is shown (b), as recorded by two temperature sensors located at the same Smart Rod (with the designation T_IN and T_OUT). It is evident that the strain recordings are related to the increase of the temperature and therefore temperature compensate is indispensable. This is also noted in Fig. 12(c) where the temperature variation has been multiplied by 10, in order to be comparable to the strain variation. The influence of the temperature on the FBG sensors has been taken into account in Fig. 12(d), where the strains recorded after thermal compensate are shown. In addition, the increased temperature during this timeframe also affects the Wall and backfilling, leading to dilation phenomena. This trend is reversed due to temperature decrease. Furthermore, in Fig. 13, acceleration recordings during the same 9-hour period are shown. During this period, no seismic event has occurred and therefore the recordings refer to ambient noise. For the transformation of wavelength measurements into acceleration and strain the conclusions derived by the analyses of the laboratory recordings (Sect. 2.1) have also been taken into consideration.

4 Conclusions

In the current study the suitability of optical fibre sensors for monitoring of historically complex sites, focusing on the Acropolis Circuit Wall has been examined, aiming to the transformation of archaeological sites into “smart”, from a structural safety point of view. At first the application of real time monitoring, utilizing optical fibre sensors has been examined, during physical model tests at the laboratory, and more specifically at a one degree of freedom earthquake simulator and at a geotechnical centrifuge. The results showed that optical fibres are suitable for such physical model tests, and conclusions derived regarding the transformation of the initial wavelength measurements into the desirable physical quantities (i.e. strain and acceleration). These conclusions were used for the transformation of the wavelength measurements into strain and acceleration during the real-time monitoring of the archaeological site of the Acropolis of Athens. More specifically an optical fibre array has been installed on the south part of the Circuit Wall of the Acropolis Hill and indicative recordings have been shown. The study showed that temperature plays an important role on the optical fibre strain recordings and thermal compensate should be taken into consideration. More specifically, is has been observed that wavelength and strain increase at high temperature levels, a fact that indicates that temperature sensors should be installed during monitoring of historically complex sites, acting complementary to the strain recordings, resulting thus to optimum results. Furthermore, sensors on the inner side of the Smart Rods were closer to the Wall and affected to a greater extent by its deformations, recording thus higher strains. Increased recorded strains were noted during the morning until noon, since at this timeframe restoration works were carried out on the Acropolis worksite. Another reason for this phenomenon was the temperature variation between the morning and noon, which affected the Circuit Wall, leading to dilation phenomena. This trend was reversed during temperature decrease.

References

Soga, K., Kwan, V., Pelecanos, L., Rui, Y., Schwamb, T., Seo, H., Wilcock, M.: The role of distributed sensing in understanding the engineering performance of geotechnical structures. In: Geotechnical Engineering for Infrastructure & Development, XVI ECISMGE, pp. 13–48 (2015)

Pelecanos, L., Soga, K., Chunge, M.P.M., Ouyang, Y., Kwan, V., Kechavarzi, C., Nicholson, D.: Distributed fibre-optic monitoring of an Osterberg-cell pile test in London. Geotechnique Lett. 7, 1–9 (2017)

Chatzi, E.: A Monitoring approach to smart infrastructure management. J.: Proc. 1(8), 755 (2017)

Kapogianni, E., Laue, J., Sakellariou, M., Springman, S.M.: The use of optical fibers in the centrifuge. In: Springman, S.M., Laue, J., Seward, L. (eds.) Physical Modelling in Geotechnics, vol. 1, pp. 343–348. Taylor & Francis Group, CRC Press, Boca Raton (2010)

Sun, D., Lee, V., Lu, Y.: An intelligent data fusion framework for structural health monitoring. In: IEEE 11th Conference on Industrial Electronics and Applications (2016)

Kapogianni, E., Sakellariou, M.G., Laue, J., Springman, S.M.: Investigation of the mechanical behavior of the interface between soil and reinforcement, via experimental and numerical modelling. Adv. Transp. Geotech. 3. J.: Proc. Eng. 143, 419–426 (2016)

Kapogianni, E., Sakellariou, M.G., Laue, J.: Experimental investigation of reinforced soil slopes in a geotechnical centrifuge, with the use of optical fibre sensors. J.: Geotech. Geol. Eng. 35(2), 585–605 (2017)

Kapogianni, E., Kalogeras, I., Psarropoulos, P., Michalopoulou, D., Eleftheriou, V., Sakellariou, M.: Suitability of optical fibre sensors and accelerographs for the multi-disciplinary monitoring of a historically complex site: the case of the Acropolis Circuit Wall and Hill. Geotech. Geol. Eng. (2019, in press)

Kalogeras, I., Stavrakakis, G., Melis, N., Loukatos, D., Boukouras, K.: The deployment of an accelerographic array on the Acropolis hill area: implementation and future prospects. In: Proceedings of a One-Day Conference, Modern Technologies in the Restoration of the Acropolis, Athens, Greece, pp. 39–42 (2010)

Ambraseys, N.: On the long-term seismicity of the city of Athens. Proc. Acad. Athens A, 81–136 (2010)

Higgins, M., Higgins, R.: A Geological Companion to Greece and the Aegean, pp. 26–31. Gerald Duckworth & Co., London (1996)

Koukis, G., Pyrgiotis, L., Kouki, A.: The Acropolis Hill of Athens: engineering geological investigations and protective measures for the preservation of the site and the monuments. Eng. Geol. Soc. Territ. 8, 89–93 (2015)

Psarropoulos, P., Kapogianni, E., Kalogeras, I., Michalopoulou, D., Eleftheriou, V., Dimopoulos, G., Sakellariou, M.: Seismic response of the Circuit Wall of the Acropolis of Athens: recordings versus numerical simulations. Soil Dyn. Earthq. Eng. 113, 309–316 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Kapogianni, E., Psarropoulos, P., Sakellariou, M. (2020). Securing the Future of Cultural Heritage Sites, Utilizing Smart Monitoring Technologies: From the Laboratory Applications to the Acropolis of Athens. In: Correia, A., Tinoco, J., Cortez, P., Lamas, L. (eds) Information Technology in Geo-Engineering. ICITG 2019. Springer Series in Geomechanics and Geoengineering. Springer, Cham. https://doi.org/10.1007/978-3-030-32029-4_64

Download citation

DOI: https://doi.org/10.1007/978-3-030-32029-4_64

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-32028-7

Online ISBN: 978-3-030-32029-4

eBook Packages: EngineeringEngineering (R0)