Abstract

This paper reports on the implementation of the Apivectoring Technology for the first time in an experimental strawberry crop (Fragaria x ananassa) in Colombia. Honey bees (Apis mellifera) were used as vector of the bio-pesticide Trichoderma harzianum for the control of Botrytis cinerea in an experimental plot of strawberry, in which 6 treatments were established that overspan different agronomic management systems. This study evaluated the foraging preference of the bees in commercial strawberry crop, the floral visitors density, the acquisition of the bio-pesticide by the vector, the distribution of the bio-pesticide in the flowers, fruits and leaves, as well as the impact of the different treatments in the control of B. cinerea and the quality of the fruits. Complementary, an analysis of the commercial potential of the Apivectoring Technology implementation was made, and finally the experience in the transfer of Apivectoring Technology to agricultural producers in Colombia was reviewed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In Colombia, a vast strawberry export potential has been detected by the country to keep the offer throughout the year (Casierra and Salamanca 2008). That is why the nation has led sectoral studies, which have allowed to determine the limiting factors for this crop, and standing out the high disease incidence is among those (Asohofrucol 2013). Botrytis cinerea Pers.:Fr, cause of the grey mold, is one of the most limiting pathogens in strawberry (Fragaria x ananassa), principally due to its great inoculum production capacity as well as its genetic diversity, which allow it to be adapted to different environmental conditions (Fernández-Ortuño et al. 2015). It is complex to calculate the losses since B. cinerea affects different production stages, including post-harvest and marketing (Steiger 2007). This pathogen is able to infect a broad range of plant species, and flowers are mainly appealing because of their nutrients. For instance, pollen and nectar are full of proteins, sugars, minerals and amino acids. These stimulate the conidia germination as well as increase the fungus growth rates (Huang and Kokko 1999; Ngugi and Scherm 2006; Reich et al. 2015). Thin-walled, waxy cuticle petals are also infected by this pathogenic fungus (Huang and Kokko 1999; Ngugi and Scherm 2006; Gossen and Swartz 2008; Reich et al. 2015).

Disease control has historically been dependent on the application of chemical pesticides. The most common management practices consist of alternating mixtures of fungicides with different modes of action (Fernández-Ortuño et al. 2015). According to the Fungicide Resistance Action Committee (FRAC), the intensive use of chemical fungicides has led to the development of fungicide resistance with the pathogen (Fernández-Ortuño et al. 2015). Moreover, it might cause low crop production and malformations due to a decrease in the germination rate of the pollen (Kovach et al. 2000). This outlook matches with the international demanding tendencies, that revolve safety and traceability requirements around clean production systems.

There is a need of valuing alternate control methods that should lead to international quality standards. It eases the access to high-value markets. The usage of bio-pesticides has the potential to help in counteracting deficiencies, regular failures, and concerns related to control practices. It often involves cultural and sanitation measures, microclimate regulation, and a great dependence on fungicides (Yu and Sutton 1997). Apivectoring Technology leverages that potential, namely the distribution of bio-pesticides as microbiological control agents with the usage of bees as vectors. Its aim leads to disease control and a synergistic effect in fruits output and quality. It is due to a higher pollination rate (Kevan et al. 2003; Mommaerts and Smagghe 2011; Smagghe et al. 2012; Hokkanen et al. 2015). This technology was developed by following a holistic approach in which the interaction between the bio-pesticide organisms, the pathogen to be controlled, the type of crop to be applied, and the interaction between the vector and the crop plants are taken into account. The bio-pesticide concentration carried by each bee and its efficiency to be settled out in the plant, in addition to the safety for human beings, insects and environment, must be kept in mind (Kevan et al. 2003; Mommaerts and Smagghe 2011; Smagghe et al. 2012; Hokkanen et al. 2015).

Just over 40 associated studies, done from the first strawberry research in the 90s, reported an increase between 26–40% in the fresh fruit weight and a disease elimination between 48–64% (Peng et al. 1992). Most studies agree on the Apivectoring Technology implementation and its outstanding pathogen control provide that precautionary approach. It is often concluded that Apivectoring Technology is such an useful tool in the setting of an integrated pest and disease management (IPDM) (Yu and Sutton 1997; Kevan et al. 2003; Al Mazra’awi et al. 2006; Kapongo et al. 2008; Mommaerts and Smagghe 2011; Reeh 2012; Shipp et al. 2012; Smagghe et al. 2012; Smagghe et al. 2013; Hokkanen et al. 2015). On the other hand, it creates a management option to promote product safety, therefore contributing to the health of producers and consumers (Kovach et al. 2000).

For the first time in Colombia, this research evaluated the effect in the control of B. cinerea by using honey bees Apis mellifera L. to distribute Trichoderma harzianum in an experimental plot of strawberry in the Andean conditions (Fragaria x ananassa). Figure 1 provides an overview of the experiments at the farm in Mosquera located in the Western Savanna Province of Colombia at 2516 meters above sea level and an average temperature of 12–14 °C, and that has a field size of 2500 m2.

Location and overview of the experiment at the farm in the municipality of Mosquera located in the Western Savanna Province of Colombia at 2516 meters above sea level and an average temperature of 12–14 °C, and that has a field size of 2500 m2. (A) Geographical location: department of Cundinamarca, Western Savanna province, Mosquera municipality. (B) Planting process, January, 2016. (C) First flowering, April 2016. (D and E). Start of fruit production, June 2016. (F) Start of the experiment, sampling, hives (A. mellifera) with inoculum devices November, 2016

1.1 Development and Perspectives of Apivectoring Technology

Apivectoring Technology derives from the early 90s. It can be seen as the use of bees as vectors of a bio-pesticide or biological control agent against a disease and/or pest in a crop. Peng et al. (1992) developed the first research looking for the disease control, the production increase, and the improvement in the strawberry quality because of the cross-pollination effect. Researchers used Clonostachys rosea Schroers, (synonym: Gliocladium roseum) vectored by A. mellifera for the control of B. cinerea in strawberry crops (Fragaria x ananassa DUCH.). As most important result of this research, there was a 60% elimination of the disease. Several projects have been implemented from then onwards. The development of different inoculum dispenser models and the assessment of different pollinators have become a result, as follows: A. mellifera (Johnson et al. 1993; Maccagnani et al. 1999; Bosch and Vicens 2000; Kovach et al. 2000; Escande et al. 2002; Dedej et al. 2004; Maccagnani et al. 2006; Shafir et al. 2006; Albano et al. 2009), Bombus impatiens Cresson (Hymenoptera: Apidae) and Bombus terrestris L. (Hymenoptera: Apidae) (Kovach et al. 2000; Maccagnani et al. 2005; Kapongo et al. 2008; Albano et al. 2009; Reeh 2012; Shipp et al. 2012; Smagghe et al. 2013; Karise et al. 2016a), and Osmia cornuta Latreille (Hymenoptera: Megachilidae) (Maccagnani et al. 2006; Maccagnani et al. 2009). Likewise, different bio-pesticides have been tested, creating commercial patents and developments (Sutton et al. 1997; Ngugi et al. 2005; Kapongo et al. 2008). Mommaerts et al. (2011) widened the definition of Apivectoring by coining the term Entomovectoring as the combination of techniques using insects as vectors of biological control agents. Its purpose focuses on making a monitoring, precision control for pests and diseases. There are studies known in which some predators are used as vectors (Zhu and Kim 2012). However, the use of bees is more usual. That is why the current document makes reference to the term (Kevan et al. 2003).

When thinking of the different components of Apivectoring Technology, the success for this control method in a specific species is emphasized. It depends on the interaction of 5 relevant factors: (1) Right vector selection, since it determines the effective transport of the bio-pesticide agent inside the crop as it is influenced by the plant-vector interaction, (2) Control potential by the bio-pesticide product, (3) Significance to use a carrier (vehicle) and formulation (carrier + bio-pesticide), since these carriers can improve the load and the vector transport, (4) Dispenser selection with a suitable design for the vector, and (5) Safety for vectors, producers and consumers (Kevan et al. 2003; Kevan et al. 2008; Mommaerts and Smagghe 2011; Smagghe et al. 2012).

This technology has been used in the control of different pathogens, including B. cinerea, source for the grey mold in strawberry, raspberry and tomato (Peng et al. 1992; Kovach et al. 2000; Shafir et al. 2006; Kapongo et al. 2008; Albano et al. 2009; Shipp et al. 2012; Hokkanen et al. 2015; Karise et al. 2016a), Erwinia amylovora, known as the source of the fire blight in the pear tree (Maccagnani et al. 2005; Maccagnani et al. 2006), Monilinia vaccinii-corymbosi that causes blueberries mummification (Dedej et al. 2004), and Sclerotinia sclerotiorum in sunflower and alfalfa crops (Escande et al. 2002; Sutton and Kevan 2013). Regarding pests, some reported ones as follows: cabbage looper (Trichoplusia ni), sunflower’s congregated moth (Cochylis hospes Walsingham), bollworm (Helicoverpa zea) (Gross et al. 1994), pollen beetle (Meligethes aeneus) (Butt et al. 1998), among others. There are also some experiments related to weeds control. The use of Metschnikovia reukaufii (Ascomycetes) was tested for the control of Asclepias syriaca (Asc. Epiadaceae) (Kevan et al. 1989; Eisikowitch et al. 1990). Table 1 sums up results from published researches about this topic.

1.2 Perspectives

Although models implemented have obtained promising results (Hokkanen et al. 2015), it is necessary to improve the system efficiency under adverse environmental conditions. It also needs to develop products with suitable formulations in order to get a better acquisition by the vector, widen the commercially formulated bio-pesticide pool, as well as develop products focused on the simultaneous precautionary control for more than one pathogenic organism or crop pest. It might also be possible to distribute low-risk chemicals.

It is also required to consider the option of using this technology to control pathogens that affect the leaf area. It is known that bees are capable of distributing the bio-pesticide onto leaves as well. For instance, distributed levels in leaves have been quantified in sweet pepper and tomato where 76%–90% of the samples tested had bio-pesticide spores (Al-Mazra’awi et al. 2006; Kapongo et al. 2008). In addition, other important crops have been investigated such as coffee, passion-flowers, blackberry, avocado, citrus fruits, Quito orange, peach tree, melon, watermelon, cucumber, among others.

With over 20,000 bee species worldwide (FAO 2016), a test about other bee species as vector is required. The pollination efficiency for some native species may be higher than the A. mellifera or B. terrestris ones. It is due to the closest co-evolutionary relationships with the target vegetal species, or simply a better adaptation to specific weather conditions. In Colombia, the use of other bee species different from A. mellifera is shown as an important option. It is due to the trend of farmers towards feeling fear of bees after the arrival of the Africanized bee hybrid in the early 80s (Sánchez et al. 2013). The aforementioned bee biotype takes up 98% of the national beekeeping nowadays (Tibatá et al. 2017).

It is also important to define standard protocols, which allow researches in different areas to be comparable. In that regard it is required to make use of techniques that allow doing a more efficient technology test. For instance, strains marked with green fluorescence protein (GFP) might be used in field distribution experiments (Reeh 2012).

Another important fact to be considered in the commercial implementation of this model is the resistance to change on behalf of the producers. Traditional agriculture limits the implementation of alternate technologies due to rooted cultural matters. In most cases these imply the application of products for the control of pests and diseases which are harmful for bees. On the other hand, the productive systems of an organic or clean type are more affordable. In either case Apivectoring Technology must be understood as part of the integrated pests and diseases management of precautionary nature. Expectations that omit technology limitations can be created, causing a counterproductive effect in its adoption by the farmers. Likewise, government support for the technology application must be asked, not only as to resources intended to its research and promotion but also in regard to legislative issues focused on the creation of clear legislations for the products commercialization and application with harmful active components for bees. Moreover, the recognition to farmers who implement these kind of practices in their crops, as seen in the European case where the reform to the European Union Common Agricultural Policy (CAP) makes reference to new statutes regarding Apivectoring Technology, in the “Alternate Crops Protection in the Berries and Fruits Production” section. This was the setting in which conventional farmers promised to replace treatments with chemical pesticides with entomovectoring by receiving 500 €/ha/year, as part of an environmental support (Hokkanen et al. 2015).

In the last 27 years, over 40 publications relating to the proof that Apivectoring Technology shows great benefits not only as a sustainable environmental option but also as economically viable. However, there are also some limitations as well as its application must be framed in an integrated model for the pests and diseases management in a precautionary approach developed with prior knowledge of the conditions for all components to work appropriately. The possibility of unifying the system completely is connected to the variability of each component, which not only requires the knowledge from each one of them but also its different interactions. This would allow necessary adaptations according to specific conditions of the productive system in which the technology is implemented plus increasing its chance for success. That is why some interdisciplinary researches are needed in different topics the technology includes, which finally allows making commercial developments for itself or strengthen the existing ones.

The first case study in Colombia as presented below in which the use of A. mellifera as vector of T. harzianum for the control of B. cinerea was tested in an experimental strawberry crop (Fragaria x ananassa), Albion selection. It is located in the municipality of Mosquera, Colombia, at an altitude of 2516 meters above sea level, with an average temperature of 12–14 °C, an average precipitation between 500 and 1000 mm/year in a bimodal pattern (dry period: late December to early March plus July, August, and September). Geographic coordinates: 4° 40′ 9. 34″ North latitude. 74° 15′ 5. 07″ West longitude (Fig. 1).

This study was developed in three stages: (i) Pollinators density associated to strawberry crops was valued, before and after introducing hives in the productive system, (ii) Biocontrol products development and testing for Apivectoring Technology implementation was done, and (iii) Disease influence and its effect on the production was valued in six different agronomic models, as follows:

1.3 Evaluation of the Foraging Preference of Africanized Bees (Apis mellifera) in Commercial Strawberry Crop

One of the necessary conditions for the Apivectoring Technology operation belongs to bees that visit on the flowers of the farming crop of interest. With the purpose of valuing this condition, two field tests were developed. The first test was based on palynology techniques to establish the bee visits frequency indirectly for the recollection of this resource. The second test evaluated the flower visitor densities through direct inspection by following FAO recommendations.

Test 1. Indirect evaluation of the recollection frequency for the strawberry pollen resource by A. mellifera with the use of palynologic techniques.

Ten A. mellifera hives were installed inside a strawberry crop for this test (Fragaria x ananassa) located in the municipality of Sibaté (Cundinamarca), during April and May 2015. Hives were found in similar development conditions in terms of population. In the same way there were young queen bees in all cases, which were introduced inside the hives 2 months prior to the data recollection. A pollen collector device was installed in each hive from which previously standardized samples were obtained and taken to the laboratory in order to carry out a palynologic analysis. Samples were collected every 3 days and nine samplings were carried out for 90 samples during a 27-days period trial. Through the sampling period, hives were weekly fed with water/sugar syrup in a relation 1:2 in weight. Each hive received 1.5 liters of syrup. Samples’ palynologic analysis was carried out with the acetolysis technique, described by Erdtman (1969), which consists of making an acid hydrolysis of the pollen material, where the intine and protoplasm of the pollen grain are degraded; only the outer wall of sporopolenin remains.

Results showed how that the most abundant botanic species were eucalyptus (Eucalyptus globulus), turnip (Brassica sp.), red clover (Trifolium pratense), white clover (Trifolium repens), passion fruit (Passiflora tripartita) and several Asteraceae (Fig. 2).

The strawberry pollen happened to be an unrepresentative resource of the recollected samples, and no case was among the six resources with higher abundance. In order to calculate the relative importance of the floral resource (in this case, strawberry pollen grains) inside the range of pollen of the 10 A. mellifera hives, the quantitative analysis was the tool used through the adaptation of the Importance Value Index (IVI) sensu Amaya et al. (2001). IVI considers the relative frequency of floral use by a species (in this case, a hive), about the total diversity of the species community (in this case, the times the strawberry pollen grain was in different samplings per hive).

According to Danka et al. (1986), the percentage of working bees that had gathered forage at a certain time for a hive of 30,000 individuals (estimation for the 10 hives of the experiment) plus a good nectar availability is around 1.2%. That is why it was considered that 360 working bees from each hive were foraging at a specific time in the strawberry crop (IVI crops were done based on this number; that is why the estimate number of abundance for field bees per hive was standardized in 360).

The modified IVI was calculated as follows:

-

Pix: it is the frequency of the Fragaria x ananassa resource use (count in palynologic samples)/total frequency of the resource used by the hive X (total counts in palynologic samples).

-

Fix: it is the number of field working bees of hive X that used the Fragaria x ananassa resource/total number of individuals in hive X.

-

M: it is the number of positive palynologic samples to the presence of Fragaria x ananassa/total number of samples taken from hive X.

On that basis, modified IVI calculations noted that Fragaria x ananassa was slightly more important for hives #9 (0.0605) and #3 (0.0572), while for #1 (0.0018), #2 (0.0036), #7 (0.0024) and #12 (0.0083) it was slightly less important (Table 2).

Working bees from some hives were more constant in their visiting to the strawberry flowers, although its relative importance was smaller (hives #1 and #2). While some others with a smaller persistence showed a low relative importance too (hives #7 and #12). No hives showed that the frequency of pollen grains in the segments placed was stable and continuous (Fig. 3).

During the tested period, results showed that all hives visited strawberry flowers to obtain pollen as food resource. However, the low resource abundance shows this pollen is unattractive and recollects itself occasionally. These results coincide with other studies in which it is concluded that the main motivation for bees to visit the strawberry flowers is the nectar recollection (Goodman and Oldroyd 1988; Coffey and Breen 1997; Poveda et al. 2018). Therefore, the preference of the bees for the pollen recollection of plant species was part of the usual environment for the strawberry crops in Colombia, as is the case of eucalyptus (E. globulus), red clover (T. pratense) and white clover (T. repens). These three species were also reported as resources with higher abundance in A. mellifera bee honeys, coming from Cundinamarca (Nates et al. 2013). This showed that these are also attractive for the nectar recollection. It must be taken into account since the strawberry crops environment shows more attractive plant species for bees in comparison with strawberry. The effects of the Apivectoring Technology can be drastically reduced on the interest crop, so a higher number of hives will be required or implement method that improve the insects visits frequency to the crop.

1.4 Evaluation of the Use of Apivectoring Technology in a Pilot Strawberry Crop

The evaluation of this technology was performed in open field. The different procedures as performed from 2015 to 2017, are described. The floral visits density was tested. A specialized product was formulated to allow an adequate bio-pesticide distribution. Then the distribution capacity of the vector was determined (flowers, leaves, and fruits), and the effectiveness of the Apivectoring Technology in B. cinerea control and its effect on the strawberry crop production were tested.

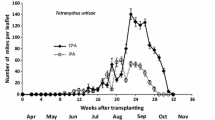

1.5 Floral Visitors’ Density Test

Since the Apivectoring effectiveness is depending directly on the visits performed by the bee to the interest crop, a procedure was done to establish the floral visitors’ density in the experimental smallholding before and after hives introduction. A 50 × 25 meters crop area, in which a 45 × 20 meters experimental area was defined. The presence of forests or bees’ productive units, other crops zones and weeds areas were characteristic in a 1 km-ratio. The experimental area was divided into sub-areas at 5, 15, 35 and 45 meters. A transect was done in each one in which 100 flowers in anthesis were tested, and flowering was guaranteed to be over 10%. Tests were performed during 4 days, before and after the hives introduction into the experimental smallholding. The number and type of pollinators and/or floral visitors were registered, inspections were done in five moments throughout the day: 6 am, 9 am, 12 m, 3 pm and 6 pm (adapted from Protocol FAO to Detect and Assess Pollination Deficits in Crops: A Handbook for its Use. Vaissière et al. 2011). For the statistical analysis, the Mann-Whitney test was used in order to compare the appearance frequencies of the floral visitor between both tests before and after bees’ introduction.

Surrounding areas characterization to the experimental smallholding showed that 80% of the tested area was grown with vegetables, mainly lettuce (Lactuca sativa) and potato (Solanum tuberosum). 5% belonged to a weed zone where Kikuyu grass prevailed (Pennisetum clandestinum), forage turnip (Brassica rapa), sow thistles (Sonchus arvensis) and red clover (T. pratense), located alongside the experimental smallholding. Moreover, the smallholding was demarcated by eucalyptus hedges (Eucalyptus) occupying 15% of the total area. There was no identification about apiary presence when testing a 1 km around the experimental smallholding.

Floral visitors’ population dynamics by transect throughout the day, before and after hives introduction in the experimental smallholding is shown in Fig. 4. The figure shows the average number of individuals per transept observed during 4 days, before and after the hives introduction in the experimental smallholding.

The observation prior to hives introduction showed that Diptera often were the most usual ones with an average of 8.35 ± 6.7 individuals per transect. Although they generally perched on the flowers, there was no evidence of an active pollination process. As a result, all individuals from Syrphidae family were counted separately. Although they are Diptera, they showed an important pollinator activity, registering an average of 1.3 ± 1.9 individuals per transect during 4 days of observation. In both cases, their labor was focused between 9 am and 3 pm. Bees showed a great difference with only 0.68 ± 1.44 individuals per transept, only bees from A. mellifera species were observed and their busiest period was between 11 am and 3 pm.

When introducing hives into the crop, the frequency of floral visitors showed meaningful changes. Although Diptera kept being the most usual ones with 3.12 ± 2.31 individuals per transect, the number of individuals observed decreased 62.6% approximately (U = 4134.5, p < 0.001). This is believed to be linked with a higher competence per resources with A. mellifera, which population duplicated to 1.65 ± 2.92 individuals per transect, being meaningfully higher than before introducing hives (U = 5934,5, p = 0.019). Therefore, the highest activity period changed between 8 am and 1 pm by having hives inside the colony. That is, the most reachable resource was the strawberry flowers. That is why the foraging activity started earlier and lasted 2 more hours.

Syrphid did not show any significant differences even though they were in a lesser amount, with an average of 0.61 ± 0.94 individuals per transept when being introduced to the hives.

In strawberry crops (Fragaria x ananassa), the flower attraction level can change among varieties (Klatt et al. 2013; Klatt 2013), due to a differential quantities production of volatile compounds. It affects the attraction level and determines the visits rate. It also determines the pollination success as well as performance and quality (Dötterl and Vereecken 2010; Karise et al. 2016a, b). In this study the attraction level for the Albión variety over A. mellifera was reflected in the amount of individuals per transept, which was 0.68 ± 1.44 before the hives introduction and it increased to 1.65 ± 2.92 individuals per transect after the colonies installation. It was concluded that the Albion variety creates a good attraction level over A. mellifera, in contrast to other varieties such as Sonata. Karise et al. (2016a) also tested two strawberry crops, located in the south of Estonia. They counted the number of visits from bumblebees, syrphids, honeybees and Diptera, and reported 0.46 ± 0.04 A. mellifera individuals per transect. Overall the attraction level of Sonata variety over the pollinators tested was low, and the introduction of bees in this B. terrestris case did not show any meaningful change in fruits weight. That is why it was concluded that this variety does not require any cross pollination.

1.6 Formulation of a Bio-Pesticide Product That Can Be Transported by Bees

Since the Apivectoring Technology is new in Colombia, there is no evidence of validated specific bio-pesticide products. In order to define the most appropriate bio-pesticide product for the development of the study, the active ingredient content of four products was tested (AI): two commercial ones (P1 and P2) and two experimental ones (P3 and P4).

The active ingredient concentration test by product was made through the content quantifying of the colony-forming units (CFU) for Trichoderma spp. As gram product, through the serial dilutions method and plate count (Valencia 2010), in modified TBS selective means, made up of glucose 3 g, NH4NO3 1 g, KH2PO4 0,9 g, MgSO4 0.2 g, KCl 0.15 g, Rose bengal 0.15 g, chloramphenicol 0.25 g, streptomycin 0.05 g, benomyl 0.5 mg, captan 0.1 g, metalaxyl 0.08 g, Tween 80 at 0.01% ml, agar 18 g and water 1000 ml (Hetong et al. 2008). Pentachloronitrobenzene was not added (PCNB) because it is not in Colombia at a commercial level. This mean it was selected due to its very demanding conditions in terms of resistance to fungicides, ideal characteristic when a bio-pesticide is applied in the field in integrated production models. Crops were incubated at 26 ± 2 °C for 48 hours, then the CFU counting was done, and the test was done in duplicate.

Products composition was as follows: P1: Commercial product based on T. harzianum with lactose as carrier. P2: Commercial product based on T. viride with lactose as carrier. P3: BVT experimental product based on T. harzianum mixed with the Vectorite carrier, provided by Bee Vectoring Technology Company (BVT) (patent pending). P4: Corn flour experimental product based on T. harzianum mixed with corn flour used as carrier (Kevan et al. 2003; Mommaerts and Smagghe 2011; Smagghe et al. 2012).

In order to create the experimental products, a T. harzianum strain was isolated in a selective-modified TBS mode (Hetong et al. 2008), of a strawberry smallholding located in Sibate, Colombia. Afterwards, its preparation was made through T. harzianum spores recollection, in 15-day period crops grown in a selective modified TBS mode (Hetong et al. 2008) that were mixed with the corresponding excipient (P3: Vectorite and P4: Corn flour), until a concentration over 1 × 108 CFU/g of product was obtained. The CFU/g quantified spores of Trichoderma spp. In every tested product is shown in Table 3.

In tested conditions, products P1 (T. harzianum) and P2 (T. viride which carrier lactose) were related to commercial products got the lowest values in product CFU/g concentration, with countings lower to 1 × 106 CFU/g. These were under the expected level from the tag (1 × 108 CFU/g). This can be related with the TBS selective means, used for the counting. This means that it is mainly used in soil isolations (Hetong et al. 2008), so it contains several fungicides (benomyl 0.5 mg, captan 0.1 g, metalaxyl 0.08 g) that could have affected the Trichoderma spp. spores germination percentage. These findings showed that these products tested in this study require some adjustments to be used with BVT. So some other products are suggested available in the market can also have some limitations.

Experimental products P3 (T. harzianum plus Vectorite) and P4 (T. harzianum plus Corn flour) with countings 2.0 × 109 CFU/g and 2.4 × 109 CFU/g, respectively, showed the highest values in the test, due to the use of isolated modified TBS T. harzianum strain from a commercial strawberry crop. It was usual to have fungicide applications, so that isolation was properly adapted to the conditions of the selective means characterized for its substances content, such as benomyl, captan and metalaxyl. That is why products P3 and P4 reached concentrations over 1 × 108 CFU/g and a high spores viability in moderate toxicity conditions. This eased its field survival under integrated production models (Kevan et al. 2008; Mommaerts and Smagghe 2011; Smagghe et al. 2012).

1.7 Acquisition of Bio-Pesticide by the Vector

Once the appropriate bio-pesticide was obtained to be used within the framework of the Apivectoring Technology and given that the number of visits of A. mellifera doubled when introducing the hives in the experimental plot, the acquisition capacity of the vector was evaluated using a two-way device, as described below.

When the crop entered the productive stage (flowering greater than 10%), two hives were located without enclosure in the center of the plot and on a platform 1.5 m high. A period of adaptation of the hives was defined 2 months after their installation in the experimental plot. Then a two-way inoculation device was installed in the entrance of the hives; 2 days later it was verified that the bees recognized entry and exit.

To evaluate the acquisition capacity to the vector of the products added with the carriers lactose (P1 and P2), BVT powder (P3) and corn flour (P4), the acquisition of CFU/bee of the bio-pesticide was determined after passing through the device.

In order to establish the initial conditions of the test, the presently occurring charge of Trichoderma spp. was quantified in the vectors. Before loading the device with the bio-pesticide, samples of thirty bees were collected at the exit of each hive in groups of five individuals and the CFU count of T. harzianum per bee was made, using the methodologies of serial dilutions and plate count (Valencia 2010) in modified TBS (Hetong et al. 2008).

In order to monitor the carrying capacity of the bees, each device was loaded with 10 grams of the product evaluated as recommended by the BVT and proceeded again to collect thirty individuals per hive and the subsequent count of CFU/bee, which was carried out daily for a period of 5 days. In order to determine the recharge time of the device, the entire procedure was performed in duplicate. For the statistical analysis of the data obtained when carrying out the counts of T. harzianum per bee for each product, the non-parametric Friedman test was applied.

To evaluate the acquisition capacity to the vector of the products added with the carriers lactose (P1 and P2), BVT powder (P3) and corn flour (P4), the acquisition of CFU/bee of the bio-pesticide was determined.

When the bees fulfilled the period of adaptation in the experimental smallholding, a Peng two-track device was installed for each hive. It was verified that the bees recognized entry and exit and proceeded to perform the evaluation of acquisition of the bio-pesticide by vector.

In order to establish the initial conditions of the test, the presently occurring loading of Trichoderma spp. was quantified on the vectors. Before loading the device with the bio-pesticide, samples of thirty bees were collected at the exit of each hive in groups of five individuals, and the CFU count of T. harzianum per bee was made, using the methodologies of serial dilutions and plate count (Valencia 2010) in modified TBS (Hetong et al. 2008).

In order to monitor the carrying capacity of the bees, each device was loaded with 10 grams of the product evaluated as recommended by the BVT and proceeded again to collect thirty individuals per hive and the subsequent count of CFU/bee. It was carried out daily for a period of 5 days, in order to determine the recharge time of the device. The entire procedure was performed in duplicate. For the statistical analysis of the data obtained when carrying out the counts of T. harzianum per bee for each product, the non-parametric Friedman test was applied.

At the end of the sampling, the average inoculum quantity with which the vectors are loaded when passing through the device was determined (Kovach et al. 2000) as well as the recharge interval for each product.

The acquisition of the bio-pesticide on the body of the bee is given by the texture and properties of the carrier. In this case the products containing lactose, P1 and P2, had amounts lower than 70 CFU/bee. This fact together the low viability of spores in conditions of moderate toxicity by fungicides (P1 = 2.7 × 105 CFU/g and P2 = 4.8 × 105 CFU/g), evidenced the need to develop commercial products that enable the successful implementation of the Apivectoring Technology at scale in the Colombian fruit and vegetable production sector. There are examples of companies that have developed business models based on Apivectoring Technology, such as BVT (Canada) or Assatek (Finland), successfully scaling up the development of products specifically formulated to be distributed by bees, which we believe could serve as basis for future developments in Colombia too. However, complementary studies are required to make high-quality formulations and ensure control of the target disease.

The products that used Vectorite (P3) and corn flour (P4) as a carrier presented a greater acquisition on the vector with average counts of 1.2 × 104 ± 1.5 × 104 and 1.1 × 104 ± 1.2 × 104 CFU/bee, respectively, although the difference between them was not statistically significant (Friedman T2 = 0.36, p = 0.551). The monitoring of the loading level of the products that showed the greatest acquisition to vector P3 (Vectorite) and P4 (corn flour) is shown in Fig. 5.

The vector acquisition values of P3 used as Vectorite carrier (1.2 × 104 CFU/bee) and P4 in which corn flour (1.1 × 104 CFU/bee) was used as a carrier, coincided with the reports from Peng et al. (1992), Maccagnani et al. (2005) Kovach et al. (2000), Albano et al. (2009) and Shafir et al. (2006) who quantified values between 1.7 × 103 and 1.5 × 105 CFU/bee (A. mellifera). In addition, it was established for both products that the recharge time was 2 days, which is consistent and ideal, since the minimum required recharge time is 1 day (Mommaerts and Smagghe 2011; Smagghe et al. 2012). This eases the management, since long recharge times reduce labor and avoid excessive manipulation of hives, facilitating the implementation of the technology to commercial level.

It can be concluded that both carriers are suitable for formulations under the Apivectoring Technology. In this case, the product P3 of T. harzianum with Vectorite was selected because it presented a slightly higher level of acquisition and when applied in the recharge tray, it was observed that the level of compaction was lower since it did not hydrate as easily as the P4 product that used corn flour as a carrier.

1.8 Bio-Pesticide Distributed in Flowers, Fruits and Leaves

To compare the level of dispersion of the bio-pesticide in strawberry plants using the Apivectoring Technology in different agronomic models, 6 treatments were established in the experimental smallholding, as described below: T1: Absolute control: No chemical or biological product is applied for the control of B. cinerea, besides bees are excluded; T2: Commercial Control: synthetic fungicides are applied for the control of B. cinerea under a traditional model, besides bees are excluded; T3: Organic Control: products are applied for the control of B. cinerea in a model of ecological agriculture, Apivectoring is included; T4: Integrated Management: Products are applied for the control of B. cinerea, in a model of clean agriculture, Apivectoring is included; T5: T. harzianum control: Only T. harzianum was applied at a concentration of 1 × 108 CFU/g of the product using fumigating pump at a rate of 2 g of product/liters of water, excluding bees, and T6: Apivectoring: Only Apivectoring is implemented. No other product is applied for the control of B. cinerea.

To carry out the exclusion of the bees in treatments one, two and five, veil meshes of 3 m × 1 m × 2 m were installed. Ten repetitions were made, for a total of 60 experimental units, in a randomized complete block design. Crop beds corresponded to the blocks. Six areas of 3 m × 0.8 m were delimited in each block, and an experimental unit of 2 m × 0.8 m was defined inside, with a distance of 2 m from each other. Likewise, the different blocks were separated leaving a bed in between to avoid drift effects when making the corresponding applications for each treatment.

The variables of interest were evaluated every 20 days during 4 months, in which a rainy season was registered comprising the months of November and December 2016 plus a dry period including the months of January and February 2017.

The number of CFU of T. harzianum present in flowers, leaves and fruits was quantified in each of the treatments established in the experimental plot, using the serial dilutions and plate count methodologies (Valencia 2010) in modified TBS (Hetong et al. 2008). A sample of 10 flowers, 3 leaves and 3 fruits was taken, for each experimental unit of 2 m × 0.8 m, a total of 60 experimental units were sampled (6 treatments, 10 repetitions), every 20 days from October 2016 to February 2017. The number of samples was defined taking into account that the successive samplings did not affect the physiology of the plants.

The statistical analysis of the bio-pesticide distributing capacity of the vector for flowers, leaves and fruits was carried out by implementing the Kruskal-Wallis test.

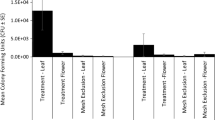

Under the study conditions, using a Peng-type two-ways dispenser that was recharged every 2 days and the P3 product based on T. harzianum and Vectorite as a carrier, each bee acquired an average charge of 1.2 × 104 CFU from the bio-pesticide, whose distribution in the crop was observed in flowers, leaves and fruits. Table 4 shows the average value of CFU/organ, obtained by treatment, during the six samplings carried out from October 2016 to February 2017.

The value by organ was averaged from the ten experimental units (10 repetitions) established in the experimental smallholding for each treatment, for sixty experimental units evaluated every 20 days for 4 months.

The organs of the plant that had the highest CFU countings of the bio-pesticide distributed by the effect of the pollinators were the flowers, showing significant differences between treatments (H = 7.36, p = 0.0002), followed by the leaves in which significant differences were also observed between treatments (H = 12.49, p < 0.0001) as shown in Fig. 6. Finally, there were fruits in which no significant differences were observed between treatments (H = 1.98, p = 0.0713).

Average dispersion of CFU of Trichoderma harzianum in strawberry plants by treatment. (a) Flowers, and (b) leaves

The presented value was averaged from the ten experimental units (10 repetitions) established in the experimental smallholding for each treatment, for sixty experimental units evaluated every 20 days for 4 months. Different letters represent statistically significant differences (P < 0.05)

When quantifying the average per organ in the ten repetitions per treatment during the six samplings, it was observed that the Absolute control (T1) and Commercial Control treatments with fungicides in a traditional model (T2), in which Apivectoring was not included, showed average levels lower than 26 CFU/organ of T. harzianum distributed in the tested strawberry plants. These findings showed distribution of conidia possibly by air. Although meshes were installed to exclude vectors, they cannot prevent the entry of spores of the bio-pesticide to those treatments. These data are also similar to those reported by Kovach et al. (2000), who argue that this is due to the bio-pesticide drift generated by bees loaded with the bio-pesticide, which frequently flew close to the meshes. Another possible explanation was the conidial drift of the T. harzianum Control treatment, in which bio-pesticide was applied with a fumigating pump (T5), although such treatment had space left between treatments and a screen was used in the lance of the sprinkler to direct the application.

The Organic Control treatment including Apivectoring (T3) presented average T. harzianum countings of 2.5 × 102 CFU and 5.1 × 102 CFU in leaves and fruits. However, the level of T. harzianum was lower in flowers than the one registered in other organs of the same treatment with 1.9 × 102 CFU. The integrated management treatment (T4) including Apivectoring and applications of fungicides in a clean agriculture model, showed higher T. harzianum levels in flowers with 7.3 × 102 CFU, than in leaves and fruits with average values less than 70 CFU/organ. While the T. harzianum Control treatment (T5), in which the bio-pesticide was applied with a spray pump, showed high levels up to 3.5 × 103 CFU of T. harzianum in all the evaluated organs. The Apivectoring treatment (T6), which did not include any application of fungicides, had a high UFC content of T. harzianum with values up to 4.9 × 103 in flowers, but in leaves and fruits, the average counts were lower to 1 × 102 CFU.

When observing the amount of CFU of T. harzianum in flowers and comparing the treatments including Apivectoring Technology T3, T4 and T6, it was observed that the Apivectoring treatment (T6) presented a higher count of bio-pesticide with a difference up to two logarithms regarding organic treatment (T3) and integrated management ones (T4).

When comparing the three treatments exposed to the visit of the inoculated bees with the bio-pesticide: Organic control (T3), Integrated management (T4) and Apivectoring (T6), a decrease in the number of T. harzianum spores in flowers in organic treatment (T3) and integrated management (T4), regarding Apivectoring treatment (T6) in which no applications of pesticides were made. This is explained because in the framework of the proposed management for treatments T3 and T4, pesticide applications had to be made, biological ones in T3 and synthetic ones in T4, which probably decreased the rate of visits of the vectors, affecting the amount of bio-pesticide deposited in the flowers.

However, CFU/organ countings were similar in leaves and fruits for the three treatments (T3, T4 and T6). This was possibly due to the drift effect caused by the air currents while bees fly near the plants (Kovach et al. 2000).

In the T. harzianum Control treatment (T5), the CFU/organ counts recorded the highest values on average. However, counts did not show significant differences specifically in flowers, regarding the Apivectoring treatment (T6) (T5 = 3.5 × 103 CFU/flower vs. T6 = 3.0 × 103 CFU/flower). So it can be concluded that the distribution level of the T. harzianum control agent reached by using bees (A. mellifera) as vectors in strawberry flowers, is equivalent to that obtained by using a spray pump. This behavior was similar to that described by Kovach et al. (2000) and evidences one of the advantages of the Apivectoring Technology as proposed by Kevan et al. (2003), Kevan et al. (2008), Mommaerts and Smagghe (2011) and Smagghe et al. (2012). Indeed, when implementing Apivectoring, flowers get inoculated which presents daily anthesis. In addition, each flower is subjected to several visits and the bee is able to distribute the bio-pesticide deeply in the floral whorls. It is also considered that there is an efficient, directed and constant distribution with a level of CFU/flower similar to that obtained when applying the bio-pesticide with fumigating pump, but the amount of water used and the necessary labor is reduced to perform the applications.

Specifically, for the Apivectoring treatment (T6) in flowers, a count of 3.0 × 103 CFU/flower was recorded. This value was higher than the one found by Albano et al. (2009) in their study in a similar experimental model in which the control exerted by T. harzianum was tested and distributed by A. mellifera on B. cinerea. They reported that between amounts of 26.3 CFU/flower and 1.1 × 102 CFU/flower, and these values differ from the results presented here, possibly because a Houle type two-track device was used and it loaded each bee with 1.7–3.9 × 103 CFU. However, they are similar to that reported by Peng et al. (1992) who evaluated the acquisition of G. roseum by A. mellifera also using a Peng inoculation device, which charged each bee with 8.8–180 × 104 CFU of G. roseum under open field conditions, obtaining distribution values in flowers in a range of 3.0 × 102–2.7 × 104 CFU/flower.

In leaves, the countings of 79.2 CFU/leaf were lower than the ones observed by Al Mazra’awi et al. (2006), who evaluated B. bassiana distribution by A. mellifera in canola, obtaining bio-pesticide countings between 1.4 × 105–2.1 × 105 CFU/leaf. It is believed that this difference can be associated with a greater preference of the vector for canola plants than for strawberry plants (Peng et al. 1992; Thapa 2006). Strawberry leaf countings were also below those reported by Shipp et al. (2012) who quantified the dispersion of Clonostachys rosea with B. impatiens in tomato, registering values of 3.2 × 103–6.1 × 103 CFU/leaf. In this case the vectors were loaded with 2.6–5.0 × 105 CFU, so that it was possible to disperse a greater quantity of inoculum from the bio-pesticide.

It should be noted that although the level of distribution in flowers was similar between treatments T5 and T6, in the T. harzianum Control treatment (T5) in which the bio-pesticide was applied with a fumigating pump, an approximate amount of control product was spent of 3600 g/ha/month, while in the Apivectoring treatment (T6), approximately 2560 g/ha/month of bio-pesticide product was spent, without the need of using water. Importantly, that is a 28% reduction for product obtained under the conditions evaluated. Under seasonal production conditions, Kovach et al. (2000) reported a decrease up to 94% for product used and also a reduced use of water resources, saving up to 2000 liters of water/ha/month.

1.9 Evaluation of the Use of Apivectoring Technology in a Pilot Strawberry Crop

In the design established in the experimental smallholding in which six agronomic treatments were included: T1: Absolute control, T2: Commercial Control, T3: Organic Control, T4: Integrated Control, T5: Trichoderma harzianum Control, and T6: Apivectoring. Dispersion of the bio-pesticide was also evaluated, the incidence of B. cinerea in flowers: quantified in five plants of each experimental unit; Total fruits: quantified in five plants of each experimental unit and harvested fruits: which only includes the fruits in physiological maturity (≥70% red), quantified in all plants of each experimental unit (Flórez and Mora 2010). All treatments of the experimental smallholding were evaluated during 4 months, sampling every 20 days. The calculation of the incidence percentage was performed as described by Hoyos et al. (2011), as shown below:

The average percentage of incidence of B. cinerea obtained in the ten experimental units of each treatment quantified for flowers and total fruits in five plants for each experimental unit and in fruits harvested in the total of the plants of each experimental unit, during the period of 4 months in which the trial was developed, is shown in Table 5, where a greater percentage of infection in flowers than in fruits is evidenced in all the treatments implemented.

Values were obtained by averaging the percentage of B. cinerea incidence in the ten experimental units evaluated for each treatment, during the six samplings carried out from October 2016 to February 2017. Different letters represent statistically significant differences.

The highest percentage of incidence occurred in the Absolute Control (T1), as T. harzianum Control (T5) in which CSF was applied with fumigating pump, followed by the Commercial Control (T2), these three treatments did not include Apivectoring and in general presented higher B. cinerea levels than compared with the treatments including it, Organic control (T3), Integrated Control (T4) and Apivectoring (T6), obtaining on average difference in percentage of incidence of the disease of 1.68% for total fruits, 7.78% for fruits harvested and 11% in flowers.

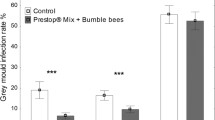

Organic Control (T3) recorded B. cinerea incidences of 7.36% in flowers, 3.22% in total fruits and 5.89% in harvested fruits. These values were lower than those obtained with Commercial Control (T2) in which chemical synthesis fungicides were applied in a traditional scheme, which presented 14.63% in flowers, 3.35% in total fruits and 8.70%. No statistically significant differences were observed between both treatments, which indicates the level of control of the disease in both was similar, as seen in Fig. 7.

The highest incidence of the pathogen was present in flowers (17.5%) of Absolute Control (T1), in which no type of control was applied to B. cinerea. This agrees with the statements by Huang and Kokko (1999), Ngugi and Scherm (2006) and Reich et al. (2015) who explained that nectar and pollen are rich in proteins, sugars, minerals and amino acids, which promote the germination of conidia and can increase growth and development of the pathogen. In addition, petals are more susceptible to the attack of microorganisms because their walls are thin and do not have a waxy cuticle (Reich et al. 2015).

In the rainy season of November and December there was a higher incidence of B. cinerea in all treatments compared to the dry period. Increased rainfall incremented the amount of free water on the structures of the plant, promoting the process of germination of conidia, thus generating new infections. In addition, it increased the distribution of the pathogen by the splash generated by the rain (Huang and Kokko 1999; Agrios 2005), in both periods in the Apivectoring treatment (T6) in which no other type of product was applied for the control of B. cinerea, more than the T. harzianum distributed by the bees. It obtained low percentages of incidence of the disease with values of 4.92% in flowers, 3.89%, in total fruits and 6.82% in harvested fruits. This was mainly due to the bees distributing bio-pesticide deeply in these organs, providing a protection constant throughout the flowering cycle and as the flowers enter anthesis (Kovach et al. 2000; Kevan et al. 2008; Smagghe et al. 2012; Hokkanen et al. 2015). This experiment validated the role of the bees as there was an efficient distribution of T. harzianum for the control of the pathogen in strawberry crops under the conditions of Colombia.

The lower percentages of incidence of B. cinerea were quantified for the Integrated Management (T4) treatment, which included Apivectoring in a clean agriculture scheme, with values of 4.06% in flowers, 3.01%, in total fruits and 3.21% in harvested fruits, being the management scheme that achieved the greatest decrease in percentage of organs affected by B. cinerea. The previous results showed that the integration of the Apivectoring Technology in the framework of an integrated management of pests and diseases is compatible both with an organic Scheme (T3) and with a clean production Scheme (T4) and allows keeping the populations of the pathogen. It is reflected in low incidence values ≤10%, which remained stable in the evaluated period, achieving the lowest epidemics of B. cinerea by integrating the Apivectoring Technology into a clean production Scheme (T4). The application reduced 50% of pest and disease control products usage. In addition, 60% of the products applied were of low impact for human health, bees and the environment, regarding commercial control (T2) that represents the current practices of production, in which calendar applications of chemical control products are made. It should be mentioned that in the traditional model obtained a percentage of incidence of B. cinerea of 14.63% in flowers, while in fruits the incidence ranged between 3.35% and 8.70%. This difference supports the argument that the applications with the fumigating pump failed to adequately protect the flowers, especially if you take into account that around 40,000 flowers/ha enter anthesis each day (Hokkanen et al. 2015).

Regarding the application of T. harzianum using a fumigant pump (T5), a high amount of the bio-pesticide was recorded in the distribution test. However, the treatment presented the highest incidence of B. cinerea. This finding is attributed to several circumstances, the bio-pesticide calendar applications that only achieve a partial protection of the flowers (Smagghe et al. 2012; Hokkanen et al. 2015), the increase in the amount of free water in the plant due to high rainfall in the first sampling, and the pump application that requires an approximate 450 liters of additional water per ha, which is in turn promoting the germination of conidia of B. cinerea and therefore the development of new infections that quickly reach high levels of B. cinerea incidence higher than 25%, in which it was difficult to control the epidemic. It should be mentioned that the method did control the disease, since the incidence of the disease in flowers in this treatment was 34% in the first sampling. In other samples, the percentage tended to decrease reaching values close to 15% in the final sampling. However, the level of control was generally much lower regarding other treatments, in which the levels of incidence did not exceed 20% in any of the six samplings performed. This behavior coincides with the one described by Shafir et al. (2006) who argued about cases where the incidence in fruits is high, neither the management of organic type, nor the handling with products of chemical synthesis, generated an adequate control of the disease.

As previously mentioned, two pillars support Apivectoring Technology: the control of pests and/or diseases, and the increase in production due to pollination. The results obtained in this project have to be interpreted in this context.

1.10 Productive Level Test for the Six Treatments of the Experimental Smallholding

The fruits harvested in all plants of each experimental unit (10 experimental units for each treatment), were classified following national parameters through the Colombian Technical Standard NTC 4103, which is based on the evaluation of the fruits by size (diameter in mm), as seen in Table 6.

The evaluation period was established in the main productive phase of the crop, which oscillated between 8 and 15 months after sowing, in order to control factors associated with the age of the plant, either the first production of superior quality or related lower qualities with the end of the productive cycle. For the statistical analysis of the data, an analysis of variance (ANOVA, p = 0.05) and Tukey multiple comparison test were carried out, in order to determine significant differences between treatments, in order to establish the best management scheme.

Table 7 shows the classification by size and category, for the fruits harvested in the six treatments implemented, averaging the data obtained in the ten experimental units of each treatment during the four samplings carried out in the evaluated period.

For gauge A, treatments T2, T4 and T6 had a higher percentage of strawberries of superior quality, with values close to 12%, while for treatments T1, T3 and T5, the percentage of strawberries of gauge A was below 8.4%.

For all treatments, the highest percentage distribution was located in grades B, C and D, in which no significant difference was observed.

Regarding gauge E, treatments T4 and T6 including Apivectoring,were highlighted with the lowest percentages of low quality strawberries, specifically values lower than 13.8%, while other treatments presented percentages higher than 15%, being statistically different (Chi2 = 32.78, gl = 20, p = 0.0357).

There is an increase in the number of larger fruit (gauge A) for T2, T4 and T6 with 4% over the other treatments. Likewise, in T4 and T6 a decrease between 2% and 5% of the quantity of strawberries of lower quality was observed compared to the treatments that did not include Apivectoring (Fig. 8).

Treatments distribution according to the classification by gauge described in the Colombian Technical Standard (CTS 4103)

Values were obtained by averaging the percentage of Botrytis cinerea incidence in ten experimental units tested for each treatment, during the six samplings carried out from October 2016 to February 2017. Different letters represent statistically significant differences (P < 0.05)

1.11 Commercial Potential of the Apivectoring Technology Implementation

Apivectoring technology is structured in two main components, namely the control of diseases and the increase of production due to pollination (Mommaerts and Smagghe 2011; Smagghe et al. 2012). Findings of this study showed that this technology represents a viable option to be implemented in strawberry crops (Fragaria x ananassa) within the framework of integrated management of pests and diseases in a clean production Scheme (T4), under the conditions of the Andean area. Under this model, control of B. cinerea was achieved in 77.4% of flowers and 79.0% of fruits, with incidences of only 4.06% and 3.21%, respectively. While the absolute control (T1) showed an average incidence of 17.95% in flowers and 15.25% in fruits, and this was with commercial control 14.63% and 8.70%, respectively. In addition, an increase of the productive variables was obtained, and results showed an increase of the weight of the fruit between 0.87 g and 2.35 g that was equivalent to a percentage of 6.7% and 18.28%. In comparison with the treatments that did not include bees, this means that implementing Apivectoring caused an increase of between 66.22 grams and 180.95 additional grams per kilo of strawberries produced. Likewise, an increase in diameters was obtained ranging between 2.7% and 6.8% for equatorial diameter and between 9.0% and 13.5% for polar diameter. This is directly related to a greater efficiency in the process of pollination that increased the number of fertilized ovules and therefore obtained a greater number of achenes (Swingle 1928; Denney 1992), achieving up to 29% more as compared to the absolute control (T1) and up to 51.8% more compared to the commercial control (T2). Similar benefits in productivity and yield have been reported by other authors who have tested the technology for the control of B. cinerea in strawberry in other countries (Kovach et al. 2000; Soboksa et al. 2014; Hokkanen et al. 2015). It is here the first time that a study of this type has been done in Colombia, therefore this work provides the baseline for future research.

In this study, Apivectoring Technology presented positive results at the technical level that represent the possibility of obtaining higher income in the productive system. Regarding the technical results obtained, the following economic benefits could be extrapolated:

-

1.

Increase in production due to pollination. There was a minimum increase of 0.87 g/fruit, which represents an average of 66.22 g per kilo produced. As farmers produce 43.5 tons/year (Ministry of Agriculture 2016), this turns into an increase in productivity of 2.8 tons/ha/year, which with an average price of $1.6 US (Ministry of Agriculture 2016), which in turn is representing an approximate additional gross income of $ 2987 US/ha/year.

-

2.

Decrease in the application of pesticides. In the clean production model, the numbers of pesticide applications were reduced by 60% (and these applications were made with category III or IV products). This turns into a reduction in the cost of the applications of approximately $1405 US/ha/year, according to the costs established by the Strawberry Chain in 2016 (Ministry of Agriculture 2016).

-

3.

Decrease in the losses by B. cinerea. In the case of harvested fruits, when comparing the commercial treatment with the Apivectoring one, a reduction in the losses by Botrytis was approximately 1.88% which is equivalent to an additional 817 kg in fruit production. With an average price of $1.06 US (Ministry of Agriculture 2016), would represent an additional income of approximately $872 US/ha/year.

According to registered values taking into account the additional income, the cost reduction and the value of the implementation of the Apivectoring Technology, it has been estimated that there is an additional utility close to $3.710 US per hectare, which is the sum of the three values mentioned above but subtracting the approximate costs for the implementation of the technology. However, it must be clarified that the values presented here are general and a deep economic analysis is required, which includes the risk factors, and quantifies the environmental benefits. Other authors have made approaches to the economic quantification of the implementation of Apivectoring Technology (Kovach et al. 2000; Hokkanen et al. 2015), although the analysis differs in scales and indicators, it is agreed that Apivectoring Technology generates the decrease of costs and the increase of the productivity of the crop.

It is clear that the Apivectoring Technology has broad advantages. However, this study also identified some limitations for the Colombian case. Since Apivectoring is an original concept in the country, there are no commercial products on the market specifically formulated for Apivectoring. Tested commercial products showed a deficiency regarding the characteristics of the added carrier, which in this case was lactose. In addition to a low conidia viability in moderate toxicity media (2.7 and 4.8 × 105 CFU per g of product), results suggested that it is necessary to promote the development of business models in the country in order to offer producers the option of finding high quality products on the market, specially formulated to be used in the framework of the Apivectoring. In this sense, both Vectorite and corn flour as carriers presented adequate levels of acquisition using a Peng-type two-ways device. No significant differences were found in terms of inoculum acquisition by the vector with P1 = BVT powder: 1.2 × 104 CFU/bee, and P2 = corn flour: 1.1 × 104 CFU/bee, demonstrating that both carriers are suitable to make the formulation. However, the Vectorite presented less compaction in the recharge tray of the device, wherefore we believe this carrier is more suitable for the formulation of products for specific use for Apivectoring.

It is therefore necessary to identify and recognize limitations and conditions of the implementation of Apivectoring Technology. It should be applied in the framework of an integrated management of pests and diseases with a preventive approach, also involving all levels of living beings. So it requires special care in the structuring of each of its components. For example, it must take into account the interaction between the plant and the vector, the type of device, the characteristics of the vector, the climatic conditions and the particular characteristics of the productive system in which the technology is to be implemented (Kevan et al. 2003; Kevan et al. 2008; Mommaerts and Smagghe 2011; Smagghe et al. 2012).

1.12 Experience in the Transfer of Apivectoring Technology to Agricultural Producers in Colombia

For the first time in the country, the development of the project allowed the validation of the Entomovectoring Technology or Apivectoring, as a tool aiming to improve the competitiveness in a crop with export potential as is the case of strawberry (Fragaria x ananassa). The research managed to adjust the technology to the local conditions present in the peripheral areas of Bogota, and showed positive results on fruit quality parameters, as well as a decrease in the incidence and severity of the entomopathogenic fungus B. cinerea, considered as one of the main health problems for this crop. The economic impact of the technology was valued, compared to the conventional management carried out by the producers of three organizations, which allowed proposing alternatives to bring the service to a commercial phase. Regarding the scope of the results obtained, these are applicable for the use of Apivectoring Technology with bees of A. mellifera in strawberry crops in the open field for the control of B. cinerea. Hence, in the future the Apivectoring Technology should be investigated and validated for its implementation in other crops, systems under cover, other bee species or the control of other diseases.

The strategy for the technology transfer with the producers was based on the implementation of the technology in three demonstrative production units with differences in the production methods. So in the first unit the production model was in soil with a conventional management, In the second productive unit the crop was under a hydroponic system with conventional chemical products management (Fig. 9). The third unit corresponded to a crop in soil with an organic management. These units worked to carry out trainings in which farmers were sensitized on the importance of bees and the advantages of the presence of insects in the crop. Given that in Colombia the predominant type of bee is the Africanized hybrid, which is characterized by a greater defensiveness, it was necessary to carry out a process of selection and genetic improvement of queens from the characteristic of meekness before the implementation of the demonstration productive units, which was carried out 3 years prior to this study including obtaining fecundated queens by artificial insemination techniques to guarantee the paternal and maternal characteristics. This activity allowed generating a greater degree of confidence with the producers and thus improving the availability to access the technology.

In total, more than 10 training activities were carried out with producers, which included Field Schools in crops, and this allowed to reach the producers of three organizations in two municipalities directly. However, it is necessary to establish a defined business model for the Apivectoring Technology in such a way that it facilitates the decision of the farmer on the adoption of the technology.

2 Final Considerations

It is necessary to understand the Apivectoring Technology, as a management tool within a structured program of pest and disease control, whether it is organic and/or traditional. In addition, it is necessary to create awareness with the farmer about the importance of carrying out the programming of applications with all the preventive measures that guarantee not only their own welfare but also the hives.

We must combine efforts in the development of products with specific formulations to be applied with the Apivectoring Technology. These must comply with high levels of quality and control in its production process. It is also recommended to evaluate the bio-pesticide that simultaneously controls several pathogens associated with the crop, in order to offer an integrated approach solution to the farmer.

In future studies, the level of attraction for bees by the different varieties that are marketed in the country should be investigated, in order to select these ones that are appropriate to implement the Apivectoring Technology.

To achieve an adequate distribution of the product, it is necessary to consider introducing an adequate number of hives, for instance 4 per hectare. These can be located in the periphery of the crop; however, it is recommended to place them in the center of the crop for better results. In the Colombian context, it is fundamental to guarantee that the colonies of A. mellifera have been selected for meekness and that the personnel is adequately trained in order to minimize the risk of accidents.

References

Agrios G (2005) In: Dreibeilbis D (ed) Plant pathology, 5th edn. Elsevier Inc, San Diego

Al Mazra’awi MS, Shipp JL, Broadbent AB, Kevan PG (2006) Dissemination of Beauveria bassiana by honey bees (hymenoptera: Apidae) for control of tarnished plant bug (Hemiptera: Miridae) on canola. Environ Entomol 35(6):1569–1577. Recovered from: http://sci-hub.tw/10.1603/0046-225x(2006)35[1569:dobbbh]2.0.co;2

Albano S, Chagnon M, De Oliveira D, Houle E, Thibodeau PO, Mexia A (2009) Effectiveness of Apis mellifera and Bombus impatiens as dispersers of the Rootshield® biofungicide (Trichoderma harzianum, strain T-22) in a strawberry crop. Hellenic Plant Protection Journal 2(2):57–66

Amaya M, Stiles G, Rangel-Ch JO (2001) Interacción plantacolibrí en Amacayacu (Amazonas, Colombia): una perspectiva palinológica. Caldasia 23(1):30132

Asohofrucol (2013) Plan de Negocios de Fresa Índice. Fondo Nacional de Fomento Hortifruticola. Bogotá Colombia. Recovered from: https://www.ptp.com.co/documentos/PLAN%20DE%20NEGOCIO%20FRESA%20diciembre.pdf

Bosch J, Vicens N (2000) Pollinating efficacy of Osmia cornuta and Apis mellifera (hymenoptera: Megachilidae, Apidae) on “red delicious” apple. Environ Entomol 29(2):235–240. Recovered from: http://sci-hub.tw/10.1603/0046-225X(2000)029[0235:PEOOCA]2.0.CO;2

Butt TM, Ibrahim L, Ball BV, Clark SJ (1994) Pathogenicity of the Entomogenous fungi Metarhizium-Anisopliae and Beauveria-Bassiana against crucifer pests and the honey-bee. Biocontrol Sci Tech 4(2):207–214. Recovered from: http://sci-hub.tw/10.1080/09583159409355328

Butt TM, Carreck NL, Ibrahim L, Williams IH (1998) Honey-bee-mediated infection of pollen beetle (Meligethes aeneus fab.) by the insect-pathogenic fungus, Metarhizium anisopliae. Biocontrol Sci Tech 8:533–538. Recovered from: http://sci-hub.tw/10.1080/09583159830045

Carreck NL, Butt TM, Clark SJ, Ibrahim L, Isger EA, Pell JK, Williams IH (2007) Honey bees can disseminate a microbial control agent to more than one inflorescence pest of oilseed rape. Biocontrol Sci Tech 17(2):179–191. Recovered from: http://sci-hub.tw/10.1080/09583150600937485

Casierra-PF, Salamanca GR (2008) Influencia del ácido giberélico y del nitrato de calcio sobre la duración poscosecha de frutos de fresa (Fragaria sp.). Revista Colombiana de Ciencias Hortícolas 2(2), 133–144 Recovered from: https://www.researchgate.net/publication/215803145_Influencia_del_acido_giberelico_y_del_nitrato_de_calcio_sobre_la_duracion_poscosecha_de_frutos_de_fresa_Fragaria_sp http://sci-hub.tw/10.17584/rcch.2008v2i1.1171

Coffey MF, Breen J (1997) Seasonal variation in pollen and nectar sources of honey bees in Ireland. J Apic Res 36:63–76

Danka R, Rinderer T, Hellmich R, Collins A (1986) Comparative toxicities of four topically applied insecticides to Africanized and European honey bees. J Econ Entomol 79:18–21

Dedej S, Delaplane KS, Scherm H (2004) Effectiveness of honey bees in delivering the biocontrol agent Bacillus subtilis to blueberry flowers to suppress mummy berry disease. Biol Control 31(3):422–427. Recovered from: http://sci-hub.tw/10.1016/j.biocontrol.2004.07.010

Denney JO (1992) Xenia Includes Metaxenia. Hortscience 27(1976):722–728

Dötterl S, Vereecken NJ (2010) The chemical ecology and evolution of beeflower zoology, interactions: a review and perspectives. Can J Zool 88:668–697

Eisikowitch D, Lachance M-A, Kevan PG, Willis S, Collins-Thompson DL (1990) The effect of the natural assemblage of microorganisms and selected strains of the yeast Metschnikowia reukaufii in controlling the germination of pollen of the common milkweed Asclepias syriaca. Can J Bot 5:1163–1165. Recovered from: http://sci-hub.tw/10.1139/b90-147

Erdtman G (1969) An introduction to the study of pollen grains and spores. In: Hafner (ed) Scandinavian university books

Escande AR, Laich FS, Pedraza MV (2002) Field testing of honeybee-dispersed Trichoderma spp. to manage sunflower head rot (Sclerotinia sclerotiorum). Plant Pathol 51(3):346–351. Recovered from: http://sci-hub.tw/10.1046/j.1365-3059.2002.00723.x

FAO F and A. O. of U. N. (2016) Pollinators vital to our food supply under threat. Recovered from: http://www.fao.org/news/story/en/item/384726/icode/

Fernández-Ortuño D, Grabke A, Li X, Schnabel G (2015) Independent emergence of resistance to seven chemical classes of fungicides in Botrytis cinerea. Phytopathology 105(4):424–432. Recovered from: http://sci-hub.tw/10.1094/PHYTO-06-14-0161-R

Flórez R, Mora R (2010) Fresa: Producción y manejo poscosecha. Corredor Tecnológico Agroindustrial, Cámara de Comercio de Bogotá

Goodman RD, Oldroyd BP (1988) Honeybee pollination of strawberries (Fragaria x ananassa Duchesne). Aust J Exp Agric 28:435–438

Gossen BD, Swartz SG (2008) Impact of flower age and colour on infection of bean and alfalfa by Sclerotinia sclerotiorum. J Can J Plant Pathol 30(1):58–65

Gross HR, Hamm JJ, Carpenter JE (1994) Design and application of a hive-mounted device that uses honey bees (Hymenoptera: Apidae) to disseminate Heliothis Nuclear Polyhedrosis Virus. Biological Control 23:493–501. Recovered from: http://sci-hub.tw/10.1093/ee/23.2.492

Hetong Y, Ryder M, Wenhua T (2008) Toxicity of fungicides and selective medium development for isolation and enumeration of trichoderma spp. in agricultural soils. Recovered from: http://www.isth.info/methods/method.php?method_id=8

Hokkanen HMT, Menzler-Hokkanen I, Lahdenpera M-L (2015) Managing Bees for Delivering Biological Control Agents and Improved Pollination in Berry and Fruit Cultivation. Sustainable Agriculture Research 4(3):89. Recovered from: http://sci-hub.tw/10.5539/sar.v4n3p89

Huang HC, Kokko EG (1999) Infection of pollen by Botrytis cinerea. Botanical Bulletin- Academia Sinica Taipei 40(403):101–106

Johnson KB, Stockwell VO, Burgett DM, Sugar D, Loper JE (1993) Dispersal of Erwinia amylovora and Pseudomonas fluorescens by honey bees from hives to apple and pear blossoms. Phytopathology 83(5):478. Recovered from: http://sci-hub.tw/10.1094/Phyto-83-478

Jyoti JL, Brewer GJ (1999) Honey bees (hymenoptera: Apidae) as vectors of bacillus thuringiensis for control of banded sunflower moth (Lepidoptera: Tortricidae). Environ Entomol 28:1172–1176

Kapongo JP, Shipp L, Kevan P, Sutton JC (2008) Co-vectoring of Beauveria bassiana and Clonostachys rosea by bumble bees (Bombus impatiens) for control of insect pests and suppression of grey mold in greenhouse tomato and sweet pepper. Biol Control 46(3):508–514. Recovered from: http://sci-hub.tw/10.1016/j.biocontrol.2008.05.008

Karise R, Dreyersdorff G, Jahani M, Veromann E, Runno-Paurson E, Kaart T et al (2016a) Reliability of the entomovector technology using Prestop-mix and Bombus terrestris L. as a fungal disease biocontrol method in open field. Sci Rep 6:31650. Recovered from: http://sci-hub.tw/10.1038/srep31650

Karise R, Muljar R, Smagghe G, Kaart T, Kuusik A, Dreyersdorff G, Mänd M (2016b) Sublethal effects of kaolin and the biopesticides Prestop-mix and BotaniGard on metabolic rate, water loss and longevity in bumble bees (Bombus terrestris). J Pest Sci 89(1):171–178. Recovered from: http://sci-hub.tw/10.1007/s10340-015-0649-z

Kevan P, Eisikowitch D, Rathewell B (1989) The role of nectar in the germination of pollen in Asclepias syriaca L. Bot Gaz 150(3):266–270. Recovered from: http://sci-hub.tw/10.1086/330177