Abstract

Coating with polyelectrolyte multilayers has become a generic way to functionalize a variety of materials. In particular, the layer-by-layer (LbL) technique allows the coating of solid surfaces to give them several functionalities, including controlled release of bioactive agents. At present there are a large number of applications of the LbL technique; however, it is still little explored in the area of textiles. In this review we present an overview of LbL for textile materials made from synthetic or natural fibers. More specifically, LbL is presented as a method for obtaining new bioactive cotton (as in cellulosic fibers) for potential application in the medical field. We also review recent progress in the embedding of active agents in adsorbed multilayers as a novel way to provide the system with a “reservoir” where bioactive agents can be loaded for subsequent release.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Antimicrobial Textiles

The number of textiles functionalized for antimicrobial activity has increased considerably over the last few years. Antimicrobial textiles were first created to prevent damage to textiles under adverse environmental conditions during their storage or use. Textiles are widely used in daily life and there has been a growing need to develop associated finishes that can offer improved protection to users, for example, from microbes (bacteria, fungi) that could pose a threat to health. Hence, there is a pressing need to develop functionalized textiles that are resistant to microbes, especially for use in healthcare activities. Synthetic antimicrobial compounds used in textile articles are very effective against a wide range of microorganisms. However, the continuous use of antimicrobial compounds can lead to bacterial resistance and desensitization of users, as well as produce a negative environmental impact [1–4].

To minimize these risks, there is currently a high demand for antimicrobial textiles produced with environmentally friendly, nontoxic natural compounds. The low incidence of adverse effects of natural compounds, compared with their synthetic counterparts, has led to such textiles being explored as attractive and promising alternatives [5–7].

Cotton is the textile substrate most widely used in the health sector. In the form of cellulose fibers [3, 4], it is known for its versatility, natural comfort, softness, breathability, and ability to absorb moisture [8]. Cotton is often used to make a variety of clothing for industrial and biomedical purposes. Because of its properties, cotton is also ideally suited as wound dressing material. In fact, cotton gauze is still the most commonly used textile for wound dressing in hospitals; however, new products have emerged for wound healing and for protection against entry of bacteria. For exudative wounds, there are a range of absorptive products (including various hydrophilic foam dressings, hydrogels, and alginates) that can absorb up to 20 times their weight [9] and can be formulated in combination with cotton substrates. At the same time, cotton is prone to act as host for the growth and development of microorganisms, making biofunctionalization with antimicrobial agents a necessity.

1.2 Current Functionalization Processes in Textile Materials

Coating is an important technique for adding value to technical textiles and a generic method of surface functionalization. In its most generic form, coatings involve polymer layers that are applied directly to one or both surfaces of a given fabric. A number of nanotechnologies have received special attention in the textile industry for fiber or fabric modification and to endow the substrates with new properties that are revealed at the nanoscale, especially multifunctional properties [10] that include antimicrobial activity to reduce the risk of microorganism transmission.

Several processes are available for coating textile materials, depending upon the requirement of the end product. The most significant processes include techniques such as sol–gel, which is a wet process that is broadly employed in the textile field and involves a simple pad or dip coating; magnetron sputter coating, which is one of several physical vapor deposition methods; plasma, which is a suitable technique for modifying the structure and topography of the surface; and others involving composite and hybrid systems [11].

These methods have a number of disadvantages, the most significant being the need for expensive solvents and equipment and the requirement for multistep and complex processing. In addition, under certain conditions it is necessary to use high temperatures, and the success of modification is often dependent on the substrate topography. It is apparent that new strategies are needed and the LbL technique, in particular, is as an attractive option because of its relative simplicity and efficiency.

The prerequisite for the success of LbL coating is the presence of a minimal surface charge on the substrate. In such cases, the LbL technique provides coatings on the surface of textiles to enable a wide range of functionalities [12]. Despite its technological appeal, the LbL deposition process has not been extensively implemented in the textile industry, particularly for natural fibers. The main reason for the slow introduction of LbL for natural fibers is their unique characteristics, including surface chemical heterogeneity, which complicates the application of such coatings.

2 LbL Assembly Technique

LbL is a simple and versatile method that can provide new types of coatings for textile materials. It was proposed by Decher and collaborators in the early 1990s [13] and the interest it has generated since then can be judged by the growing number of published papers on the subject.

LbL assembly can be applied on many kinds of charged surfaces [14], mainly to deposit multilayers of controlled architecture and composition from aqueous solutions. Electrostatic interactions are the main driving force for assembly within the neighboring layers of polyelectrolytes. Generally, LbL assembly proceeds as follows: (1) a charged substrate is immersed in a solution of an oppositely charged colloid that adsorbs as the first monolayer; (2) a washing cycle removes excess and unbound material; and (3) the coated substrate is submerged again to deposit a second layer to form a bilayer structure [15]. These cycles can be repeated as often as needed, and crosslinking is often applied to convert the obtained LbL multilayers into surface-bound hydrogels [16]. The number of deposition cycles and the type of polyelectrolyte used in the LbL construction allow full control of the thickness and roughness of the multilayered film [17]. Usually, multilayered films based on electrostatic interaction are affected by environmental conditions such as, pH, polyelectrolyte concentration, nature of solvents, and ionic strength [14, 18, 19].

LbL materials can be selected from a large variety of materials other than polyelectrolytes: small organic molecules, polymers, natural proteins, inorganic clusters, clay particles, and other colloids. In such cases, LbL can open new possibilities because a myriad of component combinations can be formulated in single devices with designed features and architectures. Importantly, the resulting functions might not be associated with those of the native (substrate) material. Surface functionality, for example, can be controlled directly by choosing appropriate polyelectrolyte combinations. This allows modification of electrical, optical, magnetic, physicochemical, and biological properties of the materials. Multilayer coating with bioactive, natural polyelectrolytes has become a new process for surface biofunctionalization.

Advantages of the LbL technique are that the process is inexpensive, relatively fast and simple, does not require sophisticated equipment and precise stoichiometry, or rely on complicated chemical reactions to deposit successive layers [20]. Another advantage of LbL deposition is its insensitivity to the size and shape of the substrate in producing comfortable coatings. This means that an LbL assembly can be realized not only on planar substrates, but also on substrates with different shapes and curvatures. For example, Caruso et al., (1998) demonstrated LbL deposition on a spherical template. After template dissolution, microcapsules were obtained [21]. Theoretically, LbL substrates can be of any size, shape, topography, or topology, and no stoichiometric control is necessary to maintain surface functionality and avoid propagation of defects [22].

In LbL deposition, pH can be used to adjust the strength of interlayer bonding and, therefore, multilayer thickness. As stated before, this requires the presence of a minimal surface charge, which, if absent, can be induced by different means [23].

Most knowledge about the LbL method has been developed in the field of drug delivery systems, allowing the creation of sophisticated materials and the production of capsules as carriers of drugs that can be released gradually. A major challenge in drug delivery is to produce controlled, sustained or triggered release systems for small encapsulated drug molecules. A discussion of these processes can be found in a review article by Wohl and Engbersen [24].

Several biomedical engineering studies have reported the creation of multilayer coatings by the LbL technique involving synthetic and natural polyelectrolytes [25]. Related multilayers have a characteristic low packing density to facilitate diffusion of bioactive agents, which in most cases are embedded throughout the multilayer. In fact, various parameters such as pH, ionic strength, temperature, light, and chemical or electrochemical stimuli have been used to tune the release and/or retention of bioactive agents within the multilayers. This allows control of drug dose, and delivery on demand with reduced toxicity and increased efficacy [16].

Using the concept of diffusion from multilayers, several authors have immobilized more than ten different water-soluble proteins in multilayers, ensuring the inhibition of protein denaturation [26–28]. Appropriate preservation of the functional characteristics of given compounds have ensured good results for effective incorporation of proteins and drugs between the multilayers, and their diffusion and subsequent release [29–33].

Several researchers have reported bioactive proteins, peptides, hormones, growth factors, and drugs that can be directly integrated into LbL architectures, without any covalent bonding with a polyelectrolyte and while maintaining their native structures and activities [29, 34–41]. The strategy described in all these efforts can be valuable in the application of a variety of drugs/bioactive agents. This opens a route for substrate functionalization via multilayers with embedded bioactive agents, in which the multilayers act as a reservoir for bioactive agents that can be gradually released and controlled.

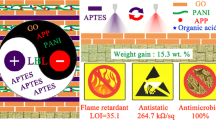

A recent review provides an exhaustive account of the potential uses of the LbL method in biomedical engineering [42]; however, the technique is still in its infancy for textile applications. In recent years, researchers have used the LbL process to modify the surface of textile fabrics to impart or improve numerous surface properties, including UV protection [43, 44], hydrophobicity/hydrophilicity [45, 46], flame retardancy [47–49], and antimicrobial activity [50–54].

Our aim in this review is to assess the feasibility of employing the LbL method to obtain functionalized cellulose (cotton) with antimicrobial properties by incorporating bioactive agents between the layers for subsequent controlled release. This approach is supported by the work of Caridade et al., who studied the production of thick membranes by LbL assembly of chitosan and alginate and the control of membrane permeability to bioactive agents [55].

3 LbL in Textile Materials

The LbL process has been widely used to create multilayer films on various substrates. However, it has not been extensively employed for textile fibers. Textile fibers present some unique challenges for LbL assembly, such as the chemical heterogeneity and irregular shape of their surfaces [56]. Because LbL is a relatively new method for material functionalization, there are only a few reports concerning its adoption for textiles. For simplicity, this review divides textile substrates into two categories, synthetic and natural fibers.

3.1 LbL Coatings on Synthetic Fiber Materials

Synthetic fibers play an important role in the textile industry. There are many different types of synthetic fibers, but the most used are polypropylene, polyethylene, polyester, polyamide (nylon), and polyvinyl alcohol. A great disadvantage of some synthetic fibers is low hydrophilicity. This affects the LbL process because the fiber surface is not easily wetted. Table 1 shows a summary of the state of the art in application of the LbL method for textile materials involving synthetic fibers, mainly polypropylene, polyester, and polyethylene terephthalate (PET). The deposition of several layers endows the textile material with several features; however, attempts to impart antimicrobial properties to synthetic textiles have been introduced only recently.

3.2 LbL Coating of Cellulose-Based Textiles

Cotton, as one of the most commonly used materials in textiles, is suitable for medical usage, especially for wound dressings as a result of its high liquid absorbency and hygienic nature. However, cotton is characterized by its heterogeneity, which causes problems in conventional coatings but creates an opportunity for application of the LbL technique. Currently, only a few reports exist on the application of the LbL method to cotton. In this section we present the most important developments in terms of functionalized cotton using the LbL technique. A special note on antimicrobial cotton obtained by LbL is discussed at the end of this section.

There are many early reports on the application of the LbL technique to cellulosic fibers, mainly wood fibers. Hyde et al. reported application of LbL to cotton substrates. They found that the cationization process produced a cotton surface capable of supporting polyelectrolyte films via LbL deposition. They observed that the LbL deposition process is more dependent on the nature of the polyelectrolytes than on the nature of the original substrate; the analyses revealed conformal and uniform coating of the cotton fibers [66]. From this work, there is indication that various functionalities can be developed for a given substrate, depending on the combinations of polyelectrolytes used. It is noteworthy that the nature of the substrate in LbL deposition has a relatively minor role, allowing the LbL to be applied smoothly onto cotton. Other publications report methods of analysis of samples obtained by the LbL technique [67]. Studies were also carried out to unveil the influence of physical parameters such as pH, concentration, ionic strength of polyelectrolytes, and cationization level of the substrate [56, 68]. In general, it was concluded that the deposition process was not significantly influenced by the degree of cotton cationization. In contrast, physical parameters were found to have a major influence on the success of LbL coating.

Protection against UV irradiation has been approached by using LbL coating of cotton fabrics [43, 44, 69, 70]. High UV protection factors were obtained as well as good resistance to washing, revealing the stability of the layers obtained by LbL on cotton. In fact, durability of the coating is often associated with the LbL technique. Another important property often reported for cotton is that of hydrophobicity [45, 71]. In this case, LbL coating is an easy method for fabrication of hydrophobic cotton fabrics.

More recently, several authors have used the LbL technique to coat cotton with specific polymers in order to enhance its flame retardancy properties. The studies showed that flame retardant coatings can be readily applied to textile fabrics for commercial and industrial applications [47–49, 72].

Providing antimicrobial properties to textiles is an effective way to prevent disease transmission in applications involving consumer and healthcare markets. Many textiles are treated to afford protection against bacteria, fungi, and other related microorganisms. During the past few years, several studies have aimed at functional antimicrobial modification via LbL assembly onto cotton fibers. Using N-halamine polyelectrolyte deposition on cotton fibers via LbL, cotton textiles were obtained with antimicrobial properties and potential application as medical textiles [73, 74]. A similar effect was obtained in our work group using chitosan and alginate as polyelectrolytes [52, 53, 75]. Other approaches for obtaining antimicrobial cotton have used chitosan [50, 51], copper [76], and ZnO [70] nanoparticles. In these works, the nanoparticles were coated via LbL onto cotton fabric to form a nanocoating.

The LbL technique also offers new opportunities for the preparation of functionalized biomaterial coatings and the possibility of incorporating bioactive molecules between the layers [77–79]. Peptides, proteins, and active agents adsorbed or embedded in multilayer films have been shown to retain their biological activities [41], whereas covalent attachment to the active agents can reduce or even destroy their biochemical activity [79]. Thus, with the LbL technique, active agents can be directly integrated into the architecture without the need for covalent bonding.

Based on this concept, Gomes et al. investigated methods for the functionalization of cotton with polyelectrolyte multilayer films that incorporated a bioactive amino acid (l-cysteine, l-Cys). In this work, the strategy was based on the use of multilayer films as reservoirs of l-Cys [80]. These kinds of systems are promising for use in biomedical textiles, specifically for wound dressings. Cotton fiber is the basis of many wound dressings, and wound dressings containing antibiotics have been developed for the inhibition of wound infection [81–83]. Note that the continuous use of antibiotics has resulted in multiresistant bacterial strains; consequently, there is an urgent for alternatives to antibiotics.

4 Antimicrobials of the Future: Antimicrobial Peptides

Antibacterial resistance is a natural biological phenomenon that occurs in microorganisms and is potentiated by indiscriminate use of antibacterial agents. If the microorganism becomes resistant to a particular antibacterial agent, when an infection occurs, the effect of the antibacterial agent is reduced or nullified. Therefore, it is urgent that new antibacterial agents are discovered and used. Recently, a large group of low molecular weight natural compounds that exhibit antimicrobial activity were isolated from animals and plants, resulting in a new generation of antibacterial agents, named antimicrobial peptides (AMPs).

AMPs are promising agents because they are natural compounds [84, 85]; have a broad spectrum of action [86, 87]; exhibit high activity, even at low concentrations [87, 88]; have a low tendency to develop resistance as a result of their different mechanism of action [84, 85, 89–91]; act quickly and efficiently against bacterial agents [87, 91]; are generally of small size; and have low mammalian toxicity [87, 91]. The ability of AMPs to kill multidrug-resistant microorganisms has gained considerable attention and clinical interest. An alternative approach to wound healing with AMPs is related to the function of AMPs in removing destructive proteases from the wound. These proteases cause considerable destruction of growth factors and connective tissue proteins during the prolonged inflammatory phase of a chronic wound [92]. The 2010 review paper by Gouveia refers to AMPs for the first time as promising antimicrobial agents for textiles [93]. AMPs can be incorporated into textiles to produce nontoxic antimicrobial textiles. AMPs produced in bacteria, insects, plants, invertebrates, and vertebrates are important components of the natural defenses of most living organisms. AMPs exhibit potent ability to kill a broad range of microorganisms, including Gram-negative and Gram-positive bacteria, fungi, and viruses [90, 94, 95].

4.1 AMPs: Characterization and Classification

Currently, databases (e.g., http://aps.unmc.edu/AP) list over 2,400 AMPs. Their characterization is complicated as a result of their great diversity, but can be simplified if based on their secondary structure. AMPs are mainly grouped into four classes: β-sheet, α-helical, loop, and extended peptides [96]. There are AMPs with positive [97] and negative [98] charges, or they can be amphipathic molecules (with both hydrophobic and hydrophilic regions). Some have sequences of less than 10 amino acids, whereas others contain nearly 100 amino acids [99]. In general, the AMPs are described as small molecules containing 12–50 amino acids with a cationic charge between +4 and +6 (as a result of the presence of the amino acids lysine and arginine) [91, 100]. Anionic AMPs generally have a net charge in the range of −1 to −7, as a result of the presence of glutamic and aspartic acids. AMPs are mainly cationic and interact with membranes in a general mechanism that involves interaction between charged residues of the peptides and anionic components of the membrane surface.

4.2 Mechanisms of Action

The AMPs in bacteria can cause disruption of the membrane, resulting in lysis or pore formation, allowing efflux of essential ion and nutrients. In this case, the AMPs are transported into the cell and inhibit DNA and RNA synthesis, inhibit ribosomal function and protein synthesis, and target mitochondria [101]. Many models of antimicrobial action at the membrane level have been proposed. Models that have greater acceptance in the scientific community include the carpet model, toroidal pore, and barrel-stave [88].

AMPs also possess antiviral properties. They inhibit viral fusion and egress, thus preventing infection and viral spread via direct interaction with the viral membranes and host cell surface molecules [101]. These properties, combined with the broad range of activity and short contact time required to induce killing, have led to the consideration of AMPs as novel therapeutic agents.

4.3 Applications of AMPs

AMPs applications are not limited to the development of new drugs, because there are also other medical, environmental, and industrial applications. Some potential medical applications of AMPs include:

-

Prevention and treatment of eye disease, and in antimicrobial coatings for contact lenses [102]

-

Antimicrobial coating on polymeric materials, such as implants and catheters, for prevention of bacterial colonization and biofilm formation on the surfaces of the implants [88]

-

Functionalization of biomedical materials (e.g., in heart valves) and other textile materials such as socks for diabetics, gauze for chronic wounds, etc. [88]

-

Wound healing, treating fibrosis, acne, Crohn’s disease [90]

Recently, our research group found AMP applications in textiles, particularly in cotton gauzes for wound dressings [95, 103]. Incorporation is the most popular method for preparing immobilized AMPs on a variety of surfaces and retaining their ability to kill bacteria [104, 105]. Gomes et al. (2015) developed a new strategy for the biofunctionalization of cotton by incorporation of AMPs, with possible application in medical textiles such as wound dressings. This study demonstrated that cotton functionalized with chitosan/alginate loaded with AMPs is effective against pathogenic bacterial strains. The results demonstrated antimicrobial activity as well as low cytotoxicity. The main advantage of using AMPs is a result of their natural existence, meaning that they are well tolerated by the human body and that low concentrations are required. In addition, their synergistic biocide mechanism of action is effective against multiresistant bacteria.

5 Concluding Remarks and Future Prospects

Successful deposition of multilayers onto the surfaces of textile fibers, especially those based on cellulose, by the LbL technique can open opportunities for the development of functional textiles in a broad range of applications. The LbL technique in textiles is entirely new and is a simple and effective method, with a strong possibility of industrial implementation.

Bioactive agents can be directly embedded between polyelectrolyte layers without the need for covalent bonding, which facilitates the development of strategies to produce antimicrobial cotton by using AMPs in polyelectrolyte multilayer films. These coatings on cellulose surfaces are new and potentially useful as antibacterial materials in a wide variety of biomedical applications. In addition, LbL deposition allows easy fabrication of multimaterial films, in which different layers carry different functionalities or control the quality and quantity of active agents. Overall, the reviewed work lays the groundwork for scale-up in cellulose-based materials and opens new avenues towards the development of nontoxic and safe biomedical textiles.

References

Gouveia IC, Sa D, Henriques M (2012) Functionalization of wool with l-cysteine: process characterization and assessment of antimicrobial activity and cytotoxicity. J Appl Polym Sci 124(2):1352–1358

Gouveia IC (2012) Synthesis and characterization of a microsphere-based coating for textiles with potential as an in situ bioactive delivery system. Polym Adv Technol 23(3):350–356

Caldeira E et al (2013) Biofunctionalization of cellulosic fibers with l-cysteine: assessment of antibacterial properties and mechanism of action against Staphylococcus aureus and Klebsiellapneumoniae. J Biotechnol 168(4):426–435

Nogueira F et al (2014) Covalent modification of cellulosic-based textiles: a new strategy to obtain antimicrobial properties. Biotechnol Bioprocess Eng 19(3):526–533

Singh R et al (2005) Antimicrobial activity of some natural dyes. Dyes Pigments 66(2):99–102

Gao Y, Cranston R (2008) Recent advances in antimicrobial treatments of textiles. Text Res J 78(1):60–72

Papaspyrides CD, Pavlidou S, Vouyiouka SN (2009) Development of advanced textile materials: natural fiber composites, anti-microbial, and flame-retardant fabrics. Proc Inst of Mech Eng L J Mater Des Appl 223(2):91–102

Chang SC et al (2014) Surface coating for flame-retardant behavior of cotton fabric using a continuous layer-by-layer process. Ind Eng Chem Res 53(10):3805–3812

Murphy PS, Evans GR (2012) Advances in wound healing: a review of current wound healing products. Plast Surg Int 2012:190436

Gowri S et al (2010) Polymer nanocomposites for multifunctional finishing of textiles – a review. Text Res J 80(13):1290–1306

MazeyarGashti FA, Song G, Kiumarsi A (2012) Characterization of nanocomposite coating on textiles: a brief review on microscopic technology. Curr Microsc Contrib Adv Sci Technol 2:1424–1437

Lee H et al (2008) Substrate-independent layer-by-layer assembly by using mussel-adhesive-inspired polymers. Adv Mater 20(9):1619–1623

Decher G, Hong JD, Schmitt J (1992) Buildup of ultrathin multilayer films by a self-assembly process. 3. Consecutively alternating adsorption of anionic and cationic polyelectrolytes on charged surfaces. Thin Solid Films 210(1–2):831–835

Decher G (1997) Fuzzy nanoassemblies: toward layered polymeric multicomposites. Science 277(5330):1232–1237

Lvov Y et al (1999) A careful examination of the adsorption step in the alternate layer-by-layer assembly of linear polyanion and polycation. Colloids Surf A Physicochem Eng Asp 146(1–3):337–346

Pavlukhina S, Sukhishvili S (2011) Polymer assemblies for controlled delivery of bioactive molecules from surfaces. Adv Drug Deliv Rev 63(9):822–836

Picart C et al (2001) Determination of structural parameters characterizing thin films by optical methods: a comparison between scanning angle reflectometry and optical waveguide lightmode spectroscopy. J Chem Phys 115(2):1086–1094

Li Y, Wang X, Sun JQ (2012) Layer-by-layer assembly for rapid fabrication of thick polymeric films. Chem Soc Rev 41(18):5998–6009

Such GK, Johnston APR, Caruso F (2011) Engineered hydrogen-bonded polymer multilayers: from assembly to biomedical applications. Chem Soc Rev 40(1):19–29

de Villiers MM et al (2011) Introduction to nanocoatings produced by layer-by-layer (LbL) self-assembly. Adv Drug Deliv Rev 63(9):701–715

Caruso F, Caruso RA, Mohwald H (1998) Nanoengineering of inorganic and hybrid hollow spheres by colloidal templating. Science 282(5391):1111–1114

Chen W, McCarthy TJ (1997) Layer-by-layer deposition: a tool for polymer surface modification. Macromolecules 30(1):78–86

Caruso F et al (2000) Microencapsulation of uncharged low molecular weight organic materials by polyelectrolyte multilayer self-assembly. Langmuir 16(23):8932–8936

Wohl BM, Engbersen JFJ (2012) Responsive layer-by-layer materials for drug delivery. J Control Release 158(1):2–14

Mano JF et al (2007) Natural origin biodegradable systems in tissue engineering and regenerative medicine: present status and some moving trends. J R Soc Interface 4(17):999–1030

Onda M et al (1996) Sequential actions of glucose oxidase and peroxidase in molecular films assembled by layer-by-layer alternate adsorption. Biotechnol Bioeng 51(2):163–167

Onda M et al (1996) Sequential reaction and product separation on molecular films of glucoamylase and glucose oxidase assembled on an ultrafilter. J Ferment Bioeng 82(5):502–506

Lvov Y et al (1996) Molecular film assembly via layer-by-layer adsorption of oppositely charged macromolecules (linear polymer, protein and clay) and concanavalin a and glycogen. Thin Solid Films 284:797–801

Caruso F et al (1997) Assembly of alternating polyelectrolyte and protein multilayer films for immunosensing.2. Langmuir 13(13):3427–3433

Cai P et al (2013) Adsorbed BMP-2 in polyelectrolyte multilayer films for enhanced early osteogenic differentiation of mesenchymal stem cells. Colloids Surf A Physicochem Eng Asp 434:110–117

Divyalakshmi TV et al (2013) Subpicomolar sensing of hydrogen peroxide with ovalbumin-embedded chitosan/polystyrene sulfonate multilayer membrane. Anal Biochem 440(1):49–55

Guillot R et al (2013) The stability of BMP loaded polyelectrolyte multilayer coatings on titanium. Biomaterials 34(23):5737–5746

Anandhakumar S, Raichur AM (2013) Polyelectrolyte/silver nanocomposite multilayer films as multifunctional thin film platforms for remote activated protein and drug delivery. Acta Biomater 9(11):8864–8874

Ladam G et al (2001) Protein adsorption onto auto-assembled polyelectrolyte films. Langmuir 17(3):878–882

Jessel N et al (2003) Bioactive coatings based on a polyelectrolyte multilayer architecture functionalized by embedded proteins. Adv Mater 15(9):692–695

Vodouhe C et al (2006) Control of drug accessibility on functional polyelectrolyte multilayer films. Biomaterials 27(22):4149–4156

Chluba J et al (2001) Peptide hormone covalently bound to polyelectrolytes and embedded into multilayer architectures conserving full biological activity. Biomacromolecules 2(3):800–805

Caruso F, Schuler C (2000) Enzyme multilayers on colloid particles: assembly, stability, and enzymatic activity. Langmuir 16(24):9595–9603

Vodouhe C et al (2005) Effect of functionalization of multilayered polyelectrolyte films on motoneuron growth. Biomaterials 26(5):545–554

Tezcaner A et al (2006) Polyelectrolyte multilayer films as substrates for photoreceptor cells. Biomacromolecules 7(1):86–94

Leguen E et al (2007) Bioactive coatings based on polyelectrolyte multilayer architectures functionalized by embedded proteins, peptides or drugs. Biomol Eng 24(1):33–41

Costa RR, Mano JF (2014) Polyelectrolyte multilayered assemblies in biomedical technologies. Chem Soc Rev 43(10):3453–3479

Wang Q, Hauser PJ (2010) Developing a novel UV protection process for cotton based on layer-by-layer self-assembly. Carbohydr Polym 81(2):491–496

Iamphaojeen Y, Siriphannon P (2012) Immobilization of zinc oxide nanoparticles on cotton fabrics using poly 4-styrenesulfonic acid polyelectrolyte. Int J Mater Res 103(5):643–647

Wang LL et al (2011) Superhydrophobic and ultraviolet-blocking cotton textiles. ACS Appl Mater Interfaces 3(4):1277–1281

Zhao Y et al (2010) Superhydrophobic cotton fabric fabricated by electrostatic assembly of silica nanoparticles and its remarkable buoyancy. Appl Surf Sci 256(22):6736–6742

Carosio F et al (2013) Green DNA-based flame retardant coatings assembled through layer by layer. Polymer 54(19):5148–5153

Carosio F et al (2011) Layer-by-layer assembly of silica-based flame retardant thin film on PET fabric. Polym Degrad Stab 96(5):745–750

Li YC et al (2010) Flame retardant behavior of polyelectrolyte-clay thin film assemblies on cotton fabric. ACS Nano 4(6):3325–3337

Joshi M et al (2011) Chitosan nanocoating on cotton textile substrate using layer-by-layer self-assembly technique. J Appl Polym Sci 119(5):2793–2799

Ali SW, Joshi M, Rajendran S (2011) Novel, self-assembled antimicrobial textile coating containing chitosan nanoparticles. AATCC Rev 11(5):49–55

Gomes AP et al (2012) Layer-by-layer deposition of antibacterial polyelectrolytes on cotton fibers. J Polym Environ 20(4):1084–1094

Gomes AP et al (2013) Layer-by-layer deposition of antimicrobial polymers on cellulosic fibers: a new strategy to develop bioactive textiles. Polym Adv Technol 24(11):1005–1010

Dubas ST, Kumlangdudsana P, Potiyaraj P (2006) Layer-by-layer deposition of antimicrobial silver nanoparticles on textile fibers. Colloids Surf A Physicochem Eng Asp 289(1–3):105–109

Caridade SG et al (2013) Free-standing polyelectrolyte membranes made of chitosan and alginate. Biomacromolecules 14(5):1653–1660

Hyde K, Dong H, Hinestroza JP (2007) Effect of surface cationization on the conformal deposition of polyelectrolytes over cotton fibers. Cellulose 14(6):615–623

Polowinski S (2005) Polyelectrolyte layer-by-layer processed coated textiles. Fibers Text East Eur 13(6):50–52

Dubas ST et al (2006) Assembly of polyelectrolyte multilayers on nylon fibers. J Appl Polym Sci 101(5):3286–3290

Polowinski S (2007) Deposition of polymer complex layers onto nonwoven textiles. J Appl Polym Sci 103(3):1700–1705

Jantas R, Polowinski S (2007) Modifying of polyester fabric surface with polyelectrolyte nanolayers using the layer-by-layer deposition technique. Fibers Text East Eur 15(2):97–99

Polowinski S, Stawski D (2007) Thermogravimetric measurements of poly(propylene) nonwovens containing deposited layers of polyelectrolytes and colloidal particles of noble metals. Fibers Text East Eur 15(4):82–85

Stawski D, Bellmann C (2009) Electrokinetic properties of polypropylene textile fabrics containing deposited layers of polyelectrolytes. Colloids Surf A Physicochem Eng Asp 345(1-3):191–194

Park JH et al (2009) Polyelectrolyte multilayer coated nanofibrous mats: controlled surface morphology and cell culture. Fibers Polym 10(4):419–424

Martin A et al (2013) Multilayered textile coating based on a beta-cyclodextrin polyelectrolyte for the controlled release of drugs. Carbohydr Polym 93(2):718–730

Martin A et al (2013) Build-up of an antimicrobial multilayer coating on a textile support based on a methylene blue-poly(cyclodextrin) complex. Biomed Mater 8(6):065006

Hyde K, Rusa M, Hinestroza J (2005) Layer-by-layer deposition of polyelectrolyte nanolayers on natural fibers: cotton. Nanotechnology 16(7):S422–S428

Wang Q, Hauser PJ (2009) New characterization of layer-by-layer self-assembly deposition of polyelectrolytes on cotton fabric. Cellulose 16(6):1123–1131

Ali SW, Rajendran S, Joshi M (2010) Effect of process parameters on layer-by-layer self-assembly of polyelectrolytes on cotton substrate. Polym Polym Compos 18(5):175–187

Zhao Y et al (2013) Superhydrophobic and UV-blocking cotton fabrics prepared by layer-by-layer assembly of organic UV absorber intercalated layered double hydroxides. Appl Surf Sci 286:364–370

Ugur SS et al (2010) Modifying of cotton fabric surface with nano-ZnO multilayer films by layer-by-layer deposition method. Nanoscale Res Lett 5(7):1204–1210

Zhao Y et al (2012) Photoreactive azido-containing silica nanoparticle/polycation multilayers: durable superhydrophobic coating on cotton fabrics. Langmuir 28(15):6328–6335

Apaydin K et al (2013) Polyallylamine-montmorillonite as super flame retardant coating assemblies by layer-by layer deposition on polyamide. Polym Degrad Stab 98(2):627–634

Cerkez I (2013) Rapid disinfection by N-halamine polyelectrolytes. J Bioact Compat Polym 28(1):86–96

Cerkez I et al (2011) N-halamine biocidal coatings via a layer-by-layer assembly technique. Langmuir 27(7):4091–4097

Gomes A, Mano J, Queiroz J, Gouveia I (2010) Assessment of bacteria-textile interactions using scanning electron microscopy: a study on LbL chitosan/alginate coated cotton. In: Méndez-Vilas A, Diaz J (eds) Microscopy: science, technology, applications and education. Formatex, Badajoz, pp 286–292

Cady NC, Behnke JL, Strickland AD (2011) Copper-based nanostructured coatings on natural cellulose: nanocomposites exhibiting rapid and efficient inhibition of a multi-drug resistant wound pathogen, A. baumannii, and mammalian cell biocompatibility in vitro. Adv Funct Mater 21(13):2506–2514

Sanders W, Anderson MR (2009) Electrostatic deposition of polycations and polyanions onto cysteine monolayers. J Colloid Interface Sci 331(2):318–321

Pedrosa VA et al (2007) Studies on the electrochemical behavior of a cystine self-assembled monolayer modified electrode using ferrocyanide as a probe. J Electroanal Chem 602(2):149–155

Martins GV et al (2010) Crosslink effect and albumin adsorption onto chitosan/alginate multilayered systems: an in situ QCM-D study. Macromol Biosci 10(12):1444–1455

Gomes AP et al (2014) New biomaterial based on cotton with incorporated biomolecules. J Appl Polym Sci 131(15):40519

Wang YC et al (2003) Fabrication of a novel porous PGA-chitosan hybrid matrix for tissue engineering. Biomaterials 24(6):1047–1057

Rujitanaroj PO, Pimpha N, Supaphol P (2008) Wound-dressing materials with antibacterial activity from electrospun gelatin fiber mats containing silver nanoparticles. Polymer 49(21):4723–4732

Dong Y et al (2010) A novel CHS/ALG bi-layer composite membrane with sustained antimicrobial efficacy used as wound dressing. Chin Chem Lett 21(8):1011–1014

Seo MD et al (2012) Antimicrobial peptides for therapeutic applications: a review. Molecules 17(10):12276–12286

Bulet P, Stocklin R, Menin L (2004) Anti-microbial peptides: from invertebrates to vertebrates. Immunol Rev 198:169–184

Reddy KVR, Yedery RD, Aranha C (2004) Antimicrobial peptides: premises and promises. Int J Antimicrob Agents 24(6):536–547

Brogden NK, Brogden KA (2011) Will new generations of modified antimicrobial peptides improve their potential as pharmaceuticals? Int J Antimicrob Agents 38(3):217–225

Costa F et al (2011) Covalent immobilization of antimicrobial peptides (AMPs) onto biomaterial surfaces. Acta Biomater 7(4):1431–1440

Maroti G et al (2011) Natural roles of antimicrobial peptides in microbes, plants and animals. Res Microbiol 162(4):363–374

Zasloff M (2002) Antimicrobial peptides of multicellular organisms. Nature 415(6870):389–395

Li YM et al (2012) Overview on the recent study of antimicrobial peptides: origins, functions, relative mechanisms and application. Peptides 37(2):207–215

Edwards JV et al (1999) Synthesis and activity of NH2- and COOH-terminal elastase recognition sequences on cotton. J Pept Res 54(6):536–543

Gouveia IC (2010) Nanobiotechnology: a new strategy to develop non-toxic antimicrobial textiles. In: Méndez-Vilas A (ed) Current research, technology and education topics in applied microbiology and microbial biotechnology. Formatex, Badajoz, pp 407–414

da Silva FP, Machado MCC (2012) Antimicrobial peptides: clinical relevance and therapeutic implications. Peptides 36(2):308–314

Pedrosa M et al. (2014) Comparison of the antibacterial activity of modified-cotton with magainin I and LL-37 with potential as wound-dressings. J Appl Polym Sci 131(21):40997. doi: 10.1002/app.40997

Giuliani A, Pirri G, Nicoletto SF (2007) Antimicrobial peptides: an overview of a promising class of therapeutics. Cent Eur J Biol 2(1):1–33

Zhang LJ, Rozek A, Hancock REW (2001) Interaction of cationic antimicrobial peptides with model membranes. J Biol Chem 276(38):35714–35722

Harris F, Dennison SR, Phoenix DA (2009) Anionic antimicrobial peptides from eukaryotic organisms. Curr Protein Pept Sci 10(6):585–606

Zhang XJ, Clark CA, Pettis GS (2003) Interstrain inhibition in the sweet potato pathogen streptomyces ipomoeae: purification and characterization of a highly specific bacteriocin and cloning of its structural gene. Appl Environ Microbiol 69(4):2201–2208

Hassan M et al (2012) Natural antimicrobial peptides from bacteria: characteristics and potential applications to fight against antibiotic resistance. J Appl Microbiol 113(4):723–736

Peters BM, Shirtliff ME, Jabra-Rizk MA (2010) Antimicrobial peptides: primeval molecules or future drugs? PLoS Pathog 6(10), e1001067

Silva NC, Sarmento B, Pintado M (2013) The importance of antimicrobial peptides and their potential for therapeutic use in ophthalmology. Int J Antimicrob Agents 41(1):5–10

Gomes AP, Mano JF, Queiroz JA, Gouveia IC (2015) Incorporation of antimicrobial peptides on functionalized cotton gauzes for medical applications. Carbohydr Polym 127:451–461

Shukla A et al (2010) Controlling the release of peptide antimicrobial agents from surfaces. Biomaterials 31(8):2348–2357

Sobczak M et al (2013) Polymeric systems of antimicrobial peptides-strategies and potential applications. Molecules 18(11):14122–14137

Acknowledgments

The authors would like to thank Fundação para a Ciência e Tecnologia (FCT) for the funding granted for the project PTDC/EBB-BIO/113671/2009 (FCOMP-01-0124-FEDER-014752) Skin2Tex. Also, we would like to thank Fundo Europeu de Desenvolvimento Regional (FEDER) through COMPETE – Programa Operacional Factores de Competitividade (POFC) for co-funding.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Gomes, A.P., Mano, J.F., Queiroz, J.A., Gouveia, I.C. (2015). Layer-by-Layer Assembly for Biofunctionalization of Cellulosic Fibers with Emergent Antimicrobial Agents. In: Rojas, O. (eds) Cellulose Chemistry and Properties: Fibers, Nanocelluloses and Advanced Materials. Advances in Polymer Science, vol 271. Springer, Cham. https://doi.org/10.1007/12_2015_318

Download citation

DOI: https://doi.org/10.1007/12_2015_318

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-26013-6

Online ISBN: 978-3-319-26015-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)