Abstract

Rehydration is related to the amount of water or other medium that a dry food absorbs during a process, and it is associated with the kinetics of the medium uptake. Water imbibition theory has a multidisciplinary validity, and has applicability in modeling the rehydration of dried porous food. Imbibition follows the general Lucas–Washburn equation. However, its utilization has highlighted the need for model improvement to overcome several discrepancies related mainly to the utilization of a single effective cylindrical capillary radius and a constant contact angle.

Basic theory of flow in porous media is widely utilized in several other domains (e.g., petroleum, chemical engineering) and plays a cardinal role in soil physics research. Because of the central role of soil water in agricultural systems, modeling of soil porous media, water flow, and mass transport has been promoted in interdisciplinary research and quantification. This multidisciplinary approach has also recently motivated a few studies on bridging of food science and soil physics, showing its high potential and providing insights into the mechanism(s) governing water and other liquid uptake by dry food particulates.

Analogous to a food sorption isotherm, the water characteristic curve of a porous media describes the functional relationship between water content and a matric potential under equilibrium conditions. This curve is an important property related to the pore size distribution and space that are strongly affected by texture and structure, as well as other related factors, including organic matter content. Continuous retention curve (RC) functions are needed in order to solve the flow equations. Numerous well-known empirical functions such as Brooks and Corey and van Genuchten have been developed. Utilization of porous media theory for modeling of food rehydration requires employment of a characteristic curve, which is time consuming and cumbersome. Bridging between sorption isotherms commonly utilized in food science with water characteristic curves employed in soil physics could furnish a novel and integrated approach paramount to overcoming some of the complexity that hampered previous attempts. This could lead to new avenues for studying and optimizing food rehydration.

The overall objective of this chapter is to depict current understanding of the rehydration process, and to highlight how a new approach derived from soil physics and porous media theory could be utilized for foods.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

In the last decade, there has been a continuous rise in the demand for convenience foods, including dehydrated products, mainly due to modern lifestyles (Marabi and Saguy 2009; Saguy et al. 2007). This trend is accompanied by a decrease in the ability, desire or time to prepare food and an increase in financial means, leading consumers to choose foods that are readily available, convenient, and require only minimal or no preparation before consumption (Tillotson 2003). The rehydration of dried foods is a fundamental unit operation in the food industry. The quality of rehydrated and reconstituted products is affected by the drying conditions and rehydration processes utilized, ultimately influencing consumer acceptance. During the drying process, physicochemical changes, including textural and structural modifications, migration of solutes, loss of volatiles and nutrients occur in an irreversible manner, and have an impact on the quality of the final product. Therefore, the drying process needs to be understood and controlled, to create a dried product with optimal nutritional, sensorial, and rehydration characteristics (Saguy et al. 2007). In addition to medium uptake, leaching of solids from the food product to the medium is another important aspect during rehydration. To address this phenomenon, nondissolvable solids were proposed (Marabi et al. 2004a) and utilized in the determination of the rehydration ratio(RR).

2 Mathematical Modeling

In recent years, the food domain has experienced an encouraging transition from the empirically-based to physically-based models. Nevertheless, most rehydration studies reported in the literature still include empirical and semiempirical models to describe the mechanisms of liquid uptake, solids leaching, and the kinetics of the processes (Marabi and Saguy 2009).

Mathematical modeling facilitates an understanding of process characteristics, providing insight into the governing mechanisms taking place, and thus it could be utilized to improve the process for better products. Liquid uptake is typically modeled by applying a mechanistic approach or employing an empirical approach. Fick’s second law of diffusion is a typical example of a mechanistic approach, whereas the first-order model is merely a curve-fitting empirical model. The development of empirical models requires considerably less effort and therefore, they are utilized frequently. However, empirical models are limited and nontransferable (Saguy et al. 2005b).

2.1 Empirical and Semiempirical Models

Five models that are often used (Saguy et al. 2007) include: the exponential model (Misra and Brooker 1980), Peleg’s model (Cunningham et al. 2007; Garcia-Pascual et al. 2006; Giraldo et al. 2006; Peleg 1988), first-order kinetics (Gowen et al. 2007; Krokida and Philippopoulos 2005); the Weibull distribution function (Cunha et al. 1998a, b; Cunningham et al. 2007; Garcia-Pascual et al. 2006; Machado et al. 1997), and the normalized Weibull distribution function (Marabi et al. 2003, 2004a, b; Marabi and Saguy 2004; Marabi and Saguy 2005).

Among the empirical models, the Weibull distribution function is used frequently and has recently been improved to describe the rehydration of dried foods. It is important to note however, that all of these empirical models offer rather limited insight into the fundamental principles involved, and in some cases, hinder understanding of the transport mechanism(s) (Marabi and Saguy 2009). Nevertheless, they provide an excellent basis for curve-fitting and allow process representation as a function of physical properties and rehydration conditions.

2.2 The Diffusion Model

The diffusion model is a combination of physical and empirical approaches, founded on Fick’s first and second laws. Solving Fick’s second law requires making numerous assumptions and simplifications (Saguy et al. 2007). To overcome some of these difficulties, the effective diffusion coefficient D eff is utilized, which is derived from experimental data and is an apparent value that encompasses all intrinsic hydraulic properties of the particles. The effective diffusivity is linked to both the porosity and tortuosity. A typical D eff value for moisture in foods ranges from 10–8 to 10–12 m2/s, generally being closer to 10–10 m2/s (Maroulis et al. 2001), and is influenced by temperature, water content, pressure, physical properties, and the dried food’s structure. However, it is well documented that some or most of the above assumptions made to solve Fick’s laws are not valid. Moreover, mechanisms of mass transfer other than molecular or Fickian diffusion may also occur. Some of the drawbacks of the Fickian approach were recently discussed (Saguy et al. 2007).

3 Paradigm Shift: Capillary Flow in Porous Media

As most empirical models are primarily utilized to avoid more complex considerations and complications such as changes occurring within the product, the actual microstructure is not considered. The alternative is to apply a physically-based approach utilizing the porous media where the actual microstructure and void channels are important. This may sound straightforward, but it requires a paradigm shift and an interdisciplinary approach is suggested (Saguy et al. 2007). The approach is based on integrating the know-how developed in other domains such as soil science to study the porous media and fluid transport in foods.

Rehydration is a very complex phenomenon involving different transport mechanisms, including molecular diffusion, convection, hydraulic flow, and capillary flow (Saravacos and Maroulis 2001). Liquid imbibition follows various mechanisms occurring in tandem (Chiralt and Fito 2003; Marabi et al. 2003; Marabi and Saguy 2005; Oliveira and Ilincanu 1999). However, the contribution of mechanisms involving mass flux due to a temperature gradient (Soret effect) is considered insignificant and therefore often is disregarded (Datta 2007a). Several studies utilizing the Washburn equation to represent the movement of liquids into porous food matrices were reviewed recently (Marabi and Saguy 2009; Saguy et al. 2007).

It is however worth noting that the rehydration mechanism is no longer relying solely on the common postulation that it is governed by Fickian diffusion. Other mathematical models based on capillary flow in porous media are also utilized. These models are derived from the well-known Lucas (1918) and Washburn (1921) equations (also called the Lucas-Washburn or Washburn-Rideal equation). This approach is based on utilization of several well-known derivations known as the Laplace, Poiseuille, and Lucas-Washburn equations (Marabi and Saguy 2009).

After imbibition of water into dried porous foods it was shown that the process followed the Washburn equation (Lee et al. 2005; Saguy et al. 2005a). However, discrepancies related to the utilization of a single “effective” cylindrical capillary radius and constant contact angle were also reported (Saguy et al. 2005a). An additional factor that may be responsible for the inaccuracies encountered when comparing experimental data with the Washburn equation may be related to the tortuosity of the pores within the food sample. The pore network is often regarded as a bundle of cylindrical and straight capillaries with a determined effective radius (Saguy et al. 2007). Thus, the Washburn equation may be utilized in its original form (Aguilera et al. 2004), or otherwise corrected with a tortuosity factor (Carbonell et al. 2004).

Other studies also concluded that there is water movement during various food processes. For instance, water transfer during vacuum osmotic drying was described as a combination of traditional Fickian diffusion and vacuum capillary flow. In this case, water transfer was closely related to the porosity of the fruit being tested (Shi and Fito-Maupoey 1994). Radial NMR micro-imaging technique utilized to study pasta rehydration indicated a non-Fickian process (Hills et al. 1996). Capillary penetration or another fast transport mechanism occurring near the interface in the rehydration of apples was also suggested (Salvatori et al. 1999).

4 Flow in Unsaturated Porous Media

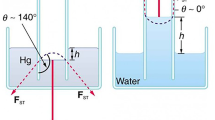

4.1 Capillarity and Tension Head

Water that has entered a porous medium but has not drained out of the sample will be retained in the pores by capillary forces or will surround the surface of the particles by molecular forces of adhesion and cohesion. Therefore, a simple measurement of water content in the medium is not sufficient to enumerate the complete status of the medium’s water. While the quantity of water present in the medium is very important, the potential or affinity with which the water is retained is perhaps more important, mainly if the dynamics of this water is considered (Saguy et al. 2007). This potential may be defined as the amount of work done or potential energy stored, per unit volume, in moving a mass of water from the reference state (typically chosen as pure free water). Matric potential could be considered as potential energy per unit volume (J m−3), which is also expressed as Pascal. This clarifies the use of the terminology “pressure potential” by soil physicists referring to matric potential as soil pressure, or if divided by bulk density, as pressure head (Wallach 2007).

Capillarity deals with both the macroscopic and statistical behavior of interfaces, rather than their molecular structure. Capillarity is also referred to as surface tension, γ (work per unit area expressed as J m−2). This phenomenon is extremely important in water retention in porous media. Surface tension occurs at the molecular level and involves two types of molecular forces: adhesive forces, which are the attractive forces of molecules of dissimilar substances and cohesive forces, which are the attractions between molecules in similar substances. Cohesive forces decrease rapidly with distance and are the strongest in solids, less strong in liquids, and the weakest in gases (Saguy et al. 2007).

As water rises in a capillary, the meniscus is spherical in shape and concave upward. By letting r equal the tube radius, the excess pressure above the meniscus compared to the pressure directly below can be described under various assumptions by 2γ/r. As the pressure on the water surface outside the capillary tube is atmospheric, the pressure in the liquid below the meniscus will be less than the atmospheric pressure above the meniscus by 2γ/r. This will force the fluid up the tube until the hydrostatic pressure of the fluid column within the tube equals the excess pressure of 2γ/r. The total force (upward) supports the weight of the fluid column to the height h c . The height of the capillary rise can be expressed as (Laplace equation):

where hc = capillary rise (water tension head) (m); g = gravity (m/s2); \( {\theta_a} \)= apparent contact angle (o).

4.2 Water Retention Curve

The water characteristic curve of porous media is also known as the water retension curve (RC), which describes the functional relationship between the volumetric water content θ and matric potential ψ under equilibrium conditions. The matric potential is usually replaced by the pressure potential head h (m), which is the energy per unit weight of water. As the water in the unsaturated porous media is at subatmospheric pressure, the pressure potential head is commonly called “tension head.” This curve is an important property related to the distribution of pore space (sizes, interconnectedness), which is strongly affected by texture and structure, as well as related factors including organic matter content. The RC indicates the amount of water in the porous medium at a given tension head (Saguy et al. 2007). It is also a primary hydraulic property required for modeling water flow in porous media. RCs are highly nonlinear functions and relatively difficult to obtain accurately (Hillel 1998; Wallach 2007).

The traditional method of determining water retention involves establishing a series of equilibria between water in the porous medium sample and a body of water at known water tensions. The medium-water system is in hydraulic contact with the body of water via a water-wetted porous plate or membrane. At each equilibrium, the volumetric water content of the medium is determined and paired with a value of the tension head (h), determined from the pressure in the body of water and the gas phase pressure in the substrate. The data pair (θ, h) forms one point on an RC. A summary of methods frequently used in soil science to determine the RC can be found in the literature (e.g., Klute 1986). It is worth noting that RC quantification resembles sorption isotherm determination in foods (Fontana and Campbell 2007; Saguy et al. 2007).

Measured values of water content and tension head (θ -h) are often fragmentary and usually based on relatively few measurements over the wetness range of interest. For modeling and analysis purposes, and characterization and comparison of different substrates and scenarios, it is essential to represent the RC in continuous and parametric form. A parametric expression of an RC model should contain as few parameters as possible, to simplify its estimation and to describe the behavior at the limits (wet and dry ends), while closely fitting the nonlinear shape of the θ -h data (Saguy et al. 2007).

Many models have been suggested to describe RC in soil science (Hillel 1998; Jury and Gardner 1991). The most frequently used are those of Brooks and Corey (1966), denoted as B-C model, and van Genuchten (1980), denoted as VG model. The parameters of the models are typically determined by curve-fitting of experimental data. B-C model follows:

where S e = effective saturation (-); h b = air entry value (m); λ = “pore size index” empirically-determined parameter (-); θ, θ r , θ s = current, residual, and saturated volumetric water contents, respectively (m3/m3); K s = saturated hydraulic conductivity (m/s); m v = empiric parameter (-).

The residual water content is somewhat arbitrarily defined as the water content at which the corresponding hydraulic conductivity is essentially zero, but very often it is used as an empirical constant when fitting hydraulic functions. As opposed to θ s , which has a clear physical significance, the meaning of θ r and its estimation have not yet been resolved (Wallach 2007).When θ r = 0 (m3/m3), S e approaches S. Note that S e varies between zero and one.

The other common parametric model for relating water content to the tension head was proposed by VG:

where α h (m−1) and m v (-) are empirical parameters (determining the shape of the RC; derived by curve-fitting techniques).

The value of the hydraulic conductivity of a saturated porous medium (K s ) depends on the properties of the medium and the flowing fluid. This dependence can be separated into two factors: fluidity f (defined as ρg/η; η = viscosity (Pa s)) and intrinsic permeability k (m2):

The intrinsic permeability of a medium is a function of pore structure and geometry. Particles of smaller-sized individual grains have a larger specific surface area, increasing the drag on water molecules flowing through the medium, which results in a reduced intrinsic permeability and K s .

4.3 Richards Equation, Boundary, and Initial Conditions

The Darcy law describes the flow equation in saturated media:

where H = the hydraulic head (m); s = distance along a stream line in the flow field (m); ΔH/Δs = the hydraulic-head gradient along the stream line (-); and J = flux density or flow per unit area opposite the direction defined by hydraulic-head gradient (m/s).

The Darcy law can be coupled with the conservation of mass principles to derive a continuity equation. Using one horizontal dimension leads to:

Equation (21.6) contains two unknowns, namely θ and h; applying the chain rule for the left hand side of (21.6) provides the h-based continuity equation:

where C(h) = ∂θ/∂h is the slope of the RC and is called the specific moisture capacity (1/m).

Applying the chain rule for the derivative to the right hand side of (21.6) provides the θ-based continuity equation, which is a diffusion-type (nonlinear) equation:

where D h (θ) = K(h)⋅∂h/∂θ (m2/s) is denoted as hydraulic diffusivity and is the ratio of the unsaturated hydraulic conductivity to the specific moisture capacity.

The advantage of the θ-based form is that D h (θ) does not vary with θ nearly as much as K(h) varies with h. The last two equations, along with their various alternative formulations, are known as the Richards equation.

4.4 Developing the Theory of Flow in Porous Media

To utilize the theory of flow in porous-media in rehydration of dry food particulates, the RC of these particulates is needed. The B-C and VG and other functions used to model the RCs have significant limitations at low-liquid saturations in that they use a parameter called residual saturation, which is the minimum liquid saturation calculated by these equations. At low water content, vapor diffusion is predominantly driven by vapor pressure differences, which in turn is driven by local vapor pressure lowering (related to capillary pressure through Kelvin’s equation). Hence, vapor flow is significantly influenced by the RC at low water contents.

The limitations of the two-phase characteristic curves in the low water content region lead to errors in liquid and vapor transport, and in the prediction of the actual water content in this region. This value is important in the transition from liquid–solid sorption to vapor-solid sorption, which is typically at 4–6 monomolecular layers, or liquid saturation of 0.11–0.16 (m3/m3) based on soil surface area of 25 m2/g (Webb 2000). At higher liquid saturations, adsorption is primarily via liquid–solid processes. As the liquid saturation decreases, however, vapor-solid sorption contributes to the adsorption process more and more and may dominate at low values of liquid saturation.

Physically-based modification of the RC has been suggested by a number of authors (e.g., Campbell and Shiozawa 1992; Morel-Seytoux and Nimmo 1999; Ross et al. 1991; Rossi and Nimmo 1994). Campbell and Shiozawa (1992) observed that the capillary pressure in the dry region is a linear function of liquid saturation on a semilog plot; using this relationship, they added a VG water content relationship to obtain the full capillary pressure curve, where the parameters in the VG equation were refit to the data assuming zero liquid residual saturation. Subsequent models have all used the linear relationship observed by Campbell and Shiozawa (1992). The model proposed by Rossi and Nimmo (1994) is based on the B-C model with zero residual saturation, which is equivalent to the expression of Campbell (1974), with the dry region function proposed by Campbell and Shiozawa (1992) in the low water content region. Morel-Seytoux and Nimmo (1999) slightly modified the Rossi and Nimmo (1994) model. Webb (2000) presented a similar approach to the dry region modification of Morel-Seytoux and Nimmo (1999) in that it merges an existing RC with a dry region expression. However, the approach of Morel-Seytoux and Nimmo (1999) requires the simultaneous solution of two nonlinear equations, while the Webb (2000) approach only requires a few iterations in a single equation.

Following these approaches, we suggested a new method to predict the RCs of porous media (food particulates in particular) from measured water sorption isotherms. This method is based on a four-step procedure (Saguy et al. 2007):

-

1.

Water sorption isotherm

The suggested method adopts the fundamental water isotherm approach to describe the relationship between water content and water activity in the dry zone. This selection is straightforward and takes into consideration the knowledge bank on the relationship between food stability and water activity. Although the utilization of glass transition theory could also be considered, in this case the relationship between water and the gas phase is of interest. The conversion from water activity to tension head is carried out by utilizing the Kelvin equation:

$$ h = \frac{{RT}}{{{\rho_w}g{M_w}}}\ln ({a_w}) $$(21.9)where R = gas constant (J·K−1·mol−1); M w = molecular water mass (0.018 kg/mol); T = absolute temperature (K); ρ w = water density (1,000 kg/m3); a w = water activity (-).

However, the theoretical aspects of the Kelvin equation at low water activities are still under development and further studies are required. A typical water sorption isotherm is depicted in (Fig. 21.1) for microcrystalline cellulose (MCC).

Fig. 21.1 Typical water sorption isotherm for microcrystalline cellulose at 25°C (Adapted from Saguy et al. 2007)

-

2.

Retention curve

Initially, the sorption isotherm data is converted to water retention data and plotted as tension head vs. volumetric volume of water to comply with the RC presentation. Note that the moisture content for each data point of the sorption isotherm (m, aw) is converted to (h, θ) by utilizing the Kelvin equation (21.9), transforming the moisture content to its volumetric value:

$$ \theta = m\frac{{{\rho_b}}}{{{\rho_w}}} $$(21.10)where m = moisture content (kg H2O/kg dry solids; DB); ρ b = bulk density (kg/m3). Typical values are presented in (Fig. 21.2).

Fig. 21.2 Typical water sorption and water retention data for microcrystalline cellulose at 25°C (prediction made using B-C model) (Adapted from Saguy et al. 2007)

-

3.

Prediction and validation of RC from aw data

The sorption isotherm data after transformation to the adequate RC scale was utilized to derive the B-C model using the two aforementioned requirements, namely continuity and smoothness at a point defined as θ*, h*. This yielded two equations from which θ* and λ were derived. Once θ * is known, it can be placed in one of the equations to derive λ and the B-C function can be drawn. Note that in our first approach, and for simplicity of treatment, it was assumed that the sorption isotherm is a linear function on a semilogarithmic scale (e.g., Webb 2000). Another requirement for using the B-C function, when physical data is absent, is to know the values of its parameters: h b , θ s (saturated water content), θ r (residual water content), and λ (pore index parameter). The first two parameters can be experimentally measured (although adaptation to food systems is required): θ r is an approximated parameter while λ is evaluated through model equations. Applying this approach in a VG model (instead of B-C one) requires an additional parameter, which adds to the complexity of the solution without gaining any further conceptual insight into the overall approach, and as such is not covered herewith.

Validation was then carried out, in which RC was measured using the hanging column method (Klute 1986) and the fit obtained, as depicted in (Fig. 21.2). Since methods used in this case for soils are probably difficult for implementation in most food systems, measurements of only a few points is recommended, starting from the wet end of the curve.

-

4.

Retention curve validation

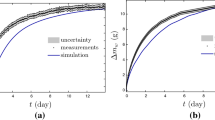

Once the water RC is known, the unsaturated hydraulic conductivity function (21.2) can be determined and the Richards equation (21.8) solved. As for the saturated hydraulic conductivity, it is independently measured. Again, certain adaptations are necessary for evaluating K s in food systems. Both the measurement and prediction of 10-cm column dry MCC rehydration are depicted in (Fig. 21.3). Simulations were made using Hydrus 1-D software (a code for simulating one-dimensional movement), based on the Richards equations for water flow (Simunek et al. 2005) for the following boundary and initial conditions: constant upper boundary flux and constant tension head at bottom boundary set to zero. The initial moisture content was assumed as oven-dry. The simulation predicted the cumulative bottom flux, was then multiplied with the sample cross-section, yielding the volume of water absorbed by the sample.

Fig. 21.3 Typical rehydration data for microcrystalline cellulose at 25°C (Adapted from Saguy et al. 2007)

-

5.

Typical experimental data on foods

To demonstrate the applicability of the above four-step procedure, imbibition tests were carried out using freeze-dried wheat groats (burghul). Simulations (not showed) illustrated that although the B-C characteristic-curve based on water absorption model yielded a shape similar to the experimental data for early times (ca. 500 s), a significant discrepancy was clearly observed at relatively long times. Rehydration times longer than ca. 1,000 s are quite lengthy, compared to the shorter duration utilized for typical “instant” consumer products. Conversely, the B-C model was quite accurate at shorter times (e.g., less than 300 s). Thus, these data suggest that prolonged food rehydration is more complex and requires additional consideration. A similar conclusion was reached after repeating the long-time rehydration experiments with freeze-dried carrots (data not shown).

Next, an empirical approach was applied using a “double” Weibull model to account for diffusion and relaxation, as both could have a completely different time scale:

$$ {w_t} = {w_{\infty 1}}\left\{ {1 - \exp \left[ { - {{\left( {t/{\alpha_1}} \right)}^{{\beta_1}}}} \right]} \right\} + {w_{\infty 2}}\left\{ {1 - \exp \left[ { - {{\left( {t/{\alpha_2}} \right)}^{\beta_2}}} \right]} \right\} $$(21.11)where w t , w ∞1, and w ∞2 = the momentary weight, infinite-weight due to diffusion, and relaxation, respectively (kg H2O/kg dry solids); t = time (s), α and β = scale parameter (s), and Weibull shape parameter (–); 1 = diffusion and 2 = relaxation.

When the combined model was utilized, the fitted data showed an excellent fit for short and long rehydration times. The model was used to simulate the contribution of each individual mechanism, namely diffusion and relaxation. As expected, relaxation lags diffusion markedly. This could explain some of the literature data in which both diffusion and nondiffusion mechanisms were reported.

The criterion utilized to differentiate between the diffusion and relaxation mechanisms is derived from the value of the Weibull shape parameter. Values of 0.6–0.8 were defined as capillary flow, while values above 1.0 were characterized as relaxation (Marabi et al. 2003). Figure 21.4 shows the ratio between relaxation and diffusion; it is clear that at short rehydration time the freeze-dried product depicts that the diffusion mechanism is dominating; however, as time progresses, relaxation also starts to play a significant role.

Fig. 21.4 This data suggests that additional considerations are required especially for long rehydration time during which water flow is not capillary-driven. It is suggested that the porosity of a dried food product (e.g., freeze-dried carrot, freeze-dried wheat groats) is hierarchical (i.e., made of pores: between- and within- the particles. The former pores are inter-porosity, while the latter are intra-porosity, which are typically dead-ended). While water flow is driven by capillarity in the interpores, it is also driven by moisture content gradients in the intrapores. This concept (also known as “mobile-immobile”) is currently under development and preliminary results are encouraging supporting the overall hypothesis that physically-based model for the simulations of porous foodstuffs rehydration is feasible.

This important topic will become apparent once internal structure data are available (see recommendations below).

4.5 Rehydration of Foods Using Porous Media: Additional Considerations

The theory of capillary imbibition for modeling the rehydration of foods was applied by several other groups. For instance, a capillary-flow approach was utilized (Weerts et al. 2003a, b) to model the temperature and anisotropy effects during the rehydration of tea leaves. The predicted values agreed well with the experimental data derived from NMR measurements, leading to the conclusion that the physically based constitutive relationships of water activity and hydraulic conductivity could be utilized to overcome the simplification of modeling water transport as a process governed by Fick’s laws. The approach could be extended to include gravity and osmotic pressure effects and also coupled with heat and solute transport in porous media for modeling heat, water, and chemical transport in general hydration and drying operations of porous food materials.

Another study (Singh et al. 2004) noted that one of the salient features of fluid transport through biological systems is the complex flow path presented by the biopolymeric matrix, thus expanding the above approach. Similarly, it was recently proposed that use of an “effective” single cylindrical capillary radius is the simplest possible model to describe capillary penetration into a porous medium. However, this model may be insufficient in many cases (Saguy et al. 2005a), especially when a significant distribution of pore size exists (Marmur and Cohen 1997), as previously shown for dried foods (Karathanos et al. 1996). More specifically, and depending upon the type of food and its processing history, it may contain pores ranging in radius from 0.1 to 300 μm, those in the 10–300 μm range being the most common (Bell and Labuza 2000).

Although numerous models have been proposed and frequently applied, additional improvements are required before modeling of the process based on the real mechanism(s) occurring becomes possible. Nevertheless, recent studies focused on more fundamental physical-based approaches have taken on a central role. Hence, significant progress is anticipated.

5 New Approaches and Other Advances

The rehydration of dried foods involves different physical mechanisms, among them water imbibition, internal diffusion (in the solid and pores), convection and diffusion at the surface and within large open pores, hydraulic flow, capillary flow, and relaxation of the solid matrix (Marabi and Saguy 2009; Saguy et al. 2007). Additionally, we have highlighted the utilization of a double Weibull model as well as mobile-immobile model. A growing body of data as well as ours indicates that simplification of the rehydration process may not be fully warranted, or in some cases, might even result in misleading conclusions (Datta 2007a, b; Saguy et al. 2005b; Weerts et al. 2003a, b). This realization is relatively new and important insights are coming to light from the merging of different scientific disciplines, including food and soil sciences, biophysics, environmental sciences, and petroleum and chemical engineering. The ultimate goal of these interdisciplinary efforts is to provide more advanced and accurate physical models that describe the mechanism(s) taking place during the rehydration process (Saguy et al. 2007).

The models recently developed and successfully applied to the flow of liquids into dried foods are based on theories usually termed as “capillary-flow approach” and/or “flow in porous media.” The theories are already well developed in other fields, as are the methodologies needed to generate the required experimental data. However, there is still a considerable lack of data and, more importantly, standard methods allowing collection of the relevant physical properties of the food matrix and its interaction with the liquid. It is expected in the near future that collaborative studies will provide the information needed to apply these theories.

The common starting point for developing models that account for fluid flow in porous media is Darcy’s equation and its Navier–Stokes analog (Datta 2007a; Saguy et al. 2005b; Weerts et al. 2003b). In addition, the main roles of the food particles’ physical properties (e.g., pore-size distribution, heterogeneity, tortuosity), the embedding liquid (e.g., density, dynamic viscosity), the external conditions (e.g., temperature, pressure), and the interface (e.g., contact angle) are also considered in order to quantify the changes occurring during drying and to facilitate the modeling of the rehydration process. These studies on fluid flow in porous media have presented, in adequate detail, the development of the models, and the reader is referred to them for more detailed information (Saguy et al. 2007).

Recent studies focusing on the various transport mechanisms in porous media include:

-

Molecular diffusion of gases, including water vapor: Darcy flow of gases resulting from pressure and liquid flow due to gas and capillary pressures (Datta 2007a).

-

Utilization of Lucas-Washburn equation in modeling rehydration of dried foods (Lee et al. 2005; Machado et al. 1997; Saguy et al. 2005a).

-

New methods and technologies to obtain experimental data (Datta 2007a, b; Saguy et al. 2005b) including: (1) density, porosity, thermal conductivity, and specific heat of solid material, (2) molecular, capillary, and effective diffusivities, (3) moisture isotherms, (4) vapor and liquid permeability, and (5) water-potential curves; data in the last two categories is either nonexistent for foods or very difficult to obtain.

It is worth noting that new technology and utilization of X-ray MCT capabilities are spreading. X-ray MCT is a powerful tool for detailed observations of microstructure of porous foods and is expected to become a pertinent method for obtaining detailed information that can be further utilized in computational simulations of the imbibition of liquids into porous media. Hence, it could open new avenues for ultimately quantifying and modeling internal changes during both drying and rehydration, thereby providing the necessary information for studying the mechanism(s) involved, and enabling better control and quality improvements.

6 Research Needs

Future research needs to focus on the accomplishment of four main goals, as recently summarized (Saguy et al. 2007): (1) expand the theory and approach outline above to different aw, and RC models and foods, (2) apply “transport in porous media” theories to model the fate of dissolved and retained substances in food particulates, (3) develop physical-based models-multidisciplinary research integrating/assimilating theories and knowledge from other fields, and (4) perform in-situ quantification–development of new methods/techniques, for in-situ quantifying of changes in food matrix microstructure, and water/vapor movement.

7 Conclusions

We have highlighted how porous media physics could be implemented for modeling the rehydration of foods. The main conclusions can be summarized as:

-

Sorption isotherm data could be extended to a complete RC for use in a rehydration model.

-

Flow in porous media theory, as demonstrated, is applicable to the rehydration of food particulates.

-

Moving from empirical models to physically-based ones for foods was demonstrated and therefore, is recommended.

-

Multidisciplinary collaboration is paramount and synergistic in opening new avenues of research.

The field is entering a new era in which innovative approaches and multidisciplinary teams will provide fresh insights, resulting in new discoveries and a better and deeper understanding of the phenomena. This will ultimately lead to much better control of the structure and rehydration, leading to improved food products with enhanced consumer appeal and acceptability.

References

Aguilera JM, Michel M, Mayor G (2004) Fat migration in chocolate: diffusion or capillary flow in a particulate solid? A hypothesis paper. J Food Sci 69:R167–R174

Bell LN, Labuza TP (2000) Moisture sorption – practical aspects of isotherm measurement and use. American Association of Cereal Chemists, St. Paul

Brooks RH, Corey AT (1966) Properties of porous media affecting fluid flow. J Irrig Drain E-Asce 2:61–68

Campbell GS (1974) A simple method for determining unsaturated conductivity from moisture retention data. Soil Sci l17:311–314

Campbell GS, Shiozawa S (1992) Prediction of hydraulic properties of soils using particle-size distribution and bulk density data. International Workshop on Indirect Methods for Estimating the Hydraulic Properties of Unsaturated Soils. University of California, Riverside, CA

Carbonell S, Hey MJ, Mitchell JR, Roberts CJ, Hipkiss J, Vercauteren J (2004) Capillary flow and rheology measurements on chocolate crum/sunflower oil mixtures. J Food Sci 69:E465–E470

Chiralt A, Fito P (2003) Transport mechanisms in osmotic dehydration: the role of the structure. Food Sci Technol Int 9:179–186

Cunha LM, Oliveira FAR, Ilincanu LA (1998a) Application of the probabilistic Weibull distribution to rehydration kinetics: relationship between the model parameters and the underlying physical mechanisms. In: Oliveira JC, Oliveira FAR (eds) Proceedings of the 3rd workshop of the Copernicus project, Leuven, Belgium

Cunha LM, Oliveira FAR, Oliveira JC (1998b) Optimal experimental design for estimating the kinetic parameters of processes described by the Weibull probability distribution function. J Food Eng 37:175–191

Cunningham SE, McMinn WAM, Magee TRA, Richardson PS (2007) Modelling water absorption of pasta during soaking. J Food Eng 82:600–607

Datta AK (2007a) Porous media approaches to studying simultaneous heat and mass transfer in food processes. I: problem formulations. J Food Eng 80:90–95

Datta AK (2007b) Porous media approaches to studying simultaneous heat and mass transfer in food processes. II: property data and representative results. J Food Eng 80:96–110

Fontana AJ Jr, Campbell GS (2007) Applications of water activity in non food systems. In: Barbosa-Canovas GV, Fontana AJ Jr, Schmidt SJ, Labuza TP (eds). Water Activity in Foods: Fundamentals and Applications. Chapter 14. IFT Press/Blackwell, Ames, IA

Garcia-Pascual P, Sanjuan N, Melis R, Mulet A (2006) Morchella esculenta (morel) rehydration process modelling. J Food Eng 72:346–353

Giraldo G, Vazquez R, Martin-Esparza ME, Chiralt A (2006) Rehydration kinetics and soluble solids lixiviation of candied mango fruit as affected by sucrose concentration. J Food Eng 77:825–834

Gowen A, Abu-Ghannam N, Frias J, Oliveira J (2007) Modelling the water absorption process in chickpeas (Cicer arietinum L.) – the effect of blanching pre-treatment on water intake and texture kinetics. J Food Eng 78:810–819

Hillel D (1998) Environmental soil physics. Academic, San Diego

Hills BP, Babonneau F, Quantin VM, Gaudet F, Belton PS (1996) Radial NMR microimaging studies of the rehydration of extruded pasta. J Food Eng 27:71–86

Jury WA, Gardner WR (1991) Soil physics. Wiley, New York

Karathanos VT, Kanellopoulos NK, Belessiotis VG (1996) Development of porous structure during air drying of agricultural plant products. J Food Eng 29:167–183

Klute A (1986) Water retention: Laboratory methods. In: Klute A (ed) Methods of soil analysis. Part I, physical and mineralogical methods, 2nd edn. American Society of Agronomy, Madison

Krokida MK, Philippopoulos C (2005) Rehydration of dehydrated foods. Drying Technol 23:799–830

Lee KT, Farid M, Nguang SK (2005) The mathematical modelling of the rehydration characteristics of fruits. J Food Eng 72:16–23

Lucas R (1918) Ueber das zeitgesetz des kapillar aufstiegs von Flussigkeiten. Kolloid-Zeitschrift 23:15–22

Machado MF, Oliveira FAR, Gekas V (1997) Modeling water uptake and soluble solids losses by puffed breakfast cereal immersed in water or milk. In: Jowitt R (ed) Proceedings of the seventh international congress on engineering and food – Part I. Sheffield Academic Press, Sheffield, UK

Marabi A, Dilak C, Shah J, Saguy IS (2004a) Kinetics of solids leaching during rehydration of particulate dry vegetables. J Food Sci 69:FEP91–FEP96

Marabi A, Jacobson M, Livings S, Saguy IS (2004b) Effect of mixing and viscosity on rehydration of dry food particulates. Eur Food Res Technol 218:339–344

Marabi A, Livings S, Jacobson M, Saguy IS (2003) Normalized Weibull distribution for modeling rehydration of food particulates. Eur Food Res Technol 217:311–318

Marabi A, Saguy IS (2004) Effect of porosity on rehydration of dry food particulates. J Sci Food Agr 84:1105–1110

Marabi A, Saguy IS (2005) Viscosity and starch particle size effects on rehydration of freeze-dried carrots. J Sci Food Agr 85:700–706

Marabi A, Saguy IS (2009) Rehydration and Reconstitution of Foods. In: Ratti C (ed) Advances in food dehydration. CRC Press, Boca Raton

Marmur A, Cohen RD (1997) Characterization of porous media by the kinetics of liquid penetration: the vertical capillaries model. J Colloid Interf Sci 189:299–304

Maroulis ZB, Saravacos GD, Panagiotou NM, Krokida MK (2001) Moisture diffusivity data compilation for foodstuffs: effect of material moisture content and temperature. Int J Food Prop 4:225–237

Misra MK, Brooker DB (1980) Thin-layer drying and rewetting equations for shelled yellow corn. Trans ASAE 23:1254–1260

Morel-Seytoux HJ, Nimmo JR (1999) Soil water retention and maximum capillary drive from saturation to oven dryness. Water Resour Res 35:2031–2041

Oliveira FAR, Ilincanu L (1999) Rehydration of dried plant tissues: Basic concepts and mathematical modeling. In: Oliveira FAR, Oliveira JC (eds) Processing foods. CRC Press, Boca Raton

Peleg M (1988) An empirical-model for the description of moisture sorption curves. J Food Sci 53:1216–1219

Ross PJ, Williams J, Bristow KL (1991) Equation for extending water-retention curves to dryness. Soil Sci Soc Am J 55:923–927

Rossi C, Nimmo JR (1994) Modeling of soil water retention from saturation to oven dryness. Water Resour Res 30:701–708

Saguy IS, Marabi A, Wallach R (2005a) Liquid imbibition during rehydration of dry porous foods. Innov Food Sci Emerg Technol 6:37–43

Saguy IS, Marabi A, Wallach R (2005b) New approach to model rehydration of dry food particulates utilizing principles of liquid transport in porous media. Trends Food Sci Technol 16:495–506

Saguy IS, Troygot O, Marabi A, Wallach R (2007) Rehydration modeling of food particulates utilizing principles of water transport in porous media. Bangkok: 10th International Symposium on the Properties of Water (ISOPOW X). (Also Chapter 17. In: Reid DS, Sajjaanantakul T, Lillford PJ, Charoenrein S (eds) Water properties in food, health, pharmaceutical and biological systems: ISOPOW 10). Wiley-Blackwell, 2010)

Salvatori D, Andres A, Chiralt A, Fito P (1999) Osmotic dehydration progression in apple tissue II: generalized equations for concentration prediction. J Food Eng 42:133–138

Saravacos GD, Maroulis ZB (2001) Transport of water in food materials. Transport properties of foods. Marcel Dekker, New York

Shi XQ, Fito-Maupoey P (1994) Mass transfer in vacuum osmotic dehydration of fruits: a mathematical model approach. Lebensm Wiss Technol 27:67–72

Simunek J, van Genuchten MTh, Sejna M (2005) The HYDRUS-1D Software package for simulating the movement of water, heat, and multiple solutes in variably saturated media. [Version 3.0] Department of Environmental Sciences, University of California, Riverside

Singh PP, Maier DE, Cushman JH, Haghighi K, Corvalan C (2004) Effect of viscoelastic relaxation on moisture transport in foods. Part I: Solution of general transport equation. J Math Biol 49:1–19

Tillotson JE (2003) Convenience foods. In: Trugo L, Finglas PM (eds) Encyclopedia food sciences and nutrition, 2nd edn. Academic, Oxford

van Genuchten MTh (1980) A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci Soc Am J 44:892–898

Wallach R (2007) Physical characteristics of soilless media. In: Raviv M, Lieth JH (eds) Soilless culture: theory and practice. Elsevier, London

Washburn EW (1921) The dynamics of capillary flow. Phys Rev 17:273–283

Webb SW (2000) A simple extension of two-phase characteristic curves to include the dry region. Water Resour Res 36:1425–1430

Weerts AH, Lian G, Martin D (2003a) Modeling rehydration of porous biomaterials: anisotropy effects. J Food Sci 68:937–942

Weerts AH, Lian G, Martin DR (2003b) Modeling the hydration of foodstuffs: temperature effects. AIChE J 49:1334–1339

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2010 Springer New York

About this paper

Cite this paper

Saguy, I.S., Troygot, O., Marabi, A., Wallach, R. (2010). Rehydration Modeling of Food Particulates Utilizing Principles of Water Transport in Porous Media. In: Aguilera, J., Simpson, R., Welti-Chanes, J., Bermudez-Aguirre, D., Barbosa-Canovas, G. (eds) Food Engineering Interfaces. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4419-7475-4_21

Download citation

DOI: https://doi.org/10.1007/978-1-4419-7475-4_21

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4419-7474-7

Online ISBN: 978-1-4419-7475-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)