Abstract

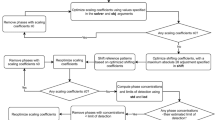

An internal standard X-ray diffraction (XRD) analysis technique permits reproducible and accurate calculation of the mineral contents of rocks, including the major clay mineral families: Fe-rich chlorites + berthierine, Mg-rich chlorites, Fe-rich dioctahedral 2:1 clays and micas, Al-rich dioctahedral 2:1 clays and micas, and kaolinites. A single XRD pattern from an air-dried random specimen is used. Clays are quantified from their 060 reflections which are well resolved and insensitive to structural defects. Zincite is used as the internal standard instead of corundum, because its reflections are more conveniently located and stronger, allowing for a smaller amount of spike (10%). The grinding technique used produces powders free of grains coarser than 20 µm and suitable for obtaining random and rigid specimens.

Errors in accuracy are low, <2 wt. % deviation from actual values for individual minerals, as tested on artificial shale mixtures. No normalization is applied and thus, for natural rocks, the analysis is tested by the departure of the sum of the measured components from 100%. Our approach compares favorably with other quantitative analysis techniques, including a Rietveld-based technique.

Similar content being viewed by others

References

Alexander, L. and Klug, H.P. (1948) Basic aspects of X-ray absorption in quantitative analysis of powder mixtures. Analytical Chemistry, 20, 886–889.

Batchelder, M. and Cressey, G. (1998) Rapid, accurate phase quantification of clay-bearing samples using a position-sensitive X-ray detector. Clays and Clay Minerals, 46, 183–194.

Bish, D.L. and Howard, S.A. (1988) Quantitative phase analysis using the Rietveld method. Journal of Applied Crystallography, 21, 86–91.

Bish, D.L. and Reynolds, R.C., Jr. (1989) Sample preparation for X-ray diffraction. Pp. 73–100 in: Modern Powder Diffraction (D.J. Bish and J.E. Post, editors). Reviews in Mineralogy, 20. Mineralogical Society of America, Washington, D.C.

Brindley, G.W. (1980) Quantitative analysis of clay mixtures. Pp. 411–438 in: Crystal Structures of Clay Minerals and their X-ray Identification (G.W. Brindley and G. Brown, editors). Monograph 5, Mineralogical Society, London.

Chung, F.H. (1974) Quantitative interpretation of X-ray diffraction patterns of mixtures. I. Matrix flushing method for quantitative multicomponent analysis. Journal of Applied Crystallography, 7, 519–525.

Drits, V.A., Sakharov, B.A., Lindgreen, H. and Salyn, A. (1997) Sequential structure transformation of illite-smectite-vermiculite during diagenesis of Upper Jurassic shales from the North Sea and Denmark. Clay Minerals, 32, 351–371.

Folk, R.L. (1980) Petrology of Sedimentary Rocks. Hemphill Publishing Co., Austin, Texas, 184 pp.

Hillier, S. (1999) Use of an air-brush to spray dry samples for X-ray powder diffraction. Clay Minerals, 34, 127–135.

Hubbard, C.R. and Snyder, R.L. (1988) RIR—measurement and use in quantitative XRD. Powder Diffraction, 3, 74–77.

Jenkins, R. (1989) Experimental procedures. Pp. 47–71 in: Modern Powder Diffraction (D.J. Bish and J.E. Post, editors). Reviews in Mineralogy, 20. Mineralogical Society of America, Washington, D.C.

Klug, H.P. and Alexander, L.E. (1974) X-ray Diffraction Procedures. J. Wiley & Sons, New York, 966 pp.

Lindgreen, H., Drits, V.A., Sakharov, B.A., Salyn, A.L., Wrang, P. and Dainyak, L.G. (2000) Illite-smectite structural changes during metamorphism in black Cambrian Alum shales from the Baltic area. American Mineralogist, 85, 1223–1238.

Lynch, F.L. (1997) Frio shale mineralogy and the stoichiometry of the smectite-to-illite reaction: the most important reaction in clastic sedimentary diagenesis. Clays and Clay Minerals, 45, 618–631.

Matulis, C.E. and Taylor, J.C. (1992) Intensity calibration curves for Bragg-Brentano X-ray diffractometers. Powder Diffraction, 7, 89–94.

McCarty, D.K., Hsieh, J.C.C., Drits, V.A. and Środorń, J. (2000) The mineralogy of mudstones: clay mineral heterogeneity. GSA, Abstracts With Programs, 32(7), p. 321.

McManus, D.A. (1991) Suggestions for authors whose manuscripts include quantitative clay mineral analysis by X-ray diffraction. Marine Geology, 98, 1–5.

Moore, D.M. and Reynolds, R.C., Jr. (1997) X-ray Diffraction and the Identification and Analysis of Clay Minerals. Oxford University Press, Oxford, 378 pp.

Mossman, M.H., Freas, D.H. and Bailey, S.W. (1967) Orienting internal standard method for clay mineral X-ray analysis. Clays and Clay Minerals, 15, 441–453.

O’Connor, B.H. and Chang, W.J. (1986) The amorphous character and particle size distribution of powders produced with the micronizing mill for quantitative X-ray powder diffractometry. X-ray Spectrometry, 15, 267–270.

Reynolds, R.C., Jr. (1989) Principles and techniques of quantitative analysis of clay minerals by X-ray powder diffraction. Pp. 4–36 in: Quantitative Mineral Analysis of Clays (D.R. Pevear and F.A. Mumpton, editors). CMS Workshop Lectures, 1. The Clay Minerals Society, Bloomington, Indiana.

Smith, D.K., Johnson, G.G., Jr., Scheible, W., Wims, A.M., Johnson J.L. and Ulimann G. (1987) Quantitative X-ray powder diffraction method using the full diffraction pattern. Powder Diffraction, 2, 73–77.

Smith, S.T., Snyder, S.L. and Brownell, W.E. (1979) Quantitative phase analysis of Devonian shales by computer controlled X-ray diffraction of spray dried samples. Advanced X-ray Analysis, 22, 181–191.

Snyder, R.L. and Bish, D.L. (1989) Quantitative analysis. Pp. 101–144 in: Modern Powder Diffraction (D.J. Bish and J.E. Post, editors). Reviews in Mineralogy, 20. Mineralogical Society of America, Washington, D.C.

Taylor, J.C. (1991) Computer programs for standardless quantitative analysis of minerals using the full powder diffraction profile. Powder Diffraction, 6, 2–9.

Taylor, J.C. and Matulis, C.E. (1994) A new method for Rietveld clay analysis. Part I. Use of a universal measured standard profile for Rietveld quantification of montmorillonites. Powder Diffraction, 9, 119–123.

Ward, C.R., Taylor, J.C. and Cohen, D.R. (1999) Quantitative mineralogy of sandstones by X-ray diffractometry and normative analysis. Journal of Sedimentary Research, 69, 1050–1062.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Środoń, J., Drits, V.A., McCarty, D.K. et al. Quantitative X-ray diffraction analysis of clay-bearing rocks from random preparations. Clays Clay Miner. 49, 514–528 (2001). https://doi.org/10.1346/CCMN.2001.0490604

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1346/CCMN.2001.0490604