Abstract

Fish oil extraction is usually carried out using mechanical means because of the need to preserve the biochemical composition of the lipids and maintain the quality of the residual solid. The present chapter deals with the use of DIC to intensify fish oil extraction by pressing. This study considers the extraction of Atlantic mackerel fillets, given the importance of this species from a nutritional point of view and its capacity to compensate for theω-6/ω-3 ratio required for the human diet. We propose to include DIC technology as part of the well-established wet rendering method as a pretreatment before pressing, instead of the standard steam cooker treatment. The inclusion of DIC reduced thermal treatment time from the 15/20 min required with traditional cooking to 20 s, with equivalent or even superior pressing extraction yields and consequently a higher quality of the residual solid product.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

This chapter is based on the results of the project “Transfer and industrialization of Instant Controlled Pressure Drop (DIC) in the field of fish oil pressing.” This project was the basis for a patent, with AZTI-Tecnalia, ABCAR-DIC PROCESS and ULR/LMTAI as the co-owners.

1.1 Fish Oil

1.1.1 Importance of Fish Oil

Unsaturated fatty acids are classified according to the position of the first double bond from the methyl end: between C9 and C10 for ω-9, C6 and C7 for ω-6, and between C3 and C4 for ω-3. The fatty acids of the ω-6 series are linoleic acid (LA; 18:2 ω-6) and arachidonic acid (AA; 20:4 ω-6), with two and four unsaturations, respectively. Fatty acids of the ω-3 series comprise alpha-linolenic acid (ALA; 18:3 ω-3) and the long chain polyunsaturated fatty acids (PUFAs) eicosapentaenoic acid (EPA; 20:5 ω-3) and docosahexaenoic acid (DHA; 22:6 ω-3). A competitive interaction exists whereby fatty acids of the 18:3 ω-3 family suppress the metabolism of the 18:2 ω-6 family, and vice versa.

Fish oil is an excellent source of ω-3, which differs from the oils found in plants in terms of its long chain EPA and DHA, and these have very important physiological roles in growth, reproduction, and brain and eye functions (Murayama et al. 2002). They are also important in preventing certain cancers (Roynette et al. 2004) and decreasing the risk of cardiovascular diseases (Schmidt et al. 2005), depression (Timonen et al. 2004), immune disorders, and others (Bilo and Gans 1990). Furthermore, a large proportion of PUFAs from seed and vegetal oils are of the ω-6 series. Today, the elevated levels of this kind of fatty acid in the human diet mean that fish and fish oil have become the most valuable sources for achieving the ω-6/ω-3 ratio required in our diet.

1.1.2 Quality Guidelines

The most important problem associated with fish oil is rancidity. The high degree of unsaturation of the fatty acids in fish oil means this product is prone to rancidity reactions, which can occur before, during, and after extraction. High temperatures, long cooking times, and metal contaminants favor fast decomposition of the oil.

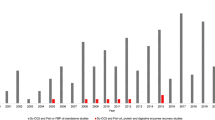

The hydrolysis of triglycerides liberates fatty acids, which are more prone to oxidation than when esterified with a glycerol molecule. Crude oils with free fatty acid (FFA) contents above 10 % are to be regarded as spoiled and, in most cases, are no longer suitable for use in the food industry as they are difficult to refine. The peroxide value (PV) is related to the primary oxidation products, and the anisidine value (AV) is related to secondary oxidation products. Values of PV and AV higher than 10 mEq/kg and 10, respectively, in the crude oil are typical of a high oxidation level, conferring poor flavor stability on the final product.

The food and pharmaceutical industries are increasingly coming under pressure to meet the requirements of the high-quality standards and to reduce their prices, given the internationalization of the market. They must also comply with constraints imposed to safeguard the environment such as a quantitative and qualitative reduction of waste and energy consumption.

1.2 State-of-the-Art Fish Oil Extraction

Fish is composed of three major fractions: solids (fat-free dry matter), oil, and water. The purpose of fish meal and oil processing is to separate these parts from each other.

1.2.1 Current Methods for Fish Oil Extraction

There are different methods employed in fish oil extraction. We can divide them into two main groups: traditional methods widely employed in factories and new methods with a promising future in the fish oil industry. Numerous papers have been published on this topic but the results have scarcely filtered to the industrial scale.

In the traditional methods, the main steps of the physical processes are: cooking to free the bound water and oil; separation of the solid phase (press cake) and the liquid phase containing water and oil; and recovering oil and solids by successive decantation centrifugation. A final drying and grinding stage can be carried out to recover the remaining solid.

New extraction techniques such as supercritical fluid extraction (SCFE) are more often employed to concentrate ω-3 fatty acids from a mixture of fatty acids (Dunford et al. 1997; Catchpole et al. 2000; Alkio et al. 2000) than to obtain fish oil directly from the structural matrix of fish. The usual approach in these cases is to extract oil from fish using conventional methods, hydrolyze the fatty acids, and esterify them before performing a CO2-SCFE.

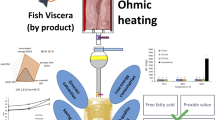

The wet rendering method is the method commonly used at the industrial scale. Most crude oil marketed around the world is fish body oil derived from pressing cooked fish. The process involves first cooking the fish to coagulate the protein and release the bound water and oil. This is followed by pressing to separate the solids from the liquids. The solid material is further dried and then milled to fish meal, and the oil is separated from the liquids by centrifugation (Fig. 1).

Fish meal and fish oil yields can vary depending on the fish species and even from season to season, but typically around 17–22 % fish meal and 5–15 % fish oil will be obtained by processing.

Once the fish is landed, operations to obtain fish oil can be resumed in three main steps:

-

1.

Cooking: the raw fish is passed through a steam-heated continuous cooker, where it is commonly heated to 95–100 °C within 15–20 min. This sterilizes the fish, coagulates the proteins, and disrupts the cell membranes to facilitate the separation of the liquid from the dry matter. Heat is transferred indirectly by a steam-heated surrounding jacket and a heated screw conveyer, which transports the fish material through the cooker. It is known that while fish oil yield is reduced at low temperatures, oxidation is enhanced at high temperatures. Indeed, it has been proved that the total amount of heat has a similar effect; low throughput means a long residence time and consequently unnecessarily high oxidation levels in the oil, which becomes less stable during storage (Aidos et al. 2002, 2003a).

-

2.

Pressing: the purpose of pressing is to squeeze out as much liquid as possible from the solid fish pulp. This is important not only to improve the oil yield and the quality of the meal but also to reduce the moisture content of the press cake as much as possible, thereby reducing the fuel consumption of the driers and increasing their capacity. The most common type of press employed in the fish meal industry is the twin-screw press. The performance of the press depends on the design of the screw and the size of the filter. Press cake moisture content has to be somewhat below 50 %. This objective can be achieved by centrifugation or using “decanters” instead of presses for the first separation of the components of cooked fish.

-

3.

Separation: the press liquor contains a liquid phase (oil plus water) and a solid residue. Both water and solid must be removed from the liquor to obtain the oil. This liquor is usually heated at a temperature of 90–95 °C in order to improve the separation. The separation can be performed in two ways. First, using a two-phase decanter to separate the suspended solids (sludge) followed by a vertical disc centrifuge to separate the water from the oil. Secondly, using a three-phase decanter (tricanter) that simultaneously separates sludge, stick water and oil.

Currently oil obtained from the decanter is not clean enough and must be centrifuged a second time or “polished” to improve its quality. It must be heated to a temperature of 90–95 °C and hot water is added to facilitate the separation in the vertical disc centrifuges. At this stage it is called crude fish oil and its typical chemical and physical properties, defined by the International Fish meal and Fish Oil Organization (IFFO), are listed in Table 1.

Traditional extraction processes have some disadvantages. In the case of the wet rendering method, indirect heating is achieved through a steam-heated jacket. Depending on the nature of the treated material, direct injections of steam and/or longer residence times in the cooker are needed for efficient heat transfer. On the one hand, factors that generally improve oil extraction yield such as temperature and heating time reduce the oxidative stability of extracted oil (Aidos et al. 2003a). Moreover, longer times and higher temperatures mean greater energy consumption. It has been also observed that temperature can even prevent the release of oil since, above a certain level, denatured proteins are closely packed (Chantachum et al. 2000).

On the other hand, it has been found that heat treatment produces oils with higher levels of PUFAs (comprising EPA and DHA) and lower saturated values than extraction by solvents (Aidos et al. 2001, 2003c).

Since the products are destined for the food and pharmaceutical sectors, it is necessary to find a compromise between factors that free the oil and those that prevent oxidation and preserve valued molecules such as EPA and DHA. Considering the process as a whole, the aim should be to reduce the cost of the operation while limiting its impact on the environment.

1.2.2 DIC Technology in the Extraction of Fish Oil

In DIC treatment, structural modifications occur as a result of the abrupt autovaporization and these depend on the thermo-hydro-rheological behavior of the material. Under appropriate conditions, the treated product may acquire a uniformly alveolated structure and large exchange surfaces, thereby improving its technological aptitude for subsequent processes.

Swell-drying was also used on seafoods (fish, Salmo salar and a Thunnus albacore). A direct DIC texturing of raw material followed by airflow drying could preserve the nutritional properties and increase the functionality of the products. The alveolation that is induced results in high rehydration kinetics and a high water holding capacity (WHC), as well as a general preservation of the lipids and proteins, together with the color.

2 Materials and Methods

2.1 DIC Treatment

The DIC equipment consisted of a 92 L vessel and a 20 m3 vacuum tank (Fig. 2).

The study concerned steam pressure (P) and heating time (t) as quantitative factors and rate of pressure drop (RD), cutting thickness of fillets (Th), and temperature during pressing (PT) as qualitative factors. A 100-fold reduction in the length of the section connecting the reactor to the vacuum tank allowed us to modify the rate of pressure drop (RD) from “High” at 0.16 s to “Low” at 6 s. The objective of this modification was to separate the mechanical effect from the thermal effect of DIC in order to analyze them independently (Table 2). Concerning the temperature of pressing, 80 °C is currently used for the highest yields of fish oil extraction although 30 °C is used for a lower thermal degradation.

As already mentioned, two cutting sizes were considered. It is worth noting, for the interpretation of the results, that the initial fat content of the bigger slices (10–20 mm thickness), 33 % db, was superior to that of the smaller thickness (3–5 mm), 25 % db. This was due to the cutting system, which pulled off the skin in thin slices and thus a higher proportion of skin and subcutaneous fat was present in the thick ones.

2.2 Extracting and Recovering Crude Oil

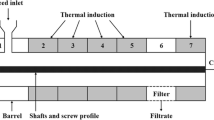

Extraction was performed in a twin-screw press. A co-rotating, intermeshing BC 21 extruder press was used (Clextral, Firminy, France). It was equipped with modular barrels, each 100 mm long, and the total length of the axes was 70 cm. The diameter of the die was slightly superior to that of the screws. The twin screws had segmental 50 mm long screw elements (Ø 25 mm) with variable profiles.

A heated jacket surrounding the barrel sections maintained the experimental conditions at 80 or 30 °C. A K TRON type KCV-KT20 twin-screw feeder fed material into the press inlet port (Fig. 3). The feeding rate was 2.34 ± 0.49 kg fish/h at 67.01 ± 2.93 % wet basis, with a 20 Hz feeder motor frequency and a press screw rotational speed of 130 rpm. Water continuously flowed through the press in order to facilitate the separation of the liquid and solid phases by the 2 mm filter of the press. A GILSON Minipuls Peristaltic pump pumped 1 L water/h into the inlet port of the press.

Two successive centrifugations at 6,640 × g for 10 min in a SIGMA 6K 15 centrifuge were performed to recover the oil from the upper phase.

2.3 Assessment of Crude Oil

The fatty acid profile of oil samples and the lipid fraction derived from the flesh of raw, cooked, and DIC-treated mackerel were analyzed to determine:

-

FFA content or acidity in the oil samples, based on the official UNE 55.011 method. The percentage of FFA was calculated as oleic acid equivalents.

-

The peroxide value (PV) of the oil samples was based on the official UNE 55.023 method and expressed in terms of mEq of peroxide per kg of lipid.

-

The anisidine value (AV) of the oil samples, which was carried out in accordance with ISO 6885.

-

Humidity and volatile matter of the oil samples, determined as the weight loss at 105 °C in a drying oven. Measurements of weight were taken every 30 min until the difference between two consecutive measurements was inferior to 5 %.

3 Results

3.1 Experimental Data

An analysis of variance (ANOVA) was carried out on the data using the statistical program STATGRAPHICS to identify the effect of different experimental factors on several dependent variables.

The dependent variables were Y: oil extraction yield, as a percentage of oil recovered in relation to the pressed matter; LR: residual lipids in the press cake; MR: residual moisture of the press cake; M_I: moisture and impurities in the oil; PV and AV: peroxide value and anisidine value of the oil. The ANOVA of the proposed qualitative variables (cutting size, pressing temperature, and rate of pressure drop during DIC) was used to determine whether significant differences existed between the conditions tested.

3.2 Oil Extraction Yield

An oil yield of 30.78 % db were obtained, which represents about 93 % of the extractable oil and 100 % of the oil extracted after cooking.

Steam pressure, and thus temperature, in the tested range (P = 0.2–0.6 MPa and temperature T ≈ 120–160 °C) did not seem to play an important role, while the heating time negatively affected the extraction of oil. It is worth noting that the faster the drop in pressure, the greater the quantity of extracted oil. Pressing by a system of co-rotating twin screws provided a more consistent and viscous texture.

3.3 Composition of the Press Cake

At first sight, it would appear that lower yields were obtained the higher the temperature in the press barrel. However, the results actually show that the temperature of pressing does not affect the lipid content in the press cake. This may indicate that during pressing the temperature does not modify the extraction behavior but it does influence the quantity of emulsion formed. The difficulty in quantifying this emulsion and its lipid content led us to consider the oil remaining in the solids after pressing as an important index of the pretreatment efficiency of extraction, as oil not present in the residual solids may be recovered. So the goal was to minimize the lipid content.

Considering the conditions that gave the best yield, a low pressing temperature, and a rapid drop in pressure, the optimal values for the DIC parameters were 0.2 MPa of steam pressure and 20 s. The optimized residual oil content in the press cake was 2.39 % db.

The quality of the oil recovered and of the press cake was compared for DIC and cooked samples (Tables 3 and 4).

The advantages of DIC accrued through the reduction of treatment time, i.e., the oxidative stability of oil and the preservation of the properties of the solids, seemed evident. Aidos et al., working on frozen herring byproducts and comparing these to fresh offal, found higher values for the oxidation state and stability parameters, such as peroxide value (PV), anisidine value (AV), and content of FFAs (Aidos et al. 2003b). With frozen mackerel fillets, we obtained oils with a high level of oxidation of around 22 mEq/kg fat and 11, for PV and AV, respectively (Table 3). The statistical analysis of PV and AV showed a direct (P < 0.05) or quadratic (P < 0.10) dependency, respectively, on the duration of DIC treatment. However, due to the high oxidations levels, we can only highlight the similarity of both parameters with oil obtained after DIC or traditional cooking.

The FFA content of the oils was within the normal range for a crude oil (2–5 % oleic acid) (Table 3). On the other hand, we noted a higher level of FFAs in DIC oil in general. It would be interesting to determine if decompression plays a role in the liberation of these fatty acids.

The results concerning the concentration in PUFAs, especially EPA and DHA, are presented in Table 4. Raw fish contained 11.77, 2.32, and 5.94 g/100 g oil of PUFAs, EPA, and DHA, respectively. Contents of around 15 % PUFAs in oils extracted by pressing confirmed that heat treatment produces oils with higher levels of PUFAs than extraction using solvents (Aidos et al. 2001). In consequence, it is necessary to limit the discussion to a comparison of oils obtained by both heating treatments. Similar mean values have been found for oil obtained after DIC treatment and after cooking.

Considering the proportion of the phases produced, it is noticeable that the values of the solid and water phases were practically inversed. The aqueous phase produced in the process incorporating DIC technology was superior to that obtained by the cooking process, which eliminated more water from the product matrix and thus gave dryer solids. This could be explained by the results obtained by Guyomard (1994) in his thesis concerning twin-screw pressing. He found that the mechanical squeeze effect, intensified by a particular configuration of the screws, allowed a better release of liquids while simultaneously reducing the yield of extracted oil. In the present case, we attributed this effect to DIC treatment, as it was not produced in the process using traditional heating. However, this effect actually does seem to favor the formation of emulsion, probably by a more intense mixing of the three phases composing the liquid that is released.

A slower flow rate of cooked fish fed into the press meant a longer residence time of treated fish in the extruder. As it is known that decreasing the feeding rate favors extraction (Aidos et al. 2003a), a reduction of the rotating speed of the screws should improve the oil extraction yield.

3.3.1 Conditions of Fish Pretreatment by DIC for the Extraction of Oil by Pressing

Figure 4 represents the different stages of the process and the general mass balance at the principal phases of the process: thermal/thermomechanical treatment and extraction–separation.

Taking into account the experimental results and optimal conditions established by the models, as well as the diversity of the raw materials available for the production of fish oil, the process for fish oil extraction by mechanical pressing has to include a thermomechanical pretreatment by DIC in the following conditions (Table 5):

With our application, we observed that a homogeneous treatment does not favor subsequent pressing of the fish matter. The necessity to create a certain difference in texture throughout the treated matter allows the treatment of thick layers of between 10 and 17 cm. We propose a thickness of around 12 cm to obtain a good technological aptitude of the matter for pressing.

4 Conclusions

The process of oil extraction includes several phases, of which heating is merely a pre-stage of the actual extraction step. It is not possible to attribute the success of the whole process to any single phase, which is why we cannot talk about the improvement of the extraction by DIC but rather about the beneficial modifications to the product structure that improve the extraction by pressing.

The general objective of heating is to break down bonds retaining oil in the structural matrix by the coagulation of proteins. However, conditions providing greater degradation are not necessarily appropriate for a subsequent extraction by pressing as the flow of already liberated liquid can be hindered.

In this regard, the creation of an internal gradient seems to be indispensable for the correct pressing of the treated matter. Either a specific distribution of the moisture content within the material or a nonhomogeneous treatment with regard to the whole treated mass confers a specific and favorable rheology to the material to be pressed.

By using co-rotating twin screws as a pressing system, more than 70 % of the theoretically extractable oil can be recovered. In this regard, pressing with Clextral’s BC21 co-rotating twin-screw press has allowed us to draw conclusions about the efficacy of DIC as a pretreatment for fish oil extraction.

The instantaneity of decompression in DIC has a mechanical effect that complements the thermal action, with a specific effect on the structure of the matter. The fact that there is no significant effect of steam pressure on the oil yield indicates that increasing the treatment temperature does not produce the equivalent effect on the product. This enables a reduction in thermal treatment time, compared to traditional cooking, from 15 min to 20 s, with equivalent or even superior extraction yields and a consequent preservation of the product quality.

It is possible, using thermomechanical DIC treatment and co-rotating pressing, to obtain a press cake with a fat content of up to 2 % db, which is nearly 50 % of that obtained after traditional cooking in the same conditions of pressing. This result introduces important advantages in relation to the production of low-fat fish meal.

References

Aidos I, Van Der Padt A, Boom RM, Luten JB (2001) Upgrading of maatjes herring byproducts: production of crude fish oil. J Agric Food Chem 49(8):3697–3704. doi:10.1021/jf001513s

Aidos I, Masbernat-Martinez S, Luten JB, Boom RM, Van Der Padt A (2002) Composition and stability of herring oil recovered from sorted byproducts as compared to oil from mixed byproducts. J Agric Food Chem 50(10):2818–2824. doi:10.1021/jf011318t

Aidos I, Kreb N, Boonman M, Luten JB, Boom RM, Van Der Padt A (2003a) Influence of production process parameters on fish oil quality in a pilot plant. J Food Sci 68(2):581–586. doi:10.1111/j.1365-2621.2003.tb05714.x

Aidos I, Schelvis-Smit R, Veldman M, Luten JB, Van Der Padt A, Boom RM (2003b) Chemical and sensory evaluation of crude oil extracted from herring byproducts from different processing operations. J Agric Food Chem 51(7):1897–1903. doi:10.1021/jf020684p

Aidos I, Van Der Padt A, Boom RM, Luten JB (2003c) Quality of crude fish oil extracted from herring byproducts of varying states of freshness. J Food Sci 68(2):458–465. doi:10.1111/j.1365-2621.2003.tb05694.x

Alkio M, Gonzalez C, Jäntti M, Aaltonen O (2000) Purification of polyunsaturated fatty acid esters from tuna oil with supercritical fluid chromatography. J Am Oil Chem Soc 77(3):315–321. doi:10.1007/s11746-000-0051-3

Bimbo AP (1998) Guidelines for characterizing food-grade fish oil. Inform 9(5):473–481

Bilo HJG, Gans ROB (1990) Fish oil: a panacea? Biomed Pharmacother 44(3):169–174, http://dx.doi.org/10.1016/0753-3322(90)90005-T

Catchpole OJ, Grey JB, Noermark KA (2000) Fractionation of fish oils using supercritical CO2 and CO2+ethanol mixtures. J Supercrit Fluids 19(1):25–37, http://dx.doi.org/10.1016/S0896-8446(00)00075-9

Chantachum S, Benjakul S, Sriwirat N (2000) Separation and quality of fish oil from precooked and non-precooked tuna heads. Food Chem 69(3):289–294, http://dx.doi.org/10.1016/S0308-8146(99)00266-6

Dunford NT, Temelli F, LeBlanc E (1997) Supercritical CO2 extraction of oil and residual proteins from Atlantic mackerel (Scomber scombrus) as affected by moisture content. J Food Sci 62(2):289–294. doi:10.1111/j.1365-2621.1997.tb03987.x

Guyomard P (1994) Etude de faisabilité d’un extrudeur bivis en pressage-extrusion de graines oléoprotéagineuses = Faisability study of a co-extruder in expression-extrusion of oleaginous seeds. Université de Technology de Compiègne, Compiègne, France

Murayama K, Yoneya S, Miyauchi O, Adachi-Usami E, Nishikawa M (2002) Fish oil (polyunsaturated fatty acid) prevents ischemic-induced injury in the mammalian retina. Exp Eye Res 74(6):671–676, http://dx.doi.org/10.1006/exer.2002.1151

Roynette CE, Calder PC, Dupertuis YM, Pichard C (2004) n-3 Polyunsaturated fatty acids and colon cancer prevention. Clin Nutr 23(2):139–151, http://dx.doi.org/10.1016/j.clnu.2003.07.005

Schmidt EB, Arnesen H, de Caterina R, Rasmussen LH, Kristensen SD (2005) Marine n-3 polyunsaturated fatty acids and coronary heart disease. Part I. Background, epidemiology, animal data, effects on risk factors and safety. Thromb Res 115(3):163–170

Timonen M, Horrobin D, Jokelainen J, Laitinen J, Herva A, Räsänen P (2004) Fish consumption and depression: the Northern Finland 1966 birth cohort study. J Affect Disord 82(3):447–452, http://dx.doi.org/10.1016/j.jad.2004.02.002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media New York

About this chapter

Cite this chapter

Pérez, I., Bald, C., de Marañón, Í.M., Allaf, K. (2014). DIC Intensification of the Mechanical Extraction of Lipids by Pressing. In: Allaf, T., Allaf, K. (eds) Instant Controlled Pressure Drop (D.I.C.) in Food Processing. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-8669-5_9

Download citation

DOI: https://doi.org/10.1007/978-1-4614-8669-5_9

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-8668-8

Online ISBN: 978-1-4614-8669-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)