Abstract

Prebiotics are nondigestible dietary fibers that benefit the host health by stimulating the growth of probiotic microorganisms in the colon. Lactulose, galacto-oligosaccharides, fructo-oligosaccharides, xylo-oligosaccharide, malto-oligosaccharides, inulin, and its hydrolysates are some commonly used prebiotics comprising of two to ten sugar moieties. The end products of these prebiotics, i.e., acetate, butyrate, and propionate, act as energy sources for host organisms. Naturally, these can be obtained in small amounts through plant sources, such as chicory, onion, garlic, asparagus, artichoke, bananas, and tomatoes. These can also be produced at large scale by using microorganisms and their enzymes. Besides refined sugar molecules, these can also be synthesized by using agro-industrial waste/by-products, such as whey, wheat and rice straw, and sugarcane bagasse, making the production process more economical. Prebiotics have bifidus-stimulating ability, immunomodulatory effect, and antioxidant properties besides their role in reducing risks of cancer, acute gastroenteritis, osteoporosis, and hyperlipidemia. The prebiotic compounds can be employed for the fortification of different food products for the development of functional foods with high nutritional and therapeutic properties. This chapter provides a comprehensive overview on common prebiotics, enzyme involved, and their production by biotechnological strategies besides potential benefits.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Prebiotics are nondigestible oligosaccharides which are not broken down by the salivary and intestinal enzymes due to the presence of “osidic” bonds. These compounds beneficially affect the host by selectively stimulating the growth and/or activity of one or a limited number of bacteria in the colon (Bifidobacteria and Lactobacilli) by suppressing the activity of entero-putrefactive and pathogenic organism and also facilitate the absorption of nutrients (Roberfroid 1997). Some of the available prebiotic compounds have range of two to ten sugar moieties, and common examples are lactulose, galacto-oligosaccharides, lactosucrose, fructo-oligosaccharides, xylo-oligosaccharide, malto-oligosaccharides, inulin, and its hydrolysates (Fig. 10.1). The end products of these prebiotics, i.e., acetate, butyrate, and propionate, act as energy sources for host organisms.

Prebiotics have bifidus-stimulating ability, immunomodulatory effect, and antioxidant properties besides their role in reducing risks of cancer, acute gastroenteritis, osteoporosis, cholesterol, and hyperlipidemia (Conway 2001). These compounds can be used for the fortification of different food products for the development of functional foods with high nutritional and therapeutic properties. These can be supplemented as ingredients in the functional foods, cosmetics, pharmaceuticals, or agricultural products. This chapter provides a comprehensive overview on fundamentals of different prebiotics and their production using biotechnological strategies.

2 Production of Prebiotics

Prebiotics can be obtained by three different routes, i.e., by extraction from natural (plant) sources, enzymatic synthesis, and enzymatic hydrolysis of polysaccharides. Small amounts of prebiotics occur naturally in the natural sources like plants including chicory, onion, garlic, asparagus, and artichoke; however, their large-scale production can also be achieved using various microorganisms and enzymes. Various raw materials and enzymes have been explored for the production of different prebiotics/oligosaccharides in both free and immobilized biocatalyst systems, which have been discussed in subsequent sections.

3 Galacto-oligosaccharides

Galacto-oligosaccharides (GOS) are a functional food ingredient consisting of β-linked galactose moieties with galactose or glucose at the reducing end. More than 30 different types of di-, tri-, and tetrasaccharides were identified as the product of various enzymatic transgalactosylation. The different unit of monomer in GOS is linked by β-(1 → 2), β-(1 → 3), β-(1 → 4), or β-(1 → 6) galactosyl moieties (Mahoney 1998; Gänzle 2011). In the commercial GOS preparations, apart from tri-, tetra-, and pentasaccharides, small amount of other carbohydrates, such as glucose-, lactose- and β-(1 → 3)-, or β-(1 → 6)-linked disaccharides, is also present (Sako et al. 1999; Splechtna et al. 2006).

3.1 Method of Production

Galacto-oligosaccharide can be synthesized by transgalactosylation of lactose, glucose, or galactose with lactose as galactosyl donor.

3.1.1 Enzymes Involved

Enzymatic production of galacto-oligosaccharide has been carried out using following enzymes:

-

1.

β-galactosidase (EC 3.2.1.23)

-

2.

β-glucosidases/β-glycosidases (EC 3.2.1.21)

β-galactosidase and β-glucosidases/β-glycosidases have both hydrolytic (lactose) and transgalactosylation activity.

3.1.2 Process

The β-galactosidase can be produced from various microbial sources like bacteria, yeast, and fungi. Among these sources, yeast has been considered as an important source of β-galactosidase from industrial point of view (Panesar et al. 2006). Apart from this, other thermostable enzymes, such as β-glucosidase/β-glycosidase, have also been used for galacto-oligosaccharide production (Akiyama et al. 2001; Choi et al. 2003). Galacto-oligosaccharide production from lactose has been carried out with microbial β-galactosidases, whole cells, permeabilized cells, as well as applying immobilized techniques (Albayrak and Yang 2002; Ladero et al. 2003; Tzortzis et al. 2005; Nakkharat et al. 2006; Nguyen et al. 2007; Sakai et al. 2008; Placier et al. 2009).

The production of GOS depends on the source of enzyme and production process. High temperature (60 °C) has been observed to favor transgalactosylation reaction and GOS yield (Cardelle-Cobas et al. 2008). The production of GOS has also been carried out by various enzymes from different microorganisms, such as thermostable β-glycosidases/β-glucosidase from Pyrococcus furiosus and Sulfolobus solfataricus (Petzelbauer et al. 2000; Boon et al. 1998; Splechtna et al. 2001) and β-galactosidase from Sirobasidium magnum and Penicillium simplicissimum (Onishi and Tanaka 1997; Cruz et al. 1999). The yield of GOS varied from 15 to 77 % by these enzymes with the lactose conversion of 45–95 % (Torres et al. 2010). GOS has been purified by continuous nanofiltration achieving a yield of 81–98 % for oligosaccharides (trisaccharide), 59–89 % for disaccharides, and only 14–18 % for the monosaccharides (Goulas et al. 2002).

Whey (by-product of dairy industry) is rich in lactose content and can be used for GOS production (López Leiva and Guzman 1995). The conversion to oligosaccharides not only depends on the reaction time but also on the initial concentration of substrate. The production of GOS has been carried out using an immobilized Aspergillus oryzae β-galactosidase on glutaraldehyde-treated chitosan beads in a plug reactor from whey. The maximum yield of GOS was found to be 26 % of the total saccharides on a dry weight basis for an initial concentration of lactose of 300 g L−1 (Sheu et al. 1998). At pilot scale membrane reactor, oligosaccharides have also been produced by hydrolysis of whey permeate (2,000 L) from Maxilact (Kluyveromyces lactis β-d-galactosidase). A yield of 31 % oligosaccharide was observed from whey permeate containing 20 % lactose and 0.5 % enzyme (Foda and Lopez-Leiva 2000).

Different substrates (lactose, ultrafiltration whey permeate, and recombined whey) with different enzyme concentrations (0.15–15 U mL−1) have been applied for GOS synthesis. The maximum production of GOS has been observed with ultrafiltration whey permeate using an enzyme concentration of 1.5 U mL−1 (HelleroVá and Čurda 2009). Continuous production of GOS has also been carried out from both lactose feed solution and whey, with PVA-immobilized β-galactosidase in a packed bed reactor. A maximum GOS production of 30 % of total sugars was achieved using 40 % lactose feed solution, whereas 15 % of total sugars have been obtained in case of whey (Jovanovic-Malinovska et al. 2012).

4 Lactulose

Lactulose (4-O-β-d-galactopyranosyl-d-fructose) is a ketose disaccharide having wide range of applications in food and pharmaceutical sectors. It is composed of fructose and galactose linked through glycosidic bonds. The linkage between galactose and fructose is neither cleaved by human digestive enzymes nor absorbed in the small intestine. In the colon, lactulose stimulates the growth of Bifidobacteria sp. and Lactobacillus sp. leading to the production of a large number of short-chain fatty acids (Méndez and Olano 1979).

4.1 Method of Production

Lactulose can be synthesized chemically or by enzymes from various microorganisms.

4.1.1 Enzyme Involved

Biocatalytic production of lactulose has been carried out by using the following enzymes:

-

1.

β-galactosidase (EC 3.2.1.23)

-

2.

β-glycosidase (EC 3.2.1.21)

4.1.2 Process

Currently, for commercial utilization, lactulose is produced by alkaline isomerization of lactose. To obtain high yields, it is advantageous to use high amounts of inorganic catalysts, such as boric acid or aluminate. This approach results in expensive separation of by-products that cause difficulty in product purification and waste management (De Harr and Pluim 1991; Zokaee et al. 2002; Aider and de Halleux 2007). The problems associated with lactulose production by chemical synthesis can be solved by an enzymatic transformation process which seems to be a useful approach for clean production and easy purification of lactulose (Tang et al. 2011). Microorganisms, such as K. lactis, S. solfataricus, Arthrobacter sp. (β-galactosidase), and P. furiosus (β-glycosidases), have been applied for both lactose hydrolysis and transglycosylation leading to lactulose synthesis (Lee et al. 2004; Kim et al. 2006; Mayer et al. 2010; Tang et al. 2011).

The optimum reaction conditions for lactulose production using permeabilized cells were 40 % (w/v) lactose and 20 % (w/v) fructose at temperature 60 °C and pH of 7.0. Under these conditions, the permeabilized cells produced approximately 20 g L−1 lactulose (Lee et al. 2004). The use of thermostable β-galactosidase can further enhance the production of lactulose (Kim et al. 2006). The continuous enzymatic production of the lactulose through transgalactosylation has also been developed using free and immobilized (Amberlite IRA-93 or Eupergit® C) thermostable β-glycosidase (Mayer et al. 2010). Dual-enzymatic system consisting of immobilized lactase and immobilized glucose isomerase in organic-aqueous two-phase media using lactose and fructose has also been applied for the synthesis of lactulose (Xiao et al. 2010). Currently, purified β-galactosidase from Arthrobacter sp. LAS has been used for lactulose production to reduce the nonenzymatic browning during biotransformations (Tang et al. 2011). The optimum pH and temperature for lactulose synthesis by this β-galactosidase were 6.0 and 20 °C, respectively.

Alkaline isomerization of lactose present in cheese whey ultrafiltrate permeate was carried out by the addition of boric acid (Hicks et al. 1984). However, expensive separation and purification steps were involved in this procedure. The synthesis of lactulose from dairy by-product (i.e., whey) can be carried out by using an enzyme (β-galactosidase) in the presence of fructose. The controlled enzymatic transgalactosylation of lactose in whey ultrafiltration permeate can improve the efficiency of lactulose synthesis. The factors that influenced the lactulose synthesis efficiency were enzyme source, substrate concentration, and also the ratio of lactose and fructose added to the reaction mixture (Adamczak et al. 2009; Jaindl et al. 2009).

5 Lactosucrose

Lactosucrose (lactosylfructoside, O-β-d-galactopyranosyl-(1 → 4)-O-α-d-glucopyranosyl- (1 → 2)-β-D-fructofuranoside) is an oligosaccharide consisting of galactose, glucose, and fructose and has several benefits. This compound is 30 % as sweet as sucrose and used as functional food ingredient. Additionally, lactosucrose also plays an important role in the refinement of sugars in the food industry (Kawase et al. 2001).

5.1 Method of Production

Lactosucrose, a trisaccharide, can be synthesized either by transfructosylation of lactose with sucrose or transgalactosylation of sucrose with lactose.

5.1.1 Enzyme Involved

The biosynthesis of lactosucrose can be obtained with lactose and sucrose as substrates by the following enzymes:

-

1.

Levansucrase (EC 2.4.1.10)

-

2.

Fructofuranosidase (EC 3.2.1.26)

-

3.

β-d-galactosidase (EC 3.2.1.23)

Levansucrase and fructofuranosidase have transfructosylation activity, whereas β-d-galactosidase has both hydrolytic and transgalactosylation activity.

5.1.2 Process

Commercially, lactosucrose (lactosylfructoside) has been produced from sucrose and lactose by transfructosylation (Gänzle et al. 2008). The microorganisms such as Zymomonas mobilis, Paenibacillus polymyxa, and Bacillus subtilis have been used as a source for levansucrase whereas Bacillus circulans and Arthrobacter sp. for β-d-galactosidase and fructofuranosidase, respectively (Kawase et al. 2001; Li et al. 2009; Han et al. 2009; Choi et al. 2004; Park et al. 2005). Increase in lactosucrose yields (from 29 to 43 %) was observed by a mixed enzyme system coupling the transfructosylation of lactose to glucose removal by glucose oxidase (Han et al. 2009). The selection of strain, substrate concentration, and reaction time along with other optimal conditions play an important role in the production of lactosucrose. B. subtilis was found to be an effective producer of levansucrase, and the maximum lactosucrose production (181 g L−1) was observed at 55 °C and pH 6.0 after 10 h of incubation (Park et al. 2005). Lactosucrose has also been produced through continuous process in a packed bed reactor using mutant strain of Sterigmatomyces elviae, which resulted in the production of 192 g L−1 of lactosucrose at 50 °C and pH 6.0 with the flow rate of 1.2 mL/min (Lee et al. 2007). Z. mobilis strain has been applied for levansucrase, and the maximum lactosucrose conversion efficiency of 28.5 % has been observed at 23 °C and pH 7.0 with lactose monohydrate (18.0 % w/v) and sucrose (18 % w/v) as substrate. The main problem associated with the low yield of lactosucrose is the presence of other carbohydrate products. To overcome this problem, a mixed enzyme system containing a levansucrase and a glucose oxidase has also been applied, and as a result of this, the efficiency of lactose and sucrose conversion to lactosucrose increases to 43.2 % (Han et al. 2009).

6 Fructo-oligosaccharides

Fructo-oligosaccharides (FOS) are low caloric carbohydrate alternative sweeteners with reduced energy production of about 2 kcal g−1 (Molis et al. 1996; Bornet et al. 2002). They are mainly composed of 1-kestose, nystose, and 1-β-fructofuranosyl nystose (Shin et al. 2004). FOS occurs naturally or can be produced by the action of fructosyltransferase enzymes from bacteria, yeast, and fungi (Sangeetha et al. 2005a; Maugeri and Hernalsteens 2007; Hernalsteens and Maugeri 2008). These complex biomolecules are enzymatically hydrolyzed into simpler forms, such as lactate, short-chain fatty acids (acetate, propionate, and butyrate), and gas, by endogenous microbiota. They bear properties of being low caloric, non-cariogenic, and non-mutagenic; absorption of ions in gut; lowering phospholipids, triglycerides, and cholesterol level; and bifidus-stimulating functionality (Vankova et al. 2008; Bali et al. 2012). Due to all these properties and bearing “Generally Recognized as Safe (GRAS)” status by Food and Drug Administration (FDA), they are being used as functional food ingredients and worth about US $200/kg (Godshall 2007).

6.1 Method of Production

FOS can be synthesized chemically or produced by the action of enzymes from various microorganisms.

6.1.1 Enzyme Involved

Fructo-oligosaccharides can be produced in large amounts by microbial enzymes bearing fructosyltransferase activity. They can be produced enzymatically by sucrose transformation (Bali et al. 2012) which leads to the production of short-chain FOS using:

-

1.

FFase, i.e., β-d-fructofuranosidase (EC 3.2.1.26)

-

2.

FTase, i.e., fructosyltransferase (EC 2.4.1.9)

FFase bears both hydrolytic and transfructosylating activity, whereas FTase bears only transfructosylating activity.

6.1.2 Process

The fructosylating enzyme can be produced from different microbial sources, such as bacterial (Bacillus macerans (Park et al. 2001), Arthrobacter sp. (Xu et al. 2009), Z. mobilis (Beker et al. 2002), Lactobacillus reuteri (Hijum et al. 2002)), fungal (Aspergillus japonicus, Aspergillus niger, Aspergillus sydowii, Aspergillus foetidus, A. oryzae, Aureobasidium pullulans, Penicillium citrinum, Penicillium frequentans, Fusarium oxysporum, Aureobasidium sp.), and yeast (Kluyveromyces and Candida sp.) (Vranesic et al. 2002; Bali et al. 2012). Microbial production, isolation, and purification of enzyme are preferred over plant sources due to ease of production and availability in large amounts. The enzyme can be produced either intracellularly or extracellularly. The whole cell synthesis of FOS can be carried out using microorganisms bearing fructosylating activity in sucrose-based media. An economical and advantageous system of recycling A. oryzae CFR 202, up to six cycles with 53 % yield, was developed for the production of extracellular FTase resulting in the synthesis of FOS under submerged fermentation (Sangeetha et al. 2005b). The technique of immobilizing the enzyme or whole cells (producing FFase or FTase) on various matrices has also been applied by various researchers for enhancing the production of FOS (Cheng et al. 1996; Jung et al. 2011).

Agro-industrial waste can act as good carbon or nitrogen source for the production of enzymes useful in the synthesis of FOS, thereby, adding up to process economics. Different agro-industrial wastes, such as soybean residue and sugarcane molasses, have been explored for the microbial synthesis of enzymes (Hayashi et al. 1992; Dorta et al. 2006). Production of β-fructofuranosidase has been carried out by fermentation using A. japonicus and soybean residue as substrate (Hayashi et al. 1992). Among the different substrates (corncobs, coffee silverskin, and cork oak) tested, coffee silverskin was reported to be the most suitable support and nutrient source for the production of FOS using A. japonicus under solid-state fermentation (Mussatto and Teixeira 2010). Low-cost complex media constituting cassava peel and cassava steep liquor, under solid-state and submerged fermentation, respectively, have been explored for the production of FTase and FOS (34 %) by Rhizopus stolonifer LAU 07 (Lateef and Gueguim kana 2012). The production of FTase by A. foetidus NRRL 337 using apple pomace as a substrate has been reported (Hang et al. 1995). Besides this, sugarcane molasses has also been used for the production of FOS using A. japonicus-FCL 119T and A. niger ATCC 20611 (Dorta et al. 2006).

The increase in the production of β-fructofuranosidase in both wild-type and mutant strain of A. niger up to 252-fold and 516-fold, respectively, was observed using wheat bran as substrate, whereas corn steep liquor improved the activity of wild-type strain up to twofold (Rajoka and Yasmeen 2005). A patented method has been reported using wheat bran as substrate for the increased production of FOS (60 % yield; w/w) using A. niger β-fructofuranosidase (Park and Pastore 2006). Molasses can be used as substrate for both enzyme and oligosaccharide production using microbial sources (Ghazi et al. 2006). Among the various agricultural by-products (such as cereal bran, corn by-products, sugarcane bagasse, cassava bagasse, and by-products of coffee and tea processing) employed for the production of FTase using A. oryzae CFR 202 by solid-state fermentation (SSF), cereal bran, rice bran, wheat bran, corn germ, spent coffee, and tea processing were observed to be most suitable as substrates (Sangeetha et al. 2004). After fermentation, the microbial cell separation is generally done using centrifugation followed by recovery of the enzyme with different precipitation methods (ethanol precipitation, ammonium sulfate precipitation, etc.). Further, analysis of FOS can be carried out by using various analytical techniques, such as HPLC, TLC, GC-MS, and NMR (Sangeetha et al. 2005a).

7 Inulin

Inulins are long-chain storage carbohydrates that occur naturally in small amounts in various edible vegetables, fruits, cereals, and plants, such as asparagus, chicory, onion, wheat, banana, shallot, artichokes, leek, garlic, rye, tomatoes, topinambuco, and honey (Van et al. 1995). Inulin and its polyfructans consists of GF n molecules (2 < n < 60) with linear β-2 → 1-linked polyfructose chains with glucose unit at its terminal (Waterhouse and Chatterton 1993). These compounds were discovered by Rose, German scientist, from hot water extract of Elecampane (Inula helenium) and the term was coined by Thomson in 1818. Oligofructose (inulin hydrolysate) is composed of GF n and F m molecules (with 2 ≤ n and m ≤ 10) with DP (degree of polymerization) ≤10. It has more solubility and 30–50 % sweetness as compared to table sugar (Niness 1999).

7.1 Method of Production

Inulin hydrolysates can occur naturally or can be produced by enzymatic methods.

7.1.1 Enzyme Involved

Inulinases produce inulin hydrolysates by partial enzymatic hydrolysis of inulin (Franck 2002). There are two types of inulinases:

-

1.

Exoinulinases (β-d-fructanfructohydrolase; EC 3.2.1.80) act on both β 2 → 1 and β 2 → 6 linkages at the nonreducing end, thereby cleaving terminal fructose residues.

-

2.

Endoinulinases (2,1-β-d-fructanohydrolase; EC 3.2.1.7) act on specific β 2 → 1 internal linkages yielding inulotriose, inulotetraose, and inulopentaose.

7.1.2 Process

Inulin can be obtained from natural plant sources by extraction using hot water diffusion followed by purification and then drying of inulin extract to obtain pure powder (Angus et al. 2005). In spite of their natural occurrence, fructans can also be produced using microbial sources like bacteria and fungi. Inulin has been used as substrate for the production of its hydrolysates using inulinase and short-chain oligosaccharides, such as inulo-oligosaccharide, oligofructose, and fructo-oligosaccharide.

Inulinases can be produced from various bacterial strains (Streptomyces sp., Pseudomonas sp., Bacillus sp.), yeast strains (Kluyveromyces sp., Pichia sp., Candida sp.), and fungal sources (Aspergillus sp., Penicillium sp.) (Mazutti et al. 2006; Neagu and Bahrim 2011). Inulinase production has also been carried out using different agro-industrial waste, such as cassava flour, corncob, oat meal, rice straw, sugar cane bagasse, and wheat bran using Aspergillus ochraceus (Guimaraes et al. 2007). Sugarcane bagasse and corn steep liquor have been used for the production of inulinases using Kluyveromyces marxianus NRRL Y-7571 under SSF (Mazutti et al. 2006). Three exoinulinases and two endoinulinases were purified from Aspergillus ficuum JNSP5-06 (Chen et al. 2009).

Thermostable extracellular immobilized inulinases from Aspergillus fumigates have been used for the hydrolysis of inulin (Gill et al. 2006). Inulobiose and other higher oligofructosides were produced using soluble (inulobiose and DP3 oligosaccharides as product; 72 % yield) and immobilized endoinulinases (higher content of inulobiose; 83 % yield) using batch fermentation (Yun et al. 1997a). Immobilized system has also been applied for the production of inulo-oligosaccharides using immobilized enzymes or enzyme-producing whole cells. Continuous production of inulo-oligosaccharides (83 % yield) has been achieved using immobilized endoinulinases produced by Pseudomonas sp. and inulin as substrate (Yun et al. 1997b). Continuous production of inulo-oligosaccharides (82 % yield) has also been reported using immobilized polystyrene-bound endoinulinase and chicory juice as substrate for 28 days at 55 °C (Yun et al. 2000). The inulo-oligosaccharide with DP2 to DP4 and DP2 to DP8 was produced at 45 °C after 72 h with partially purified (pH 6.0 and 50 % yield) and purified (pH 5.0, 70 % yield) A. ficuum endoinulinase, respectively, using 50 g L−1 inulin and enzyme concentration of 10 U g−1 substrate (Zhengyu et al. 2005). Pseudomonas mucidolens endoinulinase gene expressed on Saccharomyces cerevisiae cell surface resulted in hydrolysis of inulin (Jerusalem artichoke) with 2.31 U mL−1 of activity at temperature of 50 °C and pH of 7.0 and formation of inulotetraose (F4) as major product along with inulobiose (F2), inulotriose (F3), and inulopentaose (F5) formation (Kim et al. 2008). Similarly, K. marxianus CBS 6556 endoinulinase gene INU1 which has been expressed on citric acid producing Yarrowia lipolytica hydrolyzed 77.9 % inulin and resulted in formation of inulin-oligosaccharides (mono-, di-, and minor tri-) at 50 °C, pH 4.5 with initial 12 % inulin concentration and inulinase activity of 181.6 U g−1 within 10 h of incubation (Liu et al. 2010).

8 Malto-oligosaccharides

Malto-oligosaccharides (MOS) are low sweeteners with properties like antistaling effect on bread, high water holding capacity, and preventing sucrose crystallization. Although α-amylases produce maltose or glucose from starch, some of the microbial α-amylases lead to the production of malto-oligosaccharides which may have their applications in MOS containing syrups (Park 1992).

8.1 Method of Production

8.1.1 Enzyme Involved

The following are enzymes which play a role in the production of malto-oligosaccharides:

-

1.

α-Amylase (EC 3.2.1.1; 1 → 4-α-d-glucanohydrolase or endoamylase) results in the hydrolysis of starch by cleaving α-d-(1 → 4) glycosidic linkages, thereby producing specific or mixed malto-oligosaccharides.

-

2.

α-Amylase (EC 3.2.1.2) results in the hydrolysis of starch by formation of maltose, followed by transglucosylation of maltose using α-glucosidase (EC 3.2.1.20).

-

3.

Cyclodextrin glucanotransferase (CGTase) results in the formation of β-malto-oligosaccharides through glycosylation of bioactive tocopherols and isoflavones.

8.1.2 Process

Microbial amylases have been produced by Bacillus sp. (Nagarajan et al. 2006), Brachybacterium sp. (Doukyu et al. 2007), Marinobacter sp. (Kumar and Khare 2012), etc. for the synthesis of MOS. The transformation of maltose into isomalto-oligosaccharide using α-glucosidase from Xanthophyllomyces dendrorhous has been reported (Fernández-Arrojo et al. 2007). The production of α-amylases has also been carried out using agro-industrial waste/by-products, such as sugarcane molasses, cheese whey, rice husk, and wheat bran (Babu and Satyanarayana 1995; Baysal et al. 2003; Sodhi et al. 2005). B. subtilis has been reported to produce α-amylases on sugarcane bagasse hydrolysate (Nagarajan et al. 2006; Rajagopalan and Krishnan 2008).

Immobilized Penicillium lilacinum dextranase on Eupergit C resulted in isomalto-oligosaccharides production with 90 % relative activity up to 20 batch reactions (Aslana and Tanriseven 2007). A sandwich-structured enzyme membrane reactor has been used to convert maltose into isomalto-oligosaccharide with 100 % conversion and 58 % yield (Zhang et al. 2010). Transglucosidase producing A. niger has been reported to form various MOS (DP 2–8) from mixture of maltoheptaose and [U–13C] maltose (Ota et al. 2009). The synthesis of β-malto-oligosaccharides has also been carried out from glycitein and daidzein using Lactobacillus delbrueckii and cyclodextrin glucanotransferase (CGTase) by sequential glycosylation (Shimoda and Hamada 2010). Similarly, β-malto-oligosaccharides as tocopherol derivatives were synthesized by glycosylation of α- and δ-tocopherols using Klebsiella pneumoniae and CGTase (Shimoda et al. 2009).

9 Xylo-oligosaccharides

Xylo-oligosaccharides (XOS) are sugar oligomers made up of xylose units and are present naturally in bamboo shoots, fruits, vegetables, milk, and honey. Xylo-oligosaccharides are nondigestible food ingredients having lower degree of polymerization (DP) and are commercially produced during the hydrolysis of xylan, the main component of the plant hemicelluloses (Brienzo et al. 2010). The composition and structure of the XOS depend upon the source and the production process. Generally, XOS are mixtures of oligosaccharides formed by xylose residues linked through β-1 → 4 linkages. The number of xylose residues involved in their formation can vary from two to ten, and depending upon the number of xylose residues, they are known as xylobiose, xylotriose, and so on. The sweetness of xylobiose is equivalent to 30 % that of sucrose and possesses no off-taste or off-odor. In addition to the health effects, XOS present interesting physicochemical properties; they are moderately sweet and stable over a wide range of pH and temperatures and have organoleptic characteristics suitable for incorporation into foods (Barreteau et al. 2006).

9.1 Method of Production

Xylo-oligosaccharide production from xylan containing biomass is accomplished by xylanase which hydrolyzes β-1 → 4 glycosidic linkages in xylan.

9.1.1 Enzyme Involved

In nature, xylanolytic enzyme systems consist of following types:

-

1.

Endoxylanase (EC 3.2.1.8)

-

2.

β-d-xylosidases (EC 3.2.1.37)

-

3.

Debranching enzymes, esterases (EC 3.1.1.72)

9.1.2 Process

For the production of XOS, the enzyme complex should have low exoxylanase or β-xylosidase activity. Enzyme with high exoxylanase or β-xylosidase activity produces high amount of xylose which causes inhibition in XOS production (Vazquez et al. 2002). A variety of microorganisms are reported to produce endoxylanases that can degrade β-1 → 4 xylan in a random fashion, yielding a series of linear and branched oligosaccharide fragments. These enzymes have been widely detected in filamentous fungi, namely, Aspergillus sp., Trichoderma sp., Penicillium sp., and Thermomyces lanuginosus (Akpinar et al. 2009). Bacterial strains that are known to produce endoxylanase include Bacillus halodurans (Lin et al. 2011), Cellulosimicrobium sp. (Kim et al. 2009), Streptomyces sp. (Puchart and Biely 2008), and B. subtilis (Yuan et al. 2005). Yeasts have also been reported to produce xylanases and this group includes Malbranchea flava (Sharma et al. 2010), Pseudozyma hubeiensis (Bastawde et al. 1994), and Pichia stipitis (Yang et al. 2011). Most of the xylanases known to date are optimally active at temperatures below 50 °C and are active in acidic or neutral pH (Ryan et al. 2003). Investigation on novel sources of bacterial xylanase producers, which display high optimal xylanase activity and stability in more drastic conditions, is still in progress. Moreover, wide-scale industrial application of xylanase requires their cost-effective production to make the process economically viable. Annually, large quantities of lignocellulosic wastes are generated through industrial processes. There are many studies regarding the production of xylanases using waste biomass such as wheat bran, oat bran, rice straw, and corncobs.

Rice straw as an agricultural residue has the highest dry weight percentage of xylan, 24.5 %, and thus would appear to present a high potential for XOS production under optimized pretreatment processes. Other feed stocks having more than 20 % of xylan, such as beech, corn stover, bagasse, tobacco stalk, cotton stalk, sunflower stalk, wheat straw, switch grass, and big blue stem, also have great potential for XOS production. Corncob XOS were produced after enzymatic hydrolysis with a cumulative yield of 67.7 g/100 g (based on xylan in raw material), and the purity of xylo-oligosaccharides was over 70 g/100 g (Yang et al. 2005). Xylo-oligosaccharides have also been successfully isolated from hardwood xylan (Nishimura et al. 1998), delignified cottonseed residual cake (Sun et al. 2002). In another study, XOS was extracted from corncob xylan by acid hydrolysis. HPLC analysis of hydrolysate revealed increased production of XOS with time, but prolonged incubation resulted in higher amount of xylose (Samanta et al. 2012). The autohydrolysis of Eucalyptus globulus wood, corncobs, rice husks, and barley husks resulted in sugar oligomers, xylo-oligosaccharides, monosaccharides, acetyl and uronic acid substituents of oligomers, free acetic acid, furfural, Folin-Denis phenols, and other compounds (Parajo et al. 2004). Among different agricultural wastes, namely, tobacco stalk, cotton stalk, sunflower stalk, and wheat straw, examined for the production of xylo-oligosaccharide, the best xylan conversion into XOS was achieved with 0.25 M H2SO4 with 30-min reaction time followed by enzymatic hydrolysis (Akpinar et al. 2009).

10 Applications of Prebiotics

Prebiotics, a nondigestible oligosaccharide, have various food and non-food applications in different sectors including feed, agriculture, and pharmaceutical (Fig. 10.2). These molecules serve as substrate for probiotic bacteria, thereby, leading to selective enhancement of their growth, which in turn provides health benefits to the host. The various associated health benefits and applications of prebiotics have been discussed in subsequent sections.

10.1 Functional Foods

The health effects imparted by oligosaccharides make them active ingredients of “functional foods” which are similar in appearance to conventional foods that are consumed as part of a normal diet and have physiological benefits and/or reduce the risk of chronic disease beyond basic nutritional functions (Clydesdale 1997). As food ingredients, prebiotics have an acceptable odor and are noncarcinogenic and low caloric, allowing their utilization in anti-obesity diets (Toshio et al. 1990; Kazumitsu et al. 1997). Besides this, lactulose is also incorporated in infant formulas to stimulate health-beneficial microflora like bifidobacterium (Nagendra et al. 1995).

10.2 Gastroenterological Effects

Prebiotics, such as lactulose, FOS, and GOS, have laxative effects (Roberfroid 1993), with lactulose in particular being well established as a treatment for constipation (Schumann 2002). Lactulose increases the water content and volume of the stools in the bowel, making them softer and easier to pass, thereby preventing constipation.

10.3 Regulation of Lipid Metabolism

Nowadays, lowering of the triglyceride levels in the blood is of major concern. The deposition of cholesterol in the arterial wall may lead to atherosclerosis and coronary heart disease. Prebiotics such as galacto-oligosaccharides and xylo-oligosaccharides are reported to lower the serum cholesterol and triglyceride level, respectively, in animals (Chonan et al. 1995; Beylot 2005).

10.4 Absorption of Minerals

Minerals play an important role in various biosynthetic pathways, hardness of the bone, and overcoming various diseases like anemia (Heaney 1996). Mostly, calcium is stored in bone and Mg2+ salts are responsible for the hardness of bones (Rude 1996). The fermentation of prebiotics lowers the pH in the intestine, thereby helping in the increased absorption of various minerals, such as Mg2+, Fe2+, and Ca2+. Therefore, prebiotics can have beneficial effect in the prevention of osteoporosis and osteopenia (Amarowicz 1999; Murosaki et al. 1999).

10.5 Cancer Prevention

Intake of prebiotics can help in suppressing chemically induced colorectal cancer and precancerous colon lesions (Pierre et al. 1997; Hsu et al. 2004). Short-chain fatty acid, such as butyrate, has protective action in the colon by preventing tumor growth and cell differentiation and upregulates apoptosis (Reddy 1999).

10.6 Immunity Enhancement

Prebiotics have influential role on the immune system, microbial composition, and metabolic product formation in the gastrointestinal tract. They provide both nonspecific (physical barrier against toxins and pathogens) and specific (gut-associated lymphoid tissue) protection and improve resistance against infection (Watzl et al. 2005). Colonic microbiota is helpful in tolerance to bacterial and dietary antigens (Roller et al. 2004). Immunological effects, such as increased level of mucosal immunoglobulin production, mesenteric lymph nodes, Peyer’s patches, and altered cytokine formation and lymphocyte numbers, have been reported as an effect of prebiotic intake in the diet (Schley and Field 2002).

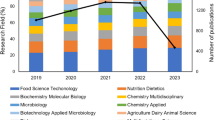

11 Market Demand of Prebiotics

Foods containing prebiotics are a growing segment in the world market due to their beneficial effects on human health (Fig. 10.3). They are known to provide specific health benefits, hence belong to a special class of foods known as functional foods. For this reason, there has been a rapid market growth in recent years all over the world. This is particularly applicable for XOS, having a selling price of 2,500 yen/kg in Japanese market, the highest among 13 different types of oligosaccharides (Stanton et al. 2001). The current largest world market for functional foods is the United States, followed by Europe and Japan, while Germany, France, United Kingdom, and the Netherlands represent the most important countries within the functional food market in Europe. According to Global Industry Analysts (GIA) report, by 2015, the US and European prebiotic market will reach nearly $225 million and $1.12 billion, respectively, mainly impacted by prebiotic meat and snack food products (Neutraceuticals world 2010). Inulin will contribute a major portion (35 %) due to its textural resemblance with fats followed by mannan oligosaccharide (25 %) and fructan oligosaccharides (10 %) as natural sweeteners (Watson 2011). There is yet an unfulfilled potential in the world market for emerging prebiotics in terms of their production and purification that can be optimized from cellulosic biomass pretreatments.

Global production status of different prebiotics (Source: Singh and Singh 2010; Reproduced with permission)

12 Summary

Worldwide awareness of consumers towards diet and health has opened up new opportunities for food industries in research and development of functional foods. Foods that contain pre- and probiotics are getting special attention of consumers and are potentially exciting component of the food market. Different prebiotics can be used for the fortification of different food products for the designing of functional foods for the special target groups. Prebiotics support the growth of beneficial bacteria, thereby adding up to potential health and nutritional benefits. These compounds are associated with prevention and treatment of various chronic diseases, such as constipation, hepatic encephalopathy, and cancer. However, to improve the economics of prebiotic production, technologies based on bio-utilization of agro-industrial waste/by-products (whey, wheat and rice straw, sugarcane bagasse, etc.) need to be further strengthened.

References

Adamczak M, Charubin D, Bednarski W (2009) Influence of reaction medium composition on enzymatic synthesis of galacto-oligosaccharides and lactulose from lactose concentrates prepared from whey permeate. Chem Pap 63:111–116

Aider M, de Halleux D (2007) Isomerization of lactose and lactulose production: review. Trends Food Sci Technol 187:356–364

Akiyama K, Takase M, Horikoshi K et al (2001) Production of galactooligosaccharides from lactose using a beta-glucosidase from Thermus sp Z-1. Biosci Biotechnol Biochem 65:438–441

Akpinar O, Erdogan K, Bostanci S (2009) Production of xylooligosaccharides by controlled acid hydrolysis of lignocellulosic materials. Carbohydr Res 344:660–666

Albayrak N, Yang ST (2002) Production of galacto-oligosaccharides from lactose by Aspergillus oryzae β-galactosidase immobilized on cotton cloth. Biotechnol Bioeng 77:8–19

Amarowicz R (1999) Nutritional importance of oligosaccharides. Rocz Panstw Zakl Hig 50(1):89–95

Angus F, Smart S, Shortt C (2005) Prebiotic ingredients with emphasis on galactooligosaccharides and fructo-oligosaccharides. In: Tamime AY (ed) Probiotic dairy products. Blackwell, Oxford, UK

Aslana Y, Tanriseven A (2007) Immobilization of Penicillium lilacinum dextranase to produce isomaltooligosaccharides from dextran. Biochem Eng J 34(1):8–12

Babu KR, Satyanarayana T (1995) α-Amylase production by thermophilic Bacillus coagulans in solid state fermentation. Process Biochem 30:305–309

Bali V, Panesar PS, Bera MB (2012) Fructo-oligosaccharides: production, purification and potential applications. Crit Rev Food Sci Nutr (accepted manuscript)

Barreteau H, Delattre C, Michaud P (2006) Production of oligosaccharides as promising new food additive generation. Food Technol Biotechnol 44:323–333

Bastawde KB, Puntambekar US, Gokhale DV (1994) Optimization of cellulase free xylanase production by a novel yeast strain. J Ind Microbiol 13:220–224

Baysal Z, Uyar F, Aytekin C (2003) Solid state fermentation for production of α-amylase by a thermotolerant Bacillus subtilis from hot-spring water. Process Biochem 38:1665–1668

Beker M, Laukevics J, Upite D et al (2002) Fructooligosaccharide and levan producing activity of Zymomonas mobilis and extracellular levan sucrase. Process Biochem 38:701–706

Beylot M (2005) Effects of inulin-type fructans on lipid metabolism in man and in animal models. Br J Nutr 93:63–68

Boon MA, van der Oost J, de Vos WM et al (1998) Synthesis of oligosaccharides catalyzed by thermostable beta-glucosidase from Pyrococcus furiosus. Appl Biochem Biotechnol 75:269–278

Bornet FRJ, Brouns F, Tashiro Y et al (2002) Nutritional aspects of short-chain fructooligosaccharides: natural occurrence, chemistry, physiology and health implications. Dig Liver Dis 34(2):111–120

Brienzo M, Carvalho W, Milagres AMF (2010) Xylooligosaccharides production from alkali pretreated sugarcane bagasse using xylanase from Thermoascus aurantiacus. Appl Biochem Biotechnol 162:1195–1205

Cardelle-Cobas A, Villamiel M, Olano A et al (2008) Study of galacto-oligosaccharide formation from lactose using pectinex ultra SP-L. J Sci Food Agric 88:954–961

Chen HQ, Chen XM, Li Y et al (2009) Purification and characterisation of exo- and endo-inulinase from Aspergillus ficuum JNSP5-06. Food Chem 115:1206–1212

Cheng CY, Duan KJ, Sheu DC et al (1996) Production of fructooligosaccharides by immobilized mycelium of Aspergillus japonicas. J Chem Technol Biotechnol 66(2):135–138

Choi JJ, Oh EJ, Lee YJ et al (2003) Enhanced expression of the gene for beta-glycosidase of Thermus caldophilus GK24 and synthesis of galacto-oligosaccharides by the enzyme. Biotechnol Appl Biochem 38:131–136

Choi H-J, Kim CS, Kim P et al (2004) Lactosucrose bioconversion from lactose and sucrose by whole cells of paenibacillus polymyxa harboring levansucrase activity. Biotechnol Prog 20:1876–1879

Chonan O, Matsumoto K, Watanuki M (1995) Effect of galactooligosaccharides on calcium absorption and preventing bone loss in ovariectomized rats. Biosci Biotechnol Biochem 59:236–239

Clydesdale FM (1997) A proposal for the establishment of scientific criteria for health claims for functional foods. Nutr Res 55:413–423

Conway PL (2001) Prebiotics and human health: the state-of-the-art and future perspectives. Scand J Nutr 45:13–21

Cruz R, Cruz VD, Belote JG et al (1999) Production of transgalactosylated oligosaccharides (TOS) by galactosyltransferase activity from Penicillium simplicissimum. Bioresour Technol 70:165–171

De Harr WT, Pluim H (1991) Method of preparing lactulose. European patent 0339749

Dorta C, Cruz R, de Oliva-Neto P et al (2006) Sugarcane molasses and yeast powder used in the fructooligosaccharides production by Aspergillus japonicus-FCL 119T and Aspergillus niger ATCC 20611. J Ind Microbiol Biotechnol 33(12):1003–1009

Doukyu N, Yamagishi W, Kuwahara H et al (2007) Purification and characterization of a maltooligosaccharide-forming amylase that improves product selectivity in water-miscible organic solvents, from dimethylsulfoxide-tolerant Brachybacterium sp. strain LB25. Extremophiles 11(6):781–788

Fernández-Arrojo L, Marín D, De Segura AG et al (2007) Transformation of maltose into prebiotic isomaltooligosaccharides by a novel α-glucosidase from Xanthophyllomyces dendrorhous. Process Biochem 42(11):1530–1536

Foda MI, Lopez-Leiva M (2000) Continuous production of oligosaccharides from whey using a membrane reactor. Process Biochem 35:581–587

Franck A (2002) Technological functionality of inulin and oligofructose. Br J Nutr 87:287–291

Gänzle MG (2011) Lactose galacto-oligosaccharides. In: Fuquay JW, Fox PF, McSweeney P (eds) Encyclopedia of dairy science, 2nd edn. Elsevier, Oxford, UK

Gänzle MG, Haase G, Jelen P (2008) Lactose: crystallization, hydrolysis and value-added derivatives. Int Dairy J 18:685–694

Ghazi I, Fernandez-Arrojo L, Gomez De Segura A et al (2006) Beet sugar syrup and molasses as low-cost feedstock for the enzymatic production of fructo-oligosaccharides. J Agric Food Chem 54(8):2964–2968

Gill PK, Manhas RK, Singh P (2006) Hydrolysis of inulin by immobilized thermostable extracellular exoinulinase from Aspergillus fumigates. J Food Eng 76:369–375

Godshall MA (2007) Future directions for the sugar industry. http://www.spriinc.org/buton10bftpp.html

Goulas AK, Kapasakalidis PG, Sinclair HR et al (2002) Purification of oligosaccharides by nanofiltration. J Membr Sci 209:321–335

Guimaraes LHS, Terenzi HF, Polizeli ML et al (2007) Production and characterization of a thermostable extracellular β-D-fructofuranosidase produced by Aspergillus ochraceus with agroindustrial residues as carbon sources. Enzyme Microb Technol 42:52–57

Han W-C, Byun S-H, Kim M-H et al (2009) Production of lactosucrose from sucrose and lactose by a levansucrase from Zymomonas mobilis. J Microbiol Biotechnol 19:1153–1160

Hang YD, Woodams EE, Jang KY (1995) Enzymatic conversion of sucrose to ketose by fungal extracellular fructosyltransferase. Biotechnol Lett 17:295–298

Hayashi S, Matsuzaki K, Kawahara T et al (1992) Utilisation of soybean residue for the production of β-fructofuranosidase. Bioresour Technol 41(3):231–233

Heaney RP (1996) Calcium. In: Raisz LG, Rodan GA, Bilezikian JP (eds) Principle of bone biology. Academic, San Diego, CA

HelleroVá K, Čurda L (2009) Influence of type of substrate and enzyme concentration on formation of galacto-oligosaccharides. Czech J Food Sci 27:327–374

Hernalsteens S, Maugeri F (2008) Purification and characterisation of a fructosyltransferase from Rhodotorula sp. Appl Microbiol Biotechnol 79(4):589–596

Hicks KB, Raupp DL, Smith PW (1984) Preparation and purification of lactulose from sweet cheese whey ultrafiltrate. J Agric Food Chem 32:288–292

Hijum SV, van Geel-Schutten GH, Rahouri H et al (2002) Characterization of a novel fructosyl transferase from Lactobacillus reuteri that synthesizes high molecular weight inulin and inulin oligosaccharides. Appl Environ Microbiol 68:4390–4398

Hsu CK, Liao JW, Chung YC et al (2004) Xylooligosaccharides and fructooligosaccharides affect the intestinal microbiota and precancerous colonic lesion development in rats. J Nutr 134:1523–1528

Jaindl K, Schuster-Wolff-Bühring R, Fischer L et al (2009) Enzymic synthesis of prebiotic lactulose in milk and whey products. DMZ Lebensmittelindustrie und Milchwirtschaft 130:24–27

Jovanovic-Malinovska R, Fernandes P, Winkelhausen E et al (2012) Galacto-oligosaccharides synthesis from lactose and whey by β-galactosidase immobilized in PVA. Appl Biochem Biotechnol. doi:10.1007/s12010-012-9850-1

Jung KH, Bang SH, OH TK et al (2011) Industrial production of fructooligosaccharides by immobilized cells of Aureobasidium pullulans in a packed bed reactor. Biotechnol Lett 33(8):1621–1624

Kawase M, Pilgrim A, Araki T et al (2001) Lactosucrose production using a simulated moving bed reactor. Chem Eng Sci 56:453–458

Kazumitsu S, Boseki I, Norio S et al (1997) Production of food and drink. Japanese Patent JP 9248153

Kim Y-S, Park C-S, Oh D-K (2006) Lactulose production from lactose and fructose by a thermostable β-galactosidase from Sulfolobus solfataricus. Enzyme Microb Technol 39:903–908

Kim HC, Kim HJ, Choi WB et al (2008) Inulo-oligosaccharide production from inulin by Saccharomyces cerevisiae strain displaying cell surface endoinulases. J Microbiol Biotechnol 16(3):360–367

Kim DY, Han MKY, Lee JS et al (2009) Isolation and characterization of a cellulase-free endo-β-1, 4-xylanase produced by an invertebrate-symbiotic bacterium, Cellulosimicrobium sp. HY-13. Process Biochem 44:1055–1059

Kumar S, Khare SK (2012) Purification and characterization of maltooligosaccharide-forming α-amylase from moderately halophilic Marinobacter sp. EMB8. Bioresour Technol 116:247–251

Ladero M, Perez MT, Santos A et al (2003) Hydrolysis of lactose by free and immobilized β-galactosidase from Thermus sp. strain T2. Biotechnol Bioeng 81:241–252

Lateef A, Gueguim kana EB (2012) Utilization of cassava wastes in the production of fructosyltransferase by Rhizopus stolonifer LAU 07. Rom Biotechnol Lett 17(3):7309–7316

Lee YJ, Kim CS, Oh DK (2004) Lactulose production by β-galactosidase in permeabilized cells of Kluyveromyces lactis. Appl Microbiol Biotechnol 64:787–793

Lee JH, Lim JS, Park C et al (2007) Continuous production of lactosucrose by immobilized Sterigmatomyces elviae mutant. J Microbiol Biotechnol 17:1533–1537

Li W, Xiang X, Tang S et al (2009) Effective enzymatic synthesis of lactosucrose and its analogues by β-D-galactosidase from Bacillus circulans. J Agric Food Chem 57:3927–3933

Lin YS, Tsengb MJ, Lee WC (2011) Production of xylooligosaccharides using immobilized endo-xylanase of Bacillus halodurans. Process Biochem 46:2117–2121

Liu X-Y, Chi Z, Liu G-L et al (2010) Inulin hydrolysis and citric acid production from inulin using the surface-engineered Yarrowia lipolytica displaying inulinase. Metab Eng 2(5):469–476

López Leiva MHL, Guzman M (1995) Formation of oligosaccharides during enzymic hydrolysis of milk whey permeates. Process Biochem 30:757–762

Mahoney RR (1998) Galactosyl-oligosaccharide formation during lactose hydrolysis: a review. Food Chem 63:147–154

Maugeri F, Hernalsteens S (2007) Screening of yeast strains for transfructosylating activity. J Mol Catal B Enzym 49:43–49

Mayer J, Kranz B, Fischer L (2010) Continuous production of lactulose by immobilized thermostable β-glycosidase from Pyrococcus furiosus. J Biotechnol 145:387–393

Mazutti M, Bender JP, Treichel H et al (2006) Optimization of inulinase production by solid-state fermentation using sugarcane bagasse as substrate. Enzyme Microb Technol 39(1):56–59

Méndez A, Olano A (1979) Lactulose: a review on some chemical properties and applications in infant nutrition and medicine. Dairy Sci Abstr 41:531–535

Molis C, Flourie B, Ouarne F et al (1996) Digestion, excretion, and energy value of fructooligosaccharides in healthy humans. Am J Clin Nutr 64(3):324–328

Murosaki S, Muroyama K, Yamamoto Y et al (1999) Immunopotentiating activity of nigerooligosaccharides for the T helper 1-like immune response in mice. Biosci Biotechnol Biochem 63(2):373–378

Mussatto SI, Teixeira JA (2010) Increase in the fructooligosaccharides yield and productivity by solid-state fermentation with Aspergillus japonicus using agroindustrial residues as support and nutrient source. Biochem Eng J 53:154–157

Nagarajan DR, Rajagopalan G, Krishnan C (2006) Purification and characterization of a maltooligosaccharide forming α-amylase from a new Bacillus subtilis KCC103. Appl Microbiol Biotechnol 73:591–597

Nagendra R, Viswanatha S et al (1995) Effect of feeding milk formula containing lactulose to infants on faecal bifidobacterial flora. Nutr Res 15:15–24

Nakkharat P, Kulbe KD, Yamabhai M et al (2006) Formation of galacto-oligosaccharides during lactose hydrolysis by a novel β-galactosidase from the moderately thermophilic fungus Talaromyces thermophilus. Biotechnol J 1:633–638

Neagu C, Bahrim G (2011) Inulinases—a versatile tool for biotechnology. Innovat Rom Food Biotechnol 9:1–11

Neutraceuticals World (2010) Report finds significant potential in prebiotics market. http://www.nutraceuticalsworld. com/contents/view_breaking-news/2010-02-23/report- finds-significant-potential-in-prebiotics-m/

Nguyen TH, Splechtna B, Krasteva S et al (2007) Characterization and molecular cloning of a heterodimeric β-galactosidase from the probiotic strain Lactobacillus acidophilus R22. FEMS Microbiol Lett 269:136–144

Niness KR (1999) Inulin and oligofructose: what are they? J Nutr 129:1402–1406

Nishimura T, Ishihara M, Tadashi I et al (1998) Alkaline xylanases from Bacillus mojavensis A21: production and generation of xylooligosaccharides. Carbohydr Res 308:117–122

Onishi N, Tanaka T (1997) Purification and characterization of galacto-oligosaccharide producing β-galactosidase from Sirobasidium magnum. Lett Appl Microbiol 24:82–86

Ota M, Okamoto T, Wakabayashi H (2009) Action of transglucosidase from Aspergillus niger on maltoheptaose and [U–13C] maltose. Carbohydr Res 344:460–465

Panesar PS, Panesar R, Singh RS et al (2006) Microbial production, immobilization and applications of β-D-galactosidase. J Chem Technol Biotechnol 81:530–543

Parajo JC, Garrote G, Cruz JM et al (2004) Effects of xylooligosaccharides and sugars on the functionality of porcine myofibrillar proteins during heating and frozen storage. Trends Food Sci Technol 15:115–120

Park K (1992) Development of new carbohydrate materials. Food Sci Ind 25:73–82

Park YK, Pastore GM (2006) Process for preparing β-fructofuranosidase enzyme and a process for producing fructooligosaccharides. US Patent 7063976

Park J, Oh T, Yun JW (2001) Purification and characterization of a novel transfructosylating enzyme from Bacillus macerans EG-6. Process Biochem 37:471–476

Park N-H, Choi H-J, Oh D-K (2005) Lactosucrose production by various microorganisms harboring levansucrase activity. Biotechnol Lett 27:495–497

Petzelbauer I, Zeleny R, Reiter A et al (2000) Development of an ultrahigh- temperature process for the enzymatic hydrolysis of lactose: II. Oligosaccharide formation by two thermostable β-glycosidases. Biotechnol Bioeng 69:140–149

Pierre F, Perrin P, Champ M et al (1997) Short-chain fructo-oligosaccharides reduce the occurrence of colon tumors and develop gut-associated lymphoid tissue in Min mice. Cancer Res 57(2):225–228

Placier G, Watzlawick H, Rabiller C et al (2009) Evolved β-galactosidases from Geobacillus stearothermophilus with improved transgalactosylation yield for galacto-oligosaccharides production. Appl Environ Microbiol 75:6312–6321

Puchart V, Biely P (2008) Simultaneous production of endo-β-1,4-xylanase and branched xylooligosaccharides by Thermomyces lanuginosus. J Biotechnol 137:34–43

Rajagopalan G, Krishnan C (2008) α-Amylase production from catabolite derepressed Bacillus subtilis KCC103 utilizing sugarcane bagasse hydrolysate. Bioresour Technol 99:3044–3050

Rajoka MI, Yasmeen A (2005) Improved productivity of β-fructofuranosidase by a derepressed mutant of Aspergillus niger from conventional and non-conventional substrates. World J Microbiol Biotechnol 21:471–478

Reddy BS (1999) Possible mechanisms by which pro- and prebiotics influence colon carcinogenesis and tumor growth. J Nutr 129:1478–1482

Roberfroid MB (1993) Dietary fibre, inulin and oligofructose: a review comparing their physiological effects. Crit Rev Food Sci Nutr 33:103–148

Roberfroid MB (1997) Health benefits of non-digestible oligosaccharides. Adv Exp Med Biol 427:211–219

Roller M, Rechkemmer G, Watzl B (2004) Prebiotic inulin enriched with oligofructose in combination with the probiotics Lactobacillus rhamnosus and Bifidobacterium lactis modulates intestinal immune function in rats. J Nutr 134:153–156

Rude RK (1996) Magnesium homeostasis. In: Raisz LG, Rodan GA, Bilezikian JP (eds) Principle of bone biology. Academic, San Diego, CA

Ryan SE, Nolan K, Thompson R et al (2003) Purification and characterization of a new low molecular weight endoxylanase from Penicillium capsulatum. Enzyme Microb Technol 33:775–785

Sakai T, Tsuji H, Shibata S et al (2008) Repeated-batch production of galactooligosaccharides from lactose at high concentration by using alginate-immobilized cells of Sporobolomyces singularis YIT 10047. J Gen Appl Microbiol 54:285–293

Sako T, Matsumoto K, Tanaka R (1999) Recent progress on research and applications of non-digestible galacto-oligosaccharides. Int Dairy J 9:69–80

Samanta AK, Jayapal N, Kolte AP et al (2012) Enzymatic production of xylooligosaccharides from alkali solubilized xylan of natural grass (Sehima nervosum). Bioresour Technol 112:199–205

Sangeetha PT, Ramesh MN, Prapulla SG (2004) Production of fructosyl transferase by Aspergillus oryzae CFR 202 in solid-state fermentation using agricultural by-products. Appl Microbiol Biotechnol 65:530–537

Sangeetha PT, Ramesh MN, Prapulla SG (2005a) Recent trends in the microbial production, analysis and application of fructooligosaccharides. Trends Food Sci Technol 16:442–457

Sangeetha PT, Ramesh MN, Prapulla SG (2005b) Fructooligosaccharide production using fructosyl transferase obtained from recycling culture of Aspergillus oryzae CFR 202. Process Biochem 40:1085–1088

Schley PD, Field CJ (2002) The immune-enhancing effects of dietary fibres and prebiotics. Br J Nutr 87:221–230

Schumann C (2002) Medical, nutritional and technological properties of lactulose. An update. Eur J Nutr 41:17–25

Sharma M, Chadha BS, Saini HS (2010) Purification and characterization of two thermostable xylanases from Malbranchea flava active under alkaline conditions. Bioresour Technol 101:8834–8842

Sheu DC, Li SY et al (1998) Production of galactooligosaccharides by β-galactosidase immobilized on glutaraldehyde-treated chitosan beads. Biotechnol Tech 12:273–276

Shimoda K, Hamada H (2010) Synthesis of β-maltooligosaccharides of glycitein and daidzein and their anti-oxidant and anti-allergic activities. Molecules 15:5153–5161

Shimoda K, Akagi M, Hamada H (2009) Production of β-maltooligosaccharides of α- and δ-tocopherols by Klebsiella pneumoniae and cyclodextrin glucanotransferase as anti-allergic agents. Molecules 14:3106–3114

Shin HT, Baig SY, Lee SW et al (2004) Production of fructo-oligosaccharides from molasses by Aureobasidium pullulans cells. Bioresour Technol 93:59–62

Singh RS, Singh RP (2010) Production of fructooligosaccharides from inulin by endoinulinases and their prebiotic potential. Food Technol Biotechnol 48:435–450

Sodhi HK, Sharma K, Gupta JK et al (2005) Production of a thermostable α-amylase from Bacillus sp. PS-7 by solid state fermentation and its synergistic use in the hydrolysis of malt starch for alcohol production. Process Biochem 40:525–534

Splechtna B, Petzelbauer I, Baminger U et al (2001) Production of a lactose-free galacto-oligosaccharide mixture by using selective enzymatic oxidation of lactose into lactobionic acid. Enzyme Microb Technol 29:434–440

Splechtna B, Nguyen TH, Steinbock M et al (2006) Production of prebiotic galacto-oligosaccharides from lactose using β-galactosidases from Lactobacillus reuteri. J Agric Food Chem 54:4999–5006

Stanton C, Gardiner G, Meehan H et al (2001) Market potential for probiotics. Am J Clin Nutr 73:476–483

Sun HJ, Yoshida S, Park NH et al (2002) Enzymatic preparation of wheat bran xylooligosaccharides and their stability during pasteurization and autoclave sterilization at low pH. Carbohydr Res 337:657–661

Tang L, Li ZA, Dong XX et al (2011) Lactulose biosynthesis by β-galactosidase from a newly isolated Arthrobacter sp. J Ind Microbiol Biotechnol 38:471–476

Torres DPM, Goncalves MDPF, Teixeira JA et al (2010) Galacto-oligosaccharides: production, properties, applications, and significance as probiotics. Compr Rev Food Sci Food Saf 9:438–454

Toshio I, Noriyoshi I, Toshiaki K et al (1990) Production of xylobiose. Japanese Patent JP 2119790

Tzortzis G, Goulas AK, Gibson GR (2005) Synthesis of probiotic galactooligosaccharides using whole cells of a novel strain, Bifidobacterium bifidum NCIMB 41171. Appl Microbiol Biotechnol 68:412–416

Van LJ, Coussement P, De Leenheer L et al (1995) On the presence of inulin and oligofructose as natural ingredients in the western diet. Crit Rev Food Sci Nutr 35:525–552

Vankova K, Onderková Z, Antošová M et al (2008) Design and economics of industrial production of fructooligosaccharides. Chem Pap 62(4):3753–3781

Vazquez MJ, Garrote G, Alonso JL et al (2002) Refining of autohydrolysis liquors for manufacturing xylooligosaccharides: evaluation of operational strategies. Bioresour Technol 96:889–896

Vranesic D, Kurtanjek Z, Santos AMP et al (2002) Optimisation of inulinase production by Kluyveromyces bulgaricus. Food Technol Biotechnol 40(1):7–73

Waterhouse AL, Chatterton NJ (1993) Glossary of fructan terms. In: Chatterton NJ, Suzuki M (eds) Science and technology of fructans. CRC, Boca Raton, FL

Watson E (2011) Frost & Sullivan: US prebiotics market to double in five years. Prebiotics. http://www.nutraingredients-usa.com/Industry/Frost-Sullivan-US-prebiotics-market-to-double-in-five-years

Watzl B, Girrbach S, Roller M (2005) Inulin, oligofructose and immunomodulation. Br J Nutr 93:49–55

Xiao H, Ruijin Y, Wenbin Z et al (2010) Dual-enzymatic synthesis of lactulose in organic-aqueous two-phase media. Food Res Int 43:716–722

Xu ZW, Li YQ, Wang YH et al (2009) Production of β-fructofuranosidase by Arthrobacter sp. and its application in the modification of stevioside and rebaudioside A. Food Technol Biotechnol 47(2):137–143

Yang H, Wang H, Song X et al (2011) Production of xylooligosaccharides by xylanase from Pichia stipitis based on xylan preparation from triploid Populus tomentosa. Bioresour Technol 102:7171–7176

Yang R, Xu S, Wang Z, Yang W (2005) Aqueous extraction of corn cob xylan and production of xylooligosaccharides. LWT-Food Sci Technol 38:677–682

Yuan X, Wang J, Yao H (2005) Antioxidant activity of feruloylated oligosaccharides from wheat bran. Food Chem 90:759–764

Yun JW, Kim DH, Kim BW et al (1997a) Production of inulo-oligosaccharides from inulin by immobilized endoinulinase from Pseudomonas sp. J Ferment Bioeng 84:369–371

Yun JW, Kim DH, Yoon HB et al (1997b) Effect of inulin concentration on the production of inulo-oligosaccharides by soluble and immobilized endoinulinase. J Ferment Bioeng 84(4):365–368

Yun JW, Park JP, Song CH et al (2000) Continuous production of inulo-oligosaccharides from chicory juice by immobilized endoinulinase. Bioprocess Eng 22(3):189–194

Zhang L, Su Y, Zheng Y et al (2010) Sandwich-structured enzyme membrane reactor for efficient conversion of maltose into isomaltooligosaccharides. Bioresour Technol 101(23):9144–9149

Zhengyu J, Jing W, Bo J et al (2005) Production of inulooligosaccharides by endoinulinases from Aspergillus ficuum. Food Res Int 38:301–308

Zokaee F, Kaghazchi T, Zare A et al (2002) Isomerization of lactose to lactulose-study and comparison of three catalytic systems. Process Biochem 37:629–635

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media New York

About this chapter

Cite this chapter

Panesar, P.S., Bali, V., Kumari, S., Babbar, N., Oberoi, H.S. (2014). Prebiotics. In: Brar, S., Dhillon, G., Soccol, C. (eds) Biotransformation of Waste Biomass into High Value Biochemicals. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-8005-1_10

Download citation

DOI: https://doi.org/10.1007/978-1-4614-8005-1_10

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-8004-4

Online ISBN: 978-1-4614-8005-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)