Abstract

Rhodium catalyzed decarbonylation has developed significantly over the last 50 years and resulted in a wide range of reported catalyst systems and reaction protocols. Besides experimental data, literature also includes mechanistic studies incorporating Hammett methods, analysis of kinetic isotope effects as well as computational studies of model systems, which give an indication of the scope of the process. In this chapter, fundamental applications of Rh-catalyzed decarbonylation reactions are surveyed and discussed, including cross-coupling reactions, tandem reactions, and alternative methodologies for process intensification.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Aldehydes

- Aryl-aryl coupling

- Continuous-flow systems

- Cross-coupling

- Decarbonylation

- Heck coupling

- Ionic liquids

- Oppenauer oxidation

- Pauson–Khand

- Rhodium

- Sugars

- Tandem reaction

1 Introduction

Carbon monoxide (CO) is a versatile and inexpensive gas, which is industrially produced in large scale by steam reforming of natural gas, incomplete combustion of other carbon containing materials or by gasification of coal [1]. In bulk chemical manufacturing CO is widely used as C1 building block [2], but its colorless and odorless properties combined with a high toxicity makes handling and storage potentially dangerous [3]. For this reason, there is a great interest – in especially smaller scale applications – to supply the CO equivalents through “in situ” generation instead of via external CO supply. This makes the overall processing less dangerous, thus contributing to generate a safer manufacture and working environment. An approach whereby CO can be generated “in situ” is to apply molecules containing carbonyl groups as source of CO via a decarbonylation reaction. Such reactions can be facilitated both thermally and catalytically, and especially the catalytic approach is attractive for aldehydes which liberate CO much easier than other functionalities, e.g., ketones [4]. In general terms, decarbonylation reactions are the reverse of CO insertion reactions, i.e., carbonylation reactions. Even though carbonylation reactions are significantly more widely applied in industrial applications, the decarbonylation reaction is a key methodology in organic synthetic chemistry, mainly in the preparation of biaryl motifs in natural products, advanced materials, and pharmaceuticals [4].

The current chapter surveys the use of rhodium metal complexes in catalytic decarbonylation. The first section describes early work on the topic and mechanistic aspects on the Rh-catalyzed decarbonylation reaction. The following sections describe potential applications of decarbonylation processes in cross-coupling reactions and tandem reaction protocols, e.g., the Oppenauer oxidation, enantioselective, and Pauson–Khand cascade decarbonylation reactions. Focus is also on the use of biomass derived compounds (sugars) as CO source, the use of ionic liquids (ILs) as alternative solvents for the decarbonylation reaction, catalyst recycling as well as process intensification by use of fixed-bed reactor technology for continuous-flow systems.

2 Early Work

The first decarbonylation reaction for aldehydes and the associated mechanism was described in 1965–1966 by Tsuji and Ohno with a stoichiometric amount of the Wilkinson’s catalyst RhCl(PPh3)3 (PPh3 = triphenylphosphine) [5] (Scheme 1). In a first reaction step, the catalyst is in presence of the aldehyde converted to RhCl(CO)(PPh3)2 (a), which is the true catalyst in the carbonylation reaction. Complex (a) is a stable, four-coordinated complex that easily can be expanded to form a six-coordinated complex as intermediate in the reaction.

The mechanism for the decarbonylation of aldehydes proposed by Ohno et al. using Wilkinson’s catalyst in stoichiometric amounts [5]

In 1982 Pignolet et al. proposed a mechanism for the decarbonylation of aldehydes using cationic catalyst complexes with chelating diphosphines as ligands, such as [Rh(dppp)2]Cl (dppp = diphenylpropanephosphine) [6]. The rationale for using chelating diphosphine ligands instead of monodentate phosphines (e.g., PPh3) was that dissociation of coordinated CO to regenerate the active catalyst was a key step during the reaction. In this regard, it was showed that cationic complexes with chelating diphosphine ligands bind CO less strongly to the metal center than RhCl(CO)(PPh3)2 complex due to a decrease in the Rh-CO π back-bonding and consequently, CO release is facilitated [6].

In 1999 Crabtree and co-workers suggested a mechanism for the decarbonylation of aldehydes by using the cationic Rh-triphos catalyst (triphos = bis(diphenylphosphinoethyl)phenylphosphine), [Rh(CO)(triphos)][SbF6] [7]. The proposed mechanism consists of four steps as depicted in Scheme 2. The first step is the oxidative addition of the aldehyde C–H bond to complex 1 generating a metal acyl complex similar to 2. Then complex 2 undergoes retro-migratory insertion of the R group to generate an alkyl/aryl hydride complex 3. The reductive elimination of complex 3 yields the alkane or arene and complex 4 that is supposed to be in equilibrium with complex 1, which close the catalytic cycle. The possibility that the reaction involved a radical mechanism was excluded by using an aldehyde (citronellal) that served as radical trap, since cyclic species such as menthone or isomenthone would be expected to form which was not the case.

Decarbonylation mechanism proposed by Crabtree et al. [7]

In 2008 Madsen et al. presented a combined experimental and theoretical study of the mechanism for the Rh-catalyzed decarbonylation of para-substituted benzaldehydes. In line with earlier work from the group, the experimental part incorporated Hammett studies and kinetic isotope effects in order to characterize the selective-determining step. In addition, the data was used to differentiate between several mechanistic proposals and used as starting point for the computational studies [8].

In the studies by Pignolet et al. the proposed mechanism was related to systems with chelating diphosphines ligands like dppp. However, the DFT calculations performed by Madsen et al. using a model ligand (dppp where Ph = H) revealed that the coordination of benzaldehyde to Rh(dppp)2 + was unfavorable. The calculations were confirmed by measuring the energy minimization of different distances between the benzaldehyde oxygen atom and the Rh(I) center. Based on the previous studies by Pignolet, Rh(dppp)(CO)2 + was suggested as the optimal catalyst, which indicates an exchange of CO for benzaldehyde as the first step in the catalytic cycle [8]. The Hammett studies of benzaldehyde and phenyl acetaldehyde derivatives revealed a buildup of negative charge in the selectivity-determining step. In contrast, the kinetic isotope effects of the two substrates were comparable, indicating that the two mechanisms had to be identical. Furthermore, the computational studies of the catalytic cycle revealed that the oxidative addition into the formyl bond was followed by a rate-determining extrusion of CO and a reductive elimination. The proposed theoretical kinetic isotope effects were in compliance with the experimental values for both substrates, but only when the rate-determining step was selected as the migratory extrusion of CO.

In 2014 Kappe and co-workers proposed a plausible mechanism for Rh-catalyzed decarbonylation of aldehydes using Wilkinson’s catalyst [9]. The catalytic cycle shown in Scheme 3 took into account results obtained from earlier experimental and computational mechanistic studies. The catalytic cycle includes a pre-step in which the square-planer Wilkinson’s catalyst 1 is converted to an unsaturated d8 complex 2. The coordinately unsaturated complex 2 coordinates with the aldehyde 7 via the oxygen atom to form 3, which reacts by a reversible oxidative addition into the formyl group of the aldehyde to form an acyl Rh(III) hydride complex 4. The cycle continues by a rate-limiting migratory extrusion of CO, in which the vacant coordination site of the complex is occupied to give the 18e− alkyl or aryl Rh(III) hydride 5. The migratory extrusion is then followed by an irreversible reductive elimination, which produces the 16e− carbonyl complex trans-[RhCl(CO)(PPh3)2] 6 and the decarbonylated product 8. Finally the unsaturated d8 complex 2 regenerates after dissociation of the extruded CO (9).

The mechanism for decarbonylation of aldehydes proposed by Kappe and co-workers using the Wilkinson’s catalyst [9]

3 Cross-Couplings

Grignard reagents have traditionally been used as stoichiometric reagents in coupling reactions with electrophilic carbon atoms, e.g., esters, ketones, hetero-atoms halides. However, transition metal catalyzed cross-couplings now play an essential role in both carbon–carbon and carbon–hetero bond formation, and the nature of the ligand coordinating to the transition metal is important in determining the selectivity and the rate of the reaction.

3.1 Cross-Coupling of Arenes with Olefins

Within the last decade, transition metal catalyzed cross-couplings have been developed in which unreactive arene C–H bonds are coupled with olefins to generate arylated olefins. Fujiwara and Moritani were the first to demonstrate that arenes could be applied as coupling partners with olefins by using a Pd-catalyst [10], but since then more active and selective catalytic systems have been developed. Hence, recent studies have demonstrated that certain directing groups facilitate regioselective C–H ortho-olefination [11]. Carboxylic acids and derivatives have also been recognized as effective coupling partners in decarbonylative cross-coupling reactions [12, 13]. Further research has been performed by applying vinyl carboxylic acids and their derivatives as olefins. With this approach, it has been possible to accomplish decarbonylation of vinyl carboxylates with direct functionalization of C–H bonds for improving the catalytic efficiency [14].

Yu and co-workers have investigated the direct olefination of arene C–H bonds by applying an Rh complex catalyst and a proper base. The direct olefination of cinnamoyl chlorides and cinnamic anhydrides tolerate a variety of functional groups (Scheme 4) and the pre-studied vinyl carboxylic acid has revealed to act as an effective reagent [15,16,17]. Further research of the decarbonylation reaction by arenes has been performed by Li and co-workers. A protocol for the decarbonylative direct olefination of arylpyridines with different vinyl carboxylic acids under mild conditions has been developed in presence of an Rh(I) catalyst in absence of an oxidant. The method provides a general and convenient procedure for Rh-catalyzed cross-coupling reactions (Scheme 5) [14].

Direct olefination with cinnamoyl and cinnamic aldehyde by Yu and co-workers [15]

Direct olefination of arylpyridines by Li and co-workers [14]

The catalytic activity of different rhodium complexes for direct olefination has been studied in a model system using 2-(meta-tolyl)pyridine and cinnamic acid with the additive pivalic anhydride ((t-BuCO)2O) in toluene (Scheme 6) [14]. The catalyst [Rh(COD)2]OTf (COD = 1,5-cyclooctadiene) showed the highest catalytic activity affording (E)-2-(5-methyl-2-styrylphenyl)pyridine. Almost similar activity was observed by applying [Rh(NBD)2]BF4 (NBD = norbornadiene) and [Rh(CO)2Cl]2, while other used Rh complexes showed no reactivity and negligible yield. Using other solvents, e.g., chlorobenzene, para-xylene, anisole, N,N-dimethylformamide, and dimethyl sulfoxide resulted in a reduced yield. Other tested additives were all inferior to the (t-BuCO)2O.

Direct olefination of 2-(meta-tolyl)pyridine with cinnamic acid [14]

A wide range of substrates with substituents on the benzene ring revealed to be effectively transformed to the E stereochemistry. Substrates with meta- or ortho-substituted aryl rings were also efficiently coupled to form the ortho-alkenylated products.

The mechanism for the decarbonylative direct olefination of aryl pyridines has been suggested by Li and co-workers (Scheme 7) [14]. In the first step, the aryl pyridine 3 reacts with the Rh(I) complex to form the aryl coordinated Rh complex A through C–H activation. The anhydrides B and C and the additive (t-BuCO)2O react with complex A forming the acyl intermediates D and E, which decarbonylates to form the allyl complexes F and G. Addition of trifluoromethanesulfonic acid (HOTf) generates complexes H and I in which the carboxylic acids are released. Product 3 is finally produced as the reductive elimination of H and I occurs and the rhodium(I) complex is regenerated to start another catalytic cycle [14].

Proposed mechanism for the decarbonylative direct olefination of aryl pyridines [14]

3.2 Heck Coupling

The Heck cross-coupling reaction was first reported by Mizoroki and Heck [18, 19], and is a fundamental method in organic synthesis for the direct arylation of terminal alkenes. The Heck reaction does not involve Grignard reagents, and accordingly carboxylic acids and their derivatives, such as acyl chloride, anhydrides, and esters, can be used in decarbonylative arylation of terminal alkenes [20]. Arylsulfonyl hydrazides and aroyl hydrazides can also be applied as aryl electrophiles in the reaction [21, 22].

In 2009 Li and co-workers presented a route for Rh/Ni co-catalyzed decarbonylative Heck-type coupling of aromatic aldehydes and conjugate alkenes using dioxygen as oxidant (Scheme 8). The reaction was accompanied by the formation of conjugate addition products [23]. In 2015 Yang and co-workers developed a general Rh-catalyzed oxidative decarbonylative Heck-type coupling of aromatic aldehydes by the use of terminal alkenes and acyl chlorides as additives (Scheme 9) [20].

Rh/Ni co-catalyzed oxidative decarbonylative arylation of conjugate alkene [20]

Rh-catalyzed oxidative decarbonylative arylation of terminal alkene [20]

Mechanistic experiments to understand the role of the acyl chloride has been performed in the studies by Miura and co-workers [24, 25]. The reaction mixture consisting of [(COD)RhCl]2 catalyst and benzoyl chloride showed formation of styrene 2 to stilbene 3a (Scheme 10a), while absence of the acyl chloride resulted in low yield. The Rh-catalyst precursor was activated in the catalytic cycle as stilbene was generated. This was supported by a reaction (Scheme 10b) in which the Rh-catalyst reacted with benzoyl chloride in the absence of styrene, which under high vacuum evaporated to afford Rh residual, which didn’t catalyze the oxidative decarbonylative Heck-type coupling of aldehydes. However, generally when catalyst loading was increased a higher product yield was obtained, and the trans isomers was by H1 NMR found to be the dominant reaction product [20]. In control experiments the benzoyl chloride was replaced with benzoic acid in presence of, e.g., lithium chloride (LiCl) and phosphoric acid (H3PO4) and no reaction product was formed (Scheme 10c).

Mechanistic experiments to understand the role of acyl chloride (a) without activation, (b) with activation and (c) with other additives [20]

Aryl aldehydes with electron withdrawing or donating substitutes have been found to afford a moderate yield of the products in the decarbonylation Heck-type coupling with no significant influence of steric effects by ortho-, meta-, and para-position substituents. In contrast, aliphatic aldehydes did not result in coupling products and aliphatic carboxylic acid was observed as product [20].

Based on literature reports Yang and co-workers proposed a mechanism for the oxidative decarbonylative coupling of aldehydes with alkenes which is illustrated in Scheme 11 [20]. An initial step in the mechanism is the oxidative addition of the aldehyde C–H bond to the activated Rh(I)-catalyst A to afford the acyl hydride Rh(III) complex B. Next, this complex is converted by tributyl phosphate (TBP) (upon liberation of ButOH) to Rh(III) complex C and further to the aryl Rh(III) complex D by CO migration. Then styrene is coordinated to yield the π-bonded Rh(III) complex E, which after C = C insertion to the alkyl Rh(III) complex F, forms the oxidative decarbonylative Heck-type coupling product 3 and Rh(III) hydride complex G after successive β-hydride elimination. The active Rh(I) catalyst A is regenerated by reductive elimination of ButOH to form Rh(I) complex H from which CO is dissociated.

Proposed mechanism for the oxidative decarbonylative coupling of aldehydes with alkenes [20]

The Rh-catalyzed oxidative decarbonylative Heck-type coupling of aromatic aldehydes with terminal alkenes has been presented as an efficient procedure. Acyl chlorides have revealed to be a poor additive for the reaction to proceed and activate the Rh-catalyst precursor by coupling with styrene [26].

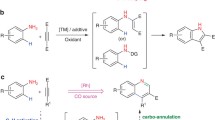

3.3 Aryl-Aryl Cross-Coupling

Protocols to form aryl-aryl bonds have been one of the core interests in organic chemistry for over a century due to the importance of biaryl motifs in natural products as well as pharmaceutical industry [27]. The most common procedure for constructing the aryl-aryl union is by far the homo- and cross-coupling of (pseudo)aryl halides and aryl metalloids via C–H bond activation. Recently, more challenging oxidative cross-coupling of simple arenes have been achieved and developed, affording biaryl products with high atom economy [28]. Based on previous studies of cross-dehydrogenative-coupling (CDC) reactions [29, 30] and decarbonylative coupling of different aldehydes and terminal alkynes [31, 32], Li and co-workers have suggested that aromatic aldehydes can be applied in CDC reactions with arenes in the presence of an oxidant (Scheme 12) [26]. The acyl metal complex 4 is generated by oxidative addition of the aldehyde to the transition metal. CO insertion to form complex 5 is then followed by reductive elimination to form a simple arene (Ar-H). The aryl metal hydride complex 5 is also capable of reacting with an alkene, alkyne, or arene [33,34,35] to obtain the decarbonylative coupling product. Furthermore, the arylmetal hydride forms the diaryl-metal complex 6 and the acyl-aryl-metal complex 6′, which results in the C–C bond formation of biaryl and biarylketones after the reductive elimination.

Aldehyde C–H bond activation and decarbonylative homocoupling [26]

The optimal conditions for the decarbonylative homocoupling reaction include the catalyst Rh(acac)(CO)2 (acac = acetylacetonate), the oxidant TBP when using PhCl as solvent [33]. Electron-rich aromatic aldehydes with methoxy-substitution in para- or meta-position were found to give a good yield of biaryls. However, even higher yield was obtained with 2-arylpyridine derivatives [33].

Li and co-workers proposed a mechanism for the homo-coupling of aryl aldehydes with 2-phenylpyridines (Scheme 13) [33]. Initially, oxidative addition of the aldehyde 2 to the Rh(I) center 4 generates Rh(III) acyl hydride complex 5, which undergoes insertion of CO at elevated temperature to give Rh(III) hydride complex 6. Next, 6 reacts with the pyridine compound 1a through C–H bond activation, which is followed by dehydrogenation promoted by TBP to give Rh(III) complex 7. Finally, reductive elimination of intermediate 7 affords the target biaryl product 3a and regenerates the Rh(I) catalyst 4.

Mechanism for the oxidative arylation of 2-phenylpyridine with aryl aldehydes [33]

Another method for oxidative decarbonylative homocoupling of aromatic aldehydes with phosphine ligands has also been developed to produce biaryl and diarylketones (Scheme 14). Different ligands have been tested in the method and [RhCl(CO)2]2 in presence of PPh3 showed the highest yield with the ratio of biaryl:diarylketones being 72:28. Changing the phosphine ligand with dppp showed no formation of biaryl. Aldehydes with weak electron-withdrawing substituents such as fluoro and chloro also showed a high yield of the biaryl product [26].

Phosphine ligand triggered oxidative decarbonylative homocoupling of aldehydes [26]

The proposed mechanism for the Rh-catalyzed oxidative decarbonylative homocoupling with phosphines is depicted in Scheme 15. First, the oxidative addition of the Rh(I) complex forms the acyl Rh(III) hydride complex 7. This complex is then converted by TBP to Rh(III) complex 8, which is decarbonylated to aryl Rh(III) complex 9. By using the ligand PPh3, the transmetalation between two aryl Rh(III) 9 complexes forms the diaryl Rh(III) complex 10, which releases the biaryl product 2 after the reductive elimination to the initial Rh(I) complex. Similar, by using the dppp ligand the transmetalation between acyl Rh(III) complex 8 and aryl Rh(III) complex 9 forms the Rh(III) complex 11, which releases the diarylketones 3 after the reductive elimination. The dissociation rate for the Rh-complex 8 decreases when dppp is applied instead of PPh3, and as a result the decarbonylation of 8 is more difficult for obtaining the aryl complex [26].

Proposed mechanism for the oxidative decarbonylative homocoupling [26]

4 Tandem Reactions

Tandem reactions consist of at least two sequential steps in which the second step occurs in virtue of the functionality from the previous reaction [36]. Tandem reactions can reduce the number of steps required to form a complex molecule, increase the atom economy as well as reduce generation of waste from the reactions [37, 38]. Recently, main focus has been on the development of asymmetric catalyzed tandem reactions by applying chiral transition metal complexes [37, 39,40,41].

4.1 Oppenauer Oxidation

In tandem reaction protocols Oppenauer oxidation of primary alcohols to aldehydes followed by decarbonylation can be combined within the same reaction mixture. The reaction protocol allows the removal of hydroxymethyl group in one step, as illustrated in Scheme 16 for the tandem Oppenauer oxidation and decarbonylation of 2-naphthaldehyde reported by Madsen and co-workers using aluminum tri(tert-butoxide) as the Oppenauer catalyst under optimized conditions [42]. Importantly, long-chain aliphatic alcohol also showed generation of the desired product, however, along with olefin byproducts.

Rhodium-catalyzed decarbonylation of 2-naphthaldehyde using different solvents [42]

The optimal conditions for the tandem Oppenauer oxidation and decarbonylation reaction were found after exploration of different phosphine ligands (Fig. 1) for the decarbonylation in various solvents [42]. Use of monodentate ligands (i.e., PPh3, PCy3(Cy = tricyclohexyl), P(o-furyl)3, and PCy2(2-biphenyl)) resulted in low conversion and the tridentate ligands 1 and 2 gave almost no conversion. The bidentate ligand dppp was more reactive than dppe (1,2-bis(diphenylphosphino)ethane) and dppb (1,4-bis(diphenylphosphino)butane). The diphosphines 3 and 4, having a more rigid backbone and a smaller bite angle compared to the other tested biphosphines, yielded only minor products amounts, while the reactivity increased for bisphophines with bite angles of 104–107°, such as the Xantphos [43]. The P,N ligand Davephos [44] gave also only a minor amount of the product, while dppf (1,1′-ferrocenediyl-bis(diphenylphosphine)) and Binap (2,2′-bis(diphenylphosphino)-1,1′-binaphthyl) gave high and similar activity for the decarbonylation, albeit the stability of the former catalyst system was quite low (resulted in black coloration of the reaction mixture). In contrast, the quite similar ligand SolPhos (7,7′-bis(diarylphosphino)-3,3′,4,4′-tetrahydro-4,4′-dimethyl-8,8′-bis-2H-1,4-benzoxazine) resulted only in traces of the product and the Walphos II and Taniaphos I ligands revealed a reactivity comparable to dppp. Hence, the best ligands – dppp, dppf, Binap, and Taniaphos I – were observed to have bite angles between 91 and 96° and a more flexible backbone, while both smaller bite angle (i.e., ligand 3 and 4) and larger bite angle (e.g., Xantphos and dppb) showed almost no conversion or a very slow reaction [43].

Phosphine ligands tested [42]

The synthetic utility of decarbonylation in tandem reactions involving a Diels–Alder reaction has also been demonstrated by Madsen et al. (Scheme 17) [45]. Here aldehyde 6 was prepared in a Diels–Alder reaction between diene 5 and acrolein and decarbonylated to the unsaturated decalin compound 7 in good yield using the Rh-dppp complex catalyst system. Notably, this two-step protocol yielded product 7, which was not possible to obtain by the direct one-step cycloaddition of ethylene and diene 5 due to a large HOMO-LUMO gap between the reagents [42].

Diels–Alder decarbonylation reaction [42]

4.2 Enantioselective Decarbonylation

The demand for optically active building blocks is important for especially asymmetric synthesis in the drug-discovery industry [46]. Earlier study has demonstrated that optically active diarylalkanes can be formed by different procedures, including asymmetric alkylations of lithiated diarylmethanes and metal-catalyzed cross-coupling of benzylsilanes with aryl triflates [47]. The cross-coupling requires an optically active precursor, which led to investigations on enantioselective alkene reductions [48].

Carreira and co-workers have developed an one-pot protocol for the preparation of optically active 1,1-diarylethanes from 2,2-diarylpropanealdehydes involving enantioselective tandem 1,4-addition decarbonylation (Scheme 18) [47]. Hence, the protocol is a new procedure for asymmetric synthesis where the aldehyde is a removable steering group [49]. A range of functional groups such as ethers, halides, esters, and nitro groups were found to be compatible for the reaction and furans, thiophenes, and indoles provided the decarbonylated products. It was suggested that compound 3 is formed as a result of β-hydride elimination of the intermediate 4 during the reaction, despite the presence of 3 could lead to erosion of the optical purity of product 2 (Scheme 19).

1,1-diarylethanes from 2,2-diarylpropionaldehydes [47]

Metal-mediated decarbonylation versus dehydroformylation [47]

The one-pot protocol using [Rh(C2H4)2Cl2] and olefin ligands allowed also conversion of cinnamaldehyde derivatives without isolating the intermediate aldehyde [50]. Despite very low yields, it is so far the first example of aldehyde decarbonylation with Rh-diene complexes in absence of phosphine ligands [47].

The conditions for the decarbonylation investigated by Carreira and co-workers have shown to be difficult for small-scale reactions or with volatile aldehydes, and the opportunity for coupling the decarbonylation to a process that consumes CO has been examined [47]. Two cyclization procedures have been developed utilizing aldehydes as a source of CO; the first involves a cascade Pauson–Khand reaction of alkyne and alkene to form substituted cyclopentenones [51] and the other involves a cascade lactonization of benzylic alcohols to form benzofuranone (Scheme 20) [52].

Chemical traps for CO lead to catalytic decarbonylation [47]

4.3 Pauson–Khand Cycloaddition

Gedye [53] and Giguere [54] reported in 1986 microwave-accelerated organic synthesis (MAOS) which has been applied in Pauson–Khand decarbonylation reactions [55, 56]. The first microwave-assisted Rh-catalyzed cascade decarbonylation Pauson–Khand reaction (PKR) was reported by Kwong and co-workers in 2008 using aromatic aldehydes and [Rh(COD)Cl]2/dppp as superior bisphosphine ligand system [57] (Scheme 21). Various enynes were successfully converted except ortho-substituted aromatic enynes which provided low yield due to steric hindrance. Remarkably, the use of CO surrogates (aldehydes) revealed better results than gaseous CO under the same reaction conditions. On the other hand, the use of oil-bath heating instead of microwave yielded only trace amount of product.

(a) Microwave-assisted Rh-catalyzed cascade PKR; (b) (S) SYNPHOS [57]

Besides the achiral cascade PKR, the possibility of achieving the first enantioselective microwave-assisted cascade transformation was examined with various substrates including O-, N-, and C-tethered enynes. Chiral diphosphine ligands were examined in place of dppp and (S)-SYNPHOS (BisbenzodioxanPhos) provided the best results in terms of product yield and enantioselectivity [57].

5 Alternative Processes

Rh-based decarbonylation catalyst systems have proved tolerant towards a wide range of functional groups when employed in total synthesis, thus making selective decarbonylation a potential strategy for upgrading carbohydrates (aldoses) and furfurals into biofuels and chemical building blocks in bio-refineries [58]. Alternative processes have also been developed with the aim of optimizing the recovery and recycling of the catalyst. The interest in new recyclable approaches has resulted in examination of ionic liquids as reaction media. Further process intensification has also been achieved by applying continuous-flow systems.

5.1 Aldoses

Procedures for altering the carbon chain length in unprotected aldoses has been a main focus area in carbohydrate chemistry the last century, but only few methods for shortening the carbon chain are actually developed [59]. In 1898 Ruff published a method for shortening the carbon chain, known as the Ruff degradation, which converts salts of aldonic acids into aldoses with one less carbon atom [60]. Another procedure for shortening the carbon chain is by oxidative degradation of aldoses into salts of aldonic acids with loss of one carbon atom [61, 62]. Notably, both reactions require stoichiometric amount of inorganic salts.

Aldoses are aldehydes that can undergo a C–H insertion reaction with a metal followed by decarbonylation. This transformation converts C n aldoses into Cn−1 alditols [63]. The conversion of aldoses to alditols was investigated by Andrew and co-workers using stoichiometric amounts of the Wilkinson’s catalyst. Alditols were isolated in yields from 37 to 87% using N-methyl-2-pyrrolidinone (NMP) as solvent at 130°C [64].

In 2007 Madsen and co-workers developed a catalytic procedure with Rh-dppp for decarbonylation of unprotected aldoses, which resulted in new opportunities for using aldoses as chiral starting compound in synthetic chemistry [63]. Screening of different additives and solvents revealed that the optimal conditions were achieved by using pyridine as additive and a mixture of diglyme and DMA as solvent (Scheme 22). The applied catalyst Rh(dppp)Cl2 – prepared in two steps from RhCl3⋅3H2O – was found to show the best catalytic performance. In contrast, the analogous in situ prepared catalyst mainly resulted in decomposition of the carbohydrate due to Rh(III) to Rh(I) reduction by the ligand followed by further reduction to Rh(0) by the carbohydrate (glucose) [42].

Decarbonylation of aldoses into alditols [63]

5.2 Ionic Liquids

Catalyst recovery and recycling are persisting challenges in homogeneous catalysis [65], but ionic liquids (ILs) have demonstrated potential to efficiently immobilize catalysts and separate the product phase in reactions such as Rh-catalyzed alkene hydroformylation [66] and methoxycarbonylation [67]. Furthermore, ILs can provide greener processes compared to traditional organic solvent systems due to their negligible vapor pressure, thermal stability, and coordination properties [66].

In 2014 Riisager et al. examined the use of different ILs (Fig. 2) as reaction media in Rh-phosphine catalyzed decarbonylation of aromatic and aliphatic aldehydes to produce benzene derivatives and alkanes (Scheme 23) [68]. The pre-catalyst [Rh(dppp)2]Cl was chosen in the study as it earlier had been reported to facilitate decarbonylation of aldehydes with different solvents and various temperatures.

ILs tested in the studied decarbonylation reaction [68]

Decarbonylation reaction with IL catalyst system [68]

The IL [BMIM]Cl (BMIM: 1-butyl-3-methylimidazolium) showed the best catalytic activity, while change of the IL cation to [EMIM]+ (EMIm: 1-ethyl-3-methylimidazolium) decreased the yield. Similar results were observed by changing the chloride anion to acetate. The better performance of the chloride-based IL could be associated with the higher thermal stability and complex dissolution. Steric and electronic influence of the tested substrates revealed that o- and m-substituted aldehydes provided a higher yield of the product due to the induced steric hindrance, as it improved the migratory extrusion step and the reductive elimination step in the catalytic cycle [68]. Furthermore, it was demonstrated that the use of ILs as reaction media resulted in a biphasic system where the IL-catalyst phase could be easily recovered and reused in three catalytic cycles [68].

5.3 Continuous-Flow Systems

Continuous-flow systems are often preferred in industrial settings as catalyst-product separation is generally easy compared to homogeneous batch catalyzed reactions. In decarbonylation of aldehydes, CO is released and vaporized from the liquid phase into the gas phase and stripped from the reaction mixture carried by an inert gas. This feature may also prevent catalyst poisoning.

Kappe and co-workers have investigated biphasic gas-liquid continuous-flow decarbonylation of aldehydes in the presence of Rh-dppp catalyst (Scheme 24). It was found that benzaldehydes without electron-withdrawing groups reacted slower than cyanobenzaldehyde, and the efficiency of the annular flow regime was highlighted by synthesis of chromenes which are a significant category of natural products, e.g., cannabinoids, anthocyanides, and flavors [9]. Different chromene derivatives were also synthesized in a flow protocol by Bräse and co-workers utilizing Michael addition/aldol condensation followed by Rh-catalyzed decarbonylation [69]. The decarbonylation reaction was performed by a procedure developed by Madsen and co-workers [42].

Decarbonylation of aldehydes under continuous-flow conditions [9]

Riisager et al. have reported the use of a solid, silica-supported [Rh(dppp)2]Cl catalyst for gas-liquid continuous-flow decarbonylation of aromatic and aliphatic aldehydes [70]. Aromatic aldehydes with electron-withdrawing groups were poorly soluble in the applied solvents, which gave rise to low product yields. Higher yields and catalyst activity were obtained with electronically activated o- and p-substituted aldehydes, which – in the former case – were related to an induced steric hindrance [8]. Preservation of intact metal-ligand centers played a pivotal role for the catalytic performance, since ligand dissociation led to catalyst deactivation and formation of less active metal nanoparticles.

6 Summary

Compiled in the present chapter are a variety of Rh-catalyzed decarbonylation reactions that have been developed over the last 50 years using different ligands and substrates. The reported experimental studies incorporate Hammett studies, kinetic isotope effects as well as different computational analysis, which are also very important for improvement and development of catalytic reactions through understanding of reaction mechanisms. Approaches for in situ generation of CO have found use in a wide range of tandem reactions, whereby the use of hazardous CO as an external reagent is avoided. Furthermore, it has been possible to carry out aldehyde decarbonylation under mild reaction conditions. The development of Rh-catalyzed decarbonylation has also resulted in new, alternative reaction approaches using ILs and continuous-flow aiming towards process intensification and eased catalyst recovery and recycling. Such progress may be of importance for possible future industrial implementation.

References

Bierhals J (2012) Carbon monoxide. In: Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH, Weinheim

Elschenbroich C, Salzer A (2006) Organometallics: a concise introduction. Wiley-VCH, Weinheim

Omaye ST (2002) Toxicology 180:139

Necas D, Kotora M (2007) Curr Org Chem 11:1566

Tsuji J, Ohno K (1965) Tetrahedron Lett 44:3969

Doughty DH, Pignolet LH (1978) J Am Chem Soc 100:7083

Beck CM, Rathmill SE, Park YJ, Chen J, Crabtree RH, Liable-Sands LM, Rheingold AL (1999) Organometallics 18:5311

Fristrup P, Kreis M, Palmelund A, Norrby P-O, Madsen R (2008) J Am Chem Soc 130:5206

Gutmann B, Elsner P, Glasnov T, Roberge DM, Kappe CO (2014) Angew Chem Int Ed 53:11557

Moritani I, Fujiwara Y (1968) Tetrahedron Lett 24:4819

Ueura K, Satoh T, Miura M (2007) Org Lett 9:1407

Baudoin O (2007) Angew Chem Int Ed 46:1373

Goossen LJ, Rodriguez N, Goossen K (2008) Angew Chem Int Ed 47:3100

Qiu R, Zhang L, Xu C, Pan Y, Pang H, Xu L, Li H (2015) Adv Synth Catal 357:1229

Jin W, Yu Z, He W, Ye W, Xiao W-J (2009) Org Lett 11:1317

Zhao XD, Yu ZJ (2008) J Am Chem Soc 130:8136

Ye W, Luo N, Yu Z (2010) Organometallics 29:1049

Heck FR, Nolley JP (1972) J Org Chem 37:2320

Mizoroki T, Mori K, Ozaki A (1971) Bull Chem Soc Jpn 44:581

Kang L, Zhang F, Ding L-T, Yang L (2015) RSC Adv 5:100452

Yang F-L, Ma X-T, Trian S-K (2012) Chem Eur J 18:1582

Zhang Y-G, Liu X-L, He Z-Y, Li X-M, Kang H-J, Tian S-K (2014) Chem Eur J 20:2765

Yang L, Correia CA, Guo X, Li CJ (2010) Tetrahedron Lett 51:5486

Sugihara T, Satoh T, Miura M, Nomura M (2003) Angew Chem Int Ed 42:4672

Sugihara T, Satoh T, Miura M, Nomura M (2004) Adv Synth Catal 346:1765

Yang L, Zeng T, Shuai Q, Guo X, Li C-J (2011) Chem Commun 47:2161

Hassan J, Sévignon M, Gozzi C, Schulz E, Lemaire M (2002) Chem Rev 102:1359

Ashenhurst JA (2010) Chem Soc Rev 39:540

Li C-J (2009) Acc Chem Res 42:335

Baslé O, Bidange J, Shuai Q, Li C-J (2010) Adv Synth Catal 352:1145

Guo X, Wang J, Li C-J (2009) J Am Chem Soc 131:15092

Guo X, Wang J, Li C-J (2010) Org Lett 12:3176

Shaui Q, Yang L, Guo X, Basle O, Li C-J (2010) J Am Chem Soc 132:12212

Yang L, Guo X, Li C-J (2010) Adv Synth Catal 352:2899

Guo X, Wang J, Li C-J (2009) J Am Chem Soc 131:15092

Tietze LF, Beifuss U (1993) Angew Chem Int Ed 32:131

Pellissier H (2006) Tetrahedron 26:1619

Nicolaou KC, Edmonds DJ, Bulger PG (2006) Angew Chem Int Ed 45:7134

Pellissier H (2006) Tetrahedron 62:2143

Enders D, Grondal C, Hüttl MRM (2007) Angew Chem Int Ed 46:1570

Grondal C, Jeanty M, Enders D (2010) Nat Chem 2:167

Kreis M, Palmelund A, Bunch L, Madsen R (2006) Adv Synth Catal 348:2148–2154

Dierkes P, van Leeuwen PWNM (1999) J Chem Soc Dalton Trans 1519

Old DW, Wolfe JP, Buchwald SL (1998) J Am Chem Soc 120:9722

Poulsen CS, Madsen RJ (2002) Org Chem 67:4441

Burke MD, Schreiber SL (2004) Angew Chem Int Ed 43:46

Fessard TC, Andrews SP, Motoyoshi H, Carreira EM (2007) Angew Chem Int Ed 46:9331

Bell S, Wuestenberg B, Kaiser S, Menges F, Pfaltz A (2006) Science 311:5761

Fessard TC, Motoyoshi H, Carreira EM (2007) Angew Chem Int Ed 46:2078

Paquin JF, Defieber C, Stephenson CRJ, Carreira EM (2005) J Am Chem Soc 127:10850

Morimoto T, Fuji K, Tsutsumi K, Kakiuchi K (2002) J Am Chem Soc 124:3806

Morimoto T, Fujioka M, Fuji K, Tsutsumi K, Kakiuchi K (2007) J Organomet Chem 692:625

Gedye R, Smith F, Westaway K, Ali H, Baldisera L, Laberge L, Rousell J (1986) Tetrahedron Lett 27:279

Giguere RJ, Bray TL, Duncan SM, Majetich G (1986) Tetrahedron Lett 27:4945

Kappe CO (2004) Angew Chem Int Ed 43:6250

Kappe CO, Dallinger D (2006) Nat Rev Drug Discov 5:51

Lee H-W, Lee L-N, Chan ASC, Kwong F-Y (2008) Eur J Org Chem 19:3403

Monard RN, Madsen R (2007) J Org Chem 7:9782

Györgydeák Z, Pelyvás IF (1998) Monosaccharide sugars: chemical synthesis by chain elongation, degradation and epimerization. Academic Press, San Diego

Ruff O (1898) Chem Ber 31:1573

Hendriks HEJ, Kuster BFM, Marin GB (1991) Carbohydr Res 214:71

Humphlett WJ (1967) Carbohydr Res 4:157

Monrad RN, Madsen R (2007) J Org Chem 72:9782

Andrews MA, Gould GL, Klaeren SA (1989) J Org Chem 54:5257

Cole-Hamilton DJ, Tooze RP (2006) Homogeneous catalysis – advantages and problems. In: Cole-Hamilton DJ, Tooze RP (eds) Catalyst separation, recovery and recycling, Catalysis by metal complexes, vol 30. Springer, Dordrecht

Haumann M, Riisager A (2008) Chem Rev 108:1474

Garcia-Suarez EJ, Khokarale SG, Van Buu ON, Fehrmann R, Riisager A (2014) Green Chem 16:161

Malcho P, Garcia-Suarez EJ, Riisager A (2014) RSC Adv 4:58151

Bröhmer MC, Volz N, Bräse S (2009) Synlett 1383–1386

Malcho P, Garcia-Suarez EJ, Mentzel UV, Engelbrekt C, Riisager A (2014) Dalton Trans 43:17230

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

García-Suárez, E.J., Kahr, K., Riisager, A. (2017). Rhodium Catalyzed Decarbonylation. In: Claver, C. (eds) Rhodium Catalysis. Topics in Organometallic Chemistry, vol 61. Springer, Cham. https://doi.org/10.1007/3418_2017_175

Download citation

DOI: https://doi.org/10.1007/3418_2017_175

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-66663-1

Online ISBN: 978-3-319-66665-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)