Abstract

The microstructure of semisolid foods can have great impact on their texture, functional properties, and rheological properties. Semisolid food microstructures can be modified during their manufacturing process by either altering processing parameters or adding functional ingredients. Functional ingredients for creating and altering food microstructures include proteins, polysaccharides, and lipids are introduced; key food structural features include protein and polysaccharide networks, emulsions, and foams. Processing strategies that can influence these food microstructures include homogenization, heat treatment, and acidification. Illustration of how formulation and processing can impact semisolid food microstructures can be found in yogurt, whipped cream, and ice cream: adding functional ingredients, such as dietary fibers, gums, calcium, and whey protein isolates, as well as altering their processing parameters, can dramatically change their microstructural features.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Overview of Semisolid Food Microstructures

Food microstructure , or how the molecules in materials are orientated, distributed, arranged, and associated with themselves and each other to form different networks, plays a critical role in determining food mechanical properties and texture attributes. A single difference in microstructural features can result in significant differences in functional properties. For example, cocoa butter, which comprises mainly triglycerides derived from palmitic acid, oleic acid, and stearic acid (Fig. 1), has different melting temperatures (16–37 °C) as well as different textures (Lopes et al. 2015) depending on how the triglycerides are oriented and packed (Fig. 2). Microstructure also determines whether a food material is fluid, semisolid, or solid. At the microscopic scale, semisolid food materials are typically amorphous solids with a disordered structure and randomly distributed molecules, similar to molecules in a fluid. Unlike many solid materials that have ionic bonding, semisolid materials are covalently or electrostatically bonded, which are weaker bonds compared to ionic bonds.

Many semisolid foods are emulsion-based, including salad dressing, sour cream, ice cream, full-fat yogurt, and mayonnaise. The structure of emulsion-based foods is affected by multiple factors, including the lipid to water ratio, type of lipid used, and presence of emulsifiers (e.g. lecithin and glycerides) and stabilizers (e.g. proteins and polysaccharides). In particular, different combinations of stabilizers and emulsifiers can have a great influence on semisolid food microstructures, rheological properties, and textures. In addition, increasing ion strength, e.g. by adding calcium ions, can induce aggregation and flocculation among droplets, thus modifying the microstructure and rheological properties of the semisolid food. Moreover, semisolid food structural properties are also influenced by processing parameters, such as shear, temperature, and pressure.

Yogurt is a semisolid food that has rheological properties and sensory texture attributes that are strongly depend on its microstructure. There are two major types of yogurt: set yogurt and stirred yogurt. Set yogurt has a continuous gel structure; however, the stirred yogurt gel is purposely disrupted during processing (hence the name), resulting in a structure that is a dispersion of protein aggregates (Karam et al. 2013). The microstructure of both set and stirred yogurt (Fig. 3) is created by aggregated casein micelle chains or clusters that form when the pH of heat-treated milk drops to the isoelectric point of casein (pH = 4.6) (Lee and Lucey 2010). Acidification can be either induced by acidulant, such as glucono delta-lactone, or culture, such as Streptococcus ssp. thermophilus and Lactobacillus delbrueckii ssp. bulgaricus , which generate lactic acid to decrease pH (Karam et al. 2013). Adding functional ingredients to yogurt and/or using different processing parameters can change yogurt microstructures, influencing their mechanical properties and texture attributes.

2 Structuring Materials for Semisolid Foods

Proteins and polysaccharides are two important structuring materials for semisolid foods. Using appropriate structing materials can not only give desirable texture and physiochemical properties, but can also be used to make heathier food products with similar textures to those of their full-fat or full-calorie counterparts.

Yogurts typically have fat contents between 0.5% and 3.5% (Lucey and Singh 1997). In the past few decades, the demand for reduced-calorie foods, including dairy products, has been grown steadily due to concerns of the current rates of obesity and obesity-related diseases (Tamime et al. 1996). Therefore, products such as non-fat or low-fat yogurt (fat content <1.5% w/w) have become more popular. In yogurt, the solids content of and type of solids used in the base milk determines the physical and textural properties of the final yogurt. Reduction of fat results in reduction of the total solids content, resulting in poor texture, weak body, and whey separation during storage (Aziznia et al. 2008). In addition, fat globules can form links between proteins in yogurt, which contributes to the overall strength of the protein network. To avoid a quality reduction in lower-fat yogurts, fat replacers, including whey protein concentrate, waxy maize starch, gelatin, xanthan gum, locust bean gum, low methoxy pectin, guar gum, and λ-carrageenan, have been used to fortify yogurt microstructures (Zhang et al. 2015).

2.1 Proteins

Proteins are important structural ingredient for the food industry. Many animal proteins, such as whey protein, casein, and gelatin, are good structuring materials for semisolid foods. In a semisolid food system, proteins can either aggregate to form protein network or interact with other food ingredients, such as polysaccharides, to build a heterogeneous network structure. The rheological properties of the final food products are heavily dependent on the structure built by the protein and its interaction with other ingredients in the food.

2.1.1 Casein

Casein is the major proteinaceous component of mammalian milk, comprising 80% of milk protein by weight, and it consists of many phosphorylated proteins (Dahbi et al. 2010). Casein monomers are amphiphilic molecules with a strong tendency for self-assembly. There are four main classes of casein: αs1, αs2, β, and κ. These caseins will assemble into a micelle with the αs1-, αs2-, and β-casein in the center of the micelle and κ-caseins on the outside of the micelle forming a “hairy” layer. This structure is held together primarily by casein interactions with calcium phosphate (Dickinson 2006). This layer prevents aggregation, keeping the micelles suspended in the milk. Casein proteins have a relatively disordered secondary structure. Their molecular structures in solution are determined by the local environment, such as pH and temperature; their structures are flexible enough to allow flow (Akhtar et al. 2006; Dickinson 2006). While they are fairly sensitive to pH, they are relatively stable even at high temperatures. Overall, these properties make casein proteins good structuring materials for foods, including cheese, milk, cream, and yogurt.

In cheese and yogurt, the lower pH, and chymosin cleavage of the glycomacropeptide from κ-casein in cheese allow casein micelles (mean size ∼300 nm) to aggregate and form a network that provides the characteristic texture and rheological properties of these products (Keogh and O’Kennedy 1998). To destabilize or strengthen the casein micelle network and therefore adjust product texture, the relative proportions of the different monomeric caseins, processing temperature and pH, ionic strength, and/or calcium ion concentration can all be manipulated (Huppertz and de Kruif 2008).

2.1.2 Whey Proteins

Whey protein comprises multiple serum-soluble milk proteins, including α-lactalbumin, β-lactoglobulin, bovine serum albumin (BSA), and immunoglobulins (Ercelebi and Ibanoǧlu 2007). Whey protein, whey protein concentrate (typically 40–70% w/w protein), and whey protein isolate (>80% w/w protein) are widely used as structuring materials for semisolid food, such as yogurt, ice cream, and chocolate milk. Because whey protein isolate contains both hydrophobic and hydrophilic regions, it can be rapidly adsorbed at the oil–water interface in the form of a protective film, providing structural support for oil droplets through a combination of electrostatic and steric interactions (Sun and Gunasekaran 2009) (Fig. 4). However, using whey protein isolates as fat replacer in yogurt can result in a compact structure consisting of fused casein particles and large whey protein aggregates that form a relatively uniform protein network (Fig. 5) (Sandoval-Castilla et al. 2004; Zhang et al. 2015). Individual protein chains were not visible in these yogurts (Aziznia et al. 2008). Whey proteins will self-aggregate when they are present in excess proportions, resulting in the formation of larger clusters and fewer individual strands.

2.1.3 Gelatin

Gelatin comprises proteins derived from animal collagen, which is obtained from bones, skin, hooves, and other animal body parts. Porcine and bovine collagen are the most common sources of gelatin in the food industry. Gelatin is widely used as a structuring material, gelling agent, and emulsifier in food products (Djagny et al. 2001), although it has been removed from many food products due to concerns of meeting kosher and halal requirements. Gelatin has a strong emulsifying ability when used alone, but it is often combined with other polysaccharides, such as gums, starch, and pectin to stabilize emulsions (Dickinson 2009). Covalent linkage (amide bond) of gelatin protein to polysaccharide can be achieved by mixing gelatin under alkaline conditions (Diftis et al. 2005). A schematic of gelatin–polysaccharide stabilized emulsion is shown in Fig. 6. Gelatin is relatively unique compared to other food structural proteins in that gelatin gels melt upon heating and reform upon cooling; most other food proteins will gel irreversibly when heated. While this melting ability can provide highly palatable textures, such as high meltaway, it also results in destabilization of products that are stabilized by gelatin when the product is heated or stored above room temperature (Michon et al. 1997).

2.1.4 Egg Protein

Both egg yolk protein (mainly vitellogenin) (Byrne et al. 1989) and egg white protein (mainly ovalbumin) (Stevens 1991) are good emulsifiers and foam agents. They are often used to stabilize semisolid foods, such as mayonnaise, which is an oil-in-water emulsion stabilized by egg yolk lecithin. Because mayonnaise contains a high percentage of oil (78.5% or more) (Worrasinchai et al. 2006) (Fig. 7), the droplets are close-packed and distorted from a spherical shape, which is not a stable state because the surface energy is high. Therefore, mayonnaise requires stabilization to reduce the surface energy and prevent oil droplet coalescence, creaming, and phase separation during storage (Depree and Savage 2001).

Egg proteins are also used to stabilize whipped cream emulsions, a emulsion-based foam with a fat content of 35–40% (Mine 1998). With addition of stabilizers to prevent the emulsion from breaking due to shear during the whipping process for incorporation of air to create a foam, ‘stiff’ (rigid) foams with around 100–120% overrun can be formed. The stabilizers also promote more uniform bubble size and a transition of the foam from a viscous fluid to a viscoelastic solid (Murray 2007).

2.1.5 Fish Protein

Fish protein , primarily myofibrillar proteins, is an important byproduct from fish tissues that are considered processing waste and not generally used as food (Mackie 1982). The use of fish protein as food ingredient has gained traction in the late twentieth and early twenty-first century due to the increasing world-wide demand for new protein-rich foods. In addition, fish gelatin has good functional properties, such as structuration and water holding (Kristinsson and Rasco 2000). Fish protein has strong gelling capability due to the large quantities of myofibrillar proteins present. During gelation, fish proteins form a three-dimensional network that stabilizes water physically and chemically within the gel structure. This structure, in many cases, helps to connect or hold other constituent particles in food, such as starch granules (Fig. 8). In general, fish gelatin is similar in functionality to porcine or bovine gelatin, although it does have a notably lower melting point (Karim and Bhat 2009). Previous studies have indicated that using fish protein as structural materials can significantly increase the structural strength of crackers (Kyaw et al. 2001), egg protein gels (Badii and Howell 2006), and food packaging materials (Cuq et al. 1995).

2.2 Polysaccharides

Polysaccharides are commonly used in food products to increase viscosity, promote gelation, or strengthen the protein network. They are also used as fat replacers and texture enhancers (Su et al. 2010). There are multiple sources for food polysaccharides, including plants, seaweed, and microbial byproducts. Given the variety of sources for polysaccharides, it is not surprising that they have a broad array of structures and functional properties.

2.2.1 Gums

Gums are plant-derived polysaccharides that are composed of long chains of monosaccharide units linked by glycosidic linkages. These chains can be broken into monosaccharides or oligosaccharides by enzymes and severe processing conditions, but are generally stable under typical food product processing and storage conditions as well as during oral processing (i.e. they are not sensitive to salivary enzymes). Gums are excellent stabilizing and thickening agents for many foods, including semisolid foods (Kaur et al. 2008) such as pudding, ice cream, custard, and yogurt. Gums with charged regions can also be good emulsifiers: their hydrophobic regions can bind to oil droplets to form a stabilizing surface layer. Furthermore, gums can interact with proteins to provide steric stabilization (Dickinson 2009). The most widely used gums in food applications are gum arabic, xanthan gum, gellan gum, guar gum, locust bean gum, and cellulose gum (Dickinson 2009).

The functionality provided by each gum is dependent on its structure, including chain length, overall charge, and size and charge of side groups (Dawkins and Nnanna 1995). The amount of xanthan gum used in whipped cream was positively correlated to the firmness, cohesiveness, and viscosity of the final product. However, increased xanthan gum also resulted in partial coalescence of fat in the whipped cream, increasing the average size of the foam bubbles (Zhao et al. 2009). Similarly, addition of locust bean gum to heavy cream increased its viscosity but also increased the time to form the whipped cream foam (Camacho et al. 1998). Using xanthan gum as a stabilizer for mayonnaise was reported to increase the droplet size; however, the rheological properties, such as yield stress, viscosity and flow behavior index were not significantly modified (Su et al. 2010). These studies highlight the need for careful consideration of how addition of a given hydrocolloid will impact not only food rheological behaviors but also their stability.

Gums have been widely used as fat replacers in yogurts. However, it is not always possible for certain gums to completely mimic the behavior of fat in food systems or provide structures that lead to desirable textures. For example, yogurt enriched with gum tragacanth had a coarser and notably more open structure than non-fat yogurt (Aziznia et al. 2008). During yogurt fermentation, the decrease in pH solubilizes colloidal calcium phosphate, which binds to the polysaccharide gum instead of casein, resulting in formation of larger pores and coarser structure (Lee and Lucey 2004). On the other hand, using locust bean gum and xanthan gum as fat replacers for yogurt did not change the size of openings in that casein protein network compared to non-fat yogurt. Instead, structures for yogurts with xanthan and locust bean gums contained filaments and small aggregates located at the surface of casein particles (Fig. 9). The filaments provided connections between casein particles without casein aggregation (Sanchez et al. 2000).

2.2.2 Carrageenans

Carrageenans are a family of sulfated, linear polysaccharides of D-galactose and 3,6- anhydro-D-galactose monomers that are extracted from red seaweed (genus Rhodophyceae). The interaction between carrageenan and proteins, especially casein, is important for structuring semisolid dairy foods, such as yogurt and milk. Figure 10 show a schematic drawing of the interactions between κ-carrageenan and either κ-casein or casein micelles. While calcium ions can be used to induce α-casein–carrageenan and β-casein–carrageenan electrostatic interactions, calcium is not needed for these interactions to occur (Snoeren et al. 1976). However, it is important to keep in mind that calcium promotes these interactions when working with products during which calcium release or addition is involved in the manufacturing process, such as when colloidal calcium phosphate is released during the fermentation step in cheese or yogurt production. Depending on the concentration of carrageenan used, these interactions can either promote stronger structures (low concentration) or cause phase inversion and potential precipitation (high concentrations) (Çakir and Foegeding 2011). Carrageenans are widely used as stabilizers for food emulsions, particularly in dairy products such as cocoa milk, creams, ice-creams and mousses due to their ability to modify texture and stability. Stabilizing ice cream, mousses, and cream results in greater stability, increased creaminess, and better consumer acceptance (Gu et al. 2005; Heertje 2014).

2.2.3 Starch

Starch is a polymeric carbohydrate comprising long glucose chains; it can be obtained from many food materials such as potatoes, wheat, maize, rice, and cassava. Unmodified starches from different sources exhibit wide variations in granule appearance and structure (Fitt and Snyder 1984). For example, large, lenticular granules and small, spherical granules have been observed in native wheat starches. Potato starch has large, round granules (Gallant et al. 1997). Mucuna beans have oval and round granule shapes with a heterogeneous size dispersion (Adebowale and Lawal 2003). However, in most starch-stabilized semisolid food products, such as instant pudding and low-fat sour cream and yogurt, starch is not present in its native form, but gelatinized by heating in the presence of water. When held at their gelatinization temperature in water, starch granules undergo irreversible swelling as they absorb free water (Ratnayake and Jackson 2008). Gelatinized starch granules can be cooled and dried into a powder to create pre-gelatinized starch, which readily absorbs cold or room temperature water and is thus used to make many ready-to-mix products (Liu et al. 2017).

Aside from pre-gelatinization, starches can undergo other modifications to alter their functional properties. Heat-modified starch solutions consist of a continuous phase enriched in amylose and a dispersed phase enriched mainly in amylopectin (Mandala et al. 2004a, b). Starches can be modified by enzymatical, physical, or chemical treatment, for example, oxidizing starch with sodium hypochlorite, treating starch with sodium hydroxide or potassium hydroxide, and treating starch with enzymes to make maltodextrin and cyclodextrin (Commission 2008). The functionality of the modified starch is usually dependent on the type and extent of modification used. Starches are usually modified to increase their solubility, alter their swelling and gelation properties, or increase their stability at lower pH (Roach and Hoseney 1995).

Modified starches have been extensively used to stabilize fluid and semisolid foods, particularly emulsified foods. Starches generally promote emulsion stabilization by binding free water to increase product viscosity and reduce flocculation and creaming rates, forming an interfacial layer on lipid droplets, or both (Charoen et al. 2011). The mechanism of stabilization is dependent on the type of starch used and the modifications made to that starch. Salad dressings stabilized by modified starch had greater storage modulus values and higher viscosity compared to unstabilized dressings (Dolz et al. 2006). Additionally, using enzyme-treated starch to stabilize mayonnaise increased both droplet size and yield stress (Mun et al. 2009). Emulsions stabilized with hydrophobic starch particulates were reported to have smaller particle size and greater stability (Yusoff and Murray 2011).

Yogurts that are stabilized by starch have structures that comprise casein micelles linked in chains. While non-fat yogurt has a relatively open, loose structure , starch-enriched yogurt has a large number of interspaced voids of varying dimensions. The interspaced voids can significantly increase firmness and adhesiveness, and reduce cohesiveness (Sandoval-Castilla et al. 2004). During the pasteurization step in yogurt processing, starch granules absorb water and gelatinize. The swelling process often results in leakage of amylose molecules into the surrounding serum phase. Continued heating, especially under shear, can lead to starch granule rupture and release of more amylose molecules and amylopectin. Some of the solubilized amylose can penetrate into the casein micelle network and generate open spaces in the protein network, disrupting the continuous casein micelle network. On the other hand, if sufficient free amylose is present, it can form an interpenetrating gel structure with the protein network, increasing yogurt gel strength (Fig. 11) (Sandoval-Castilla et al. 2004).

2.2.4 Dietary Fiber

Dietary fiber is a mixture of non-digestible plant carbohydrate polymers, both oligosaccharides and polysaccharides, that includes cellulose, hemicelluloses, pectic substances, gums, resistant starch, and inulin. It cannot be digested by enzymes found in the human body because human enzymes do not have the correct activation sites to cleave the bonds connecting the monomers in fiber (Slavin 2005). For example, human α-amylase can leave the α-1-4 bonds in starch, but not the β-1-4 bonds in cellulose. Therefore, cellulose is not digested in the body and considered dietary fiber (Van Soest et al. 2010).

Dietary fibers can be found primarily in edible plant foods such as cereals, fruits, vegetables, dried peas, nuts, lentils, and grains (Elleuch et al. 2011). Some dietary fibers are water soluble, including oat bran, barley bran, and psyllium. Soluble fibers can lower blood lipid levels and slow food digestion by attracting water to increase the viscosity of the food or form a weak gel with the stomach and intestinal contents, delaying stomach emptying and making the digesta less accessible to enzymes. Insoluble fibers, such as cellulose and wheat bran, are typically linked to laxative properties because they increase the bulk of the mass moving through the intestines and absorb water, which softens the mass and makes it easier to transport (Slavin 2008). Because dietary fiber has multiple health benefits, increased fiber in the diet is encouraged. But although the recommended intake for total fiber is 38 g for men and 25 g/d for women, the median intake of dietary fiber is only 16.5–17.9 g/d for men and 12.1–13.8 g/day for women (Slavin 2005). Accordingly, there is a push to increase the amount of fiber added to food products, and many food manufacturers are seeking to create palatable high-fiber foods, including energy bars, yogurt, and beverages.

Unfortunately, adding fiber to foods can create challenges in terms of palatability and functionality. Added fiber tends to product a rough, gritty, particulate texture, which is especially unpalatable in foods that generally have a smooth texture, such as yogurt (Iriondo-Dehond et al. 2018). Fiber can also modify the food’s microstructure, which may significantly change the rheological properties and thus the sensory texture (Dello Staffolo et al. 2004). Both soluble and insoluble fiber can have these effects. For example, adding soluble fiber from the Mexican yam bean to yogurt resulted in the formation of a cotton candy-like structure that covered the protein network (Fig. 12). It also promoted a more open and relaxed protein network than the one observed in a non-fat yogurt control (Ramirez-Santiago et al. 2010). It was also reported that adding up to 4% inulin, a starchy substance found in many fruits, vegetables, and herbs, resulting in a less compact protein network in both non-fat and full fat yogurts (Guggisberg et al. 2009). Inulin can form gel structures in yogurt, breaking the continuous phase of protein network and promoting a more open microstructure (Crispín-Isidro et al. 2015). However, addition of soluble fibers to yogurt does not necessarily result in a less compact protein network. Yogurt with added pectin derived from passion fruit and bacterial exopolysaccharides had a protein network with a more compact structure. The pectin was present in the casein gel as a needle-shaped blade (Fig. 13); this shape allowed it to penetrate the protein network without disrupting it (Espírito-Santo et al. 2013). In addition to pectin, agave fructans, a soluble fiber derived from the agave plant, can act as a sort of “cement” for casein-based microstructures by covering the casein micelles and promoting particle flocculation to form a gel (Fig. 14). Increased agave fructan concentration resulted in thicker branches of the protein network and more compact structure comparing to that found in full fat yogurt (Crispín-Isidro et al. 2015).

Unlike soluble fibers, insoluble fibers derived from soy, rice, oat, corn, apple, wheat, bamboo, and sugar beet do not bind with or penetrate into the casein protein network. Rather, they act as a bulking agent in yogurt and tend to disrupt the continuity of the protein chains and clusters, producing a looser protein network (Fig. 15) (Dello Staffolo et al. 2004; Fernández García and McGregor 1997).

2.3 Lipids and Water

Both water and lipid, in different forms, play a major role in food structure, physicochemical properties, mechanical properties, and textural characteristic. For semisolid foods such as yogurt, milk, and ice cream, lipids and water help build structure through formation of droplets or crystals of different sizes and shapes and interaction with other food components (Heertje 2014).

2.3.1 Lipids

Lipids are hydrophobic or amphiphilic small molecules that do not or do not easily dissolve in water. These molecules include fatty acids, waxes, sterols, fat-soluble vitamins, monoglycerides, diglycerides, triglycerides, and phospholipids. In semisolid dairy products such as sour cream, dairy spreads, yogurt, and whipped cream, the major lipid composition is milk fat, which consists of >400 individual fatty acids. About 15–20 fatty acids comprise 90% w/w of milk fat: straight chain, saturated fatty acids that have 4 to 18 carbons (4:0, 6:0, 8:0, 10:0, 12:0, 14:0, 16:0, 18:0); monounsaturated fatty acids (16:1, 18:1); and polyunsaturated fatty acids (18:2, 18:3) (Fox and Mcsweeney 2015). Due to the high saturated fat content, milkfat is a soft solid at room temperature.

In milk, milkfat droplets are dispersed during processing by homogenization, which breaks the fat phase into small droplets, preventing it from separating into a cream layer during storage (Fig. 16). Milkfat droplet or crystal particle size not only influences the microstructure, but also plays a major role in the microstructures of products made from the milk, such as cheese (Michalski et al. 2004), yogurt (Ciron et al. 2010), and milk gels (Xiong et al. 1991). Small oil droplets can fill the voids in protein networks, but big oil droplets may disrupt the continuous phase of the protein network. For fat crystals, butter with larger fat crystals has a higher melting point and is easier to spread (Narine and Marangoni 1999).

Plant oils or vegetable oils such as canola oil, cocoa butter, avocado oil, coconut oil, and olive oils, are triacylglycerol-based lipids that are generally liquid at room temperature (Gunstone 2011). They are often used for structuring salad dressings (e.g. Fig. 17) and providing textural features such as fatty mouthcoat, reduced firmness, and creaminess. Smaller oil droplets have been shown to increase salad dressing viscosity (Carrillo and Kokini 1988; Lai and Lin 2004). Similar rheological behavior was also reported in mayonnaises; however, sensory evaluation indicated that mayonnaises with larger oil droplets were more acceptable (Liu et al. 2007).

2.3.2 Water

Water is a key component of both semisolid and fluid foods; it often makes up the bulk of the food’s weight. Water in foods can be present as a continuous phase, such as in oil-in-water emulsions (Fig. 17); in droplet form, such as in water-in-oil emulsions; or in crystal form (ice crystals), such as in ice cream (Fig. 18). The particle size distribution of water droplets, and therefore the subsequent ice crystals upon freezing, can be controlled by using different processing strategies, such as homogenization (Innocente et al. 2009), shear force during mixing (Lian et al. 2006), and rapid freezing (Goff 1997). The size of ice crystals can significantly influence the texture and rheological properties of ice cream: large ice crystals promote a coarse, icy texture, while smaller crystals provide a smoother, more palatable texture (Trgo et al. 1999; Wildmoser et al. 2004).

3 Ingredient Strategies for Adjusting Semisolid Food Structures

It is often necessary to adjust semisolid food textures to yield products that are easier to process, have better storage stability, and possess palatable textures. This is especially true for emulsions and foams, which can separate or collapse rapidly if not properly stabilized. One way to provide stabilization while also adjusting rheological and sensory behaviors is to incorporate various functional ingredients into the food formulation. Because the specific functionality of a given ingredient is often system-dependent, a proper understanding of the food system and ingredient functionality over a broad range of environments is needed to select appropriate stabilizing and texturizing ingredients for a given food emulsion or foam.

3.1 Emulsions

Many semisolid foods are emulsion-based, e.g. frozen desserts, margarine, full-fat yogurt, sour cream, and custard. Emulsions are colloidal systems containing either water droplets dispersed in a continuous oil phase (w/o emulsions) or oil droplets dispersed in a continuous water phase (o/w emulsions). (Dickinson 2010). Most food emulsions are o/w; butter, being a w/o emulsion, is a notable exception.

Emulsions are thermodynamically unstable and will separate into two phases if not stabilized. Phase separation can be slowed by decreasing droplet size and the density difference between the two phases. Additionally, emulsions can stabilized by surfactants and emulsifiers. Both of these are molecules with a hydrophilic (polar) section and a hydrophobic (non-polar) section. As the molecules reach the interface between the oil and aqueous phase, they align so that the hydrophilic portion is in the aqueous phase and the hydrophobic end is in the oil phase (Fig. 19). Sufficient concentration of emulsifiers or surfactants allow complete coating of all droplets in the system, preventing the droplets from flocculating or coalescing (Dickinson 1987). The primary difference between an emulsifier and a surfactant is that surfactants is their size and stabilization mechanism. Surfactants, such as mono- and diglycerides, have relatively low molecular weight and promote emulsion stability by lowering the interfacial surface tension, making the conditions to form an emulsion more favorable (Kralova and Sjöblom 2009). Emulsifiers, such as proteins and polysaccharides, have higher molecular weights and stabilize emulsions by forming a continuous interfacial layer that provides steric stabilization, electrostatic repulsion, or both. Both emulsifiers and surfactants can be used in the same food system; however, care must be taken when selecting the particular emulsifier(s) and surfactant(s) and their respective concentrations (Hasenhuettl and Hartel 2008). Certain combinations of surfactants and emulsifiers can result in emulsifier–surfactant competition for the interface, which can destabilize the emulsion and promote phase separation (Kralova and Sjöblom 2009).

Amphiphilic proteins and polysaccharides are often used as emulsifiers for semisolid foods (Fig. 20). While surfactants can also be used to stabilize emulsions, the push for clean-label foods has encouraged food manufacturers to remove these ingredients from their formulations and replace them with proteins and polysaccharides, providing a more consumer-friendly label. Potato protein and chitosan have been used as emulsifiers for stabilizing high-oleic sunflower o/w emulsions. Higher concentrations of chitosan resulted in smaller oil droplets and greater emulsion stability during storage. The viscosity and complex modulus of these emulsions also increased with higher chitosan concentration, generating a thicker and more elastic texture (Calero et al. 2013). Similar observations were reported for o/w emulsion systems stabilized with soy protein (Roesch and Corredig 2003), whey protein and gum arabic (Chanamai and McClements 2002), whey protein and xanthan gum (Sun and Gunasekaran 2009), pectin and guar gum (Erçelebi and Ibanoǧlu 2009) and milk protein and locust gum (Mandala et al. 2004a, b).

3.2 Foams

Many semisolid foods are foams, including ice cream, beaten egg whites, and whipped cream. Foams have similar structure to emulsions, but foams comprise a gas, usually air or carbon dioxide, dispersed within a fluid. They can be formed by applying high shear and agitation to a fluid over a certain period of time. The combination of shear and agitation entrains small air bubbles into the fluid (Fig. 21). The factors affecting stability of emulsions also apply to foams (Brooker 1993). In general, foams with smaller air bubbles are more stable.

Foam characteristics of primary importance include foaming ability, foam volume, and stability (Kralova and Sjöblom 2009). Foaming ability refers to the amount of energy required to form the foam, while foam volume refers to how much air can be incorporated into the foam. Foam stability refers to the time elapsed before significant foam drainage and collapse (Ansbacher et al. 2010; Panyam 1996). In general, foams with good foaming ability, volume, and stability are desired by the food industry. Unfortunately, fluids that foam easily and with high volume typically do not have good stability, and vice versa. Two classic examples of this phenomena are milk and egg white foams. As can be seen by giving a young child a glass of milk and a straw, milk protein foams with high volume are quite easy to form. However, these foams also collapse quickly due to the high drainage rate of the fluid phase (Ansbacher et al. 2010). Egg white foams, on the other hand, are much more stable, but as anyone who has tried to whip egg whites by hand has noticed, they require large amounts of energy to form and do not have nearly the volume of a foam formed by an equivalent amount of milk protein solution (Pernell et al. 2002).

Foam stability is a major concern in the food industry, as the time needed for an unstabilized foam to collapse (minutes to hours) is notably shorter than the desired shelf life of foamed products (days to weeks). For example, the milk foams on many coffee beverages will quickly collapse, requiring these products to be made right before they are given to the consumer rather than prepared ahead of time. To stabilize a foam, the gas bubbles must be protected by a stable interfacial film that mitigates fluid drainage and bubble coalescence. In general, a good emulsifier, such as proteins and polysaccharides, is also a good foaming agent. However, the main differences between an emulsion and a foam are that the size of foam bubbles are generally much bigger than emulsions droplets and the continuous phase surrounding the gas bubbles is very thin because the volume fraction of air in a foam is much higher than the volume fraction of oil in an emulsion (Green et al. 2013; Heertje 1993; Patino et al. 1999). Therefore, foams have poor stability compared to emulsions.

Among the many food foaming agents, egg white has been reported be the best foaming agent for food (McClements 2015). When egg white is whipped, the proteins denature and interact with each other to form a stable, viscoelastic, interfacial film. Moreover, egg white proteins include glycoproteins, which contain carbohydrate. When these proteins adsorb at the fluid–air interface, the carbohydrate sections orient toward the aqueous phase. The proteins bind water due to their hydrophilicity and increase the viscosity of the fluid. This helps to reduce drainage, increasing foam stability (McClements 2015).

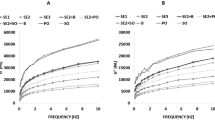

Food foams are often made from combination of proteins and polysaccharides. Foams made with a combination of whey protein and xanthan gum showed that increased whey protein content resulted in more homogeneous and smaller bubbles. Foam stability and density also increased with higher whey protein and xanthan gum content, while foam viscosity increased with higher xanthan gum concentration (Martínez-Padilla et al. 2015). A mixture of guar gum, carrageenan, locust bean gum, and soy lecithin significantly decreased bubble size in whipped cream, resulting in increased foam stability (Smith et al. 2000). A combination of egg proteins and a potato maltodextrin stabilizer showed higher moduli values and greater elastic-type behavior with increased maltodextrin concentration, indicating that maltodextrin was an effective stabilizer for this system (Pycia et al. 2016).

4 Processing Strategies for Altering Semisolid Food Structures

4.1 Manipulating Ionic Strength

Ionic strength can influence emulsion stability. In an emulsion system, stability is influenced by electrostatic repulsion and steric stabilization (Fig. 22). Reducing electrostatic repulsion by adding ions to neutralize charges can destabilize an emulsion. For example, adding small amounts of calcium ions to caseinate-stabilized emulsions can improve emulsion stability, but higher amounts of calcium result in flocculation (Dickinson and Golding 1998). The mechanism for stability is primarily electrostatic repulsion. When no calcium is added, the adsorbed caseinates at the oil–water interface are attracted to each other, and depletion flocculation occurs. Adding small amounts of calcium ions promotes casein aggregation, which actually inhibits depletion flocculation because the binding sites on the free casein molecules become occupied by calcium and cannot interact with the absorbed casein. However, addition of greater amounts of calcium ions results in a flattening of the emulsifier layer around the droplets due to increased charge screening and casein–casein interactions, reducing the effectiveness of steric stabilization (Dickinson et al. 2003; Radford et al. 2004).

Calcium is commonly used to manipulate the ionic strength of food systems, especially dairy systems. A diavalent cation, the double charge on calcium compared to sodium or potassium makes calcium highly effective for adjusting ionic strength at low concentrations, reducing the impact on food flavor. Moreover, calcium is an importance micronutrient and is widely used in food manufacturing as a nutritional additive. However, it is far from an inert substance in foods. Calcium can form ionic bonds and serves as a bonding agent in many food materials such as yogurt, improving their texture (Singh and Muthukumarappan 2008). In yogurt, casein micelles are held together primarily by hydrophobic interactions and colloidal calcium phosphate crosslinks (Fig. 23). Calcium enrichment is often used to improve both yogurt texture and nutritional quality. Increasing the number of casein–calcium crosslinks typically increases the attractive forces between and within casein chains, forming large protein clusters and agglomerates (Fig. 23) (Lee and Lucey 2010). Yogurts made from milk containing 23% more calcium than a standard yogurt formula formed protein clusters with an average diameter > 50 um. Large pores with diameters that were >20 um could also be observed in this network. Yogurts made from milk containing 28% more colloidal calcium phosphate showed larger protein agglomerates than a non-fat control yogurt (Karam et al. 2013). These additional crosslinks and larger agglomerates promote a firmer yogurt gel.

4.2 Including Exopolysaccharides

In yogurt fermentation, ‘ropy’ starter cultures , such as certain strains of Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus salivarius ssp. thermophilus, can produce exopolysaccharides (EPS) (Gentès et al. 2011). A portion of the secreted EPS connect the surface of the bacteria to the casein network; other EPS are neither attached to the protein network nor the surface of bacteria cells, but are present as free molecules (Fig. 24) (Espírito-Santo et al. 2013). EPS in yogurt contribute to desirable rheological properties and texture characteristics. They typically create a long, stringy texture in yogurts. Depending on the concentration and type of EPS in the yogurt, this texture can be smooth or slimy (Martin et al. 1999). The texture produced by a particular EPS is often a function of its structure; the structure of EPS produced by different bacterial strains can vary significantly. Factors that affect the structural characteristic of EPS in fermented milk include monosaccharide composition, charge, linkage types, branching, molecular weight, and the ability to interact with milk protein (Espírito-Santo et al. 2013). Thus, it is important to select the appropriate ropy bacterial strain for generating a particular textural profile in the finished product.

4.3 Applying External Force

External shear forces, such as agitating, whipping, and stirring, are critical for forming desirable semisolid food structures. For example, during whipping of cream, the size of air bubbles decreases, proteins unfold, and the lipid phase breaks into free fat and aggregated fat globules. Therefore, the o/w emulsion in the original cream breaks down and a three-dimensional protein–lipid framework structure forms in the continuous phase. This structure becomes increasingly rigid as whipping (shearing) continues, more proteins unfold, and fat interacts with the newly unfolded proteins (Noda and Shiinoki 1986). The structure traps the air bubbles incorporated into the fluid, forming a foam (Fig. 25). During ice cream production, agitating or stirring can break down large ice crystals into smaller ones and make cooling more efficient (Hartel 1996).

External force can also influence the texture and microstructure of yogurts. Stirring modifies the microstructure of yogurt gels by breaking down the protein network into small gel pieces (Fig. 26). Stirred yogurt is a concentrated dispersion of aggregates consisting of 30 um-diameter protein particles (van Marle 1998). For yogurt fermented by ropy culture, EPS detaches from the surface of the bacteria at high shear rate (>200 s-1) (Teggatz and Morris 1990). It should be noted that because yogurt is thixotropic, excessive shearing of yogurt gels, by using too high shear rates, overly long shearing times, or both, can result in a thin, runny yogurt body. This texture is not desirable in most yogurt products, and the original thickness is usually not recoverable even after prolonged storage. Various stabilizers can be used to decrease the shear sensitivity of yogurt, such as modified starches and xanthan gum, but care is still needed during processing to prevent overshearing yogurt. In general, the gel of stirred yogurt should be broken using low shear rates and the resulting semisolid should be pumped at low velocities to the packaging unit to prevent an unwanted drop in viscosity.

4.4 Adjusting Thermal Treatment

Thermal treatments are commonly used to modify the texture, microstructure, and rheological properties of yogurt. The intensity and duration of heat treatment can significantly modify yogurt structures. Yogurt thermal treatments during processing typically range from 75 °C for 1–5 min to 95 °C for 5–10 min. In some cases, different combination of temperature and time are employed, such as high temperature short time (HTST) or ultra-high temperature (UHT) (Sodini et al. 2004; Supavititpatana et al. 2008) . The major impact of heat treatments on yogurt microstructure is the extent of whey protein denaturation and aggregation of whey proteins with caseins and fat globules (Fig. 27). Heat-denatured whey proteins become a cross-linking agent due to heat-induced exposure of previously inaccessible hydrophobic groups (Lucey et al. 1997). Under temperatures >90 °C and time >60 min, two main types of whey protein–casein micelles interactions occur: (1) a direct interaction between β-lactoglobulin and casein micelles via κ-casein binding and (2) an interaction between α-lactalbumin and β-lactoglobulin within the casein micelles (Mottar et al. 2010). Although heat treatment alters the interactions between casein and whey, the solubilization of calcium, inorganic phosphate, and magnesium from the micelles are not significantly influenced during heat treatment (Singh et al. 1996). Therefore, the overall casein micelle structure is not significantly affected.

Scanning electron microscopy has shown that yogurt produced with no heat treatment has a tortuous, clustered network composed of large casein particles joined together in large clusters or aggregates. The size of the void spaces in these particles range from 5 um to 20 um. However, after heat treatment, yogurt exhibited a finer and more continuous branched kind of network, and the size of void spaces decreased to 3–10 um (Kalab 1990; Parnell-Clunies 1987). The finer microstructure of yogurt formed by heat treatment was ascribed to the increase of bridging capacity of denatured whey proteins which decreased the size of micelle (Kalab et al. 1976). Overall, heat treatment is an easy way to adjust yogurt microstructure and therefore its texture attributes.

4.5 High Pressure Processing

High (hydrostatic) pressure processing (HPP) has received increasing attention in the early twenty-first century as a non-thermal processing technique that can improve both the quality and safety of food products. In HPP, the food is sealed in a flexible package and placed in a hydrostatic chamber. The chamber is pressurized to up to 900 MPa with water, held at this pressure for a certain amount of time, then depressurized. The extreme pressure can denature proteins and burst microbial cells, making HPP a potential tool for enhancing the microbial safety of food products. The protein denaturation can have significant impact on the structure, rheological behaviors, and sensory texture of the HPP-treated food. For example, HPP treatment of milk induces a partial and irreversible dissociation of casein–casein bonding (hydrogen bonds, hydrophobic bonds and ionic bonds) and whey protein unfolding. These changes give rise to the formation of disulfide bonds between the denatured whey proteins and the caseins, which leads to the formation of a number of interaction products. In addition, more compact casein micelle structures can be formed after pressure release (Harte et al. 2003; Needs et al. 2000; Walsh-O’Grady et al. 2001). Figure 28 shows a diagram of how HPP influences the formation of casein-whey network compared to heat treatment.

HPP (100–800 MPa) has been used to treat yogurt milk base to change the microstructure of the final yogurt, leading to modifications in rheological properties and texture, such as increased firmness and smoothness (Penna et al. 2007). High-pressure treatments (676 MPa for 5 min) were also reported to significantly reduce the particle size and the appearance of casein micelles compared to those in heat-treated milks. Casein micelles in HPP-treated milk have more uniform particle size and more spherical shape compared to casein micelles in heat-treated milks (Penna et al. 2007). In addition, HPP-treated yogurt exhibited more interconnected clusters of densely aggregated proteins (Sanchez et al. 2000). Furthermore, HPP-treated ice cream mix had higher viscosity and produced a final ice cream with significantly higher overrun compared to a conventionally processed ice cream. The acceptance and stability of the ice cream was also improved by high pressure (Lim et al. 2008). While HPP shows promise as a tool to modify food structure and texture, it is a relatively new and expensive technology that is difficult to scale to full commercial production quantities. Additional research and technological breakthroughs are needed before HPP becomes commonly used in the food industry (Naik et al. 2013).

4.6 Adjusting pH

Electrostatic interactions and steric stabilization are two major contributors to emulsion stability in semisolid foods. However, electrostatic interactions can be attenuated by adjusting pH close to the isoelectric point of the protein emulsifiers, causing aggregation and flocculation. Previous studies reported that emulsions stabilized with κ- and ι-carrageenan were very unstable at pH 6 (Gu et al. 2005), emulsions stabilized by gum arabic and whey protein were easy to flocculate at pH 7 (Chanamai and McClements 2002), and emulsions stabilized by sodium caseinate and guar gum were unstable at pH 5.5 (Neirynck et al. 2007). During product development, the final food pH should be considered when selecting emulsifiers, as their performance can be notably different at different pH.

Yogurt pH is adjusted by either acid-producing bacterial cultures or a chemical acidulant, such as glucono-delta-lactone. Typically, yogurt fermentation is stopped at pH 4.6, although both microbial and chemical acidulants can reduce the pH further. The final pH and the rate at which pH decreases affects yogurt microstructure by influencing intermicellar interactions. At pH below their isoelectric point (pH = 4.6), casein micelles are positively charged; therefore, the repulsion force between micelles below the isoelectric point is greater than that at the isoelectric point, where there is no net charge. The increased repulsion results in larger pores in the protein network and more whey separation (serum expulsion) during storage (Harwalkar and Kalab 1986). In addition, some studies indicated that pH <4.6 also promoted the production of EPS by ropy bacteria (Beal et al. 1999; Martin et al. 1999), which would promote a stronger network structure and a longer, smoother texture.

4.7 Adjusting Storage Time

Storage time can significantly change the microstructure of stirred yogurt. Longer storage times allow stirred yogurt to form more bonds between the protein molecules, which can reinforce stirred yogurt structure and promote a firmer texture. In addition, longer storage time results in more EPS production by ropy bacteria and more protein hydration (Beal et al. 1999), also promoting a firmer texture. However, increased storage time can also result in increased serum expulsion from the gel, resulting in a more compact gel structure with a layer of free serum on the surface of the yogurt. While the exact mechanism of this serum expulsion is unknown, it can be exacerbated by improper formulation, processing, and storage conditions, such as lack of stabilizer or improper stabilization, pasteurization at too high a temperature, overagitation of the gel during gel breaking, and vibration or temperature cycling during storage (Beal et al. 1999).

Typically, for all semisolid foods containing emulsions, the emulsion droplet size increases with longer storage time due to flocculation and coalescence of small particles into bigger droplets. Previous studies have reported such phenomena in milk (Chen and Dickinson 1993), cream (Korhonen et al. 2001), whipped cream (Long et al. 2012), and mayonnaise (Karas et al. 2002). Time-dependent emulsion destabilization also resulted in more shear-thinning behavior, lower apparent viscosity, and lower storage modulus in semisolid foods (Korhonen et al. 2001; Long et al. 2012). In ice cream, longer storage time, especially under temperature cycling, can result in melting and recrystallization of ice crystals, generating larger ice crystals and altering sensory attributes, such as hardness, firmness, and creaminess (Dolan et al. 1985).

4.8 Adjusting Homogenization Parameters

Homogenization is used to create an emulsion of two or more immiscible fluids. This is achieved by breaking down one continuous phase into extremely small droplets distributed uniformly throughout the other fluid. Homogenization can also be used to evenly disperse particulates through a fluid. In the food industry, this is typically achieved by a homogenizer, which applies high shear and pressure to the fluids, providing the energy required to break up the dispersed phase into tiny droplets (Fig. 29). Through homogenization, the particle size of food materials can be reduced significantly, which usually results in textural changes such as increased smoothness and reduced grittiness and graininess (Amador-Espejo et al. 2014).

During milk processing, the milk is usually homogenized at pressures between 10 and 20 MPa before heat treatment. Homogenization of milk can prevent fat separation during subsequent processing and storage, improve final product consistency, increase milk whiteness, and reduce whey separation in fermented products (Lucey and Singh 1997). The major effect of homogenization of the milk base for yogurt on yogurt microstructure is fat particle size reduction, which increases the overall fat surface area. It was reported that homogenization reduced the average fat globule diameter to 1.43 um, with 99.9% of globules smaller than 3 um (Aguilera and Kessler 1989). Smaller fat globules can more easily fill the void spaces in the porous structure of the gel matrix, making the system more stable (Fig. 30). These particle size changes can impact emulsion rheological properties. Increased homogenization pressure resulted in particle size reduction and increased the viscosity of o/w emulsions stabilized by locust bean gum (Perrechil and Cunha 2010). In ice cream, homogenization can significantly reduce the size of fat globules, producing increased melting resistance (Koxholt et al. 2001). These changes can promote more palatable sensory textures, such as smoothness and creaminess (Schmidt and Smith 2010).

5 Summary

Semisolid food microstructures have great influence on their functionality, physiochemical properties, and sensory attributes. The most influential factor that determines structural features is how the molecules, including proteins, polysaccharides, lipids, water, and ions, are arranged and interact with each other. Therefore, effective approaches for manipulating food structures include adjusting the overall composition of semisolid food, pH, ionic strength, and processing temperatures, shear forces, and pressures. Using those approaches, the original inter- and intramolecular interactions can be changed, and new structures formed through aggregation, flocculation, and dispersion. A fundamental understanding of how to alter food structure allows food manufacturers to design food products with desirable processing behaviors and palatable sensory attributes.

References

Adebowale, K. O., & Lawal, O. S. (2003). Microstructure, physicochemical properties and retrogradation behaviour of mucuna bean (Mucuna pruriens) starch on heat moisture treatments. Food Hydrocolloids. https://doi.org/10.1016/S0268-005X(02)00076-0.

Aguilera, J. M., & Kessler, H. -G. (1989). Properties of mixed and filled-type dairy gels. Journal of Food Science. https://doi.org/10.1111/j.1365-2621.1989.tb05957.x.

Akhtar, M., Murray, B. S., & Dickinson, E. (2006). Perception of creaminess of model oil-in-water dairy emulsions: Influence of the shear-thinning nature of a viscosity-controlling hydrocolloid. Food Hydrocolloids. https://doi.org/10.1016/j.foodhyd.2005.08.006.

Amador-Espejo, G. G., Suàrez-Berencia, A., Juan, B., Bárcenas, M. E., & Trujillo, A. J. (2014). Effect of moderate inlet temperatures in ultra-high-pressure homogenization treatments on physicochemical and sensory characteristics of milk. Journal of Dairy Science. https://doi.org/10.3168/jds.2013-7245.

Ansbacher, S., Flanigan, G. E., & Suplee, G. C. (2010). Certain foam producing substances of milk. Journal of Dairy Science. https://doi.org/10.3168/jds.s0022-0302(34)93294-x.

Aziznia, S., Khosrowshahi, A., Madadlou, A., & Rahimi, J. (2008). Whey protein concentrate and gum tragacanth as fat replacers in nonfat yogurt: Chemical, physical, and microstructural properties. Journal of Dairy Science. https://doi.org/10.3168/jds.2007-0875.

Badii, F., & Howell, N. K. (2006). Fish gelatin: Structure, gelling properties and interaction with egg albumen proteins. Food Hydrocolloids. https://doi.org/10.1016/j.foodhyd.2005.06.006.

Beal, C., Skokanova, J., Latrille, E., Martin, N., & Corrieu, G. (1999). Combined effects of culture conditions and storage time on acidification and viscosity of stirred yogurt. Journal of Dairy Science. https://doi.org/10.3168/jds.S0022-0302(99)75283-5.

Brooker, B. E. (1993). The stabilization of air in foods containing fat -- a review. Food Structure, 12, 12.

Byrne, B. M., Gruber, M., & Ab, G. (1989). The evolution of egg yolk proteins. Progress in Biophysics and Molecular Biology. https://doi.org/10.1016/0079-6107(89)90005-9.

Çakir, E., & Foegeding, E. A. (2011). Combining protein micro-phase separation and protein-polysaccharide segregative phase separation to produce gel structures. Food Hydrocolloids, 25, 1538–1546. https://doi.org/10.1016/j.foodhyd.2011.02.002.

Calero, N., Muñoz, J., Cox, P. W., Heuer, A., & Guerrero, A. (2013). Influence of chitosan concentration on the stability, microstructure and rheological properties of O/W emulsions formulated with high-oleic sunflower oil and potato protein. Food Hydrocolloids, 30, 152–162.

Camacho, M. M., Martínez-Navarrete, N., & Chiralt, A. (1998). Influence of locust bean gum/λ-carrageenan mixtures on whipping and mechanical properties and stability of dairy creams. Food Research International, 31, 653–658.

Carrillo, A. R., & Kokini, J. L. (1988). Effect of egg yolk and egg yolk + salt on rheological properties and particle size distribution of model oil-in- water salad dressing emulsions. Journal of Food Science. https://doi.org/10.1111/j.1365-2621.1988.tb09275.x.

Chanamai, R., & McClements, D. J. (2002). Comparison of gum arabic, modified starch, and whey protein isolate as emulsifiers: Influence of pH, CaCl2 and temperature. Journal of Food Science. https://doi.org/10.1111/j.1365-2621.2002.tb11370.x.

Charoen, R., Jangchud, A., Jangchud, K., Harnsilawat, T., Naivikul, O., & McClements, D. J. (2011). Influence of biopolymer emulsifier type on formation and stability of rice bran oil-in-water emulsions: Whey protein, gum arabic, and modified starch. Journal of Food Science. https://doi.org/10.1111/j.1750-3841.2010.01959.x.

Chen, J., & Dickinson, E. (1993). Time-dependent competitive adsorption of milk proteins and surfactants in oil-in-water emulsions. Journal of the Science of Food and Agriculture. https://doi.org/10.1002/jsfa.2740620312.

Ciron, C. I. E., Gee, V. L., Kelly, A. L., & Auty, M. A. E. (2010). Comparison of the effects of high-pressure microfluidization and conventional homogenization of milk on particle size, water retention and texture of non-fat and low-fat yoghurts. International Dairy Journal. https://doi.org/10.1016/j.idairyj.2009.11.018.

Commission, C. A. (2008). Codex General Standard for Food Additives (GSFA) online database. Codex Stand. 118–1979.

Crispín-Isidro, G., Lobato-Calleros, C., Espinosa-Andrews, H., Alvarez-Ramirez, J., & Vernon-Carter, E. J. (2015). Effect of inulin and agave fructans addition on the rheological, microstructural and sensory properties of reduced-fat stirred yogurt. LWT- Food Science and Technology. https://doi.org/10.1016/j.lwt.2014.06.042.

Cuq, B., Aymard, C., Cuq, J. -L., & Guilbert, S. (1995). Edible packaging films based on fish myofibrillar proteins: Formulation and functional properties. Journal of Food Science. https://doi.org/10.1111/j.1365-2621.1995.tb04593.x.

Dahbi, L., Alexander, M., Trappe, V., Dhont, J. K. G., & Schurtenberger, P. (2010). Rheology and structural arrest of casein suspensions. Journal of Colloid and Interface Science. https://doi.org/10.1016/j.jcis.2009.10.042.

Dawkins, N. L., & Nnanna, I. A. (1995). Studies on oat gum [(1→ 3, 1→ 4)-β-D-glucan]: Composition, molecular weight estimation and rheological properties. Food Hydrocolloids, 9, 1–7.

Dello Staffolo, M., Bertola, N., Martino, M., & Bevilacqua, A. (2004). Influence of dietary fiber addition on sensory and rheological properties of yogurt. International Dairy Journal. https://doi.org/10.1016/j.idairyj.2003.08.004.

Depree, J. A., & Savage, G. P. (2001). Physical and flavour stability of mayonnaise. Trends in Food Science and Technology. https://doi.org/10.1016/S0924-2244(01)00079-6.

Dickinson, E. (1987). Food emulsions and foams. New York: Elsevier.

Dickinson, E. (2006). Structure formation in casein-based gels, foams, and emulsions. Colloids and Surfaces A: Physicochemical and Engineering Aspects. https://doi.org/10.1016/j.colsurfa.2006.01.012.

Dickinson, E. (2009). Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocolloids. https://doi.org/10.1016/j.foodhyd.2008.08.005.

Dickinson, E. (2010). Food emulsions and foams: Stabilization by particles. Current Opinion in Colloid & Interface Science. https://doi.org/10.1111/j.1536-7150.1989.tb03180.x.

Dickinson, E., & Golding, M. (1998). Influence of calcium ions on creaming and rheology of emulsions containing sodium caseinate. Colloids and Surfaces A: Physicochemical and Engineering Aspects. https://doi.org/10.1016/S0927-7757(98)00573-1.

Dickinson, E., Radford, S. J., & Golding, M. (2003). Stability and rheology of emulsions containing sodium caseinate: Combined effects of ionic calcium and non-ionic surfactant. Food Hydrocolloids. https://doi.org/10.1016/S0268-005X(02)00055-3.

Diftis, N. G., Pirzas, T. A., & Kiosseoglou, V. D. (2005). Emulsifying properties of gelatin conjugated to pectin under alkaline conditions. Journal of the Science of Food and Agriculture. https://doi.org/10.1002/jsfa.2029.

Djagny, K. B., Wang, Z., & Xu, S. (2001). Gelatin: A valuable protein for food and pharmaceutical industries: Review. Critical Reviews in Food Science and Nutrition. https://doi.org/10.1080/20014091091904.

Dolan, K. D., Singh, R. P., & Wells, J. H. (1985). Evaluation of time-temperature related quality changes in ice cream during storage. Journal of Food Processing & Preservation. https://doi.org/10.1111/j.1745-4549.1985.tb00725.x.

Dolz, M., Hernández, M. J., & Delegido, J. (2006). Oscillatory measurements for salad dressings stabilized with modified starch, xanthan gum, and locust bean gum. Journal of Applied Polymer Science. https://doi.org/10.1002/app.24125.

Elleuch, M., Bedigian, D., Roiseux, O., Besbes, S., Blecker, C., & Attia, H. (2011). Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chemistry. https://doi.org/10.1016/j.foodchem.2010.06.077.

Ercelebi, E. A., & Ibanoǧlu, E. (2007). Influence of hydrocolloids on phase separation and emulsion properties of whey protein isolate. Journal of Food Engineering. https://doi.org/10.1016/j.jfoodeng.2006.05.027.

Erçelebi, E. A., & Ibanoǧlu, E. (2009). Rheological properties of whey protein isolate stabilized emulsions with pectin and guar gum. European Food Research and Technology. https://doi.org/10.1007/s00217-009-1056-6.

Espírito-Santo, A. P., Lagazzo, A., Sousa, A. L. O. P., Perego, P., Converti, A., & Oliveira, M. N. (2013). Rheology, spontaneous whey separation, microstructure and sensorial characteristics of probiotic yoghurts enriched with passion fruit fiber. Food Research International. https://doi.org/10.1016/j.foodres.2012.09.012.

Fernández García, E., & McGregor, J. U. (1997). Fortification of sweetened plain yogurt with insoluble dietary fiber. Zeitschrift für Lebensmittel-Untersuchung und -Forschung. https://doi.org/10.1007/s002170050108.

Fitt, L. E., & Snyder, E. M. (1984). Photomicrographs of starches. In Starch: Chemistry and technology. https://doi.org/10.1016/B978-0-12-746270-7.50029-X.

Fox, P., & Mcsweeney, P. (2015). Dairy chemistry and biochemistry. https://doi.org/10.1007/978-3-319-14892-2.

Gallant, D. J., Bouchet, B., & Baldwin, P. M. (1997). Microscopy of starch: Evidence of a new level of granule organization. Carbohydrate Polymers. https://doi.org/10.1016/S0144-8617(97)00008-8.

Gentès, M.-C., St-Gelais, D., Turgeon, S. L., Gentès, M.-C., St-Gelais, D., & Turgeon, S. L. (2011). Gel formation and rheological properties of fermented milk with in situ exopolysaccharide production by lactic acid bacteria. Dairy Science & Technology, 91, 645–661. https://doi.org/10.1007/s13594-011-0039-0.

Goff, H. D. (1997). Colloidal aspects of ice cream - A review. International Dairy Journal. https://doi.org/10.1016/S0958-6946(97)00040-X.

Green, A. J., Littlejohn, K. A., Hooley, P., & Cox, P. W. (2013). Formation and stability of food foams and aerated emulsions: Hydrophobins as novel functional ingredients. Current Opinion in Colloid & Interface Science, 18, 292–301.

Gu, Y. S., Decker, E. A., & McClements, D. J. (2005). Influence of pH and carrageenan type on properties of β-lactoglobulin stabilized oil-in-water emulsions. Food Hydrocolloids. https://doi.org/10.1016/j.foodhyd.2004.04.016.

Guggisberg, D., Cuthbert-Steven, J., Piccinali, P., Bütikofer, U., & Eberhard, P. (2009). Rheological, microstructural and sensory characterization of low-fat and whole milk set yoghurt as influenced by inulin addition. International Dairy Journal. https://doi.org/10.1016/j.idairyj.2008.07.009.

Gunstone, F. (2011). Vegetable oils in food technology: Composition, properties and uses. Hoboken: John Wiley & Sons.

Harte, F., Luedecke, L., Swanson, B., & Barbosa-Cánovas, G. V. (2003). Low-fat set yogurt made from milk subjected to combinations of high hydrostatic pressure and thermal processing. Journal of Dairy Science. https://doi.org/10.3168/jds.S0022-0302(03)73690-X.

Hartel, R. W. (1996). Ice crystallization during the manufacture of ice cream. Trends in Food Science and Technology. https://doi.org/10.1016/0924-2244(96)10033-9.

Harwalkar, V. R., & Kalab, M. (1986). Relationship between microstructure and susceptibility to syneresis in yoghurt made from reconstituted nonfat dry milk. Food Structure, 5, 13.

Hasenhuettl, G. L., & Hartel, R. W. (2008). Food emulsifiers and their applications. New York: Springer.

Heertje, I. (1993). Structure and function of food products: A review. Food Structure, 12, 7.

Heertje, I. (2014). Structure and function of food products: A review. Food Structure. https://doi.org/10.1016/j.foostr.2013.06.001.

Huppertz, T., & de Kruif, C. G. (2008). Structure and stability of nanogel particles prepared by internal cross-linking of casein micelles. International Dairy Journal. https://doi.org/10.1016/j.idairyj.2007.10.009.

Innocente, N., Biasutti, M., Venir, E., Spaziani, M., & Marchesini, G. (2009). Effect of high-pressure homogenization on droplet size distribution and rheological properties of ice cream mixes. Journal of Dairy Science. https://doi.org/10.3168/jds.2008-1797.

Iriondo-Dehond, M., Miguel, E., & Del Castillo, M. D. (2018). Food byproducts as sustainable ingredients for innovative and healthy dairy foods. Nutrients. https://doi.org/10.3390/nu10101358.

Kalab, M. (1990). Microparticulate protein in foods. Journal of the American College of Nutrition. https://doi.org/10.1080/07315724.1990.10720396.

Kalab, M., Emmons, D. B., & Sargant, A. G. (1976). Milk gel structure. V. Microstructure of yoghurt as related to the heating of milk. Milchwissenschaft, 31, 402–408.

Karam, M. C., Gaiani, C., Hosri, C., Burgain, J., & Scher, J. (2013). Effect of dairy powders fortification on yogurt textural and sensorial properties: A review. The Journal of Dairy Research. https://doi.org/10.1017/S0022029913000514.

Karas, R., Skvarča, M., & Žlender, B. (2002). Sensory quality of standard and light mayonnaise during storage. Food Technology and Biotechnology.

Karim, A. A., & Bhat, R. (2009). Fish gelatin: Properties, challenges, and prospects as an alternative to mammalian gelatins. Food Hydrocolloids. https://doi.org/10.1016/j.foodhyd.2008.07.002.

Kaur, L., Singh, J., Singh, H., & McCarthy, O. J. (2008). Starch-cassia gum interactions: A microstructure - Rheology study. Food Chemistry. https://doi.org/10.1016/j.foodchem.2008.03.027.

Keogh, M. K., & O’Kennedy, B. T. (1998). Rheology of stirred yogurt as affected by added milk fat, protein and hydrocolloids. Journal of Food Science. https://doi.org/10.1111/j.1365-2621.1998.tb15687.x.

Korhonen, M., Hellen, L., Hirvonen, J., & Yliruusi, J. (2001). Rheological properties of creams with four different surfactant combinations - effect of storage time and conditions. International Journal of Pharmaceutics. https://doi.org/10.1016/S0378-5173(01)00675-5.

Koxholt, M. M. R., Eisenmann, B., & Hinrichs, J. (2001). Effect of the fat globule sizes on the meltdown of ice cream. Journal of Dairy Science. https://doi.org/10.3168/jds.S0022-0302(01)74448-7.

Kralova, I., & Sjöblom, J. (2009). Surfactants used in food industry: A review. Journal of Dispersion Science and Technology. https://doi.org/10.1080/01932690902735561.

Kristinsson, H. G., & Rasco, B. A. (2000). Fish protein hydrolysates: Production, biochemical, and functional properties. Critical Reviews in Food Science and Nutrition. https://doi.org/10.1080/10408690091189266.

Kyaw, Z. Y., Yu, S. Y., Cheow, C. S., Dzulkifly, M. H., & Howell, N. K. (2001). Effect of fish to starch ratio on viscoelastic properties and microstructure of fish cracker (‘keropok’) dough. International Journal of Food Science and Technology. https://doi.org/10.1046/j.1365-2621.2001.00481.x.

Lai, L. S., & Lin, P. H. (2004). Application of decolourised hsian-tsao leaf gum to low-fat salad dressing model emulsions: A rheological study. Journal of the Science of Food and Agriculture. https://doi.org/10.1002/jsfa.1757.

Lee, W. J., & Lucey, J. A. (2004). Structure and physical properties of yogurt gels: Effect of inoculation rate and incubation temperature. Journal of Dairy Science. https://doi.org/10.3168/jds.S0022-0302(04)73450-5.

Lee, W. J., & Lucey, J. A. (2010). Formation and physical properties of yogurt. Asian-Australasian Journal of Animal Sciences. https://doi.org/10.5713/ajas.2010.r.05.

Lian, G., Moore, S., & Heeney, L. (2006). Population balance and computational fluid dynamics modelling of ice crystallisation in a scraped surface freezer. Chemical Engineering Science. https://doi.org/10.1016/j.ces.2006.08.075.

Lim, S.-Y., Swanson, B. G., Ross, C. F., & Clark, S. (2008). High hydrostatic pressure modification of whey protein concentrate for improved body and texture of lowfat ice cream. Journal of Dairy Science. https://doi.org/10.3168/jds.2007-0391.

Liu, H., Xu, X. M., & Guo, S. D. (2007). Rheological, texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT- Food Science and Technology. https://doi.org/10.1016/j.lwt.2006.11.007.

Liu, Y., Chen, J., Luo, S., Li, C., Ye, J., Liu, C., & Gilbert, R. G. (2017). Physicochemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology. Carbohydrate Polymers. https://doi.org/10.1016/j.carbpol.2017.07.084.

Long, Z., Zhao, M., Zhao, Q., Yang, B., & Liu, L. (2012). Effect of homogenisation and storage time on surface and rheology properties of whipping cream. Food Chemistry. https://doi.org/10.1016/j.foodchem.2011.09.028.

Lopes, D. G., Becker, K., Stehr, M., Lochmann, D., Haack, D., Zimmer, A., & Salar-Behzadi, S. (2015). Role of lipid blooming and crystallite size in the performance of highly soluble drug-loaded microcapsules. Journal of Pharmaceutical Sciences. https://doi.org/10.1002/jps.24660.

Lucey, J. A., & Singh, H. (1997). Formation and physical properties of acid milk gels: A review. Food Research International. https://doi.org/10.1016/S0963-9969(98)00015-5.

Lucey, J. A., Teo, C. T., Munro, P. A., & Singh, H. (1997). Rheological properties at small (dynamic) and large (yield) deformations of acid gels made from heated milk. The Journal of Dairy Research. https://doi.org/10.1017/S0022029997002380.

Mackie, I. M. (1982). Fish protein hydrolysates. Process Biochemistry, 17, 26–27.

Mandala, I., Michon, C., & Launay, B. (2004a). Phase and rheological behaviors of xanthan/amylose and xanthan/starch mixed systems. Carbohydrate Polymers. https://doi.org/10.1016/j.carbpol.2004.07.003.

Mandala, I. G., Savvas, T. P., & Kostaropoulos, A. E. (2004b). Xanthan and locust bean gum influence on the rheology and structure of a white model-sauce. Journal of Food Engineering. https://doi.org/10.1016/j.jfoodeng.2003.10.018.

Martin, N. C., Skokanova, J., Latrille, E., Beal, C., & Corrieu, G. (1999). Influence of fermentation and storage conditions on the sensory properties of plain low fat stirred yogurts. Journal of Sensory Studies. https://doi.org/10.1111/j.1745-459X.1999.tb00109.x.

Martínez-Padilla, L. P., García-Rivera, J. L., Romero-Arreola, V., & Casas-Alencáster, N. B. (2015). Effects of xanthan gum rheology on the foaming properties of whey protein concentrate. Journal of Food Engineering. https://doi.org/10.1016/j.jfoodeng.2015.01.018.

McClements, D. J. (2015). Food emulsions: principles, practices, and techniques. Boca Raton: CRC press.

Michalski, M.-C., Camier, B., Briard, V., Leconte, N., Gassi, J.-Y., Goudédranche, H., Michel, F., & Fauquant, J. (2004). The size of native milk fat globules affects physico-chemical and functional properties of Emmental cheese. Le Lait. https://doi.org/10.1051/lait:2004012.

Michon, C., Cuvelier, G., Relkin, P., & Launay, B. (1997). Influence of thermal history on the stability of gelatin gels. International Journal of Biological Macromolecules. https://doi.org/10.1016/S0141-8130(97)00024-X.

Mine, Y. (1998). Emulsifying characterization of hens egg yolk proteins in oil-in-water emulsions. Food Hydrocolloids. https://doi.org/10.1016/S0268-005X(98)00054-X.

Mottar, J., Bassier, A., Joniau, M., & Baert, J. (2010). Effect of heat-induced association of whey proteins and casein micelles on yogurt texture. Journal of Dairy Science. https://doi.org/10.3168/jds.s0022-0302(89)79355-3.

Mun, S., Kim, Y. L., Kang, C. G., Park, K. H., Shim, J. Y., & Kim, Y. R. (2009). Development of reduced-fat mayonnaise using 4αGTase-modified rice starch and xanthan gum. International Journal of Biological Macromolecules. https://doi.org/10.1016/j.ijbiomac.2009.02.008.

Murray, B. S. (2007). Stabilization of bubbles and foams. Current Opinion in Colloid & Interface Science. https://doi.org/10.1016/j.cocis.2007.07.009.

Naik, L., Sharma, R., Rajput, Y. S., & Manju, G. (2013). Application of high pressure processing technology for dairy food preservation-future perspective: A review. Journal of Animal Production Advances, 3, 232–241.

Narine, S. S., & Marangoni, A. G. (1999). Relating structure of fat crystal networks to mechanical properties: A review. Food Research International. https://doi.org/10.1016/S0963-9969(99)00078-2.

Needs, E. C., Capellas, M., Bland, A. P., Manoj, P., Macdougal, D., & Paul, G. (2000). Comparison of heat and pressure treatments of skim milk, fortified with whey protein concentrate, for set yogurt preparation: Effects on milk proteins and gel structure. The Journal of Dairy Research. https://doi.org/10.1017/S0022029900004301.

Neirynck, N., Dewettinck, K., & Van Der Meeren, P. (2007). Influence of pH and biopolymer ratio on sodium caseinate—guar gum interactions in aqueous solutions and in O/W emulsions. Food Hydrocolloids, 21, 862–869.

Noda, M., & Shiinoki, Y. (1986). Microstructure and rheological behavior of whipping cream. Journal of Texture Studies. https://doi.org/10.1111/j.1745-4603.1986.tb00404.x.

Panyam, D. (1996). Enhancing the functionality of food proteins by enzymatic modification. Trends in Food Science and Technology. https://doi.org/10.1016/0924-2244(96)10012-1.

Parnell-Clunies, E. (1987). Microstructure of yogurt as affected by heat treatment of milk. Milchwissenschaft, 42, 413–417.

Patino, J. M. R., Nino, M. R. R., Dickinson, E., & Patino, J. M. R. (1999). Food emulsions and foams: Interfaces, interactions and stability. Cambridge: Royal Society of Chemistry.

Penna, A. L. B., Subbarao, G., & Barbosa-Canovas, G. V. (2007). High hydrostatic pressure processing on microstructure of probiotic low-fat yogurt. Food Research International. https://doi.org/10.1016/j.foodres.2007.01.001.

Pernell, C. W., Foegeding, E. A., Luck, P. J., & Davis, J. P. (2002). Properties of whey and egg white protein foams. Colloids and Surfaces A: Physicochemical and Engineering Aspects. https://doi.org/10.1016/S0927-7757(01)01061-5.

Perrechil, F. A., & Cunha, R. L. (2010). Oil-in-water emulsions stabilized by sodium caseinate: Influence of pH, high-pressure homogenization and locust bean gum addition. Journal of Food Engineering. https://doi.org/10.1016/j.jfoodeng.2009.10.041.

Pycia, K., Juszczak, L., & Gałkowska, D. (2016). Effect of native potato starch maltodextrins on stability and rheological properties of albumin foams. Starch-Stärke, 68, 611–620.

Radford, S. J., Dickinson, E., & Golding, M. (2004). Stability and rheology of emulsions containing sodium caseinate: Combined effects of ionic calcium and alcohol. Journal of Colloid and Interface Science. https://doi.org/10.1016/j.jcis.2003.12.045.