Abstract

On-going research is concerned with the losses that occur at junctions in lightweight building structures. Recently the authors have investigated the underlying uncertainties related to both measurement, material and craftsmanship of timber junctions by means of repeated modal testing on a number of nominally identical test subjects. However, the literature on modal testing of timber structures is rather limited and the applicability and robustness of different curve fitting methods for modal analysis of such structures is not described in detail. The aim of this paper is to investigate the robustness of two parameter estimation methods built into the commercial modal testing software B&K Pulse Reflex Advanced Modal Analysis. The investigations are done by means of frequency response functions generated from a finite-element model and subjected to artificial noise before being analyzed with Pulse Reflex. The ability to handle closely spaced modes and broad frequency ranges is investigated for a numerical model of a lightweight junction under different signal-to-noise ratios. The selection of both excitation points and response points are discussed. It is found that both the Rational Fraction Polynomial-Z method and the Polyreference Time method are fairly robust and well suited for the structure being analyzed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

16.1 Introduction

Currently, lightweight building techniques are advancing due to an increasing awareness regarding the use of environmentally friendly materials combined with low production costs, quick installation and easy transportation. However, lightweight building structures suffer serious drawbacks in terms of poor low frequency sound insulation, due to the low mass of the constructions. As the trend is going towards increasing demands to the acoustic performance of building elements, inaccurate prediction methods and poor performance calls for over-dimensioning of the elements. This increases both weight and cost, which contradicts the idea of using lightweight elements in a building. Modern production techniques with prefabricated lightweight modules are rapidly evolving, and encourage re-thinking the design of building elements. On-going research is concerned with the losses that occur at junctions in lightweight structures. Recently the authors have investigated the underlying uncertainties related to both measurement, material and craftsmanship of timber junctions by means of repeated modal testing on a number of nominally identical test subjects [1]. However, the literature on modal testing of timber structures is rather limited and the applicability and robustness of different curve fitters for modal analysis of such structures is not described in detail. Lightweight structures often have non-linear properties, and since conventional modal analysis is based on linear theory, the applicability of modal analysis of such structures depends on how well the principle of superposition of modes fits the dynamic behavior of the structure. Furthermore, closely spaced modes and broad frequency ranges of interest needs to be dealt with in the process of modal parameter estimation.

The present paper compares two different curve fitting methods implemented in the commercial software Pulse Reflex Advanced Modal Analysis from Brüel & Kjær. One is the Rational Fraction Polynomial-Z method, and the other is the Polyreference Time method. Both are global higher order curve fitting methods, generally well suited for a wide range of analyses.

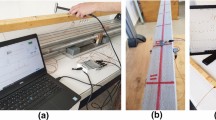

The robustness of each of the two methods is investigated by applying increasing amounts of noise to the frequency response functions (FRFs), which are being analyzed in Pulse Reflex. The ability of each method to correctly capture all the modes—when influenced by noise—is used to judge the robustness of the methods. The frequency response functions are obtained from a non-linear numerical model made with the finite element (FE) code Abaqus [2]. The structure being modeled is a T-junction between a particleboard plate and a spruce beam (as subjected to measurements in [1], see Fig. 16.1). The only non-linearities included in the FE model are the contact properties of the junction itself. The materials are assumed to have linear elastic properties. A comparison of modes found by modal analysis of the non-linear model, to modes found by the (computationally) much simpler Lanczos Eigenvalue solver—which is built in to Abaqus—is included, to demonstrate why linear perturbation analysis does not work for this type of structure.

Experimental setup used for measurements in [1]

The use of a numerical model—rather than actual measurements—has been chosen to ensure a controlled environment, such that the initial FRFs are unbiased by measurement error and noise. However, there is a tradeoff, since the numerical model may introduce numerical error, and/or may not mimic the behavior of actual real life wooden junctions in sufficient detail. By using a dynamic implicit time domain solver in Abaqus, the model accounts for non-linear contact properties in the coupling.

In Section 16.2 the methodology is described in detail. Sections 16.3 and 16.4 present and discuss the results, while ideas for future work are proposed in Section 16.5. Finally, findings are summarized and conclusions drawn in Section 16.6.

16.2 Methodology

The analyses presented here consist of three main stages:

-

1.

A series of measurements for modal analysis is simulated by a numerical FE-model in Abaqus. Impact testing using three excitation points and 32 response points is simulated by utilizing an implicit dynamic solver.

-

2.

The response time signals for each degree-of-freedom (DOF) at each impact are exported from Abaqus as acceleration signals. These are then imported into Matlab, where Gaussian white noise is added before applying an exponential window and calculating the FRFs by means of the fast Fourier transform (FFT).

-

3.

The resulting FRFs are imported in Pulse Reflex Advanced Modal Analysis where they are analyzed using each of the two curve fitting methods being investigated in the present paper.

The following sections describe each step of the analysis in detail.

16.2.1 Computational Model in Abaqus

The T-junction is modeled in the commercial FEM package Abaqus. The model consists of just two parts; the plate and the beam. The two parts are supposed to be connected to each other by three screws, which for simplicity are modeled as full surface ties at three 5 mm by 5 mm square interfaces. The contact between the remaining parts of the surfaces is assumed to have a tangential friction coefficient of 0.5, while the normal behavior is modeled using linear pressure-overclosure with contact stiffness 50 GN/m.

All parts are modeled using solid continuum finite elements. 20-node brick elements with quadratic spatial interpolation of the displacement are adopted. The mesh size is put to 50 mm to ensure a sufficiently high resolution of the model in the investigated frequency range. The mesh is designed such that the nodes constituting the plate mesh align with the nodes on the frame structure. The mesh is shown in Fig. 16.2. As three-dimensional solid continuum elements have no rotational degrees of freedom, only displacements are considered. Free-free boundary conditions are assumed. Isotropic and homogeneous materials are assumed if not directly stated otherwise.

The material properties are the same as used in [1]. The properties of the beam are: Young’s modulus E = 8. 5 GPa, Poisson ratio ν = 0. 3, density ρ = 480 kg/m3. Damping is set to 5% of the stiffness. The damping is applied as structural damping, i.e. the damping forces are assumed proportional to the forces caused by stressing of the structure. This simulates the effects of friction in the timber. Generally a spruce beam would not be expected to have isotropic material properties, but since it (in terms of stiffness) mainly contributes in one direction in the present experiment, it is assumed to be isotropic. Regarding the material properties of the particleboard plates, experiments have shown that they behave in an orthotropic manner, which may be related to the way such plates are manufactured. As a crude estimate, a quick fit has been made by adjusting the Young’s Moduli and shear moduli until a decent fit between measurement and model (in terms of natural frequencies and modeshapes) was obtained. The resulting values are: Young’s moduli E 1 = 3. 45 GPa, E 2 = 3. 00 GPa and E 3 = 4. 00 GPa, Poisson ratio \(\nu _{12} =\nu _{13} =\nu _{23} = 0.2\), shear moduli G 12 = 1. 35 GPa and \(G_{13} = G_{23} = 1.20\) GPa, density ρ = 645 kg/m3. Damping is set to 2% of the stiffness.

Each impact has been modeled as a concentrated force in a single node located at the bottom of the plate, while the responses are taken at nodes on the top of the plate. The responses are extracted as acceleration in nodes corresponding to where accelerometers had been placed in [1]. Likewise, the impact nodes correspond to positions of excitation used in [1]. The (transient) impact signal is a narrow Gauss shaped signal:

where a = 100 N, t 0 = 0. 01 s, and \(b = 7 \cdot 1{0}^{-5}\) s. By utilizing dynamic implicit time integration in Abaqus/Standard and requesting output a time points with a sample rate of 10 kHz for a time period of two seconds after each impact, acceleration time signals are obtained for each DOF for each of the three impacts. From these time signals, the FRFs can be calculated and subjected to modal analysis, which will be described in the following sections.

16.2.2 Post Processing in Matlab

The time signals from Abaqus are imported to Matlab, where the transformation from time domain to frequency domain is carried out by means of the fast Fourier transform. Before applying the FFT, noise is added to the signals by means of the Matlab function awgn() – Add White Gaussian Noise. After adding noise, an exponential window is applied before performing the FFT. Finally, frequency response functions are obtained as the frequency domain ratio of response (acceleration) to excitation (force). SNRs from 50 to 0 dB are considered in 5 dB steps.

Figure 16.3 shows an example of a time signal obtained from Abaqus before and after applying noise and windowing. The signal depicted in the figure is a driving point response, and the amount of noise added is such that the signal-to-noise ratio is 5 dB. The corresponding FRFs are shown in Fig. 16.4

16.2.3 Modal Analysis in Pulse Reflex

The FRFs are imported to B&K Pulse Reflex Advanced Modal Analysis, where they are subjected to modal parameter estimation by two different methods: The Rational Fraction Polynomial-Z method and the Polyreference Time method. The frequency range of analysis is 20-250 Hz. Both methods are global higher order methods and all settings have been left at their default values.

Figure 16.5 shows the geometry as seen in Pulse Reflex with 32 response DOFs and three impact DOFs. Analyses have been carried out using all three impacts at once as well as for each impact alone.

Once a stability diagram is generated, the built-in automatic mode select function is used to obtain an unbiased selection of modes. An example of such a stability diagram is given in Fig. 16.6, which shows a screen dump from Pulse Reflex. After the mode table have been generated by the automatic procedure, the modes are examined one by one in order to reject falsely selected modes.

16.3 Results

Figure 16.7 shows the modeshapes of the structure within the frequency range of interest. Notice how two of the shapes are nearly identical – this behavior has been observed in measurements [1] of a number of nominally identical structures in previous investigations. It is believed that this behavior is caused by the first torsional mode of the beam exciting the second bending mode of the plate, and vice versa.

Each of the two curve fitting methods has been tested with various amounts of noise added to the signal before analysis. In Pulse Reflex the ‘auto’ mode select feature has been utilized to ensure objective results without user interference. The auto-generated mode table has been compared to the reference case (i.e. the noise free case) and based on either low MAC value (see [3]) or extreme complexity, some of the modes have been rejected. The results are depicted in Fig. 16.8, where the numbers of ‘correctly found’ modes are plotted against the signal-to-noise ratios for each of the two methods. The results are shown for four cases; 1) All three impact DOFs are used, 2), 3) and 4) only one impact DOF is used for the analysis.

Number of modes found by the ‘auto’ select feature in the modal analysis software. The modes are compared to a reference set by means of MAC value and frequency. ‘False’ modes have been rejected. Top left: Analysis using three driving points. Top right and bottom: Only one of the three driving points has been used for the analysis

Figure 16.9 shows a comparison of modal parameters found by the two curve fitters being investigated. The data are for the case of using all three impacts for analysis and the plots show mean value and standard deviation for signal-to-noise ratios ranging from 50 dB to 0 dB in 5 dB steps.

Finally, Table 16.1 shows a comparison of natural frequencies for modes found by modal analysis of the non-linear model to those found by using a linear perturbation in Abaqus (Lanczos solver). Since contact properties cannot change during a linear perturbation, only the ‘screw’ interfaces are tied, while the remaining parts of the plate and beam are free to move, regardless of wether it is physically possible or not.

16.4 Discussion

From Fig. 16.8 it is seen, that no single impact point sufficiently covers the all of the modes, while in the case of using all three impact positions, both the Rational Fraction Polynomial-Z and the Polyreference Time method are fairly robust in regards to capturing all the modes even when the ‘measurements’ are contaminated with noise at relatively high levels. At relative noise levels up to SNR 5 dB, all modes are found by both methods (except at SNR 35 dB, where the polyreference time method misses one mode). The Rational Fraction Polynomial-Z method, however, selects more ‘false’ modes than the Polyreference Time method does.

Looking at the modal parameters shown in Fig. 16.9, it is seen that the two methods are in good agreement with each other at both natural frequencies and damping values. The results are similar and the standard deviations are low. For the complexity it is seen that the Rational Fraction Polynomial-Z method is better at capturing the sixth mode, while the Polyreference Time method is slightly better at the third mode. However, at the third mode both methods have significantly higher standard deviation than at the other modes.

Regarding the damping values, it should be emphasized that the exponential window adds significant amounts of damping, especially at the lower frequencies.

Finally, from Table 16.1 it is demonstrated how a linear perturbation analysis is not directly applicable for this type of junction, unless action is taken to account for the interaction between the two parts of structure, e.g. by assuming a linear elastic relation, which may or may not work depending on the type of junction considered. Notice how the structure is much stiffer at two modes with the strongest coupling between torsion of the beam and bending of the plate (mode numbers four and five), compared to what is predicted by the linear perturbation analysis. In the linear perturbation, the first torsion mode of the beam is only lightly coupled to the plate (at 43 Hz), while the actual mode (when including non-linear contact properties) is to be found at 130/136 Hz.

16.5 Future Work

Modeling the true behavior of screw connections in wooden junctions is not an easy task, since effects like friction, elasticity, damping and deformation may be important factors subject to great variation between nominally identical junctions. An extension of the work presented here would be to include bolt loads instead of surface tie constraints for the screw connections in the Abaqus model. By using bolt loads, the behavior of screw connections may possibly be closer to how real connections behave. However, plastic deformation of the wood will probably have to be taken into account as well. Preferably, a decent linear approximation should be found (if possible), since this would simplify the computations significantly.

Furthermore, it still seems that measured signals are significantly more damped than the simulated responses from the present analysis. The effect of added damping from the surrounding air needs to be investigated.

16.6 Conclusion

The robustness of two parameter estimation methods built into the commercial modal testing software B&K Pulse Reflex Advanced Modal Analysis has been investigated in the present paper. The investigations were based on simulated impact tests inspired by actual measurements done by the authors in a previous paper [1]. The structure being modeled was a T-junction between a particleboard plate and a spruce beam, connected to each other by screws. The simulations were utilizing an FE model made with the commercial FE code Abaqus. The FE model included non-linear contact properties, and the effect of those were discussed.

Two different parameter estimation methods were compared: The Rational Fraction Polynomial-Z method and the Polyreference Time method. The robustness of each of the two methods was investigated by applying increasing amounts of noise to the frequency response functions, before they were analyzed in Pulse Reflex. The ability of each method to correctly capture all the modes—when influenced by noise—was used to judge the robustness of the methods. To ensure unbiased mode selection, the built-in automatic mode selection feature of Pulse Reflex was used.

It has been found that both the Rational Fraction Polynomial-Z method and the Polyreference Time method are fairly robust and well suited for the structure being analyzed. Overall, the Rational Fraction Polynomial-Z method seems to perform slightly better than the Polyreference Time method, but at the cost of including more ‘false’ modes in the auto selected mode table.

The investigations showed that no single impact position was sufficient in capturing all of the modes within the observed frequency range.

It should be noted, that the robustness of the underlying Abaqus time domain solver has not been thoroughly investigated.

References

Dickow KA, Andersen LV, Kirkegaard PH (2012) An evaluation of test and physical uncertainty of measuring vibration in wooden junctions. In: Proceedings of ISMA2012/USD2012, Leuven, Belgium, September 2012

ABAQUS Analysis (2010) User’s manual version 6.10. Dassault Systmes Simulia Corp., Providence

Allemang RJ (2003) The modal assurance criterion – twenty years of use and abuse. Sound Vib 37:14–23

Acknowledgements

The present research is part of the Interreg project “Silent Spaces”, funded by the European Union. The authors highly appreciate the financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 The Society for Experimental Mechanics, Inc.

About this paper

Cite this paper

Dickow, K.A., Kirkegaard, P.H., Andersen, L.V. (2013). Robustness of Modal Parameter Estimation Methods Applied to Lightweight Structures. In: Catbas, F., Pakzad, S., Racic, V., Pavic, A., Reynolds, P. (eds) Topics in Dynamics of Civil Structures, Volume 4. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-6555-3_16

Download citation

DOI: https://doi.org/10.1007/978-1-4614-6555-3_16

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-6554-6

Online ISBN: 978-1-4614-6555-3

eBook Packages: EngineeringEngineering (R0)