Abstract

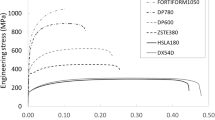

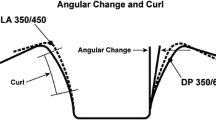

During sheet metal forming on a double-action press, drawbeads on the blankholder supply a restraining force which controls the flow of metal into the die. As metal is drawn through the drawbead, the restraining force has two components, bending deformation and friction. In this study, these components were separated and analyzed. Drawing load, clamping load and strain were measured for sheet steels and aluminums which were drawn through a short section of simulated drawbead. The bending deformation component was isolated by replacing the shoulders and bead of the drawbead by rollers which reduced the friction to a negligible value. The experimental data is analyzed in terms of the materials effects which must be included in a mathematical model of drawbead forces. It was found that an isotropic hardening assumption would not adequately model the strain hardening but that a kinematic hardening assumption that takes cyclic hardening into account is necessary. It is also shown that strain rate hardening must be modeled for steel but not for aluminum. Friction is adequately represented by a coefficient of friction, µ. Experimental values of µ were obtained. Drawbead forces were calculated employing these experimental coefficients of friction and good agreement was found between the measured and calculated frictional components.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

M. A. Swift, Engineering, 166 (1948), 333.

R. W. Landgraf, J. D. Morrow and T. Endo, J. Materials, 4 (1969), 176.

A. K. Ghosh and J. V. Laukonis, Proc. 9th Biennial Congress IDDRG, ASM, Ann Arbor, (1976), 167.

F. P. Bowden and D. Tabor, The Friction and Lubrication of Solids, Oxford Press, 1954.

F. A. Bowden and D. Tabor, The Friction and Lubrication of Solids, Oxford Press, Part I I, 1964.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1978 Plenum Press, New York

About this chapter

Cite this chapter

Nine, H.D. (1978). Drawbead Forces in Sheet Metal Forming. In: Koistinen, D.P., Wang, NM. (eds) Mechanics of Sheet Metal Forming. Springer, Boston, MA. https://doi.org/10.1007/978-1-4613-2880-3_8

Download citation

DOI: https://doi.org/10.1007/978-1-4613-2880-3_8

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4613-2882-7

Online ISBN: 978-1-4613-2880-3

eBook Packages: Springer Book Archive