Abstract

The impact of heterogeneity on the flow behavior of CO2 foam in the presence of crude oil is investigated in a complex, heterogeneous porous medium. A microfluidic device is fabricated featuring low and high permeability regions using a sequential photolithography technique. Two types of CO2 foams are used as the injectant: (i) foam stabilized with surfactants and (ii) foam stabilized with a blend of silica nanoparticles (Si NPs) and surfactants. High-resolution images of the medium during displacement experiments reveal a phase separation between the high versus low permeability regions; foam sweeps the high permeability regions, whereas the surfactant solution, along with few gas bubbles, appears to invade the low permeability region. The gains in recovery from the low-permeability region are attributed to the resistance to flow due to a relatively high apparent viscosity of foam in the high-permeability region and the resulting diversion of flow into the low-permeability region. The enhanced stability of foams stabilized with Si NPs appears to reduce the phase separation between the two regions, which contributes to an additional recovery gain from the low-permeability region.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

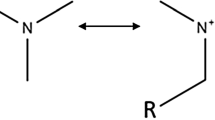

Heterogeneities in porous media, along with unfavorable contrasts of viscosity and density between the resident and invading phases, contribute to flow instabilities and relatively low sweep efficiencies in subsurface systems [1, 2]. Foam injection has the potential to improve the sweep efficiency due to its relatively high apparent viscosity, which contributes to an increase in resistance to flow in high-permeability regions [3, 4]. This phenomenon helps redirect the transport of the flowing phases into the otherwise under-swept regions in heterogeneous porous media [5, 6]. Foam injection experiments using microfluidic devices are often conducted using homogeneous porous media, which do not address the flow dynamics related to heterogeneities [7, 8]. A heterogeneous microfluidic device featuring a complex pore network with rigid walls would help elucidate the flow dynamics in subsurface systems [9]. Nanoparticle (NP)-surfactant mixtures synergistically generate foams with improved apparent viscosity and stability characteristics compared with those generated with surfactants alone [6]. This work examines the impact of heterogeneities on the flow behavior and the spatial distribution of foam within porous media. Two types of CO2 foams are used as the injectant: (i) foam stabilized with surfactants and (ii) foam stabilized with a blend of silica nanoparticles (Si NPs) and surfactants. This work aims to demonstrate that foam stability is a significant contributing factor to sweep efficiency in heterogeneous systems. A glass heterogeneous porous medium is fabricated using a map of the channel network of a Berea sandstone. The porous medium has a centrally-located low-permeability region, bound on each side by a high-permeability region [10]. High-resolution images of the porous medium are captured during the flow experiments using a monochromatic 60 MP sensor. Pixel intensities are used to analyze the phase separation and displacement in high and low permeability regions.

2 Experiments

Dispersions of Si NPs (T30, 100% SiOH coverage) in deionized (DI) are mixed with lauramidopropyl betaine (LAPB) and alpha-olefin sulfonate (AOS) surfactant mixtures (Table 1). CO2 gas, a 30,000-ppm sodium chloride brine, and a Gullfaks Blend crude oil with a viscosity of 45.9 cp are used in the experiments. All measurements were carried out at 20 °C. The porous medium covers an area of approximately 1.6 in. × 1.4 in. Channels have a uniform depth of approximately 14 and 6 μm in the high-permeability and low-permeability regions, respectively. The two permeability regions have a permeability contrast of approximately two (0.28 Darcy vs. 0.13 Darcy).

3 Results

An injection rate of 1 μL/min is used in all displacement experiments. Brine is injected in the oil saturated medium for 30 min, at which point the maximum water flooding oil recovery of approximately 50% is achieved. Subsequently, the surfactant, or the NP-surfactant mixture, and CO2 gas are injected simultaneously. Figure 1 shows sample images of the medium after injection of two pore-volumes (PV) of foam. Approximately 40 and 49% incremental oil was recovered from the high and low permeability regions, respectively, as a result of the injection of the surfactant-stabilized foam. Compared to the foam generated using surfactants only [11], the more stable NP-assisted foam exhibits a higher lamella density in the high-permeability region. As a result, the mobility of the displacing fluid in this region is further reduced and the flow is redirected to the lower permeability region. A phase separation between the two regions is observed for both foams; however, the separation appears to be less severe in the case of NP-assisted foam. As a consequence, a higher incremental oil recovery from the low-permeability region is achieved using the more stable foam. The presence of gas bubbles in the low-permeability region of the NP-assisted foam flood indicates that a higher gas fraction is present in this region compared to the one with the less stable foam.

The porous medium after two pore-volumes of foam injection. a and c are examples of the high-permeability region and b and d are examples of the low-permeability region. a and b are under flood by foam generated using surfactants only, whereas c and d are under flood by the NP-assisted foam. Gas bubbles in (d) are highlighted for clarity

4 Discussion

Most of the oil remaining in the medium at the conclusion of the waterflood phase resides in the low-permeability region. Foam is able to mobilize and displace a portion of this trapped oil. Unlike the foam flood using surfactants only, a continuous foam phase is present in the high-permeability region of the NP-stabilized CO2 foam flood, where almost all of the resident phase is displaced after two PVs of foam injection. The incremental recovery from the low-permeability region, during the foam-flooding phase, is superior in the case of the more stable foam. This is in part attributed to the invasion of the low-permeability region by gas bubbles, whereas in the case of the less stable foam, this region is mainly invaded by the surfactant solution with occasional gas bubbles in the periphery. The improved stability of the NP-assisted foam appears to enhance the recovery from heterogeneous porous media. Foam stability is a major contributing factor in its mobility control, which, in turn, has an appreciable impact of its ability to mobilize the resident fluid trapped in low-permeability regions of heterogeneous media.

5 Conclusions

Foam stability is demonstrated to have a significant impact on foam mobility control and sweep efficiency in a heterogeneous medium. Oil displacement experiments are conducted using CO2 foams with different stability behaviors and a glass heterogeneous microfluidic device. The NP-assisted foam exhibits higher stability and a higher lamella density in the medium, which leads to an improvement in the overall oil recovery from both high and low permeability regions. A ‘smart rheology’ (phase separation) is observed in both foam experiments—as the foam invades the low permeability region, it becomes more liquid-rich. Nevertheless, as demonstrated by the presence of gas bubbles, the more stable foam exhibits a less severe phase separation, caused by the heterogeneity and a relatively higher gas fraction in the low-permeability region compared to the less stable foam.

References

Aryana, S.A., Kovscek, A.R.: Experiments and analysis of drainage displacement processes relevant to carbon dioxide injection. Phys. Rev. E 86(6), 66–78 (2012)

Furtado, F., Pereira, F.: Crossover from nonlinearity controlled to heterogeneity controlled mixing in two-phase porous media flows. Comput. Geosci. 7(2), 115–135 (2003)

Guo, F., Aryana, S.: An experimental investigation of nanoparticle-stabilized CO2 foam used in enhanced oil recovery. Fuel 186, 430–442 (2016)

Fernø, M.A., Gauteplass, J., Pancharoen, M., Haugen, Å., Graue, A., Kovscek, A.R.: Experimental study of foam generation, sweep efficiency, and flow in a fracture network. SPE J. 21(4), 1140–1150 (2016)

Xiao, S.Y., Zeng, Y.C., Vavra, D.E., He, P., Puerto, M., Hirasaki, J.G., Biswal, L.S.: Destabilization, propagation, and generation of surfactant-stabilized foam during crude oil displacement in heterogeneous model porous media. Langmuir 34(3), 739–749 (2018)

Shi, S., Wang, Y., Li, Z., Ding, M., Chen, W.: Experimental study on stability and improving sweep efficiency with microfoam in heterogeneous porous media. J. Dispersion Sci. Technol. 37(8), 1152–1159 (2015)

Muggeridge, A., Cockin, A., Webb, K., Frampton, H., Collins, I., Moulds, T.: Recovery rates, enhanced oil recovery and technological limits. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 372(2006), 1–25 (2014)

Riche, C.T., Zhang, C., Gupta, M., Malmstadt, N.: Fluoropolymer surface coatings to control droplets in microfluidic devices. Lab Chip 14(11), 1834–1841 (2014)

Mijatovic, D., Eijkel, J.C.T., van den Berg, A.: Technologies for nanofluidic systems: top-down vs. bottom-up-a review. Lab Chip 5(5), 492–500 (2005)

Guo, F., Aryana, S.A.: Improved sweep efficiency due to foam flooding in a heterogeneous microfluidic device. J. Petrol. Sci. Eng. 164, 155–163 (2018)

Guo, F., He, J., Johnson, P.A., Aryana, S.A.: Stabilization of CO2 foam using by-product fly ash and recyclable iron oxide nanoparticles to improve carbon utilization in EOR processes. Sustain. Energy Fuels 1(4), 814–822 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Guo, F., Aryana, S.A. (2019). Foam Flooding in a Heterogeneous Porous Medium. In: Banerjee, S., Barati, R., Patil, S. (eds) Advances in Petroleum Engineering and Petroleum Geochemistry. CAJG 2018. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-030-01578-7_16

Download citation

DOI: https://doi.org/10.1007/978-3-030-01578-7_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-01577-0

Online ISBN: 978-3-030-01578-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)