Abstract

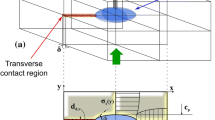

Previous sintering models (4), (6) that attempted to calculate the shrinkage rates associated with atom fluxes from grain boundary to neck have treated volume diffusion and grain boundary diffusion separately. In the present model the uniform shrinkage condition at the grain boundary is applied to the sum of the volume and grain boundary fluxes rather than to each flux separately. The assumption of the earlier models that each flux provided uniform shrinkage at the grain boundary cannot be justified on physical grounds. The present model also differs from previous ones in that the surface curvature of the neck surface is inserted in the problem in functional form; by this we mean that correct account is taken of the way in which surface curvature varies at the neck region. The ability to insert an arbitrary form and value for the surface curvature give this proposed solution a good deal of flexibility.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

R.L. Eadie, D.S. Wilkinson, and G.C. Weatherly, Acta Met., 22, 1185, (1974).

B.H. Alexander and R.W. Balluffi, Acta Met., 5, 666, (1957).

C. Herring, “The Physics of Powder Metallurgy”, Chap. 8, McGraw Hill, (1951).

D.L. Johnson, J.Appl.Phys., 40, 192, (1969).

M.F. Ashby, Acta Met., 22, 275, (1974).

T.L. Wilson and P.G. Shewmon, Trans. Met. Soc. A.I.M.E., 236, 48, (1966).

R.L. Coble, J. Appl. Physics, 32, 787, (1961).

R.L. Eadie and G.C. Weatherly, Scripta Met., 9, 285, (1975).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1975 Plenum Press, New York

About this chapter

Cite this chapter

Eadie, R.L., Weatherly, G.C. (1975). Contributions of Grain Boundary and Volume Diffusion to Shrinkage Rates during Sintering. In: Kuczynski, G.C. (eds) Sintering and Catalysis. Materials Science Research, vol 10. Springer, Boston, MA. https://doi.org/10.1007/978-1-4684-0934-5_16

Download citation

DOI: https://doi.org/10.1007/978-1-4684-0934-5_16

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4684-0936-9

Online ISBN: 978-1-4684-0934-5

eBook Packages: Springer Book Archive