Abstract

In serial femtosecond crystallography (SFX), protein microcrystals and nanocrystals are introduced into the focus of an X-ray free electron laser (FEL) beam ideally one-by-one in a serial fashion. The high photon density in each pulse is the double-edged sword that necessitates the serial nature of the experiments. The high photon count focused spatially and temporally leads to a diffraction-before-destruction snapshot, but this single snapshot is not enough for a high-resolution three-dimensional structural reconstruction. To recover the structure, more snapshots are required to sample all of reciprocal space from randomly oriented crystal diffraction, and in practice, some redundancy is necessary in these measurements. This chapter explores the different sample delivery techniques developed over the years to help enable serial crystallography experiments.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

5.1 Overview

In serial femtosecond crystallography (SFX), protein microcrystals and nanocrystals are introduced into the focus of an X-ray free electron laser (FEL) beam, ideally, one-by-one in a serial fashion. The high photon density in each pulse is the double-edged sword that necessitates the serial nature of the experiments. The high photon count focused spatially and temporally leads to a diffraction-before-destruction snapshot, but this single snapshot is not enough for a high-resolution three-dimensional structural reconstruction. To recover the structure, more snapshots are required to sample all of reciprocal space from randomly oriented crystal diffraction, and in practice, some redundancy is necessary in these measurements. Please see Chap.~8 for more details.

Fixed targets were initially used to verify the diffract-before-destruction idea central to biological imaging with X-ray FELs and specifically serial femtosecond crystallography (SFX) experiments [1]. In most traditional optical imaging experiments, the sample is mounted onto a glass slide, goniometer pin, electron microscopy grid, or some other substrate; therefore, fixed targets seem a logical first step for X-ray FEL sample delivery. However, the repetition rate of the FEL pulses combined with their destructive power made the efficient use of fixed targets difficult. At the time of the first X-ray FEL experiments, fixed targets could neither be replenished at the X-ray repetition rate nor could they be properly protected from the adverse effects of the vacuum environment without drastically increasing background scattering. This drove the desire and need to use flowing liquid sample delivery methods. Later in the chapter, the idea of fixed targets for in-vacuum and ambient experiments is revisited.

Biological samples, which are by nature sensitive to damage by X-rays, should be replenished, at the minimum, with the X-ray FEL repetition rate, which has, until recently, ranged up to 120 Hz at X-ray facilities that have operated for a few years. If synchronized with a 120 Hz source, every sample, most commonly a crystal of a particular biological molecule, that is hit by a focused X-ray pulse is destroyed after the pulse has passed through; within 8.3 ms the debris must be cleared out and a new crystal is ideally supplied for the next pulse. With the advent of superconducting accelerators, an average repetition rate of 27 kHz (4.5 MHz peak) and up to 1 MHz will be available with the opening of the European XFEL and the LCLS-II upgrade, respectively. To make use of the peak repetition rates at these facilities, samples must be replaced every 220 ns or 1 μs, respectively. Figures 5.1 and 5.2 show the effects of the intense incident X-ray pulses on a solid substrate and a liquid water jet in vacuum.

SEM images of a pattern etched with a focused ion beam into a 20 nm silicon nitride membrane, before (left) and after (right) of an incident FEL pulse. The damage is evident, yet the authors were able to reconstruct the original structure, thus verifying the diffraction-before-destruction concept. The right image demonstrates the destructive power of the incident X-rays which affect the interaction region (central 20 μm) as well as the adjacent area [1]. Reproduced with permission from Chapman et al. [1]

A Rayleigh jet of water (20-μm-diameter) injected into vacuum, imaged stroboscopically, to view the effects of the incident X-ray FEL pulse on the stream of liquid. Varying time delays after the incident X-ray pulses (0.75 ± 0.08 mJ, 8.2 keV, 120 Hz) are shown. A gap forms after the X-ray pulse vaporizes the liquid explosively. Liquid from the jet forms thin conical films of water, which later collapse onto the jet, while the liquid continues to flow (downwards in the image). Reproduced with permission from Stan et al. [2]

The first structural biology experiments at an X-ray FEL were performed at soft X-ray energies [3, 4]. At these lower energies (<2 keV), X-rays interact more strongly with electrons than at the higher energies typical for X-ray crystallography (>6 keV). Due to the low photon energy, the first experiments were performed in vacuum to prevent strong interactions between ambient gas molecules and soft X-rays. Additionally, the samples had to consist of nanometer sized crystals or single particles to prevent excessive X-rays absorption by the sample. The hydration layer around the sample had to be small, to minimize absorption from surrounding water molecules, and to minimize background scatter in the case of single particles.

Flowing liquid delivery systems were thought to be able to both sufficiently replenish the samples and keep them protected in vacuum. For single particles (e.g., viruses, whole cells), Seibert et al. [4] used an aerodynamic lens stack, similar to that shown in Fig. 5.3, in which an aerosolized sample passes through a series of chambers at decreasing pressure, separated by apertures. The pressure gradient from atmosphere to vacuum through each section acts as a focusing lens. As the aerosolized particles accelerate with the gas passing through the focusing apertures, the particles’ inertia keeps them closer to the centerline while the carrier gas quickly expands, creating a focused particle beam, while simultaneously evaporating a volatile solvent. Ultimately, the particles arrive at the X-ray interaction region with minimized hydration shell, ensuring low background scattering critical to imaging single particles while still protecting the particle from the detrimental effects of vacuum. Transmission inefficiencies and low particle densities at the interaction region make the aerodynamic lens less than ideal [for SFX experiments], and aerosol injection for single particle imaging experiments is still an area of ongoing research [6,7,8].

Cross-sectional schematic of an aerodynamic lens stack. Aerosolized particles are generated (left) from an electrospray, for example (not shown), and focused through an aerodynamic lens stack towards the interaction region (to the right). Differential pumping regions are serially decreasing in pressure from left to right towards the interaction region, [with typical pressure values corresponding to the colored chambers]. Modified with permission from Bogan et al. [5]

For crystallographic applications, an increased water layer around the sample is more tolerable due to the increased scattering intensity at the Bragg peak locations. Therefore, liquid sample delivery directly into the beam is more commonly used. The most familiar liquid jet is a Rayleigh jet. Seen in faucets, garden hoses and fountains, a Rayleigh jet is formed when there is sufficient flow rate to overcome the resistive properties intrinsic in a fluid, such as its viscosity and/or surface tension. Rayleigh was able to describe the eventual breakup of the jet into droplets from small surface perturbations [9, 10]. Faubel et al. [11] and later, for the purpose of SFX, Weierstall et al. [12] demonstrated that liquid streams could be created and delivered into vacuum. Rayleigh jets use large quantities of sample, on the order of 100–1000s of μL/min. Small jet diameters with reduced flow rate and improved stability compared to Rayleigh jets were made possible by the gas dynamic virtual nozzle (GDVN) [13]. In the next section, the fluid mechanics that governs liquid injection devices is introduced and discussed. These concepts set up the boundary conditions of sample delivery for SFX and allow the reader to appreciate the nuances of the subsequent, seemingly similar, sample delivery methods.

SFX takes advantage of some of the unique capabilities of X-ray FELs by keeping protein crystals in a solvated state and close to room temperature. The crystal concentration should ideally be adjusted so that, on average, only one crystal is in the interaction region during a given X-ray pulse. For a 1–10 μm X-ray focus, typical concentrations are 107–1010 particles per milliliter and are optimized during the experiment.

The requirements for SFX sample delivery are therefore:

-

Replenish the protein crystals at the X-ray interaction region as efficiently as possible

-

The delivery method should be compatible with the experimental environment (e.g., vacuum, helium, air)

-

No sample damage due to the injection process (compatible carrier media/support and sample, no undue shear forces, charging, etc.)

-

Minimal background scattering from the carrier media or support

-

Reliable operation for hours

Sample delivery for SFX experiments can be nuanced and complicated for crystallographers looking to perform an experiment for the first—or n-th time. The following section will serve as a primer of the underlying fluid mechanics that govern sample delivery. The problem of delivering a slurry of crystals to the incident X-ray beam in the most efficient way is not trivial and is at the crux of a successful experiment. It can be the difference between hours of frustrating, fruitless data collection and a successful experiment. By the end of this chapter, the reader should have an appreciation for the status quo of the numerous sample delivery techniques available to interface with the myriad crystallization conditions possible, while being able to identify the pros and cons of each technique and how a specific sample delivery approach might mate with their particular crystal system.

In this chapter, several different methods are presented which have been used to deliver microcrystals to an X-ray FEL beam. In Sect. 5.2 the gas dynamic virtual nozzle (GDVN) is introduced, which has been the workhorse for many SFX experiments since the start of user operations at the first hard X-ray FEL. These are, historically, handmade nozzles which help minimize clogging by the crystal solution or foreign objects, since they produce a micron sized jet (<10 μm) from a larger aperture; passing the same crystal slurry through a micron sized orifice is quite impractical due to clogging issues. To make them more reproducibly, high-resolution 3D printing is currently being employed and first results are shown. GDVNs have a relatively high flow rate and jet speed, which leads to considerable sample waste when used at low repetition rate X-ray FELs such as the Linac Coherent Light Source (LCLS) and the SPring8 Angstrom Compact free electron LAser (SACLA). High viscosity injectors, such as the lipidic cubic phase (LCP) injector, which were initially developed due to their compatibility with membrane protein crystal growth, and later were adapted for multiple sample types to reduced sample waste, are introduced in Sect. 5.3. These allow a reduction of the sample flow rate by a factor of 100 as long as the media has a high viscosity similar to LCP, a high viscosity growth medium for many membrane proteins. In Sect. 5.4 the microfluidic electrokinetic sample holder (MESH) and its variant, the concentric MESH (coMESH), is introduced, which borrows methods from electrospray and electrospinning to move the sample in a charged stream through the X-ray focus. Sample flow rates with this technique are lower than with the GDVN and can be as low as with the high viscosity injectors, therefore filling the gap between these two techniques in terms of sample consumption.

Section 5.4 introduces two variants of the GDVN, double flow focusing nozzles and mixing nozzles. Mixing nozzles are currently of great interest when studying enzyme reactions in a time-resolved fashion. Double flow focusing nozzles are more reliable than regular GDVNs since clogging events are largely avoided due to the use of an outer focusing liquid and they also allow a reduction of the sample consumption, since the sample flow can be pinched off by the outer liquid flow. Section 5.5 introduces other viscous carrier media that can be used for SFX with the high viscosity injector. In addition, it presents a drop-on-demand system synchronized with the X-ray FEL pulses for SFX, which has been developed at SACLA. The in-helium atmosphere at SACLA has different considerations for sample delivery as compared to the in-vacuum techniques initially developed to interface with LCLS. An example of a fixed target sample holder is presented in Sect. 5.7. With fixed target sample holders, thousands of microcrystals are mounted on a solid support and scanned through the X-ray beam. One microcrystal is exposed to an X-ray pulse, then the support is moved to the next crystal. The sample support has to be moved from crystal to crystal at the repetition rate of the X-ray laser. Fixed target sample delivery results in very high hit fractions since ideally every X-ray pulse hits a crystal. The chapter closes with an outlook on what is next in the field of sample delivery as mixing experiments and high repetition rate sources start to become the new norm for SFX.

5.1.1 Fluid Mechanics for Crystallographers

Any crystallographer knows the delicate balance needed between the protein and its surrounding mother liquor—the fluid composition that coaxes the protein out of solution and into a crystalline lattice. Finding the right conditions for crystals to grow can take years, and even optimizing them for cryo-conditions or improved resolution can take a whole career. By the end of this chapter you will appreciate that it is ultimately the protein crystals and their mother liquor that govern the performance, and thus success, of an SFX experiment using liquid sample delivery. The fluid properties of the mother liquor alone can vary from low surface tension detergents to high viscosity polymers and lipids or simple salt and water brines, and these differences can be felt as early as during pipetting in the lab. The addition of suspended protein crystals increases the apparent viscosity and introduces complexities to the experiment, such as potentially disrupting any meniscus exposed from a capillary opening, causing clogs at junctions and throughout liquid lines when transporting the sample through liquid lines, and sedimentation in reservoirs. If performing the experiment in vacuum, the evaporation of the exposed meniscus modifies the local chemistry and can cause precipitation of salts and dehydration of the sample and severely impede the experiment; the chemicals that cause your proteins to precipitate into crystals can also cause salts to precipitate once exposed to vacuum, for example. The following section will give a brief overview of some fundamental fluid mechanics that govern the different sample delivery methods and setup the physical constraints which might answer the crystallographers first question when [planning for sample delivery] for an SFX experiment: “Why do we have to do that?” A successful SFX crystallographer will be familiar with these concepts and work closely with the sample injection team to get the crystals through one of the major SFX bottlenecks.

To understand the constraints of sample injection, and thus the need for different sample delivery techniques, pressure-driven fluid flow in a pipe should be understood; more simply the Hagen–Poiseuille [14] flow equation:

where the flow rate Q, of a fluid with dynamic viscosity μ, is driven by a pressure gradient ΔP, over a length of tubing L, with radius r. The dynamic viscosity (or simply viscosity) here, in SI units of Pa·s, is indicative of the fluid’s resistance to shear stresses. This is the parameter we intuit when we say that honey is thicker than water; that is, honey has a higher dynamic viscosity than water. The dynamic viscosity is different from the kinematic viscosity, ν = μ/ρ, with SI units of m2/s. The kinematic viscosity represents the ratio of the fluid’s viscous force to the inertial force and indicates how fast momentum is diffused throughout the fluid. For example, the viscosity of air and water at standard atmospheric conditions are approximately 0.02 and 1 mPa·s respectively, which agrees with our expectation that water is thicker than air. The kinematic viscosities, however, are 1 × 10−5 m2/s and 1 × 10−6 m2/s, respectively, implying that momentum diffuses through air faster than in water. The kinematic viscosity is important when discussing velocity profiles within the fluid, as well as mass diffusion. An ion of hydrogen has a diffusivity of 10−10–10−9 m2/s in water, meaning that momentum information of the bulk water diffuses 3–4 orders of magnitude faster than the mass diffusion of hydrogen ions; for example, the parabolic velocity profile of flowing water in a pipe is established sooner than a uniform pH.

A fluid deforms continuously as a shear stress is applied to it, whereas a solid object resists this applied force. Both liquids and gases are fluids and can exhibit similar behaviors. Most of the basic fluid mechanics concepts discussed here will assume Newtonian fluids. A Newtonian fluid, such as water and oil, is one whose viscosity is a property of the fluid’s state and is not affected by the applied shear rate. In contrast, toothpaste, ketchup, blood, polymer solutions, or colloidal suspensions like mayonnaise and paint, are non-Newtonian fluids. Here an increased shear rate can cause the fluid to move easier or more difficultly depending on the specific flow properties of the fluid. It is likely that certain protein crystallization conditions might lead to fluids which exhibit these complex behaviors, but the basic principles discussed here will focus on a Newtonian fluid assumption. In later sections some injection methods will be discussed where non-Newtonian viscous media, such as lipidic cubic phase of monoolein (LCP), agarose, or high molecular polymer solutions, are used as carrier media for sample delivery. See White [14] or other fluid mechanics texts for more details on shear thinning, shear thickening, Bingham plastic, or thixotropic fluids.

The fluid properties of a crystal’s mother liquor might dictate the viscosity and thus cannot be readily changed. Under many circumstances, the size of the protein crystals itself begins to limit the geometries suitable for the SFX experiment. In most fluid mechanics calculations applicable to SFX, the fluid is treated as a continuum and species inside of the fluid are treated as dilute, solvated species, not causing changes in the bulk properties of the fluid. This assumption cannot be maintained when dealing with a suspension of solid protein crystals on the order of 100s of nanometers to dozens of micrometers in dimension. The crystals themselves have solvent channels that can interact with the fluid but this is beyond the scope of this discussion. The idea should be clear, though, that a crystal slurry and the same fluid without crystals will invariably behave differently, whether it be different effective viscosities, or non-Newtonian behaviors, much like the way particles suspended in water prevent ketchup from moving until a sufficiently high shear rate is applied.

Although not always physically accurate, a useful heuristic in understanding basic fluid flows is to use an electric circuitry analogy. The terms in the pipe flow equation above can be grouped to define a hydrodynamic resistance R. Much like an element in an electronic circuit has some resistance to the flow of current from an applied voltage (Ohm’s law), a capillary of fluid will restrict volumetric flow with the application of a volumetric potential (i.e., the pressure (ΔP)). Ignoring the effects of evaporative cooling possible at a vacuum orifice, if water is placed inside a 50 μm inner diameter capillary tube, 1 m in length, with atmospheric pressure applied to one end and vacuum applied to the other, the water will flow at approximately 1 μL/min. This fluid flow is so low that the ensuing fluid meniscus on the vacuum side will freeze due to evaporative cooling in vacuum. Changing the fluid’s properties or driving the flow much faster (creating a Rayleigh jet), would be the only way to prevent that meniscus from freezing. However, the high flow rate of a Rayleigh jet (>100 μL/min) can be prohibitive for most protein crystal slurries. The Hagen–Poiseuille equation indicates that the only ways to reduce the sample consumption through the capillary tube are to decrease the pressure difference, increase the length of the tube, decrease the tube diameter, or to increase the viscosity. We will briefly discuss the implications of a change in these parameters.

Pressure Gradient

Although serial crystallography experiments do not necessarily require in-vacuum injection, many have been and continue to be done in vacuum. In the case of vacuum injection, a way to reduce the pressure gradient below one atmosphere is to apply vacuum upstream of the sample reservoir. This can lead to outgassing of the solution in the capillary, which can lead to cavitation and bubble formation and can severely limit or interrupt the jetting ability, and thus the data collection. This might also affect the stability of the suspended protein crystals as the solution chemistry is potentially affected through dehydration. At the vacuum end, differential pumping schemes can be employed to keep the exposed meniscus nearer to atmospheric pressures, thus diminishing the pressure gradient. In non-vacuum experiments, the pressure gradient is arbitrary and bounded by the injection method rather than the vacuum conditions.

Tubing Inner Diameter

One of the most powerful relationships for fluid flow in a pipe is the fourth-power dependence on the inner diameter of the tube. Going from a 50-μm diameter tube to a 100-μm tube can give a 16-fold increase in flow rate or a 16-fold decrease in pressure to run the same flow rate. In practice, to maintain the same liquid jet, the pressure will stay and the flow rate will have to compensate. A gross simplification of the process of ejecting liquid streams from a liquid’s surface would be to imagine that sufficient kinetic energy must be imparted onto the fluid by some sort of potential energy well, be it pneumatic, hydraulic, electrostatic, or other. Once the applied potential energy is enough to fight resistive forces in the bulk fluid and the exposed meniscus, mainly the viscosity and surface tension, then the remaining energy is used to flow the jet. In order to further focus the meniscus of the fluid into a small stream, one must add some excess kinetic energy to the system [to accelerate the flow], and herein lies one of the fundamental challenges to sample delivery. The atmosphere pressure difference, in our hypothetical system above, dictates a minimum flow rate of 1 μL/min, as most SFX experiments have historically occurred within a vacuum. Adding energy might increase this flow rate, as seen with either the GDVN, where flow rates on the order of tens of microliters per minute are necessary to make a thin stable jet, or the thicker Rayleigh jet with hundreds of microliters per minute. See Eggers and Villermaux’s review on the physics of liquid jets for more details [15].

As appealing as it seems to then reduce the capillary diameter, modifications to the tubing diameter quickly come at odds with the necessary driving pressure. For example, to run at 10 μL/min (similar to flows of a nominal GDVN) through a 1 m-long capillary with an inner diameter of 25 μm, a driving pressure of over 2500 psi (∼170 bar) is needed, as opposed to 160 psi (∼11 bar) needed for the same flow rate through a 50 μm inner diameter capillary with the same length. These values assume the capillary meniscus is in air and does not take into account whether the flow creates a liquid jet or not. The pressure values would likely change if modified to create a jet, however, the relative pressure differential between the two capillary diameters will remain. Such a large operating pressure approaches safety limits of common fluid handling and microfluidic equipment and might cause failures, and although not prohibitive, this quickly becomes non-ideal.

The smaller the tubing diameter gets, the easier it can clog with the protein slurries as well as any foreign particulates. A general heuristic is that the largest crystal dimension should not exceed 2/5 of the inner diameter of the tubing. The more concentrated the crystal slurry gets, the higher the likelihood that even small nanocrystals can clog a 50 μm opening. A macroscopic analogy would be a crowd of people exiting a doorway. Although one person fits easily through the doorway, moving many people through quickly can cause “clogging.” Unfortunately, capillary diameters are not a readily tunable parameter for sample delivery, even though a narrow range of sizes are typically employed: 30, 40, 50, 75, and 100 μm inner diameters have been used with varying success depending on the size of the suspended crystals. Increasing the diameter to accommodate for larger crystals or to prevent clogging will quickly lead to exponentially higher sample consumption rates.

Tube Length

The experimental geometry can quickly become complicated with vacuum chambers as large as 1 m wide to support the necessary equipment to execute the experiment. This results in capillary lengths on the order of 1 m in order to have the sample injector close to the interaction region while reaching relevant sample injection equipment outside of the vacuum chamber. Making the capillaries longer is not as problematic; however, increases in length cause increases in the necessary driving pressure. Keep in mind that minor modifications in tubing diameters can give similar results to increases in tubing length; for example, going from 100 to 50 μm inner diameter has the same effect on the necessary pressure as increasing the larger tube’s length from 1 to 16 m.

Viscosity

The mother liquor’s viscosity can be one of the most important differentiators between applicable SFX jet techniques. Of the four parameters outlined to diminish the flow rate, it is the only one intrinsic to the system, while the others are externally applied parameters. The viscosity of a protein crystal slurry is not readily modified due to the effects that a change in electrochemistry might have on the quality of the crystals. Modifications of the viscosity—if possible—can lead to reductions in sample consumption. The viscosity of a solution can be quickly increased by simply adding long polymer chains of large molecular weight and glycerol [16, 17].

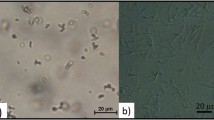

As previously outlined, the viscosity of the fluid is one of the key parameters that capture how a fluid will resist the transfer of momentum required to make a liquid jet. As the viscosity of a fluid is increased by either dissolving additives or suspending high-density particulates, there is a need to supply more potential energy (e.g., pressure) to overcome the added resistance and drive the flow. Einstein theorized [18] and Hiemenz [14] and references therein later verified experimentally, that the viscosity of a dilute solution will increase by 1 + 2.5ϕ, where φ is the volume fraction of the suspended particles (no greater than 0.02). These are empirical approximations and have since been further modeled. Probstein [19] notes that volume fractions as high as 0.1 have been used in the past. For reference, Fig. 5.4b) shows typical volume fractions of protein crystals, which are generally around 0.2 but can be higher [20]. Assuming the largest volume fraction in the dilute assumption (φ = 0.1) the viscosity increases 25% thus affecting the flow conditions accordingly.

Custom-made syringes (a) mounted on an anti-settling device near the sample chamber. The gravity vector, g, points down in all images; the syringe oscillates about a fixed radius of rotation, R, about the central black and white cross 0.17 m away (not to scale). The centerline of the syringe is parallel to the radial vector (perpendicular to the axis of rotation). Reproduced with permission of the International Union of Crystallography [20]. Lysozyme crystals in high concentration (b). The crystals on the left were resuspended just before the picture was taken, while those on the right were allowed to settle (minutes to hours); Reproduced with permission from Lomb et al. [20]. An alternative anti-settling device (c), where the centerline of the syringe is perpendicular to the radial vector (parallel to the axis of rotation). From the anti-settling device, the sample is brought into the interaction region, in vacuum, by means of a liquid jet; Reproduced with permission from Sierra et al. [21]

As an example, running a typical 50 μm inner diameter GDVN with water will give typically a minimum flow rate of 3–4 μL/min with a driving pressure of approximately 400 psi. Running a suspension of lysozyme crystals (similar to those in Fig. 5.4 with >10% volume fraction), with mother liquor of water, salt, and acetic acid through the same nozzle, causes the minimum flow rates to increase by dozens of microliters per minute and causes the driving pressure to increase as well. This increase is much more than the 25% increase we previously approximated from the dilute suspension assumption (<10% volume fraction). The slurry’s properties create different conditions at the meniscus and in the bulk fluid, resulting in higher driving pressures to overcome the resistance from the small solid crystal chunks, which periodically pass through the capillary and meniscus. The resulting liquid jet length is now significantly shorter before breaking up. The driving pressure can increase by no more than fivefold, as many of the fittings and tubings might fail past 2000 psi. This implies that a standard 50-μm inner diameter GDVN is well suited for injection of liquids with viscosity similar to water, but might struggle as soon as viscous additives and high concentrations of crystals are added.

High pressure steel fittings (withstanding up to 10,000 psi) are common commercially; however, throughout many of the injection schemes we will discuss, fused silica capillaries are common, which interface with polymer fittings and polymer tubing sleeves, which might not withstand the high pressures. Also, common pressurized gas cylinders only go up to ∼2000 psi meaning that HPLC pumps running at constant flow are the only option to drive the flow. The issue of high pressure is not insurmountable; it just requires additional design restrictions that might not be tolerable in some cases. The section on high viscosity extrusions shows how a pressure amplifier can achieve these high pressures to extrude viscous media through small fused silica capillaries. Although Johansson et al. [22] showed that more viscous media, such as lipidic sponge phase, can pass through a GDVN, this has proven quite difficult to reproduce. Therefore the GDVN can be used with lower water-like viscosities, and the High Viscosity Extrusion (HVE) method can handle higher viscosities, leaving a wide range of viscosities in between. (The MESH and double flow focusing nozzle (DFFN) sections will address this.)

An added complication with gas focused jets and viscosity is that the boundary condition necessary to focus the liquid meniscus with the gas sheath must have matching shear rates, a condition dependent on each fluid’s viscosity. The more viscous the liquid meniscus, the higher shear rate the gas must apply, again running into an upper limit of applicable gas pressure values. A normal GDVN gas sheath mass flow rate is 20 mg/min which requires a gas pressure of about 400 psi when using a 2 m long gas tubing with 100 μm inner diameter. A 5–6 times increase is tolerable (assuming a full gas cylinder of ∼2500 psig), with a higher probability of some connection failure happening before that point. The increased gas load on the vacuum chamber from the helium sheath gas might present issues for the turbo pumps or sensitive electronic equipment. This helps explain why more viscous substances will have difficulty injecting through a GDVN nozzle and why the helium sheath gas in a HVE does not focus the media and simply helps straighten the extruded media and prevent the sample from curling upon itself and the nozzle. Note that recently, a concentric flow GDVN, the dual flow focusing nozzle (DFFN) injector, was developed as a way to handle different media through a gas focused injector by focusing an intermediate fluid, such as ethanol, which in turn focuses the central fluid containing the sample [23] (as well as Sect. 5.5). A useful metric is to calculate the hydrodynamic resistance of the system, R, as defined in Eq. (5.1) in order to determine the liquid injection method best suited for a given sample. Estimate your system’s resistance and compare it to a published injection methods estimated resistance and see if your system might be compatible.

One important restriction made on the geometry by the crystals is a minimum inner diameter to accommodate the protein crystal dimensions. The 2/5 approximation seems to hold for crystals with morphologies of low aspect ratios, such as cubes, blocks, diamond, etc. as evidenced by a 20 μm filter being used on 50 μm inner diameter GDVN geometries. High aspect ratio crystals might not obey this approximation, since the long dimension might flow align and not cause the same concern. However, this should be tested prior to the experiment to ensure there are no issues of clogging. Of course, smaller, uniform crystal sizes are better for sample injection in all sample delivery methods and lead to injection more similar to flow conditions without suspended crystals. Unfortunately, crystal size and uniformity are not always controllable parameters.

5.1.1.1 Suspended Solids

Much of the work used to describe fluid flows typically considers the bulk flow with the properties of the fluid being a continuum. Typically dissolved salts and other soluble objects are assumed dilute enough to not disturb the continuum characteristics of the properties [19]. In the case of sample injection for SFX, it is inherently a two-phase flow, with solid crystals subject to the continuous fluid they are suspended in. The best crystalline suspension is one that is uniform in size and monodisperse, making the fluid behavior less erratic due to variations in size, as well as aiding in the X-ray data collection.

The Reynolds number (Re) is an important dimensionless parameter in fluid mechanics. It represents the ratio of inertial forces to viscous forces in the media. It is calculated as Re = ρUD/μ where the mass density ρ, the characteristic bulk velocity U, the characteristic length D, and dynamic viscosity μ, are properties of the fluid and the relevant physical parameters. To describe flow through a tube, the characteristic length that dictates the flow phenomena is the wetted diameter; flow over a flat plate would have the length of the plate as the characteristic length; flow around a small object suspended in a semi-infinite fluid would have the largest particle dimension as its characteristic length. Fluid flows in tubes with Reynolds numbers less than 2300 empirically move in laminar sheets and lack any turbulent effects [19] (and references therein). In the case of small particles suspended in solutions, they are typically at Re < 1 and are in a regime called creep (or Stoke’s) flow, where inertial forces are completely negligible and viscous or other forces might dominate. In this flow regime, particles can readily sediment, and they will sediment at different rates, based on their morphology, size, and their alignment with the gravitational field [14]. A particle in a parabolic flow field, typical in fully developed pipe flow, will stay on a streamline unless it diffuses out due to Brownian motion (Taylor dispersion) or some external force, such as gravity [14, 19, 24]. For reference, water flowing at 10 mm/s through a 50 μm orifice has Re = 0.5 (Q, the volumetric flow rate ∼2 μL/min); slower flows and more viscous flows will have even lower Re values. Unlike inertially dominated flows, two bodies suspended in creep flow can affect each other’s flow fields significantly; for example, two identical particles 5 diameter-lengths apart can still feel the others’ presence, whereas inertially dominated flows around a particle would return to the bulk velocity at such distances. Creep flow fields never have an increase in velocity as opposed to inertial flow fields, meaning nearby objects slow each other down; for example, objects sedimenting in creep flow near a wall settle more slowly than those away from the wall.

Unions and Filters

High viscosity and MESH injectors typically have no more than one union connecting the capillary tip at the interaction region to the sample reservoir. GDVN and DFFN injections more commonly use tubing unions. Unions rarely connect two tubings of the same inner diameter; rather it is most common to go from larger inner diameters and interface down to smaller inner diameters, such as the final size in the liquid injector. Even when connecting two of the same capillaries, the union itself has an inner diameter which might not match (e.g., common tubing unions have a 250 or 500 μm inner diameter, connecting two capillaries of 50 μm inner diameters will go from the original capillary dimension to one 5–10 times larger, and back down to the original dimension). The crystals flowing near the periphery of the larger diameter tube cannot easily cross streamlines to get into the next smaller inner diameter line, thus causing a buildup at the union interface, which quickly culminates into clogging. Taneda showed how streamlines around a corner in low Reynolds number flow can create a vortex in the corner, where particles remain trapped [25]. The interface between capillaries and unions of differing inner diameters effectively create corners for crystals to become trapped and eventually interfere with the flow of incoming crystals, and should be minimized where possible.

In order to ensure the crystal slurry does not clog the capillary it is sometimes necessary to filter the larger crystals from the slurry. Off-the-shelf stainless steel and PEEK filtration frits are common in chromatography applications to filter out particulates of different sizes, such as 2 or 20 μm cutoffs. These filters are effective for biological fluids with objects typically much smaller and more flexible able to pass through unharmed while filtering foreign particulates. However, crystals are more rigid and might not pass through these filters. Testing should be done to understand how the crystals interact with the filtration method or devise new gentler filtration methods compatible with the crystals.

Sedimentation

Except for the high viscosity injection methods, settling is one of the most prevalent problems throughout all injection techniques—given sufficient time crystals can even sediment in high viscosity media. For μm-sized crystals, it is more a matter of when, not if, the crystals will sediment. Placing a cylindrical reservoir vertically with the sample exit at the bottom seems ideal, but it will lead to an eventual clog. Most crystal slurries are in the creep flow regime, where viscous forces are left to balance the gravitational forces. Particles the size of the protein crystals reach their terminal velocity quite readily. Balancing the Stoke’s drag of a particle moving at its terminal velocity with its buoyant forces results in an equation for the particle velocity

of a particle with radius a, and the particle’s mass density ρ, suspended in a fluid with viscosity and mass density μ and ρ 0, respectively. The velocity of sedimentation helps determine when the particles have sufficiently sedimented and will likely no longer flow through appropriate flow paths. As the particle concentration at the bottom of the reservoir continues to increase, the connected capillary will ultimately clog, despite the crystal sizes being smaller than the capillary diameter. Placing the reservoir horizontally with the exit to the side avoids the issue of clogging from sedimentation, but now the sample sediments past the streamlines that will guide the crystals into the capillary entrance towards the interaction region. A standard SFX reservoir inner diameter is approximately 5 mm and it would take approximately 90 min for 1 μm sized objects to settle past the capillary entrance (at the reservoir’s midline) if it were suspended in water; 20 min for 2 μm objects (assuming an object with density similar to that of a protein ∼1.2 g/cm3).

The most commonly used method to prevent sedimentation in the sample reservoirs is to rotate the reservoirs in order to modify the direction of the gravity vector. Lomb et al. [20] has shown an approach where the sample is loaded into syringe-like reservoirs and rotated. There have been some modifications made to the technique, but the basic idea of rotating the sample slowly back and forth has been used frequently in SFX experiments. It is not an infallible approach and should be tested prior to the experiment to ensure the crystal morphologies and the properties of the fluids are properly matched to the rotation speeds and frequencies of the sample shaker. Recall, it is a device to slow the sedimentation and not resuspend it. Once the particles are settled, the properties of the creep flow regime make it difficult to resuspend them by shaking or moving the plunger back and forth. Properties of laminar flow mean that the particles will flow back and forth to the same position along the same streamlines and require turbulence or mixing or some other external force to homogeneously redistribute them. This is the same physical phenomena that explains why microscopic spermatazoa swim with cork screw tail motions instead of the back and forth motion typical in humans and fish swimming at the macroscale [26].

Key Takeaways

-

The crystal slurry dominates the flow physics

-

Particle size sets minimum capillary diameters (<2/5 capillary diameter)

-

Fourth order dependence on transport tube inner diameter can increase flow rates too much, setting upper and lower size limits

-

The viscosity of the mother liquor combined with the increased viscosity caused by the suspended particles means sample fluids in capillaries are more viscous than expected

-

-

Flows are typically laminar and dominated by viscous forces rather than inertial; diffusion and viscosity limited, no turbulence.

-

Settling affects numerous sample delivery methods and can be a detriment to experiments.

-

In vacuum experiments have an intrinsic minimum pressure gradient not present at ambient pressure.

-

Although not discussed in the chapter, proper microfluidic hygiene is important

-

Smooth perpendicular cuts to tubes and capillaries

-

Minimize flow impedances

-

Prime bubbles out of the lines, as trapped gasses can be large flow capacitances

-

Resistances such as too many unions, or small flow restrictions should be minimized

-

Minimize swept, or dead, volumes to conserve sample.

-

-

-

There is no substitute for testing and characterizing the experiment as faithfully as possible, that is, injection tests with the actual crystalline samples, if possible, in the actual vacuum chamber in front of an X-ray source will minimize surprises during the beam time. Successfully delivering just the mother liquor in air or rough vacuum is a good start but can be misleading compared to [the actual] sample slurry.

5.2 Standard Liquid Injectors

In Serial Femtosecond Crystallography, every nanocrystal that is hit by an X-ray pulse is destroyed by the interaction that deposits a lot of energy in a small volume. Most of the requirements on SFX sample delivery listed in the overview can be fulfilled with a liquid jet injector. A microscopic liquid jet can be obtained in the simplest way by discharging a liquid through an orifice at high liquid pressure. A continuous liquid jet emerges, with a diameter identical to the orifice diameter (Rayleigh jet) [27], which breaks up into droplets due to capillary forces. The droplets have a diameter of about twice the jet diameter and an average spacing of 4.5 times the orifice diameter [28]. In X-ray FEL experiments with liquid jets, the X-ray pulses hit the liquid stream ideally before it breaks up into droplets to assure a high efficiency (every X-ray pulse hits the liquid). However, Rayleigh jets have a few disadvantages: high flow rate (0.4–7 mL/min) and high jet speed (100 m/s), large jet diameter (10–100 μm), susceptibility to clogging for smaller orifice diameter (especially when the liquid contains protein crystals) and susceptibility to freezing in vacuum when the flow is interrupted. The liquid jet diameter for serial femtosecond crystallography should ideally be similar to the X-ray beam diameter, which is between 10 μm and 0.1 μm at LCLS for example. Liquid jets of such diameter cannot be obtained with a Rayleigh jet nozzle due to clogging issues.

These issues have been solved with the Gas Dynamic Virtual Nozzle (GDVN). This nozzle was developed based on the observation that shear and pressure forces of a sheath gas can reduce the diameter of a liquid jet to a value smaller than the orifice diameter [13, 29]. GDVN nozzles generate a liquid stream of micron to submicron diameter with flow speeds of 10–100 m/s at flow rates of 1–20 μL/min. They consist of an inner sample capillary with typically 40–75 μm inner diameter, and an outer gas capillary that provides a co-flowing gas stream that accelerates the liquid and thereby reduces the diameter of the stream (see Fig. 5.5).

Schematic view of GDVN. The end of the nozzle is beveled to allow diffracted X-rays (the red cone) to reach the detector. Green lines are gas streamlines, which accelerate and compress the liquid to produce a small jet from a larger orifice. Blue is the liquid containing protein microcrystals. The X-ray FEL pulses hit the liquid jet before it breaks up into droplets

The acceleration and reduction in jet diameter occurs over a very short distance at the exit aperture of the nozzle. The liquid microjet breaks eventually up into droplets due to the Rayleigh–Plateau instability [27]. The diameter of the liquid jet is reduced by a factor of 10–50 compared to the inner diameter of the sample capillary. Any particle which is smaller than the sample capillary inner diameter but larger than the jet diameter (e.g., a large crystal) will simply pass through the system and only momentarily disrupt the jet, that is, the nozzle does not clog as easily as a physical nozzle of a size similar to the GDVN jet size. The inner sample capillary is centered in the outer gas tube by laser-cut Kapton spacers. The mass flow rate of the co-flowing gas stream is 20–30 mg/min and the sheath gas used is typically Helium or Nitrogen, where the use of Helium usually results in a more reliable jet. Due to the low viscosity of the mother liquor used to grow most protein crystals, microcrystals settle in the liquid due to gravity, and therefore an anti-settling device [30], as discussed in the previous section, is required for SFX to slowly rotate the sample reservoir and prevent settling.

The X-ray beam is focused onto the contiguous part of the jet, before the droplet breakup, usually 100–200 μm away from the nozzle exit. The background scattering from the contiguous jet is lower than from the droplets, since the droplets have about twice the diameter of the jet. Scattering from the cylindrical shape of the jet leads to a streak in the diffraction pattern at low spatial frequencies if the X-ray beam is not significantly smaller than the jet.

The outside of the GDVN is beveled at the end to avoid shadowing of the diffracted X-rays. The gas focusing aperture is formed by flame polishing and variations in shape and size between different nozzles are almost unavoidable. For the liquid jet to emerge aligned with the axis of the GDVN, the sample capillary must be accurately centered on the axis of the gas-focusing aperture. To make centering easier, a square outer glass tube may be used [31] for automatic centering of the round sample capillary. But even in this case, the flame polishing procedure may not result in a gas aperture hole which is exactly on the center axis of the square glass tube. These manufacturing difficulties led to the introduction of 3D printed GDVN nozzles [32]. A high resolution two-photon 3D printer is used to print the critical GDVN endpiece with high precision at a resolution of 500 nm, and a liquid and gas capillary are glued into the 3D printed part (see Fig. 5.6 and Fig. 5.7). A key advantage of 3D printing technology is that more complicated shapes can be printed (e.g., mixing nozzles [33] or double flow focusing nozzles [23]) as will be discussed further in this chapter.

3D printed nozzles: left: this design requires a micromanipulator and mounting stage to glue the capillary into the printed nozzle tip. Right: the new design is easier to attach to the gas and liquid capillaries. Grey: Steel or Glass, light brown: printed material, dark brown: polyimide-coated glass capillary, blue: epoxy

GDVN jets can be used at atmospheric pressure and in a vacuum environment. Using the GDVN in a vacuum environment can create challenges: High vacuum can be easily maintained in the presence of a microscopic liquid Rayleigh jet [11], but the focusing gas introduced into the vacuum raises the base pressure of the experimental chamber. Therefore, a differential pumping system is used, for example, at the Coherent X-ray Imaging (CXI) endstation at LCLS to protect the high vacuum system and the beamline optics and X-ray detector. The GDVN is mounted on a nozzle rod in a differential pumping shroud, which contains several openings for cameras and pump lasers for pump probe experiments. The nozzle rod can be retracted behind a gate valve and removed from the vacuum system for nozzle changes. Several motorized stages allow alignment of the nozzle relative to the X-ray beam [34]. An initially installed in-vacuum microscope for nozzle observation [34] has since been replaced by an optical system (microscope objective and transfer lens in vacuum), which allows the use of more sophisticated cameras outside the vacuum chamber. This allowed the use of high-speed cameras or stroboscopic recording modes to visualize the damage inflicted onto the jet during X-ray exposures [2].

GDVNs have been successfully used in many SFX and Wide Angle X-ray Scattering (WAXS) experiments at LCLS and SACLA, as well as in electroflow-focusing mode to aerosolize single particle samples in an aerodynamic lens system (as shown in Fig. 5.3) [35]. The flow rate and jet speed of the GDVN is not optimized for the X-ray pulse repetition rates of SACLA or LCLS: at 120 Hz repetition rate and 10 m/s jet speed, the distance that the jet travels between two pulses is about 8 cm. This means most of the sample goes to waste in between pulses. This is unacceptable for many membrane proteins which can only be expressed in small quantities. Therefore, other injection methods have been explored which consume less sample, as will be described in the following chapters. For future high repetition rate X-ray FELs, sample waste with the GDVN is not expected to be a problem. At the European XFEL with bunch trains arriving at 10 Hz, where the pulse repetition rate within each bunch is 4.5 MHz, it remains to be seen if the GDVN jet speed is even fast enough to keep up with the high repetition rate pulses. This is especially a problem if shock waves from the sample explosion travel upstream in the jet and cause additional damage [2]. At LCLS-II, with a sustained repetition rate of 1 MHz, the jet speed seems to be perfectly matched to make use of the entire sample with minimal waste. This however presents a new challenge with sample debris. Currently, for a GDVN, most of the sample collects in a catcher away from the interaction region. With a high intensity, high repetition rate X-ray FEL beam, most of the sample will be vaporized by the beam, no longer collecting in a catcher away from the interaction region but rather rapidly coating every surface close to the interaction region, including the nozzle tip. The extent to which debris will be a problem with high repetition rate machines remains to be seen. Sample consumption with the GDVN can be reduced by a factor of about eight by using a double flow focusing nozzle [23], where the sample flow can be reduced by a second focusing liquid, before gas focusing occurs (see Sect. 5.5).

5.3 High Viscosity Injectors

In recent years, protein crystallization in lipidic cubic phase (LCP) has led to structures of many important human membrane proteins, which are highly important and the subject of Chaps. 4 and 11 of this book. The desire to stream protein crystals in LCP into the X-ray FEL beam for SFX led to the development of the high viscosity injector. LCP has a viscosity comparable to car grease or tooth paste (dynamic viscosity of ∼48.3 Pa·s [36] compared to water at 8.9 × 10−4 Pa·s and Ethanol at 1.1 × 10−3 Pa·s) and thus cannot be used with a GDVN, since the long sample capillary with an inner diameter of tens of microns would require impractically high pressures to make the liquid flow. Therefore, a new injector had to be designed that uses only a very short sample capillary and a hydraulic stage to achieve the high pressure needed to drive the sample through this capillary. Figure 5.8 shows a schematic of one version of an LCP or high viscosity injector.

High viscosity injector. It consists of a hydraulic stage, which is pressurized by an HPLC pump. The piston pressurizes the sample in the reservoir and drives it through the capillary. The ceramic nozzle ensures that sheath gas surrounds the extruded high viscosity material and keeps the flow on axis

An HPLC pump supplies water at constant flow rate and moves a plunger in a syringe body. The plunger has a large diameter on the water side and a smaller diameter on the sample side, where it applies pressure on a Teflon ball. The ratio of the two plunger diameters equals the pressure amplification of the hydraulic stage. The Teflon ball acts as a secondary plunger, it is sitting in the reservoir bore, which has a slightly smaller inner diameter then the ball diameter, thus forming a tight seal against pressures up to 15,000 psi. The LCP sample is pushed by the Teflon ball from the reservoir into a capillary with a diameter of 20 to 50 μm, selected depending on crystal size. An LCP stream emerges at the distal end of the capillary (Fig. 5.9). Different reservoir sizes can be made, for example: 25, 40 and 120 μL.

The diameter of the extruded stream is identical to the capillary inner diameter. To keep the stream straight and on axis, a co-flowing gas is surrounding the stream. The distal end of the capillary is ground in a conical shape and protrudes out of the gas aperture, which has a square inner diameter and opening to allow a path for the sheath gas (see Fig. 5.10). A ceramic injection molded gas aperture is used, which has a more reproducible shape and longer life than the previously used hand melted glass tubes [37]. The high viscosity of LCP prevents crystal settling due to gravity on the time scales of a measurement. The sample flow rate can be adjusted and optimized for the X-ray FEL pulse repetition rate, so that the stream advances only the distance needed to replenish the damaged material from the last pulse.

Unlike in the GDVN, the LCP stream cannot be focused down to a smaller diameter by the sheath gas. However, another high viscosity medium does allow a reduction of the stream diameter by shear forces from the sheath gas, as seen in Fig. 5.11 for PEO, a gel polymer of high-molecular-weight poly(ethylene oxide). The PEO stream, which shows already reduced background scattering compared to LCP [38] (by a factor of about 1.5 in the diffuse ring region), can be reduced in diameter from initially 50 μm to about 20 μm, which reduces scattering background further. PEO extrusion works best at ambient pressure, for example at the MFX beamline at LCLS or the DAPHNIS endstation at SACLA [39] and at Synchrotrons. It is particularly hard to start a stream of PEO with the high viscosity injector, since PEO is very sticky and tends to ball up at the end of the nozzle. Once started, though, the PEO stream runs very reliably if the sample does not contain any gas bubbles. Injection of short bursts of isopropanol into the gas line with a switching valve to remove PEO accumulation at the nozzle tip makes starting the stream much easier. Using a mass flow meter in the gas line also helps to find the correct gas flow for proper operation.

PEO extrusion with high viscosity injector into ambient pressure. Nitrogen sheath gas exits the nozzle surrounding the capillary cone, which is protruding out of the ceramic gas aperture. Left: mass flow rate of sheath gas (Nitrogen): 5 mg/min. Right: mass flow rate of sheath gas (Nitrogen): 15 mg/min. Same liquid flow rate in both images: 90 nL/min

Other high viscosity media for crystal embedding have been developed (e.g., hydrophobic media like grease [40] and Vaseline [41]) which form emulsions with crystals in small droplets of mother liquor. These carrier media however produce high background scattering and are often incompatible with membrane proteins. Hydrophilic viscous carrier media do not have these disadvantages, and several have been described: agarose [42], hyaluronic acid [43], and two hydrophilic gelling polymers [44].

The high viscosity injector uses sample much more economically: the flow rate of the microjet from a GDVN is usually 10–30 μL/min, whereas the sample flow rate with the high viscosity injector can be adjusted from 0.01 to 2 μL/min. This means that sample consumption is greatly reduced compared to GDVN injection. This is highly desirable for samples like G-Protein Coupled Receptors (GPCRs) which can only be expressed in small quantities. There is an increase in stream diameter compared to the GDVN, but the drastic reduction in flow speed from 10 m/s with the GDVN to ∼2 mm/s with the LCP injector leads nevertheless to a large reduction in sample consumption.

Several GPCR crystal structures have been solved by SFX in LCP using the high viscosity injector, for example the human Smoothened (SMO) receptor in complex with cyclopamine [45], the angiotensin receptor [46], the human δ-opioid receptor [47] and rhodopsin bound to arrestin [48] and the human glucagon receptor. Pump probe experiments with bacteriorhodpsin crystals in an LCP stream have been performed [49] as well as native phasing measurements on human A2A adenosine receptor, which after phase extension lead to a 1.9 Å structure [50]. Microcrystals of soluble proteins have been mixed into LCP and used with the high viscosity injector for structure solutions [51]. For LCP SFX experiments in vacuum, as at the LCLS CXI instrument, extra measures must be taken to prevent a phase change of monolein LCP into a lamellar phase due to water loss by desiccation and temperature reduction due to evaporative cooling. This would lead to strong diffraction rings which mask weak Bragg reflections. To that end, a shorter chain length lipid can be added to the LCP post crystallization [45] which lowers the phase transition temperature.

Serial crystallography experiments with high viscosity micro streams can also be done at synchrotron sources, albeit without the dramatic reduction in radiation damage possible at XFELs. Fast detectors allow shutterless data collection from a stream of microcrystals in its LCP growth medium with 20–100 ms exposure times. The extrusion speed of the sample and exposure time can be adjusted depending on the flux of the beamline to allow for full exposure of each crystal to the damage limit at room temperature. Serial Millisecond Crystallography has been demonstrated successfully at the Advanced Photon Source [38], the Swiss Light Source [41] and the European Synchrotron Radiation Facility [52].

5.4 The Microfluidic Electrokinetic Sample Holder

Mating the protein crystal suspension with a type of sample delivery method is one of the most critical aspects to successfully execute an experiment at an X-ray FEL. A major concern in SFX is sample consumption, since many proteins cannot be readily crystallized in arbitrary quantities. In 2009, Chapman and Seibert et al.’s [3, 4] first biological experiments at an X-ray FEL were limited to soft X-rays (<2 keV) and thus required a vacuum sample environment and the low solvent background and sample replenishment of a thin liquid jet or a solvent-less aerosol injector. To address the issue of higher sample consumptions, the microfluidic electrokinetic sample holding (MESH) technique was developed in 2011, where instead of accelerating the meniscus with aerodynamic or hydrodynamic forces, electrokinetic forces are employed. A room temperature structure of thermolysin was originally solved to better than 4 Å [53], demonstrating the MESH technique, but as better data analysis algorithms were developed, the same data could be used to extend the resolution to 2.1 Å [54]. The MESH was successfully used to solve room temperature structures of photosystem II [55,56,57], demonstrate minimal electronic structure changes caused by high intensity X-ray FEL pulses by collecting simultaneous X-ray emission spectra and diffraction [58, 59], collect X-ray emission spectra in the soft X-ray regime [60,61,62], and collect novel structures on nanocrystals [63]. In all of these experiments, the mother liquor was doped in order for the crystals to survive the vacuum injection. The capillary geometries varied from 50 to 100 μm, with the flow rate not exceeding 3 μL/min, and in good running conditions, having flow rates in the sub-microliter per minute regime.

The following sections will explain how to use the MESH technique to deliver sample for in-vacuum SFX experiments. After discussing the MESH, a new method involving a concentric flow that keeps the low flow rate and allows the MESH technique to be applied to a broader range of fluid conditions will be discussed. The chapter concludes with a discussion on how a technique like the MESH and its variants fit into the grander scheme of a suite of sample delivery techniques available for SFX.

5.4.1 The Microfluidic Electrokinetic Sample Holder

The main difference between the MESH injection and other SFX injection methods is the way it supplies energy to the microfluidic system: an applied voltage rather than applied pressures. The microfluidic electrokinetic sample holder (MESH) technique is physically identical to electrospraying or electrospinning techniques [64]; however, the MESH technique is interested in the thin liquid jet created after the Taylor cone but before the eponymous spray or spun filaments typical of the other techniques. The applied voltage causes any free charge in the solution, typically solvated ions, to migrate towards or away from the voltage source, subject to the polarities. A net excess charge builds at the exposed meniscus, which continues to repel from the like-charged voltage source. Once the applied voltage potential is high enough to overcome the opposing surface tension and viscous forces, fluid is ejected from the meniscus. A balance in flow rate and applied potential will then cause the meniscus to achieve different states, such as a dripping mode, the cone-jet mode, or the multiple jet modes (listed in order of increasing voltage, for a fixed flow rate).

The ability to eject charged particles is the real power of the MESH technique. Most biological fluids have free ions in solution and will respond to an externally applied voltage. The range of tubing and fluid properties typical in SFX experiments leads to currents at, and typically below, the μA range. Considering Faraday’s constant (∼96,485 C/mol), a fluid with 100 mM ionic strength operating in MESH conditions at 1 μA is ejecting 1 pmol of charged particles per second or consuming approximately 6 nL/min. Therefore, once a flow rate and voltage are found to stably create a cone-jet Taylor cone, there is minimal additional cost in sample consumption by the electrokinetics. The applied voltage focuses the meniscus and creates a thin liquid stream, but it minimally affects the fluid’s flow rate, or the sample consumption.

The GDVN partially mitigates freezing in vacuum by always running a sheath gas, which accelerates the meniscus to make a jet and keeps the fluid at ambient temperature [13, 65]. To run the MESH in vacuum, the crystal slurry must be doped with a cryoprotectant, such as 40% glycerol [53]. The addition of glycerol interferes with the fluid’s properties such that it will not evaporate and freeze or precipitate in vacuum. Typical—not all—additives tend to also increase the viscosity and alter other fluid properties, such as density and surface tension, which aid in reducing the flow speed as well as maintaining a homogeneous protein crystal suspension for longer.

5.4.1.1 Charging the System

To create a MESH injection from the free surface of a liquid drop at the end of a capillary, an electric field must be present across the meniscus. The free ions in the solution will begin to accumulate and will slowly begin to be repelled from one another, because of their like charges, until they can overcome the surface tension and viscous forces holding them together as a liquid meniscus. Eventually, the meniscus will go from a hanging drop to the more familiar Taylor cone shape. A stable cone-jet mode passing protein crystals from the reservoir, through the capillary to the thin jet filament, and finally probed by photons is essentially the MESH technique.

In order to create this electric field, the meniscus can be placed between two charged electrodes, or a charged and grounded electrode. In the case of the MESH injector, the fluid is charged at its reservoir. This is intentionally done to avoid unwanted voltage arcs to discharge from charged metal towards sensitive scientific equipment in the sample chamber (e.g., detectors or motors). The difference between charging at the tip and creating an external electric field, versus charging within the fluid and having the meniscus create the electric field, are subtle but very important to understanding the operation of the MESH technique and its shortcomings.

5.4.1.2 Creating the Driving Electric Field

The charged fluid in the capillary acts like a conductive wire, where the fluid is poorly conducting and the fused silica and polyamide coating of the outer capillary walls insulate the charge. In order for the MESH technique to work properly, all charge must be contained in the capillary and reservoir and allowed only to escape through the meniscus via the leaky capacitor of the cone-jet physics.

At the meniscus, it should be the charge buildup that ejects charge via the cone-jet physics. If charge is taken away from the meniscus by the local atmosphere, this will prevent sufficient charge to buildup and MESH jetting will not be observed. MESH operation has been observed in air at ambient pressure, but below (<∼200 Torr) ceased to operate until the vacuum pressure was sufficiently low (<5 × 10−2 Torr), where it would begin to form a cone-jet again [53].

When the meniscus is the source of the electric field, any changes in the electrical properties of the meniscus create a varying electric field as non-conductive phases, such as the protein crystals, pass by. The ionizing X-rays can also affect the field if shot too deep in the meniscus. Even the vacuum dehydrating the meniscus can play a role in disrupting the local electrokinetics of the meniscus. A shortcoming of charging the reservoir is that any bubbles trapped in the sample capillary line, even small bubbles that do not fill the full diameter, severely hinder or completely stop the transfer of charge. The air bubble can act like an infinite resistor and will prevent the Taylor cone from forming, while the vacuum continues to draw in fluid as a large droplet; so crystal slurries should be bubble free for best injection.

5.4.1.3 A Poorly Conducting Wire

The fluid-filled capillary can be treated as a wire with a known resistance that increases linearly with length, and inversely with both the cross sectional area and the conductivity. For commonly used fluid conductivities, through a meter-long, 50 μm capillary, resistances [typically] vary from 0.1 to 10 GΩ. The flow of ions typically have the MESH operating in the 100s of nA regime. These values indicate that no more than a few hundred volts can be dropped across the length of the capillary; however, if higher viscosity fluids are used, which diminish the conductivity as charge cannot easily move, then higher driving voltages might be needed to account for the high resistance of the line. Currents much higher than this are indicative of a charge leak, which can severely diminish the functionality of the MESH injection.

Since the crystal solution is conductive, there can be no internal electric fields, as the free ions will quickly move to shield any unbalanced charge. The structures determined using MESH thus far have not shown any differences between their MESH and conventionally-determined structures. Voltage-sensitive structures would potentially be affected by the electrokinetics of the MESH; recent [unpublished] data has suggested further studies are necessary. To date, there are no apparent adverse effects on structures by applying voltages typical of the MESH technique.

To properly MESH, a non-conductive tubing, such as fused silica capillary or polymer tubing, and a counter electrode is needed. The droplet exiting the capillary will wet upwards along the outside of the capillary if the closest grounding sources are the polymer fittings and mounting material holding the capillary into vacuum. The capillary should protrude at least 1 mm away from these to minimize external wetting. Note that if the capillary is protruding too much, the capillary starts to oscillate from the downstream spinning process. Everything in the MESH geometry should be a polymer or a non-conducting material except for the charging material. Any excess buildup of liquid, or fluids that wet backwards towards the sleeves and fittings can disrupt the field or cause a current leak.

The next sections will discuss counter electrode designs that will draw the charged meniscus in the correct direction for the experiment.

5.4.1.4 Counter Electrode Design

Counter electrode (CE) design and function are very important to the MESH injection. Aside from the need to dope the fluid for vacuum injection, the counter electrode design considerations differentiate MESH injection from standard electrospray and electrospin techniques. A counter electrode close to the meniscus will give a high driving electric field, but it might interfere with the diffraction data. The shape should promote a homogeneous electric field like those between two parallel plates, yet precipitates from the sample can buildup and interfere with the electric field and ultimately grow back into the interaction region.

Typically, MESH injection charges the fluid and leaves the counter electrode at earth ground. However, the counter electrode can be charged and the fluid left grounded and the familiar Taylor cone will form (likely at different voltages). The ions in the fluid will collect at the meniscus and mirror the charges at the counter electrode. Eventually they will build up enough charge to begin to repel themselves and begin the Taylor cone phenomenon again. However, it is strongly recommended that the counter electrode be simply connected to earth ground rather than charged via a bias voltage because it is more dangerous to electrify the counter electrode the higher density of “free” electrons in metals. Copper, assuming one free electron per copper atom, has a [charge] density of over 13,000 C/mL whereas a fluid with 100 mM ionic strength has barely 10 C of ions per mL. Consequently, the metal in vacuum can readily discharge three orders of magnitude more charges than a typical MESH fluid of the same volume but this is not a concern when the counter electrode is properly grounded instead.

5.4.1.5 Counter Electrode Geometries

An ideal geometry for the counter electrode is one that creates straight electric field lines from the meniscus to the counter electrode, much like those between two plates in a parallel plate capacitor, but is impractical to implement. Instead, a counter electrode with a hole to allow the ejected, non-ionized mass through with proper spacing to create a sufficient electric field while not shadowing the diffraction detector is necessary. The distance of the counter electrode for the MESH injection is typically at least 5 mm, depending on the radius of the counter electrode. The counter electrode should be the closest conductive object to the capillary tip. A smaller hole is ideal for straight field lines from the meniscus (ideally a point source of charge), but the small opening can quickly build up debris and strengthen the field towards mass buildup, leading to injection failure. Nominally, the opening size in the CE is of the same order as the spacing from the capillary tip, typically 5–10 mm. Figure 5.12 shows different iterations of CE geometries used in atmospheric and vacuum conditions.

Different counter electrode geometries used for MESH injections. (clockwise) conical with flat and large hole (capillary visible above the hole); flat surface with hole (stainless steel optical post; capillary above hole); 2 mm pointed stainless steel pin (protein debris deposited on electrode after injection); thin-walled conical stainless steel with hole (deposited polymer and protein debris buildup visible); flat stainless steel with hole (MESH-on-a-stick geometry); copper wire loop. For scale, capillaries are 360 μm outer diameter, standard PEEK fittings are for 1/16” OD tubing, optical post hole is tapped 1/4”–20 (in top middle image)

5.4.1.6 Sample Reservoirs

The preferred reservoir for MESH injection is a pressure-driven vessel. This method was described in Sierra et al. [53] and can be seen in Fig. 5.13. Here an open centrifuge vial is loaded with the 0.1–1 mL of sample and into an acrylic pressure vessel. The vessel is pressurized with an inert gas (<∼100 psig), such as compressed air or nitrogen, while the capillary and a charging wire are submerged into the fluids like straws. The advantage of this technique is the simplicity of the sample loading as it uses common centrifuge vials. The plastic acrylic housing is adapted from an electrospray aerosol generator (Model 3480, TSI) and easily screws open to hold the reservoir and interface the capillary and wire. A steel nut on the lid of the acrylic housing has a platinum wire soldered to the bottom that is long enough to reach the bottom of the vial; the high voltage is connected to the outside of the nut, which in turn charges the submerged wire and the fluid. With the capillary submerged to the bottom of the vial, there is less concern with settling and clogging, as the sample is drawn in, as opposed to being forced in with other reservoirs. In this setup, there is a possibility for the sample to settle and become so concentrated that the fluid may continue to enter the capillary while the crystals aggregate and form a filter-like structure that prevent further crystals from entering.

A schematic of the modified pressure reservoir used for typical MESH injections, with actual picture inset. The pink centrifuge vial holds the sample and is held in place by the bottom of the acrylic housing. A Swagelok adapter with appropriate polymer tubing sleeve (green in photo) allows a capillary to be submerged into the vial, while maintaining pressure. A platinum wire electrically connected to the Swagelok fitting is also submerged into the vial

It’s important to recall that many fundamental fluid mechanics equations assume a homogenous fluid or dilute solutions. In the case of SFX sample delivery, homogeneity is not always a luxury. Growing the crystals in large batches rarely produces identical crystals. Even if the crystals are identical in size and morphology they are suspended in the solution as opposed to solvated in a solution. This contrast from a solid object to a liquid media makes a difference in injection behavior. The solid objects passing through a meniscus provide enough disruption that the Rayleigh breakup of the liquid jet comes sooner than the breakup of a pure liquid jet. It is important to recognize these potential differences and understand that testing simply the mother liquor without suspended crystals is not enough to guarantee a jetting success as the bulk fluid slurry will behave like a more viscous media and need typically higher parameters to create an equivalent jet of pure fluid. Homogeneity is also a problem with viscous injection methods where insufficient mixing to create the media can create pockets of low and high viscosity causing running instabilities and erratic sample consumption. Many times the difference between a jet running mother liquor and a slurry carrying protein crystals can be evident from optical imaging; however, the jet behavior can be more telling. If the jet’s behavior at the interaction region begins to stabilize and improve it is likely too good to be true: the crystals are no longer flowing and obstructing the meniscus. A later section discusses the effects these suspended solids had on the design of the MESH injection method.