Abstract

The design and automation of a steel making process is getting more complex as a result of the advances in manufacturing and becoming more demanding in quality requirements. It is essential to have an intelligent business process model which brings consistent and outstanding product quality thus keeping the trust with the business stakeholders. Hence, schemes are highly needed for improving the nonlinear process automation. The empirical mathematical model for steel making process is usually time consuming and may require high processing power. Fuzzy neural approach has recently proved to be very beneficial in the identification of such complex nonlinear systems. In this chapter, we discuss the applicability of an Adaptive Neuro-Fuzzy Inference System (ANFIS) to model the dynamics of the hot rolling industrial process including: roll force, roll torque and slab temperature. The proposed system was developed, tested as well as compared with other existing systems. We have conducted several simulation experiments on real data and the results confirm the effectiveness of the ANFIS based algorithms.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Due to the increasing quality requirements of steel products over the past few years, with very strict limits to meet the market demands, steel production system demands more accurate and speedy automated systems. A major stage in steel production is hot rolling. In order to produce a good quantitative description of the industrial operation, the automation of hot rolling processes requires the development of several mathematical models to identify the simulation process including system parameters and variables [1]. Although empirical mathematical models demand high processing power and more computation time, but still give poor performance. Providing fast, reliable, and accurate models are of great importance for predicting the roll force, roll torque and slab temperature. These models are significantly useful for a hot rolling process in order to generate pass schedules on-line [2]. Section 13.3 presents a more detailed description of the hot rolling process.

The advances in Fuzzy Logic (FL) and Artificial Neural Networks (ANNs) research have opened avenues for new advances in system modeling and identification. An application of fuzzy neural to model and control nonlinear industrial processes has been intensively studied in recent years [3, 4]. Moreover, ANNs have been used to assist in building a reasonable model structure for physical nonlinear systems to serve for process control [4]. FL has been used to develop a mathematical model for many industrial processes and showed significant improved results [5, 6]. Many researchers have focused their works on developing new automation techniques to meet the required quality of hot rolling processes [1, 7–9].

Complex generated models based on neural networks and fuzzy logic make it possible to work with higher performance of rolling forces, larger reductions and better flatness control [10, 11]. Application for quality monitoring in hot rolling process based on ANNs and fuzzy logic was presented in [12]. Accordingly, there is opportunity of further research to model the rolling process both theoretically and empirically based on the data measured in experimental or industrial rolling operations [6, 13, 14]. To improve the prediction ability of the rolling force model, many researchers have focused on evolving more effective physical models for the rolling force prediction [1]. Many important requirements of the hot rolling process including roll force, roll torque and slab temperature, should be affirmed in modeling a plate hot rolling process. Perhaps the most important requirement that should be exactly determined is the temperature of the slab at the entry of each pass in the rolling schedule, because of the fact that the strength of hot steel is highly dependent on temperature [15]. The prediction accuracies for the rolling force and torque are still vital issues from the point of the physical limitations of the rolling mill, and hence there are other requirements that must be emphasized, too [16].

In this chapter, we present an Adaptive Neuro-Fuzzy Inference System to model the structure of a hot rolling manufacturing process which consists of three subsystems. Three models for force, torque and slab temperature in the plate mill are precisely developed. The obtained results are compared to the earlier observed results based on fuzzy logic [6], conventional mathematical models [2] and FeedForward (FF) neural network models.

The methodologies which will be outlined in this chapter can also be transferred to other problem domains. They can help to analyse data which, for instance, is provided by a data warehouse. Besides, the approaches presented in the following sections can also be valuable for performance management, for instance in the field of business activity monitoring.

2 Motivation to use ANFIS?

Neural Networks (NNs) have been used successfully in identification of nonlinear systems. However, the conventional NN techniques for locating a suitable mathematical model from the input–output dataset of a system follow three familiar factors:

-

1.

The first factor is related to the experimental data being driven, where the model qualities are mostly influenced by the quality of data being used.

-

2.

The second factor is concerned with the network architecture, whereas different network architectures may result in a different estimation performance.

-

3.

The third factor is directly correlated with the model size and its complexity. This factor is strongly dependent on the network training, which may be the most important factor, as it holds as an identification task to the model parameters that must fit with the given data.

Actually, a small network may not be able to represent the real situation of the model estimation, due to its limited capability, while the results of a large network may be distorted by noise or over fitting in the training data, which fails to provide a good generalization. Because of these reasons, search for adaptive modeling techniques are being pursued. Two observations have been made. First, the behavior of most dynamic systems is nonlinear. Second, Fuzzy Neural approach is suitable for system identification task, and it avails working with nonlinear systems. Adaptive Neuro-Fuzzy Inference System (ANFIS) [17] is a well-established method of combining Fuzzy and Neural approaches. ANFIS has been shown to be effective in identifying a model for a sufficient input–output data driven [3, 4], and is able to approximate any continuous function to an arbitrary accuracy. Considering the observations, we present in this chapter the use of ANFIS models in dealing with hot rolling plants automation as part of steel making systems.

3 Hot Rolling Plants: Problem Domain

3.1 Process Description

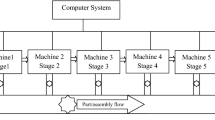

The processes involved in mill plants and production of steel have become more complicated. In this aspect, the hot rolling industrial process was considered as a plant-wide problem. Ereg̃li Iron and Steel factory in Turkey used the hot rolling mill plant (see Fig. 13.1) to provide the experimental data. Hot rolling process [13, 14] is based on an actual system developed in Ereg̃li Iron and Steel factory. The system is a well-posed problem for analysis and identification design of a nonlinear rolling process. A large number of interacting processes and manipulated variables are incorporated into the model, making it a truly significant plant-wide problem. The plant consists of two slab furnaces, pre-rolling mill, edger, reversible mill, seven strip rolling stands, a cooling system, a hot leveller, and a shearing system. The plant has also a data acquisition and a computer control system modified by General Electrics.

Data acquisition and computer control systems are normally controlled by operators to achieve certain system performance goal. In manufacturing process, a mechanical or electrical controller is used to adjust the cooling system and the hot leveller for certain level. Steel strips with a thickness of 15–16 mm can be produced in the rolling mill plant. In a normal production cycle, each slab passes five times in forward and backward directions in the reversible mill. In this plant, the dimensions of slabs are monitored continuously during every passes with X-ray system, the temperature of slab with a pyrometer, roll force and torque with four load cells placed along the mill. But averages of these measured values for each pass are used for identification. The nonlinear dynamics of the rolling mill plant are mainly due to the chemical composition of the low-carbon steels within the hot rolling. The chemical composition of the low-carbon steels used, in this study, is given in Table 13.1.

3.2 Hot Rolling Process

The Ereg̃li Iron and Steel Factory has four rolling mill plants: two are cold and two are hot. Cold rolling plants have a total capacity of 2.3 million tons per year. Hot rolling mill plants have 540.000 tons per year capacity. This corresponds to a total product capacity of 2.84 million tons per year. The dataset that describes the behavior of the rolling process was collected in order to measure different outputs of the rolling process and how it responds to various inputs. The dataset consists of 640 points and was generated from 128 different slabs by a General Electric’s data acquisition system. The thickness and width distribution of the data ranged from 31.68 mm to 168.6 mm and 948.76 mm to 1457.26 mm, respectively.

4 System Identification Process

It is a common practice in engineering modeling for control system design is to first create and test a model offline for the system. This is called indirect control modeling. Identifying and modeling the hot rolling process requires some procedures.

The system identification process consists of constantly adopting a class of model structures, picking up the best model in the structure, and testing the model’s performance whether it is acceptable. We use it for modeling the three sub-processes of the hot rolling process. The succession can be summarized as follows:

-

1.

Experimental design: Collect input–output data from the process to be identified.

-

2.

Pre-processing the data: Clean it to remove trends and outliers, and data scaling can be applied.

-

3.

Select a class of models: Define a set of candidate systems in which a solution can be found.

-

4.

Select a model structure: Pick the best model in the model structure set according to the input–output data and the selected performance criteria.

-

5.

Model estimation: Estimate the model parameters and check the developed model’s properties.

-

6.

Model validation: If the model passes a given criterion, then stop; otherwise go back and try another model set.

4.1 Experimental Design

The collected measurements were practically measured for roll force, roll torque and slab temperature of the rolling process. We emphasis on modeling the hot rolling process using a neuro-fuzzy approach. The process is divided into three sub-processes: (i) the force f, (ii) the torque G and (iii) the slab temperature T. Each of the sub-process has six input variables. The force f and the torque G have the same input variables; u 1,u 2,u 3,u 4,u 5 and u 6. These inputs are standing for Entry Temperature (T i ), Width (W s ), Carbon Equivalent (C e ), Gauge (h i ), Draft (i) and Roll diameter (R), respectively. The six input variables u 1,u 2,u 3,u 4,u 5 and u 6 for the slab temperature T are the T i , W s , C e , h i , Torque (G i ), Power (E i ), respectively. The output of each sub-process is stated as y(k). Figure 13.2 shows the six main inputs for both the force and the torque, while Fig. 13.3 shows the six main inputs for each of the slab temperature of the rolling mill plant.

4.2 Pre-processing the Data

Model development based on the neuro-fuzzy approach requires some necessary preparation stages, which must be completed first to provide a good modeling process. These stages include data collection, preparation and suitable system modeling. The dataset is split into two parts: (i) the training dataset, which is used to train the neuro-fuzzy model and (ii) a testing dataset, which is used to verify the accuracy of the developed neuro-fuzzy model. The training dataset consists of approximately 78 % of the total dataset and the testing dataset consists of the remaining 22 %.

The quality and quantity of the training data is an important issue for neural networks training and for the accuracy of the fuzzification process. Usually, the success of neural network performance relies heavily on large amounts of data, but this demands more computing time for training. In order to reduce the amount of data whilst maintaining the model quality, the data used must be carefully selected to ensure that they are sufficiently ‘rich’. A major concern with the high precision of neuro-fuzzy is data pre-processing, the scaling of data is needed to prevent data with larger magnitude from overriding the smaller, and impeding the premature learning process. In our study, the input and output data are scaled in the range of (0.1–0.9).

4.3 Select a Class of Models

The known empirical modeling techniques were unable to compensate the changes in size and chemical components. Therefore, carbon equivalent (C e ) and width (W s ) were added as inputs to the neuro-fuzzy model of the roll force and the roll torque. It is also difficult to get the correct force and torque values from the mathematical model itself. This is because a part of slight changes there would exist a highly nonlinear and complex structure, and with some various conditions some un-measurable parameters appear, such as, friction coefficient, yield stress, and disturbances. Moreover, reduction, chemical composition and temperature factors cannot be well suited and are not being considered in the mathematical model [2]. Also, a typical adaptation of these mathematical models to such a process would be a kind of fragmented look-up table. This approach has some drawbacks arising from the large size of the look-up tables due to the large product variety.

We consider the neuro-fuzzy approach in our study because it has a capability for good quality prediction, and it can produce a pure algebraic relationship between outputs and inputs. This means the predictor will be stable even if the system is not [3]. So we can overcome the instability of immeasurable parameters in the cases of torque and force. The ANFIS was used for evaluating and testing the neuro-fuzzy output error between the actual and the estimated outputs. ANFIS uses Fuzzy Inference System (FIS) structure such that relationships between train data and test data are adjusted until the specified inputs yield the desired output. Through these activities, the ANFIS learns the correct input–output response behavior. Thus, the ability of neuro-fuzzy models to model the hot rolling process can be improved.

4.4 Select a Model Structure

ANFIS is one of the most successful schemes which combines the benefits of both neural and fuzzy paradigms into a single channel [17]. ANFIS works by applying neural learning rules to identify and tune the parameters and the structure of FIS. The ANFIS is a multilayer feedforward network which uses ANN learning algorithms and fuzzy reasoning to characterize an input space to an output space. The architecture of the employed ANFIS is developed in the form of a zero-order Takagi-Sugeno-Kang (TSK) fuzzy inference system [18, 19].

ANFIS uses a hybrid learning algorithm to identify the membership function parameters of single-output, Sugeno type FIS. The architecture of ANFIS has been suggested by Roger Jang [17], which can be used for tuning the membership functions (i.e. the membership functions bounds) leading to improved performance. ANFIS requires the antecedent MFs and fuzzy rules in the training phase to initialize the neuro-fuzzy system; the MFs should be specified before the training. This employed training process is stopped whenever the designated iteration number is reached, or the training error goal is achieved. In this research, an ANFIS model is conducted to predict the future actions of the hot rolling process in an effort to formalize an identification task.

4.5 Model Estimation

The testing and validation processes are among the important steps in developing an accurate process model. The validation was performed by calculating some of the measurement criteria to evaluate the proposed models. The testing stage includes a criterion of fit and an iterative search algorithm. A neuro-fuzzy approach was used for estimating the hot rolling process, because it provides a rapid convergence and generally can be considered a very robust approach. The capability of neuro-fuzzy approach to emphasize the model validity was assured using the Mean Square Error (MSE) criterion between the actual and the estimated outputs. The relationship between the fuzzy model input and output is represented by what is called the Membership Function (MF).

In principle, the model validation should not only validate the accuracy of the model, but also verify whether the model can be easily interpreted to give a better understanding of the modeled process. It is therefore important to combine data-driven validation, aiming at checking the accuracy and robustness of the model, with more subjective validation, concerning the interpretability of the model. Takagi-Sugeno (TS) fuzzy models, which is based on fuzzy rules with crisp conclusions, were suitable to model a large class of dynamic datasets as stated in [20–22]. Once the model structure and parameters have been identified, it is necessary to validate the quality of the resulting model.

4.6 Model Validation

The performance of the ANFIS models in both training and testing data are evaluated, and the best training/testing data set is selected according to MSE and Variance-Account-For (VAF) [20]. VAF is computed to measure how close the measured values are to the developed values. The VAF is defined in Eq. (13.1).

where, y and \(\hat{y}\) are the actual output and the estimated neuro-fuzzy model output, respectively.

5 Experimental Setup and Algorithms

5.1 Data Preparation

We consider the length of training and testing data set of 78 % and 22 % of the samples to improve the generalization properties of the adopted ANFIS. For each case of the rolling process, two ANFIS models of the same size, but different in initialization weights, were trained to study the stability and robustness of the each model. The best weights, which give the minimum MSE of two different training sessions over each input/output training set, were chosen as the final ANFIS models. Overall, the neuro fuzzy approach based on the adopted ANFIS model was accepted for modelling the hot rolling process, since it gives reasonable results and the prediction output is closely related to the actual output.

5.2 Learning Methodology

The neuro fuzzy system with the learning capability of neural network and with the advantages of the rule-base fuzzy system can improve the performance significantly. It can also provide a mechanism to incorporate past observations into the classification process. This approach uses neural networks for the membership function and mapping between fuzzy sets that are utilized as fuzzy rules. In the training process, a neural network adjusts its weights in order to minimize the MSE. According to the neuro-fuzzy approach, a neural network is utilized to implement the fuzzy system and to automatically tune the system parameters. The ANFIS structure is accomplished by defining, adapting and optimizing the topology and the parameters of the corresponding neuro-fuzzy network. The neuro-fuzzy models are trained based on ANFIS training approach. The checking data method uses the validation data to prevent over fitting of the training dataset that has the same format as the training data. The toolbox function ANFIS in Matlab constructs the FIS whose membership function parameters are tuned. The configuration parameters of the employed ANFIS for modeling the rolling process are shown in Table 13.2.

A neuro fuzzy system is a combination of neural network and fuzzy systems combined in such a way, in which neural networks are used to determine the parameters of the fuzzy system, with a kind of automatic tuning method. To be more precise, optimizing the parameters, which are linearly related in a nonlinear way, neural networks and nonlinear optimization can be employed. A fuzzy model can be seen as a layered structure network similar to neural networks.

6 Experimental Results

6.1 Developed Neuro-Fuzzy Models

In this chapter, a neuro-fuzzy is proposed as a compensator of both fuzzy logic and neural networks to build a suitable model structure for three subsystems of the hot rolling process. It performs as a powerful method which has the ability to cover all the system variances for a typical rolling mill process. The neuro-fuzzy models are capable of producing estimated outputs similar to the actual outputs of each subsystem. This is accomplished by using the ANFIS method based on the MSE training errors.

After training and testing cases, the MSE became steady in all subsystems of the hot rolling system. We run 25 experiments to produce our results. The best and the average error are reported over all the experiments. For example, in the slab temperature subsystem, the convergence training results of best and average are shown in Fig. 13.8.

It is observed from the developed error curves in Fig. 13.4 that the errors converged to optimum MSE values. The actual and estimated responses of the neuro-fuzzy models for the rolling process are shown in Figs. 13.5, 13.6 and 13.7. Figures 13.5, 13.6 and 13.7 show that the error between the actual and the predicted output of the model is very insignificant. This means that the neuro-fuzzy approach has learned to model the dynamics of a hot rolling process quite accurately. Overall, all models display promising results in the training and testing sets for all the developed models.

6.2 Developed FeedForward Levenberg-Marquardt (FF-LM) Models

We avoid a restrictive mathematical model by selecting a particular class of models because of the limitations of the traditional model building approaches. The capability of neural networks to learn from examples seem to make it an ideal choice for modeling the hot rolling process. Multi-layer feedforward networks are the first to be used for the identification purposes. The neural networks of interest that we considered in this chapter are the feedforward backpropagation networks. The network model was trained based on Levenberg-Marquardt (LM) algorithm [23, 24]. The LM search algorithm was used as an iterative training algorithm, because it provides a rapid convergence. The MSE criterion was used for evaluating the ANN output using the LM optimization algorithm.

The network structure has an input layer, one hidden layer and an output layer with ten nodes in the hidden layer. The algorithm starts by assigning a random set of weights to the ANN, and the network adjusts its weights each time it comes across an input–output pair. The weights are adjusted in order to minimize the errors, where, the errors are propagated back to the connections preceding from the input nodes and the weights are adjusted accordingly. This type of model has been accepted for modeling the hot rolling process, as it produces a prediction output which is very close to the real actual output.

A feedforward back-propagation network approach based on LM algorithm was implemented to perform the same modeling task as in the case of the neuro-fuzzy approach. In Fig. 13.8, we show the error convergence when training a FF-LM neural network. The performances of the neural models in tracking the actual data in each sub-process of the hot rolling process are illustrated in Figs. 13.9, 13.10 and 13.11. The neural network models outputs follow the desired outputs quite closely. This indicates that the MSE reached the global minimum for all subsystems of the hot rolling system. As a result, the NN based LM method capable to learn the behavior of the industrial processes. The VAF values are considered for evaluating the experimental results.

6.3 Comparisons

In the neuro-fuzzy approach, an error tolerance of zero was used, and the ANFIS was trained with 200 epochs. The best error convergence curve in roll force achieved minimum MSE values at the last iteration of 0.0140 and 0.0187 for training and testing, respectively. While the roll torque achieved minimum MSE values to be 0.0134 and 0.0569, at the last iteration for training and testing cases, respectively. recorded best MSE values at the last iteration were 0.0017 and 0.0026 for training and testing, respectively. In Table 13.3, the VAF computed values using neuro-fuzzy, FF-LM, fuzzy logic and the empirical model as presented in [6] and [16], respectively are reported.

Roll torque and slab temperature models on the other hand, yield good results. This means that these models are highly stable towards the end of processing phase. Moreover, the performance of neuro-fuzzy for modeling the rolling process is slightly better than both of fuzzy logic and FF-LM, and shows better performance than the empirical model. In addition, the neuro-fuzzy and the fuzzy logic approaches have nearly the same VAF values. This confirms that both neuro-fuzzy and fuzzy logic approaches are adequate with a sufficient accuracy to model complex processes. Overall, VAF results reveal the fact that the proposed modeling methods reflect the nature of the hot rolling plant process quite well.

7 Conclusions and Future Work

This chapter explored the use of Takagi-Sugeno technique to develop adaptive neuro-fuzzy models for the hot rolling manufacturing process. Three models (i) roll force, (ii) roll torque, and (iii) slab temperature were implemented. A comparison of results between the neuro-fuzzy models and other developed models are presented successfully. The developed neuro-fuzzy models showed a distinct better performance with promising results. Due to adaptation and predictability, the proposed neuro-fuzzy models can be used to design model-based intelligent regulators especially in strip rolling in which the model parameters are updated online. The presented methodologies can also be applied to other problem domains. They offer an efficient way to analyse data and can support business activity monitoring in the field of performance management

References

Kwak, W.J., Kim, Y.H., Park, H.D., Lee, J.H., Hwang, S.M.: Fe-based on-line model for the prediction of roll force and roll power in hot strip rolling. ISIJ Int., 40(20), 1013–1018 (2000)

Öznergiz, E., Gülez, K., Ozsoy, C.: Neural network modeling of a plate hot-rolling process and comparision with the conventional techniques. In: International Conference on Control and Automation, vol. 1, pp. 646–651 (2005)

Al-Hiary, H., Braik, M., Sheta, A., Ayesh, A.: Identification of a chemical process reactor using soft computing techniques. In: 2008 IEEE International Conference on Fuzzy Systems (FUZZ 2008), pp. 845–853 (2008)

Sheta, A., Al-Hiary, H., Braik, M.: Identification of model predictive controller design of the Tennessee Eastman chemical process reactor using ANN. In: International Conference of Artificial Intelligence (ICAI’09), pp. 25–31 (2009)

Sheta, A.: Modeling the Tennessee Eastman chemical reactor using fuzzy logic. In: The ISE Book Series on Fuzzy System Engineering-Theory and Practice. Nova Science, New York (2005). ISBN: 3-540-25322-X

Sheta, A., Öznergiz, E., Abdelrahman, M.A., Babuška, R.: Modeling of hot rolling industrial process using fuzzy logic. In: CAINE-2009, San Francisco, CA, USA, 4–6 November 2009 (2009)

Kirihata, A., Siciliano, F. Jr., Maccagno, T.M., Jonas, J.J.: Mathematical modelling of rolling of multiply-alloyed mean flow stress during medium carbon steels. ISIJ Int. 38(2), 187–195 (1998)

Cowling, P.: A flexible decision support system for steel hot rolling mill scheduling. Comput. Ind. Eng. 45(2), 307–321 (2003)

Feng, X., Liu, Y., Luo, H., Tang, H., Liu, C.: Numerical simulation during expansion for hot rolling sheet strip. In: Proceedings of the First International Workshop on Knowledge Discovery and Data Mining, WKDD ’08, Washington, DC, USA, pp. 310–313. IEEE Comput. Soc., New York (2008)

Cser, L., Gulyás, J., Szücs, L., Horváth, A., Árvai, L., Baross, B.: Different kinds of neural networks in control and monitoring of hot rolling mill. In: Proceedings of the 14th International Conference on Industrial and Engineering Applications of Artificial Intelligence and Expert Systems, IEA/AIE ’01, pp. 791–796. Springer, London (2001)

Lee, D.M., Lee, Y.: Application of neural-network for improving accuracy of roll force model in hot-rolling mill. Control Eng. Pract. 10(2), 473–478 (2002)

Bouhouche, S., Yahi, M., Hocine, B., Bast, J.: Soft sensor—based artificial neural networks and fuzzy logic: application to quality monitoring in hot rolling. In: Proceedings of the 10th WSEAS International Conference on Automatic Control, Modelling & Simulation, ACMOS’08. World Scientific and Engineering Academy and Society, pp. 149–154. Stevens Point, Wisconsin (2008)

Tarokh, M., Seredynski, F.: Roll force estimation in plate rolling. J. Iron Steel Inst. 208, 694 (1970)

Özsoy, C., Ruddle, E.D., Crawley, A.F.: Optimal scheduling of a hot rolling process by nonlinear programming. Can. Metall. Q. 3(31), 217–224 (1992)

Mandal, M., Pal, S.K.: Pseudo-bond graph modelling of temperature distribution in a through-process steel rolling. Math. Comput. Simul. 77(1), 81–95 (2008)

Öznergiz, E., Özsoy, C., Delice, I.I., Kural, K.: Comparison of empirical and neural network hot-rolling process model. J. Eng. Manuf. 223, 305–312 (2009)

Jang, J.S.R.: ANFIS, adaptive network based fuzzy inference systems. In: IEEE Transaction on Systems, Man and Cybernetics, vol. 23, pp. 665–684 (1993)

Jang, J.S.R., Sun, C.T., Mizutani, E.: Neuro-Fuzzy and Soft Computing. Prentice-Hall, Englewood Cliffs (1997)

Takagi, T., Sugeno, M.: Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man Cybern. 15(1), 116–132 (1985)

Babuška, R., Roubos, J.A., Verbruggen, H.B.: Identification of MIMO systems by input–output TS fuzzy models. In: Proceedings of Fuzzy—IEEE’98, Anchorage, Alaska (1998)

Babuška, R., Verbruggen, H.: Identification of composite linear models via fuzzy clustering. In: Proceedings of European Control Conference, Rome, Italy, pp. 1207–1212 (1995)

Babuška, R., Verbruggen, H.B.: Applied fuzzy modelings. In: Proceedings of IFAC Symposium on Artificial Intelligence in Real Time Control, Valencia, Spain, pp. 61–66 (1994)

Subudhi, B., Jena, D.: Differential evolution and Levenberg Marquardt trained neural network scheme for nonlinear system identification. Neural Process. Lett. 27(3), 285–296 (2008)

Asadi, S., Hadavandi, E., Mehmanpazir, F., Nakhostin, M.M.: Hybridization of evolutionary Levenberg-Marquardt neural networks and data pre-processing for stock market prediction. Knowl.-Based Syst. 35, 245–258 (2012)

Acknowledgements

Authors would like to thank Prof. Dr. Can Özsoy and the Ereg̃li Iron and Steel Factory for providing the required technical assistant and the data for this developed research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag London

About this chapter

Cite this chapter

Sheta, A.F., Braik, M., Öznergiz, E., Ayesh, A., Masud, M. (2013). Design and Automation for Manufacturing Processes: An Intelligent Business Modeling Using Adaptive Neuro-Fuzzy Inference Systems. In: Rausch, P., Sheta, A., Ayesh, A. (eds) Business Intelligence and Performance Management. Advanced Information and Knowledge Processing. Springer, London. https://doi.org/10.1007/978-1-4471-4866-1_13

Download citation

DOI: https://doi.org/10.1007/978-1-4471-4866-1_13

Publisher Name: Springer, London

Print ISBN: 978-1-4471-4865-4

Online ISBN: 978-1-4471-4866-1

eBook Packages: Computer ScienceComputer Science (R0)