Abstract

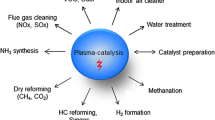

Plasma catalysis is a hybrid technique where a catalytic material is used in conjunction with a gas discharge yielding a viable technique which gives enhanced performance for a range of gas processing applications such as removal of pollutants including NOx, SOx and volatile organic compounds (VOCs) and production of a range of chemicals such as ammonia from N2 and H2, hydrogen and oxygenates by the reforming of hydrocarbons and a range of added-value chemicals from the conversion of CO2. This chapter gives an introduction and brief background to our current process and understanding in the field of plasma catalysis.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1.1 Historical Introduction

Plasma catalysis (sometimes called plasma-enhanced catalysis, plasma-catalyst coupling, plasma-assisted catalysis or plasma-driven catalysis) is a hybrid technique where a catalytic material is used in conjunction with a gas discharge yielding a viable technique which gives enhanced performance for a range of gas processing applications such as removal of pollutants such as NOx, SOx and volatile organic compounds (VOCs) and production of a range of chemicals such as ammonia from N2 and H2, hydrogen and oxygenates by the reforming of hydrocarbons and a range of added-value chemicals from the conversion of CO2 [1,2,3,4,5,6,7,8,9]. Perhaps in order to properly set the scene for discussing the mechanism and impact of plasma catalysis, it is necessary to separately examine the two techniques that were brought together to form this hybrid process.

Heterogeneous catalysis in which a solid catalytic material is placed into a stream of reactive gases can provide alternative reaction pathways with lowered energy barriers. These can increase the rates of the reactions involved, increasing the overall yield of the process at a given temperature and thereby improving the efficiency of the process. Mechanistically, these alternative reaction pathways may also improve the yield or selectivity for particular products, and using different catalysts can favor particular outcomes. This technique, often called thermal catalysis, has been used for hundreds of years and now forms the basis of many large-scale industrial processes particularly in the oil, gas and chemical industries. Catalysis was discovered by Sir Humphry Davy in 1817 who noted that heated platinum gauze or foil would bring about the slow combustion of vapors such as alcohol, ether, coal gas and methane below their ignition temperature [10]. Davy conducted his research at the Royal Institution in London and is probably most remembered for his invention of a miners’ safety lamp. (See the very readable account of the life of Davy by Thomas [11] for more information.) The Swedish chemist, Berzelius, acknowledged Davy’s discovery in his treatise on catalysis where that word was first used. Berzelius recognized the existence of a catalytic force that ‘is reflected in the capacity that some substances have, by their mere presence and not by their own reactivity, to awaken activities that are slumbering in molecules at a given temperature’ [12]. We now most commonly use the definition given by Ostwald: “Catalysis is the acceleration of a chemical reaction, which proceeds slowly, by the presence of a foreign substance which is not in itself necessary for the reaction” [13]. It is a question of the kinetics rather than the energetics of the overall reaction.

The study of gas discharges where a high voltage is applied to electrodes in a glass tube at reduced pressure had its origins at the start of the eighteenth century when Francis Hauksbee, an English draper, observed a glow in an evacuated tube containing mercury when the tube became electrically charged: electroluminescence [14]. It took another century before significant advances in gas discharges were obtained. This in part came from the development of better vacuum pumps such as that of Geissler in 1855. This allowed Geissler to make evacuated tubes with platinum electrodes containing different gases and show that discharges of different colors could be produced that were characteristic of the gas in the tube. These tubes were initially regarded as scientific novelties [15]. Michael Faraday, who worked at the Royal Institution in London, as Humphry Davy’s assistant, looked at the structures or strata of light that were produced in gaseous discharges noting that the glow was not uniform but was brighter close to the electrodes with a dark space in between [16]. In time, such observations led to an understanding of the identity of the species responsible for luminescence and conductivity in gaseous discharges.

In 1834, Faraday also laid down the foundations for the mechanism of heterogeneous catalysis based on his observation of the spontaneous combination of oxygen and hydrogen on a platinum surface at room temperature [17]. He proposed that the two gases were condensed on the surface of the metal and that “the approximation of the particles to those of the metals may be very great”. He stated that there would be a continual interchange of particles between the adsorbed layer and the gas in contact with it. The water product was less attracted by the platinum than the reacting gases and so could evaporate. He emphasized the importance of the forces between the different species stating: “I admit … that the sphere of action of the particles extends beyond those other particles with which they are immediately and evidently in union, and in many cases produces effects arising into considerable importance” [18]. It could be said that the work of Davy and Faraday at the Royal Institution played a key role in establishing the foundations of the two components that would come together a century later to form the basis of plasma catalysis.

Plasma is an ionized gas containing an equal number of positive ions as of electrons and negative ions. It is thus electrically neutral and its degree of ionization can range from very low, i.e. partially ionized, to 100%, or fully, ionized. In the laboratory or factory, plasma can be created by a variety of discharge techniques involving chambers with electrodes energized by direct dc, pulsed or ac currents including electrodes screened by a dielectric material or electrode-less systems such as inductively or capacitively coupled radio frequency radiation and microwaves. These discharges bring about a breakdown of the gas and create a range of species such as electrons, ions, dissociated and excited species giving plasma reactive properties that can potentially bring about chemical transformations, and which might be enhanced when a catalyst is present.

Additionally, we can characterize plasma by the pressure regime in which it operates which can be either low, being less than atmospheric, typically ca. 100 mbar or high pressure which is atmospheric or higher. Working at pressures less than atmospheric requires the provision of vacuum pumps which adds to the complexity and cost of the system, but low pressure conditions favor surface collisions making catalytic effects easier to notice, and they also minimize the deactivation of the excited states produced in the plasma through gas-phase collisions but at the price of reduced gas throughput. Another distinction concerns the degree of thermal equilibrium achieved in the plasma. In thermal plasma, all the degrees of freedom including the electrons, ions and neutral species are equilibrated and have the same temperature as the bulk gas (typically >1000 K). Nonthermal plasma has a high degree of non-equilibrium between the light electrons and the heavier particles such as the ions, radical and molecules. The disparity in mass between the electron and the gaseous species means that little kinetic energy is transferred between them and the heavy atomic and molecular species remain close to their ambient temperature. Thus, a nonthermal discharge can create excited and reactive species that can only be produced in an equilibrium system such as an arc or flame at very high temperatures. This means that we can have an ionized, excited and reactive gas interacting with the catalyst at temperatures at which conventional thermal catalysis would be inactive. Typically, much of the research in plasma catalysis has focused on the use of atmospheric pressure, nonthermal plasma because of the simplification in engineering systems without the need for vacuum systems and its operation at low temperatures that minimize corrosion and deterioration of the catalyst through sintering or coking.

It is unclear whether the discovery of the effect of combining a catalyst with plasma was a deliberate act or just a serendipitous observation. Kim [1] has given an extensive history of the development of plasma catalysis which pinpoints the first experiment where a catalyst was intentionally combined with an electrical discharge as being performed in 1921 by Ray and Anderegg [19]. They attempted to oxidize carbon monoxide to carbon dioxide by first using a silent discharge in an atmospheric pressure mixture of oxygen and carbon monoxide and then passing these gases over a silver catalyst. They noted that: “It is obvious that part of the oxidation takes place in the ozonizer while the gases are under the influence of the silent discharge and that part takes place while the gases are under the influence of the catalyst”. The use of a catalyst downstream gave enhanced oxidation of the CO compared to experiments performed in 1879 by Berthelot [20] who used a similar configuration but without a catalyst and attributed the incomplete CO oxidation to decomposition of the CO2 product back to CO [13].

Over the next three or four decades, reports were relatively infrequent and focused on systems of industrial interest where potential improvement in efficiency could be transformational. These included gas to liquid conversion of hydrocarbons, ammonia production and decomposition and the removal of VOCs. Experiments were performed both at atmospheric and reduced pressures where the latter has more potential for identifying any possible influence of the catalyst as the ratio of surface to gas-phase collisions increases as the gas pressure decreases. If we use the number of publications as an indicator of activity in the field of plasma catalysis, it would seem from Fig. 1.1 that research in the field took off in the 1990s, and, while still relatively modest, it is increasing rapidly.

1.2 The Plasma Catalysis Effect

There are two main configurations in which a catalyst can be combined with plasma. In one, the catalyst is place directly in contact with the plasma (variously called a one-stage arrangement or in-plasma catalysis, IPC) and, in the second, the catalyst is placed downstream of the discharge (a two-stage arrangement or post-plasma catalysis, PPC). These arrangements can be extended in a complex way by using a sequence of catalysts each with a different role. For example, the destruction of low concentrations toluene in air was achieved by initially treating the gas stream using a series of packed-bed discharges followed by two downstream catalysts in sequence [21]. These were MnO2 followed by a MnO2/CuO mixed catalyst. In the absence of the catalysts, the plasma only destroys a proportion of the toluene, but the addition of either of the catalysts results in complete removal. Oxidation of toluene gives CO2, but CO is also produced due to incomplete oxidation. The MnO2/CuO catalyst promotes the conversion of CO to CO2. The MnO2 catalyst is effective in totally removing any excess ozone that is produced in the discharge from the breakdown of air and not used in the catalytic oxidation of the toluene.

Compared to a thermal catalysis experiment where the energy needed to promote reaction comes from supplied heat, in plasma-activated catalysis the energy comes from the electrical discharge. This produces reactive and energetic species in the gas phase that may then come into contact with the surface of the catalyst. The primary species produced in plasma are generally short-lived and consist of electrons, photons, ions, excited-state atoms or molecules and radicals. In the one-stage plasma-catalyst arrangement, it will be these species that will interact with the catalyst. But in a two-stage plasma-catalyst configuration, it will only be the relatively long-lived species that exit from the plasma that are in contact with the downstream catalyst. These will be the end-products, by-products and long-lived reactive intermediates from the plasma processing (of which ozone is an important and common example, as noted above) and, possibly, vibrationally excited species. Vibrational energy can be a significant mode for efficiently activating surface adsorption and desorption processes.

The effectiveness of plasma catalysis processing can be assessed in several ways. Commonly, the products of the processing are determined by analysis of the downstream gas either in real time or by taking samples for remote analysis. A variety of spectroscopic and analytical techniques are employed such as Fourier-transform infrared spectroscopy (FTIR), gas chromatography (GC) and mass spectrometry. The formation of liquid products can also be monitored by downstream condensation and collection. To be useful, the analysis of the end products should be performed in a quantitative manner although the extent of removal of the input gas can be achieved by a relative measurement. Qualitative measurement of the minor end products or intermediates, which aids their identification, may be of value in determining the reaction mechanism. The primary quantities that are measured include the degree of conversion or destruction, X, of the input species, AB, usually expressed as a percentage:

Another important quantity is the selectivity, S, for the formation of a particular product, CD,

where appropriate allowance must be made for the stoichiometry of the reaction.

The prime consideration in the assessment of the effectiveness of the combination of plasma with catalyst is that there should be some improvement in either of these two parameters as a consequence of hybridizing the two techniques. One measure of this is to determine whether any synergy results from the combination. This can be evaluated using a synergy factor where the measured effect of the processing (e.g. the conversion or selectivity) using the combination of plasma and catalyst must be greater than the sum of the effect of processing using plasma alone and of catalyst alone under equivalent conditions [22]. The synergy factor will be greater than one when the combination is synergistic. This is illustrated in Fig. 1.2 from the work of Wang et al. [23] on the decomposition of NH3 in a dielectric barrier discharge reactor packed with a range of metal catalysts.

Demonstration of the synergistic effect of plasma catalysis for the conversion of NH3 at a specific energy density of 28 kJ/L using a dielectric barrier reactor packed with a range of supported metal catalysts at a temperature of 450 °C. Results are presented for plasma alone, catalyst alone and the plasma-catalyst combination. (Reproduced from Ref. [23] with permission. Copyright 2015, the American Chemical Society)

Unfortunately, far too many publications mistakenly assume that the combination of plasma and catalysis will always be synergistic, but that is not necessarily true, and only the calculation of a synergy factor that is greater than unity will provide the evidence of synergy. The addition of the catalyst to a discharge may improve the conversion or product selectivity compared to using the discharge on its own, but that does not necessarily demonstrate a synergistic effect. Vandenbroucke et al. studied the plasma catalysis decomposition of the decomposition of trichloroethylene (TCE) and found that the synergy factor for the degree of dissociation of TCE ranges from 0.78 to 4.78 in a range of experiments with changing parameters demonstrating that synergy may only exist under certain experimental conditions in a particular plasma catalysis system [22].

Another very important criterion for judging the effectiveness of plasma catalysis is to consider the energy efficiency of the processing. This is of vital importance in objectively comparing one plasma catalysis process with another that may use a different catalyst or plasma configuration. It is also a way in which the technology of plasma catalysis can be compared with other competitive technologies and is a key way in which to judge the economics and hence the commercial viability of plasma catalysis as a processing technology for a particular application. Essentially, the energy efficiency tells us how much material we can convert or produce for a defined amount of energy. It can be expressed in a bewildering array of units, e.g. kg/J, mol/J, molecule/eV, mol/kWh, etc., but they can be easily interconverted! The reciprocal of the energy efficiency is sometimes used and called the specific energy. Gutsol et al. have provided a very useful review with summaries of different ways of describing energy efficiency in plasma systems [24]. Alternatively, the energy efficiency can be expressed by comparing the actual energy required to create (or destroy) a given amount of material with the theoretical energy required for the same process. This theoretical energy for the formation or destruction process can be identified with the reaction enthalpy for that process if a clear reaction mechanism has been identified.

In considering the performance of a plasma catalysis system, a balance often has to be struck between different outcomes. For example, it is not always possible to maximize conversion or yield and energy efficiency simultaneously. It is commonly found that as the energy supplied to the system (commonly represented as the specific energy density, SED, or the specific energy input, SEI, which is the energy input per unit volume of the reactor) increases, the conversion increases, but the energy efficiency decreases. Figure 1.3 demonstrates this for the decomposition of CO2 in a packed bed plasma reactor filled with BaTiO3. It can be seen that the optimal energy efficiency is obtained at the lowest SEI value, while the magnitude of the dissociation increases with increasing energy input.

A comparison of the variation of % CO2 conversion and the energy efficiency as a function of the SEI for the treatment of an atmospheric pressure stream of pure CO2 in a DBD reactor packed with BaTiO3 beads. (Drawn using data taken from Ref. [25])

In Fig. 1.4, this effect is demonstrated by a plot that shows the optimum regions in terms of energy efficiency and the obtained decomposition of CO2 for a range of different plasma sources with and without catalysts [26]. Such a plot can be used as an aid to evaluate which plasma or plasma-catalyst combination will be best to achieve a particular performance. This methodology has been extended to a wider range of plasma systems for the conversion of pure CO2 and the dry reforming of CH4 with methane CO2 and demonstrates that certain plasma systems are more effective for certain processes. (See Figs. 24 and 32 in [8].)

Comparison of conversion and energy efficiency for CO2 decomposition with different types of nonthermal plasmas. Square symbols represent pure CO2; triangles, CO2-Ar mixture; inverted triangle, CO2-H2O mixture; diamond, CO2-H2O-Ar mixture. MW microwave, RF radio frequency, GAP gliding arc plasmatron, MW-ss microwave (supersonic flow), DBD dielectric barrier discharge. The SEI is given for reference. (Reproduced from Ref. [26] with permission. Copyright 2017, Elsevier)

1.3 How Does Plasma Catalysis Work?

1.3.1 What Does the Plasma Do to the Catalyst?

It is not the aim of this section to give an answer to this question as that will be the focus of many of the chapters that follow. Instead, I will just illustrate the way in which researchers have attempted to rationalize the observation of a plasma catalysis effect. Essentially there are two basic ways in which plasma catalysis works as mentioned before. First, it could be that placing a catalyst either directly in a plasma or downstream from it changes the operation of the discharge in a physical or chemical way that enhances the processing. Alternatively, using plasma to activate a catalyst changes the behavior of the catalytic process in a beneficial way. Basic theories of catalysis tell us that there are several stages involved in a catalytic reaction [27]. Firstly, species in the gas phase must collide with the surface and become adsorbed. Following adsorption, they might migrate on the surface to a reactive site that might be located within a pore inside the catalyst. At this stage, surface reaction can take place between species adsorbed on the surface, which is called a Langmuir-Hinshelwood mechanism, or a species still in the gas phase may react with one that is adsorbed, which is designated an Eley-Rideal process. Then, the surface-bound reaction product must desorb from the surface and make its way back into the bulk gas.

In thermal catalysis, the surface is heated to supply energy to overcome any barriers to adsorption. Species can be strongly adsorbed onto the catalyst with bonds that are comparable to chemical called chemisorption, or the bonding can be weaker in magnitude comparable to physical forces such as van der Waals and that is called physisorption. The nature of binding to the catalyst depends on its chemical composition giving the active sites for binding and the nature of the adsorbed species. Adsorption may be of the species in the same form as it is when gaseous or it might involve the dissociation into more reactive fragments, e.g. the dissociation of molecular hydrogen into two hydrogen atoms when adsorbed on Ni, a process called dissociative chemisorption. Adsorption of species onto a surface can improve reactivity by increasing their interaction time with the plasma, and this goes someway to explaining why enhanced performance can be obtained in plasma catalysis systems when using materials such as alumina, Al2O3 or titania, TiO2, that in conventional catalysis would be regarded as being inert support materials. It is important to realize that the rate of progress of a plasma catalysis process can be determined not only by the adsorption of the reagents, but also if a reaction product (or intermediate) is strongly adsorbed onto the surface and the reaction slows down as fewer surface sites become available for adsorption. The relative binding energies to the surface (enthalpies of adsorption) for the reagents, intermediates and products are key in determining the effectiveness of the catalytic process. As an example, using infrared in situ probing of the surface loading of a TiO2 catalyst during plasma catalysis, Barakat et al. [28] have investigated the oxidation of isopropanol by ozone in a downstream configuration and find that the rate of formation of gaseous end-products is limited by the rate of oxidation of an acetone intermediate, which saturates the surface.

As we have previously mentioned, there is a rich wealth of species in the plasma that includes many species that are potentially reactive including ions, excited atomic and molecular species and molecular and atomic free radicals created from gas-phase dissociation that are all created in the discharge. Once created, these species can undergo gas-phase collisions that can create further unstable species by reaction or excitation. Alternatively, the collisions can bring about deactivation by quenching or by recombination. Some short-lived excited species will decay by emitting a photon, a process called fluorescence that in the case of electronically excited species yields ultraviolet or visible emission giving the characteristic color to the discharge as was observed by Hauksbee and Faraday in their nineteenth century experiments with gaseous discharges.

In determining how these discharge-produced species might interact with the catalyst, it is not just necessary to consider how energetic or reactive they might be, but we must also consider their lifetimes in the gas phase that result from the collisional processes of activation, reaction and deactivation, just described and also how far they can travel during this lifetime. In other words, do these plasma-created species make it to the catalyst? Typically at atmospheric pressure and room temperature, they travel less than 100 nm and the time between collisions is less than 1 ns. The lifetime of a ground state oxygen atom, O(3P), in an atmospheric pressure plasma in dry air is about 14 μs [29] and that of a ground state OH radical depends on the gas composition but is typically 100 μs in an air plasma although this reduces to about 20 μs when a potential reagent such as trichloroethylene is added [30]. This means that there will only be a narrow region immediately above the catalyst surface from which the short-lived plasma-created species can be adsorbed. Kim et al. [31] have calculated that for ground state oxygen atoms or OH radicals, this layer will have a thickness of ~50 μm. Outside of this layer, species produced by the plasma will react or be deactivated in the gas phase in the same way that they do in the absence of the catalyst. This suggests that to gain the maximum effect from plasma catalysis, the reactor must be designed in a way that produces the reactive species very close to the surface of the catalyst.

Many catalysts consist of a metal coated onto a support material, and the effectiveness of the catalyst depends not only on the identity of the metal but also on the fractional coverage of the support by the metal and the size of the deposited metal particles. In many experiments, it is found that using nanoscale particles increases their effectiveness. At a molecular level, the dynamics of the reactive processes involved in the plasma-catalytis processes are of many types. In Fig. 1.5, some possible processes for the formation of ammonia in hydrogen/nitrogen dielectric barrier plasma with a Ru metal catalyst deposited on an alumina support are illustrated [32]. These indicate the interplay between gas-phase excitation and dissociation processes and adsorption onto both the metal particle and the alumina support, spillover onto the alumina from the Ru and migration of species across the alumina surface, followed by surface reaction and desorption of products. Gaseous excited N2 molecules created in the discharge adsorb dissociatively onto the alumina, while H2 is either dissociated in the gas phase or on the Ru metal. Diffusion of N and H atoms from the metal across the surface of the alumina creates NH3 in a stepwise manner by two different reactions where the H atoms created on the Ru metal react more quickly with the N atoms on the Al2O3 than do the H atoms adsorbed directly from the gas phase. This of course is a mechanism proposed to explain kinetic measurements without any direct identification of species on the catalyst surface.

Schematic diagram of the reaction pathways in the formation of NH3 from a N2/H2 plasma on a Ru/Al2O3 catalyst. (Taken from Ref. [32] by permission. Copyright 2007, Springer)

Another important effect that the plasma may have on the catalyst is that of surface modification. Indeed, plasma is increasingly being used as a method of pre-treating catalysts for conventional thermal processing [33, 34]. For example, using a low pressure glow discharge or radio frequency plasma with Ar, He, N2 or air as a source of energetic electrons, it is possible to reduce a metal in a more environmentally sustainable way than with conventional thermal or chemical processing [35, 36]. Plasma preparation can change the dispersion of metals on a catalyst, allowing for the treatment of sensitive low temperature materials and the production of novel classes of catalysts involving selective doping and the production of nanoparticles. It seems clear that if plasma can be used to prepare a catalyst in isolation under controlled conditions, then with the normal operating conditions of a one-stage plasma catalysis process, some of the plasma activity may result in a continual dynamic modification of the catalytic surface. Marinov et al. [37] have noted this for a SiO2 surface under exposure to a low pressure nitrogen plasma commenting that the surface under contact with the plasma is not static and suggesting that this type of behavior is expected for a range of surfaces and plasma chemistries. This dynamic interaction between plasma and catalyst may give a unique benefit in terms of reduced poisoning or coking and increased stability and activity.

Finally, we should consider how the catalyst and its adsorbed species will behave when exposed to the electrons produced by the discharge. Electron-stimulated desorption is a well-known process in surface science. This can arise due to local heating of the surface by electron impact leading to thermal desorption. It is also possible that the addition of electrons can affect the bonding between a molecular adsorbate and the surface creating repulsive interactions leading to desorption. Dissociative electron attachment of a species on the surface giving an anion that then dissociates may be an important process when dealing with electronegative species. It has been shown [38] that electron attachment to a CO2 molecule that is adsorbed onto an oxygen vacancy on a TiO2 surface brings about dissociation of the CO2− anion to give CO and the filling of the oxygen vacancy by the O− ion. The CO may then desorb migrate to another region of the surface. Mei et al. [39] have developed this mechanism to describe the dissociation of CO2 on photocatalytic materials such as BaTiO3 and TiO2 where plasma-produced electrons of sufficient energy can create electron-hole pair states in an analogous method to the excitation of these materials by photons of the same energy in photocatalysis. This process is shown schematically in Fig. 1.6.

A schematic mechanism for the plasma catalysis conversion of CO2 on the surface of a photocatalyst. (Reproduced from Ref. [39] with permission. Copyright 2017, Elsevier)

1.3.2 What Does the Catalyst Do to the Plasma?

In general terms, placing a catalytic material into plasma will affect the physical and electrical properties of the gas discharge that might thereby cause some modification to the outcomes of the plasma-catalytic processes. The addition of packing material might change the nature of the discharge from a filamentary form that propagates as microdischarges or streamers through the gas between the electrodes to that of a surface discharge that moves on the surface of the material. Such surface discharges on a catalytic surface have recently been imaged for the first time [40]. This change in discharge type may also be associated with an alteration of the electron energy distribution that may result in changes to the yields and identities of the species formed in the discharge. Neyts and Bal [41] has recently suggested that the addition of a catalytic material to a discharge can introduce an additional electric field influencing the retention time of the species at the catalyst surface and altering the charge distribution at the surface increasing reactivity. The efficiency of the processing will also depend on the structural features of the catalyst such as its morphology, porosity and chemical activity as these may interact with the nature of the plasma. The use of dielectric materials as packing can have a profound effect on the electrical properties of the discharge by changing the capacitance of the reactor. This can influence the breakdown voltage and the charge that can be transferred between the electrodes. In general, more electrical energy can be deposited into a discharge when materials of higher dielectric constant are used resulting in the formation of more electrons of higher energy giving increased yield of ionized and excited species. However, the overall effect of using high dielectric materials on the efficiencies and selectivities for the plasma catalysis processing is by no means clear and is found to vary between systems suggesting that there may be a subtle interplay between several effects that is not completely understood.

Interesting observations have been made where a dielectric barrier discharge reactor is filled with spherical beads of a high dielectric material such as BaTiO3 or ZrO2. Such materials are often ferroelectric, and polarization effects can cause enhanced electric fields at the points of contact between the beads giving higher concentrations of excited species. The discharge transitions from streamers propagating in the gas when there is no packing to a mixture of gaseous and surface discharge when there is packing present. Increased conversion of CO2 is observed [25, 42,43,44] in these arrangements, and simulations [45, 46] confirm that there are enhanced electric fields where the beads touch and the electron density is higher in these regions. This causes stronger and faster development of the plasma. The bead size is also important in affecting the conversion of the CO2 and increases as the bead size decreases as long as it is possible to sustain a discharge as the breakdown voltage for plasma action increases strongly as the size decreases [44]. Michielsen et al. [43] suggest that all these observations have wider implications for plasma catalysis as the conversion obtained is not just a function of the active sites on the catalyst which is deposited on a support material but also on how that support materials is packed into the reactor. There is a positive contribution of the packing on the conversion obtained, due to electric field enhancement at the contact points, but a negative contribution due to the lower residence time of the gases because of the volume reduction at a given flow rate and a positive or negative effect depending on the nature of material inserted into the voids. This conclusion that the important role played by how a reactor is packed with catalyst is supported by observations that using a dielectric barrier discharge (DBD) reactor that is only partially filled with a catalyst doubles the CH4 conversion and H2 yield during the dry reforming of CH4 with CO2 compared to a filled reactor [47].

The nature of the catalyst surface can have an effect on the electric field in the discharge, and irregularities in the surface such as roughness or the presence of pores can create local variations in the electric field and local regions of field intensification that can become a source of high-energy electrons. The islands of nanosized dispersed metals on a support will also encourage enhanced electrical fields as will edges, steps or other irregularities in the crystalline structure of the catalyst. Pores can selectively adsorb molecules depending on their size increasing their reactivity, and penetration of plasma into the pores may specifically excite such species. Experimental studies on the removal of pollutants from air [48] show that for nanoporous materials (pore size <0.8 μm), the electrical discharge does not penetrate into the pores, but for mesoporous materials (≥15 μm), it is possible for microdischarges to penetrate into the pores and that excited species can be stabilized in the pores giving enhanced reaction times. This is supported by modeling studies [49] that suggest that plasma species can be created within pores on the μm scale which may interact with the catalyst surface and affect the plasma catalytic process. Kim [31] has demonstrated that estimates of the rates of diffusion indicate that penetration into pores of nanometer dimension (<2 nm) is unfeasibly slow but that on the mesoscale (2–50 nm) it could be possible.

1.4 How Can We Learn More About Plasma Catalysis?

Having given an introduction and brief background to our current progress and understanding in the field of plasma catalysis, it is appropriate to outline the directions in which research might be focused in order to increase our understanding. The following chapters of this book contain detailed accounts, expertly written, on many of these areas. Much of our understanding so far has come from a very wide-ranging survey of many types of plasma-catalyst experiments applied to a wide range of systems involved in the fields of pollution control, energy and environmental aspects of reuse and conversion of materials and the production of high-value chemicals from different feedstocks. While many of these experiments are largely phenomenological in type, there are many examples of systematic studies where the grossly complicated, interacting, multiparameter monster that is plasma catalysis has been tamed to a degree by isolating different aspects and divining what the key parameters are. In this way, much progress has been made in understanding different aspects of the process including the relative contributions of chemical, physical and engineering principles. We now understand much about the physics of gas discharges and how this impinges upon the nature of the electrical inputs in terms of how the electrical power can be supplied in terms of the spectrum used (from microwave, radiofrequency, ac, pulsed to dc) and how these combine with the construction to determine the electrical field strengths and how the plasma will develop and propagate. We know much about how a wide range of ionizations, excitations and fragmentations results from collisions of the electrons produced in the discharge with the gaseous species and can calculate densities under certain conditions. We can also make deductions about the kinetics and reaction mechanisms by comparing the results of modeling with experiment particularly in terms of being able to predict the yields of reaction products and how these change with processing parameters. To a limited degree, we can model using realistic 2- and 3-D representations of our reactors and take account of mass and heat transport in the system. As we explore more, we become aware of areas where we do not have detailed experimental observations of key phenomena nor adequate models to describe our results. Most of our experimental observations are on steady state systems or involve processes with relatively long time constants. We know very much more about the outcomes of the processing than we do about the intermediate stages in the process. We can identify the major end products but know nothing about the intermediates other than the prediction of computation.

Kim [1] has recently discussed the timescales over which some of the different aspects of plasma catalysis take place and has presented an excellent summary in pictorial form displayed here in Fig. 1.7.

Characteristic timescales in plasma and catalytic processes. (Taken from Kim et al. [1], by permission. Copyright 2016, Springer)

It can be seen that the different processes cover timescales ranging from nanosecond to second. Herein lie many of difficulties and limitations that prevent a complete description and experimental study of plasma processes. We need to cover this range, but no single technique will allow this, and different techniques are needed for different timescales. In the plasma, the electron-induced processes that create the reactive species take place on the nanosecond scale whereas the subsequent chemical reactions in the gas phase and processes on the surface are considerably slower (microsecond to millisecond and longer) and compete with deactivation processes that may decrease yields by removing reagents and encouraging back-reactions converting products back to reagents and reduce selectivities by allowing for the formation of unwanted by-products.

Another aspect of our lack of understanding is also apparent from the diagram that concerns heating, heat flow, thermodynamics and temperature. In using nonthermal plasma, we operate in a regime of nonthermal equilibrium where the use of a single temperature to describe different properties of the system is not valid. The electrons will have a very large mean energy (1–10 eV, typically several thousand degrees Kelvin, if they can be described by Boltzmann statistics). In the gas, there will be a disequilibrium between the different degrees of freedom (electronic, translation and vibrational and rotational for a molecular species) which means that there is no single temperature that can describe the gas and in general Tvibrational > Trotational ≈ Ttranslational. This trend reflects the relative rates of relaxation, which depend on the identity of the gas and the pressure. The gas temperature in a plasma experiment is often equated to the rotational temperature of some gas, e.g. N2 which is determined spectroscopically by Raman or optical emission spectroscopy. The retention of vibrational excitation by some molecules or radicals is recognized as being of particular importance in plasma catalysis systems because such species may be easier to dissociate and also may adsorb more easily on a surface. It was recognized at an early stage of the development of plasma catalysis that vibrational excitation could provide enhanced adsorption onto catalyst surfaces and increase the reactivity for endothermic processes such as the production of NO from N2 and O2 on WO3 and MoO3 catalysts [50]. It has also been shown that vibrationally excited CH4 chemisorbs with more than three orders of magnitude greater efficiency on a Ni surface than it does when in its ground vibrational state [51]. The extent of electronic excitation depends on the radiative lifetime, τ0, of the state and the appropriate quenching rates. Species commonly encountered in plasma include atomic and molecular states of oxygen (O(1D), E = 1.967 eV, τ0 = 150 s: O2 (a1Δ), E = 0.977 eV, τ0 = 64.6 min) and nitrogen (N(2D), E = 2.38 eV, τ0 ~ 17 h: N(2P), E = 3.576 eV, τ0 ~ 12 s: N2 (A 3Σu), E = 6.224 eV, τ0 = 2.0 s). The high reactivity of O(1D), for example, reduces its lifetime to ~1 ns in a humid atmospheric pressure, air plasma due to quenching with air molecules and reaction with water to form the radical OH. The high-energy metastable nitrogen state, N2 (A 3Σu), plays an important role in plasma chemistry as it can collisionally dissociate many molecules [7].

In describing the operation of the catalyst during plasma catalysis, the concept of a single temperature is also problematic. In the experiment, the plasma may be externally heated but a more common configuration is to just place the catalyst into the discharge. It would however be a mistake to assume that the temperature of the catalyst surface will be the same as that of the surrounding gas. The impact of the plasma on the catalyst may bring about some heating due to electron or dielectric heating and the effects of the exo- or endothermicity of the reactions taking place on the surface that will either add or remove heat from the catalyst, respectively. Thermal imaging experiments by Nozaki and Okasaki [52] clearly show the non-uniformity of temperature along the surface of a Ni/Al2O3 catalyst mounted in a dielectric barrier discharge reactor during the exothermic steam reforming of methane with the temperature increasing along the direction of the gas flow. Correspondingly, a temperature decrease in the catalyst bed can be seen during the endothermic dry reforming reaction of CH4 with CO2 [53]. Further difficulties in using a single temperature to describe the catalyst come from the enhanced electric fields associated with surface irregularities or the points of contact formed between the catalytic particles as discussed above. These can give rise to local hotspots where a disproportionally high amount of the plasma catalysis processing may take place [9]. A final comment relates to the timescales noted in Fig. 1.7 relating this time to the timescale for heat transfer where the catalyst may be in the form of nanoscale metal particulates on a support material such as alumina. Because the metal particles (10 nm) are much smaller than the size of support particle (2 mm), as energy is supplied to the catalyst by the plasma, the metal will be heated at a much more rapid rate than the support giving heating times of 10−12 and 5 s, respectively. Thus, the metal particles will heat and cool much more rapidly than the support.

All of this goes to show that believing that the plasma catalysis process takes place at a single temperature could be a very big mistake as there are multiple temperatures needed to describe the species in the gas phase and on the catalyst that may vary with position within the reactor and also with time. In essence, there is a high degree of inhomogeneity with respect to time and position for many of the properties association with the plasma catalysis process which include the concentrations of the different species (including the electrons), the electron energies, the electric fields and the temperatures.

References

Kim, H. H., Teramoto, Y., Ogata, A., Takagi, H., & Nanba, T. (2016). Plasma catalysis for environmental treatment and energy applications. Plasma Chemistry and Plasma Processing, 36, 45–72.

Patil, B. S., Wang, Q., Hessel,V., & Lang, J. (2016). Plasma-assisted nitrogen fixation reactions. In G. Stefanidis & A. Stankiewicz (Eds.), Alternative energy sources for green chemistry (pp. 296–338). Cambridge, UK: Royal Society of Chemistry.

Yu, Q., Wang, H., Liu, T., Xiao, L., Jiang, X., & Zheng, X. (2012). High-efficiency removal of NOx using a combined adsorption-discharge plasma catalytic process. Environmental Science & Technology, 46, 2337–2344.

Tao, X., Bai, M., Li, X., Long, H., Shang, S., Yin, Y., & Dai, X. (2011). CH4-CO2 reforming by plasma – challenges and opportunities. Progress in Energy and Combustion Science, 37, 113–124.

Whitehead, J. C. (2010). Plasma catalysis: A solution for environmental problems. Pure and Applied Chemistry, 82, 1329–1336.

Whitehead, J. C. (2014). Plasma catalysis for volatile organic compounds abatement. In Handbook of advanced methods and processes in oxidation catalysis (pp. 155–172). London: Imperial College Press.

Whitehead, J. C. (2016). Plasma-catalysis: The known knowns, the known unknowns and the unknown unknowns. Journal of Physics D-Applied Physics, 49, 243001.

Snoeckx, R., & Bogaerts, A. (2017). Plasma technology – A novel solution for CO2 conversion? Chemical Society Reviews, 46, 5805–5863.

Neyts, E. C. (2016). Plasma-surface interactions in plasma catalysis. Plasma Chemistry and Plasma Processing, 36, 185–212.

Davy, H. (1817). Some new experiments and observations on the combustion of gaseous mixtures, with an account of a method of preserving a continuous light in mixtures of inflammable gases and air without flame. Philosophical Transactions of the Royal Society A, 107, 77–85.

Thomas, J. M. (2015). Sir Humphry Davy and the coal miners of the world: A commentary on Davy (1816) ‘An account of an invention for giving light in explosive mixtures of fire-damp in coal mines’. Philosophical Transactions – Royal Society. Mathematical, Physical and Engineering Sciences, 373, 20140288.

Berzelius, J. J. (1836). Considerations respecting a New Power which acts in the Formation of Organic Bodies. Edinburgh New Philosophical Journal, 21, 223.

Ostwald, W. (1894). Zeitschrift für Physikalische Chemie, 15, 705–706.

Hauksbee, F. (1709). Physico-mechanical experiments on various subjects; containing an account of several surprizing phenomena touching light and electricity, producible on the attrition of bodies, with many other remarkable appearances... together with the explanations of all the machines... and other apparatus us’d in making the experiments. London: For the author; pr. R. Brugis.

Maia, E., Serra, I., & Peres, M. (2010). The gas discharges in history and teaching of physics and chemistry. Travaux de laboratoire institut Rocha Cabral Lisbonne, 100, 1–14.

Faraday, M. (1838). Experimental researches in electricity. −Thirteenth series. Philosophical Transactions. Royal Society of London, 128, 125–168.

Faraday, M. (1834). On the power of metals and other solids to induce the combination of gaseous bodies. Philosophical Transactions of the Royal Society A, 124, 55–76.

Robertson, A. J. B. (1983). The development of ideas on heterogeneous catalysis: Progress from Davy to Langmuir. Platinum Metals Review, 27, 31–39.

Ray, A. B., & Anderegg, F. O. (1921). The oxidation of carbon monoxide by passage with oxygen or air through the silent discharge and over ozone decomposing catalysts. Journal of the American Chemical Society, 43, 967–978.

Berthelot, P. E. M. (1879). Recherches sur l’ozone et sur l’effuse électrique. Comptes rendus de l’Académie des Sciences, 88, 50–52.

Harling, A. M., Glover, D. J., Whitehead, J. C., & Zhang, K. (2009). The role of ozone in the plasma-catalytic destruction of environmental pollutants. Applied Catalysis B-Environmental, 90, 157–161.

Vandenbroucke, A. M., Mora, M., Jimenez-Sanchidrian, C., & Romero-Salguero, F. J. (2014). TCE abatement with a plasma-catalytic combined system using MnO2 as catalyst. Applied Catalysis B-Environmental, 156, 94–100.

Wang, L., Yi, Y., Zhao, Y., Zhang, R., Zhang, J., & Guo, H. (2015). NH3 decomposition for H2 generation: Effects of cheap metals and supports on plasma-catalyst synergy. ACS Catalysis, 5, 4167–4174.

Gutsol, A., Rabinovich, A., & Fridman, A. (2011). Combustion-assisted plasma in fuel conversion. Journal of Physics D-Applied Physics, 44, 274001.

Xu, S., Whitehead, J. C., & Martin, P. A. (2017). CO2 conversion in a non-thermal, barium titanate packed bed plasma reactor: The effect of dilution by Ar and N2. Chemical Engineering Journal (Amsterdam, Netherlands), 327, 764–773.

Chen, G., Godfroid, T., Britun, N., Georgieva, V., Delplancke-Ogletree, M., & Snyders, R. (2017). Plasma-catalytic conversion of CO2 and CO2/H2O in a surface-wave sustained microwave discharge. Applied Catalysis B-Environmental, 214, 114–125.

Froment, G. F., Bischoff, K. B., & De Wilde, J. (1990). Chemical reactor analysis and design (Vol. 2). New York: Wiley.

Barakat, C., Gravejat, P., Guaitella, O., Thevenet, F., & Rousseau, A. (2014). Oxidation of isopropanol and acetone adsorbed on TiO2 under plasma generated ozone flow: Gas phase and adsorbed species monitoring. Applied Catalysis B-Environmental, 147, 302–313.

Holzer, F., Roland, U., & Kopinke, F. D. (2002). Combination of non-thermal plasma and heterogeneous catalysis for oxidation of volatile organic compounds part 1. Accessibility of the intra-particle volume. Applied Catalysis B-Environmental, 38, 163–181.

Hibert, C., Gaurand, I., Motret, O., & Pouvesle, J. M. (1999). OH(X) measurements by resonant absorption spectroscopy in a pulsed dielectric barrier discharge. Journal of Applied Physics, 85, 7070–7075.

Kim, H. H., Teramoto, Y., Negishi, N., & Ogata, A. (2015). A multidisciplinary approach to understand the interactions of nonthermal plasma and catalyst: A review. Catalysis Today, 256, 13–22.

Mizushima, T., Matsumoto, K., Ohkita, H., & Kakuta, N. (2007). Catalytic effects of metal-loaded membrane-like alumina tubes on ammonia synthesis in atmospheric pressure plasma by dielectric barrier discharge. Plasma Chemistry and Plasma Processing, 27, 1–11.

Glonek, K., Wroblewska, A., Makuch, E., Ulejczyk, B., Krawczyk, K., Wrobel, R. J., Koren, Z. C, & Michalkiewicz, B. (2017). Oxidation of limonene using activated carbon modified in dielectric barrier discharge plasma. Applied Surface Science, 420, 873–881.

Liu, L., Zheng, C., Wu, S., Gao, X., Ni, M., & Cen, K. (2017). Manganese-cerium oxide catalysts prepared by non-thermal plasma for NO oxidation: Effect of O2 in discharge atmosphere. Applied Surface Science, 416, 78–85.

Liu, C., Li, M., Wang, J., Zhou, X., Guo, Q., Yan, J., & Li, Y. (2016). Plasma methods for preparing green catalysts: Current status and perspective. Chinese Journal of Catalysis, 37, 340–348.

Wang, W., Wang, Z., Wang, J., Zhong, C., & Chang, J. (2017). Highly active and stable Pt-Pd alloy catalysts synthesized by room-temperature electron reduction for oxygen reduction reaction. Advanced Science, 4, 1600486.

Marinov, D., Guaitella, O., de los Arcos, T., von Keudell, A., & Rousseau, A. (2014). Adsorption and reactivity of nitrogen atoms on silica surface under plasma exposure. Journal of Physics D-Applied Physics, 47, 475204.

Lee, J., Sorescu, D. C., & Deng, X. (2011). Electron-induced dissociation of CO2 on TiO2(110). Journal of the American Chemical Society, 133, 10066–10069.

Mei, D., Zhu, X., Wu, C., Ashford, B., Williams, P. T., & Tu, X. (2016). Plasma-photocatalytic conversion of CO2 at low temperatures: Understanding the synergistic effect of plasma-catalysis. Applied Catalysis B-Environmental, 182, 525–532.

Kim, H.-H., Teramoto, Y., & Ogata, A. (2016). Time-resolved imaging of positive pulsed corona-induced surface streamers on TiO2 and gamma-Al2O3-supported Ag catalysts. Journal of Physics D-Applied Physics, 49, 415204.

Neyts, E. C., & Bal, K. M. (2017). Effect of electric fields on plasma catalytic hydrocarbon oxidation from atomistic simulations. Plasma Processes and Polymers, 14, 1600158.

Mei, D., Zhu, X., He, Y., Yan, J. D, & Tu, X. (2015) Plasma-assisted conversion of CO2 in a dielectric barrier discharge reactor: Understanding the effect of packing materials. Plasma Sources Science & Technology, 24, 015011.

Michielsen, I., Uytdenhouwen, Y., Pype, J., Michielsen, B., Mertens, J., Reniers, F., Meynen, V., & Bogaerts, A. (2017). CO2 dissociation in a packed bed DBD reactor: First steps towards a better understanding of plasma catalysis. Chemical Engineering Journal, 326, 477–488.

Butterworth, T., Elder, R., & Allen, R. (2016). Effects of particle size on CO2 reduction and discharge characteristics in a packed bed plasma reactor. Chemical Engineering Journal, 293, 55–67.

Zhang, Y., Wang, H., Jiang, W., & Bogaerts, A. (2015). Two-dimensional particle-in cell/Monte Carlo simulations of a packed-bed dielectric barrier discharge in air at atmospheric pressure. New Journal of Physics, 17, 083056.

Koen Van, L., & Annemie, B. (2016). Fluid modelling of a packed bed dielectric barrier discharge plasma reactor. Plasma Sources Science and Technology, 25, 015002.

Tu, X., & Whitehead, J. C. (2012). Plasma-catalytic dry reforming of methane in an atmospheric dielectric barrier discharge: Understanding the synergistic effect at low temperature. Applied Catalysis B-Environmental, 125, 439–448.

Roland, U., Holzer, F., & Kopinke, F. D. (2002). Improved oxidation of air pollutants in a non-thermal plasma. Catalysis Today, 73, 315–323.

Zhang, Y., Van Laer, K., Neyts, E. C., Bogaerts, A. (2016). Can plasma be formed in catalyst pores? A modeling investigation. Applied Catalysis B-Environmental, 185, 56–67.

Gicquel, C., Cavadias, S., & Amouroux, J. (1986). Heterogeneous catalysis in low-pressure plasmas. Journal of Physics D: Applied Physics, 19, 2013–2042.

Juurlink, L. B. F., McCabe, P. R., Smith, R. R., DiCologero, C. L., & Utz, A. L. (1999). Eigenstate-resolved studies of gas-surface reactivity: CH4 (ν3) dissociation on Ni(100). Physical Review Letters, 83, 868–871.

Nozaki, T., & Okazaki, K. (2013). Non-thermal plasma catalysis of methane: Principles, energy efficiency, and applications. Catalysis Today, 211, 29–38.

Kameshima, S., Tamura, K., Mizukami, R., Yamazaki, T., & Nozaki, T. (2017). Parametric analysis of plasma-assisted pulsed dry methane reforming over Ni/Al2O3 catalyst. Plasma Processes and Polymers, 14, 1600096.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Whitehead, J.C. (2019). Plasma Catalysis: Introduction and History. In: Tu, X., Whitehead, J., Nozaki, T. (eds) Plasma Catalysis. Springer Series on Atomic, Optical, and Plasma Physics, vol 106. Springer, Cham. https://doi.org/10.1007/978-3-030-05189-1_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-05189-1_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05188-4

Online ISBN: 978-3-030-05189-1

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)